Introduction: Navigating the Global Market for vulcanized ribber

In the ever-evolving landscape of global manufacturing, sourcing high-quality vulcanized rubber can present a myriad of challenges for international B2B buyers. From ensuring product durability to navigating supply chain complexities, the stakes are high when it comes to selecting the right materials for your business needs. This comprehensive guide aims to empower B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Vietnam—by providing in-depth insights into the world of vulcanized rubber.

Throughout this guide, we will explore various types of vulcanized rubber, their extensive applications in industries ranging from automotive to consumer goods, and crucial factors to consider when vetting suppliers. Additionally, we will break down cost considerations and provide actionable strategies for making informed purchasing decisions. By equipping you with the knowledge needed to navigate the complexities of sourcing vulcanized rubber, this guide serves as a valuable resource for enhancing your procurement strategies and ensuring you achieve optimal product performance. Whether you are a seasoned buyer or new to the market, understanding the nuances of vulcanized rubber will enable you to make confident and strategic choices that align with your business objectives.

جدول المحتويات

- Top 5 Vulcanized Ribber Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vulcanized ribber

- Understanding vulcanized ribber Types and Variations

- Key Industrial Applications of vulcanized ribber

- 3 Common User Pain Points for ‘vulcanized ribber’ & Their Solutions

- Strategic Material Selection Guide for vulcanized ribber

- In-depth Look: Manufacturing Processes and Quality Assurance for vulcanized ribber

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vulcanized ribber’

- Comprehensive Cost and Pricing Analysis for vulcanized ribber Sourcing

- Alternatives Analysis: Comparing vulcanized ribber With Other Solutions

- Essential Technical Properties and Trade Terminology for vulcanized ribber

- Navigating Market Dynamics and Sourcing Trends in the vulcanized ribber Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vulcanized ribber

- Strategic Sourcing Conclusion and Outlook for vulcanized ribber

- تنويه هام وشروط الاستخدام

Understanding vulcanized ribber Types and Variations

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Natural Rubber Vulcanizate | Derived from rubber tree latex, excellent elasticity | Automotive tires, footwear, gaskets | الإيجابيات: High elasticity, good tensile strength. السلبيات: Susceptible to UV and ozone degradation. |

| Synthetic Rubber (SBR) | Made from petroleum by-products, cost-effective | Tires, conveyor belts, seals | الإيجابيات: Cost-effective, good abrasion resistance. السلبيات: Less elastic than natural rubber. |

| EPDM (Ethylene Propylene Diene Monomer) | Excellent weather resistance, good thermal stability | Roofing membranes, automotive parts | الإيجابيات: Superior weather resistance, ozone resistant. السلبيات: تكلفة أولية أعلى. |

| Neoprene (Chloroprene Rubber) | Oil and solvent resistant, maintains flexibility | Wetsuits, gaskets, electrical insulation | الإيجابيات: Good chemical resistance, durable. السلبيات: Limited temperature range. |

| Silicone Rubber | High-temperature resistance, flexible at low temps | Medical devices, automotive seals | الإيجابيات: Excellent thermal stability, biocompatible. السلبيات: Generally more expensive. |

What Are the Characteristics of Natural Rubber Vulcanizate?

Natural rubber vulcanizate is derived from the latex of rubber trees, making it highly elastic and strong. Its superior tensile strength makes it an ideal choice for applications requiring flexibility, such as automotive tires and footwear. However, buyers should consider its susceptibility to degradation from UV light and ozone, which can affect longevity in outdoor applications. When purchasing, ensure that the rubber is treated with anti-ozonants for enhanced durability.

Why Choose Synthetic Rubber (SBR) for Your Manufacturing Needs?

Synthetic rubber, particularly Styrene-Butadiene Rubber (SBR), is favored for its cost-effectiveness and versatility. It is widely used in applications such as tires and conveyor belts due to its good abrasion resistance. While SBR is less elastic than natural rubber, its synthetic nature allows for better performance in various environments, making it a reliable choice for manufacturers. Buyers should evaluate the specific requirements of their applications to determine the optimal formulation.

What Makes EPDM a Preferred Choice in Harsh Environments?

Ethylene Propylene Diene Monomer (EPDM) rubber is renowned for its exceptional weather resistance and thermal stability, making it ideal for outdoor applications like roofing membranes and automotive parts. Its ability to withstand extreme temperatures and ozone exposure makes it a durable option. While it may come with a higher initial cost, the long-term benefits of reduced maintenance and replacement make it a wise investment for many industries.

How Does Neoprene Stand Out Among Vulcanized Rubber Types?

Neoprene, or chloroprene rubber, is distinguished by its resistance to oils and solvents, making it suitable for applications like wetsuits and gaskets. Its ability to maintain flexibility under varying temperatures is another key advantage. However, buyers should be mindful of its limited temperature range, which can restrict its use in certain high-heat applications. When sourcing neoprene products, consider the specific chemical exposure levels they will encounter.

Why Is Silicone Rubber Considered a Premium Option?

Silicone rubber is celebrated for its high-temperature resistance and flexibility at low temperatures, making it essential in medical devices and automotive seals. Its biocompatibility is a significant advantage in healthcare applications. Despite its generally higher cost, the long-term performance and safety benefits justify the investment for many businesses. Buyers should ensure they choose the right grade of silicone rubber for their specific application needs to maximize performance.

Key Industrial Applications of vulcanized ribber

| الصناعة/القطاع | Specific Application of Vulcanized Rubber | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | Tire Manufacturing | Enhanced durability and performance under various conditions | Quality assurance certifications and compliance with regional standards |

| الإنشاءات | Seals and Gaskets | Improved resistance to weathering and chemical exposure | Compatibility with existing materials and environmental regulations |

| السلع الاستهلاكية | Footwear and Apparel | Increased comfort and longevity of products | Material sourcing for sustainability and ethical production practices |

| Electronics | Keypads and Insulation | Enhanced tactile feedback and protection against moisture | Specifications for electrical resistance and durability testing |

| Aerospace | Vibration Dampening Components | Improved safety and performance in high-stress environments | Compliance with aerospace industry regulations and certifications |

How is Vulcanized Rubber Used in the Automotive Sector?

In the automotive industry, vulcanized rubber is primarily utilized for manufacturing tires, which require exceptional durability and performance. The vulcanization process enhances the rubber’s strength and elasticity, allowing tires to withstand varying temperatures, pressures, and road conditions. For international buyers, especially in regions like Africa and the Middle East, sourcing high-quality vulcanized rubber that meets local and international safety standards is crucial. Additionally, companies should consider the rubber’s resistance to wear and tear, which directly impacts vehicle safety and longevity.

What Role Does Vulcanized Rubber Play in Construction?

In construction, vulcanized rubber is commonly used for seals and gaskets that protect structures from water and air infiltration. The enhanced resistance to weathering and chemical exposure makes vulcanized rubber an ideal choice for both indoor and outdoor applications. Buyers in South America and Europe should focus on sourcing materials that comply with local building codes and environmental regulations. Ensuring compatibility with existing construction materials is also essential to maintain structural integrity and performance.

How is Vulcanized Rubber Beneficial in Consumer Goods?

The consumer goods sector leverages vulcanized rubber for footwear and apparel, where it significantly enhances comfort and product longevity. The elasticity and durability of vulcanized rubber allow for the production of flexible yet robust items that can endure daily wear. B2B buyers should prioritize sourcing practices that emphasize sustainability, as consumers increasingly demand eco-friendly products. Understanding the supply chain’s ethical implications can also enhance brand reputation in competitive markets.

What Applications Does Vulcanized Rubber Have in Electronics?

In the electronics industry, vulcanized rubber is utilized for keypads and insulation materials. Its properties provide enhanced tactile feedback and moisture protection, which are critical for device functionality. Buyers should ensure that the vulcanized rubber meets specific electrical resistance requirements and durability testing standards, particularly in markets like Europe and the Middle East, where compliance with stringent regulations is mandatory. Proper sourcing can prevent costly failures and enhance product reliability.

How is Vulcanized Rubber Used in Aerospace Applications?

In the aerospace sector, vulcanized rubber is essential for vibration dampening components, which help to absorb shocks and reduce noise in aircraft systems. The material’s superior strength and resilience are crucial in high-stress environments, ensuring safety and performance. B2B buyers must consider compliance with aerospace industry regulations and certifications when sourcing vulcanized rubber. Understanding the specific performance requirements can also influence the choice of materials, impacting overall operational efficiency and safety.

Illustrative image related to vulcanized ribber

3 Common User Pain Points for ‘vulcanized ribber’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Vulcanized Rubber

المشكلة B2B buyers often struggle to find reliable suppliers of high-quality vulcanized rubber. This challenge is compounded in regions like Africa and South America, where local suppliers may not meet international quality standards. Buyers may receive inconsistent product quality, leading to increased production costs and potential project delays. In industries such as automotive and construction, the strength and durability of vulcanized rubber are critical, and sourcing subpar materials can jeopardize the integrity of the final products.

الحل: To overcome sourcing challenges, B2B buyers should establish partnerships with certified suppliers who have a proven track record in the vulcanized rubber market. It is advisable to request samples and conduct rigorous testing against industry standards before making bulk purchases. Additionally, buyers should prioritize suppliers with transparent supply chains and certifications, such as ISO 9001, which indicate adherence to quality management principles. Engaging in regular communication with suppliers can also facilitate better understanding of material specifications and lead times, ensuring that the vulcanized rubber meets both performance and delivery expectations.

Scenario 2: Inadequate Understanding of Material Specifications

المشكلة Many buyers lack in-depth knowledge about the specific properties and applications of vulcanized rubber, which can lead to incorrect material selection for their projects. For instance, using a type of vulcanized rubber that is not resistant to certain chemicals or temperatures can result in product failure, safety hazards, and financial losses. This is particularly problematic in industries such as pharmaceuticals and food processing, where compliance with stringent safety standards is essential.

Illustrative image related to vulcanized ribber

الحل: Buyers should invest time in understanding the various grades and formulations of vulcanized rubber available in the market. Collaborating with technical experts or rubber engineers can provide valuable insights into selecting the right material for specific applications. It is also beneficial to utilize detailed datasheets provided by suppliers, which outline the physical and chemical properties of the rubber. Additionally, buyers can engage in workshops or training sessions focused on material science to enhance their knowledge and application of vulcanized rubber, thus ensuring they make informed decisions that align with industry standards.

Scenario 3: Challenges in Customizing Vulcanized Rubber Products

المشكلة B2B buyers often encounter difficulties when trying to customize vulcanized rubber products to meet unique specifications. Standardized products may not fit the specific needs of various applications, particularly in niche markets like aerospace or medical devices. This lack of customization can lead to inefficiencies in production and increased operational costs.

الحل: To address customization challenges, buyers should work closely with suppliers who offer tailored solutions and have the capability to produce custom vulcanized rubber products. Engaging in a collaborative design process with the supplier can ensure that the unique requirements are met effectively. It is crucial to provide detailed specifications, including dimensions, performance criteria, and environmental conditions the rubber will face. Utilizing prototyping services can also help visualize the final product before full-scale production. By leveraging advanced manufacturing technologies, such as 3D printing for initial prototypes, buyers can minimize risks and ensure that the final vulcanized rubber products meet their specific needs.

Strategic Material Selection Guide for vulcanized ribber

When selecting materials for vulcanized rubber applications, it is essential to consider various types of rubber compounds that can significantly impact product performance and suitability for specific industries. Below are analyses of four common materials used in vulcanized rubber, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to vulcanized ribber

What Are the Key Properties of Natural Rubber in Vulcanized Applications?

Natural rubber, derived from the latex of rubber trees, is known for its excellent elasticity and resilience. It typically has a temperature rating of -50°C to 80°C, making it suitable for a variety of applications. Natural rubber also exhibits good abrasion resistance and tensile strength, which are critical for products like tires and seals.

الإيجابيات: The primary advantage of natural rubber is its superior elasticity and flexibility, which allows it to perform well under dynamic loads. It is also biodegradable, making it an environmentally friendly option.

السلبيات: However, natural rubber is susceptible to degradation from UV light, ozone, and certain chemicals, which can limit its use in harsh environments. Additionally, sourcing natural rubber can be affected by climate conditions, impacting availability and cost.

التأثير على التطبيق: Natural rubber is compatible with a wide range of media, including water and air, but may not perform well with oils and solvents.

اعتبارات للمشترين الدوليين: Buyers should ensure compliance with international standards such as ASTM D2000 for rubber materials. In regions like Africa and South America, sourcing may be influenced by local environmental regulations and sustainability practices.

How Does Synthetic Rubber Compare in Vulcanized Applications?

Synthetic rubber, such as Styrene-Butadiene Rubber (SBR), is engineered to provide specific performance characteristics. It typically has a temperature range of -40°C to 100°C and offers good resistance to abrasion and aging.

الإيجابيات: The main advantage of synthetic rubber is its versatility and ability to be tailored for specific applications, including resistance to oils and chemicals. It is often more cost-effective than natural rubber, especially in large-scale manufacturing.

السلبيات: On the downside, synthetic rubber can lack the elasticity of natural rubber and may not perform as well in extreme temperatures.

Illustrative image related to vulcanized ribber

التأثير على التطبيق: SBR is particularly well-suited for applications involving oils and fuels, making it ideal for automotive and industrial uses.

اعتبارات للمشترين الدوليين: Buyers should be aware of the different grades of synthetic rubber and their compliance with standards such as ISO 9001 for quality management. In the Middle East, for example, the demand for synthetic rubber is increasing due to the region’s focus on industrialization.

What Are the Benefits of EPDM Rubber in Vulcanized Products?

Ethylene Propylene Diene Monomer (EPDM) rubber is known for its excellent weather resistance and durability. It maintains its properties across a temperature range of -50°C to 150°C, making it suitable for outdoor applications.

الإيجابيات: EPDM offers superior resistance to UV light, ozone, and aging, which extends its lifespan in outdoor applications. It is also compatible with a variety of chemicals.

السلبيات: However, EPDM is not suitable for use with petroleum-based products, which can limit its application in certain industries.

التأثير على التطبيق: EPDM is commonly used in roofing membranes, seals, and gaskets, particularly in environments exposed to harsh weather conditions.

اعتبارات للمشترين الدوليين: Compliance with local building codes and standards (e.g., EN 13501 for fire performance) is crucial for construction applications in Europe and the Middle East.

How Does Neoprene Rubber Enhance Performance in Vulcanized Applications?

Neoprene rubber is a synthetic rubber that offers excellent chemical stability and flexibility. It typically operates within a temperature range of -40°C to 120°C, making it suitable for various industrial applications.

Illustrative image related to vulcanized ribber

الإيجابيات: Neoprene is resistant to oils, solvents, and weathering, making it an ideal choice for applications in automotive and marine industries.

السلبيات: Its higher cost compared to other rubber types can be a limiting factor for some manufacturers.

التأثير على التطبيق: Neoprene is particularly effective in environments where exposure to oils and chemicals is common, enhancing the durability of products like seals and gaskets.

اعتبارات للمشترين الدوليين: Buyers should check for compliance with ASTM D1418 and other relevant standards, especially in regions with stringent quality requirements like Europe.

Summary Table of Material Selection for Vulcanized Rubber

| المواد | Typical Use Case for vulcanized ribber | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| Natural Rubber | Tires, seals, and gaskets | Excellent elasticity | عرضة للأشعة فوق البنفسجية والتحلل الكيميائي | متوسط |

| Synthetic Rubber | Automotive parts, industrial products | Cost-effective and versatile | Lower elasticity than natural rubber | منخفضة |

| EPDM Rubber | Roofing, seals, and outdoor products | Superior weather resistance | Not compatible with petroleum products | متوسط |

| Neoprene Rubber | Automotive and marine applications | مقاومة ممتازة للمواد الكيميائية | Higher cost than other rubber types | عالية |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vulcanized ribber

What Are the Main Stages in the Manufacturing Process of Vulcanized Rubber?

The production of vulcanized rubber involves several key stages, each critical to ensuring that the final product meets the necessary performance standards for various applications.

Material Preparation: What Goes Into Creating Vulcanized Rubber?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate rubber base, which can be either natural or synthetic. Natural rubber, derived from the latex of rubber trees, offers excellent elasticity, while synthetic options like styrene-butadiene rubber (SBR) provide enhanced resistance to heat and aging. These raw materials are carefully weighed and mixed with additives such as sulfur, accelerators, and fillers. Each ingredient serves a specific purpose, from enhancing elasticity to improving durability.

Forming: How Is Vulcanized Rubber Shaped?

Once the materials are prepared, the next stage is forming. The mixed rubber is typically processed using techniques such as extrusion, molding, or calendering. In extrusion, the rubber is forced through a die to create specific shapes, while molding involves placing the rubber into a pre-formed cavity to achieve the desired configuration. The choice of forming technique depends on the end-use application and the complexity of the product being manufactured.

Assembly: What Happens After Forming?

For products that require multiple components, the assembly stage comes next. This might include attaching fabric reinforcements, adding metal parts, or integrating other materials to create a composite product. The assembly process must be conducted with precision to ensure that all parts fit together correctly, which is crucial for the performance and longevity of the final product.

Illustrative image related to vulcanized ribber

Finishing: How Is the Product Prepared for Market?

The finishing stage includes processes like trimming, surface treatment, and quality inspection. Trimming ensures that any excess material is removed, while surface treatments can include painting or applying anti-abrasive coatings. This stage is also critical for preparing the product for packaging and shipping, ensuring that it meets customer specifications and regulatory requirements.

What Quality Control Measures Are Essential for Vulcanized Rubber?

Quality control (QC) is a vital aspect of the manufacturing process for vulcanized rubber, ensuring that products meet international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

International standards play a significant role in the quality assurance of vulcanized rubber products. ISO 9001 is a widely recognized standard that outlines requirements for an effective quality management system. Compliance with this standard indicates that a supplier is committed to continuous improvement and customer satisfaction. Other industry-specific standards, such as CE marking for products sold in the European market and API standards for products used in the oil and gas industry, may also apply depending on the application.

Illustrative image related to vulcanized ribber

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في عملية التصنيع؟

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that any defects are caught early. These checkpoints typically include:

-

مراقبة الجودة الواردة (IQC): This initial stage involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

-

مراقبة الجودة أثناء العملية (IPQC): During production, ongoing inspections monitor parameters such as temperature, pressure, and material consistency. This helps to identify any deviations from the established process.

-

مراقبة الجودة النهائية (FQC): Once the product is completed, it undergoes a final inspection to verify that it meets all design specifications and quality standards before it is shipped to customers.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for vulcanized rubber can include physical tests (e.g., tensile strength, elongation, hardness), chemical tests (e.g., resistance to oils and solvents), and environmental tests (e.g., aging and ozone resistance). These tests help to ensure that the rubber will perform as expected in its intended application.

كيف يمكن لمشتري B2B التحقق من مراقبة جودة الموردين؟

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to mitigating risk.

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control measures. Buyers should consider visiting the manufacturing facility to observe processes firsthand. During the audit, it’s essential to review quality management documentation, including quality assurance reports and inspection records.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an additional layer of assurance. These independent entities can conduct random checks during the production process and verify compliance with international standards. This approach can help buyers ensure that the products they receive meet the required specifications.

What Nuances Should International Buyers Be Aware Of?

International buyers should also be aware of the nuances in quality certification across different regions. For instance, certain markets may have stricter regulations regarding the use of specific materials or chemical additives in rubber products. Understanding these regulations is crucial for ensuring compliance and avoiding costly delays or penalties.

الخاتمة

The manufacturing and quality assurance processes for vulcanized rubber are intricate and require meticulous attention to detail. By understanding the key stages of production and the importance of quality control, B2B buyers can make informed decisions when selecting suppliers. Adhering to international standards and conducting thorough audits can help ensure that the products meet their specific requirements, ultimately leading to successful business relationships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vulcanized ribber’

مقدمة

Sourcing vulcanized rubber can be a complex process, especially for international B2B buyers. This guide provides a comprehensive checklist to help you navigate the procurement journey effectively. By following these steps, you can ensure that you select high-quality vulcanized rubber that meets your specific application needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the vulcanized rubber you need. This includes physical properties such as hardness, tensile strength, and elasticity, as well as any industry-specific standards.

– Consider Application Needs: Different applications, from automotive parts to industrial seals, will have unique demands.

– Identify Environmental Conditions: Take into account factors like temperature extremes, exposure to chemicals, and mechanical stress.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in vulcanized rubber. Look for manufacturers with a proven track record in your industry.

– Check Online Directories and Trade Shows: Utilize platforms like Alibaba or attend industry-specific trade shows to find reputable suppliers.

– Read Reviews and Testimonials: Insights from other businesses can provide valuable information about supplier reliability and product quality.

Illustrative image related to vulcanized ribber

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that potential suppliers hold the necessary certifications. This ensures that they adhere to industry standards and quality control practices.

– Request Certification Copies: Look for ISO certifications or other relevant quality management standards.

– Confirm Compliance with Regulations: Ensure that the supplier meets any local or international regulations applicable to your industry.

Step 4: Request Samples for Testing

Before making a bulk purchase, always request samples of the vulcanized rubber. This step is vital to assess the material’s quality and suitability for your application.

– Conduct Quality Tests: Evaluate the samples for physical properties, durability, and performance under expected conditions.

– Compare Samples: If possible, obtain samples from multiple suppliers to compare quality and pricing.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules.

– Discuss Minimum Order Quantities (MOQs): Understand the minimum quantities required and assess how that fits your budget and needs.

– Clarify Shipping and Lead Times: Ensure you are clear about delivery timelines and any potential shipping costs.

Step 6: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of vulcanized rubber throughout the supply chain. This step is essential to maintain product consistency and performance.

– Set Up Regular Inspections: Schedule inspections during production and upon delivery to verify that the rubber meets your specifications.

– Document Quality Issues: Keep a record of any quality discrepancies to address with your supplier promptly.

Step 7: Build a Long-Term Relationship with Suppliers

Finally, focus on developing a strong partnership with your suppliers. This can lead to better pricing, priority service, and improved communication.

– Provide Feedback: Share your experiences and any issues with your supplier to foster a collaborative relationship.

– Consider Long-Term Contracts: If the supplier meets your expectations, consider entering into a long-term agreement to secure favorable terms.

By following this checklist, B2B buyers can streamline their sourcing process for vulcanized rubber, ensuring they find reliable suppliers and high-quality products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for vulcanized ribber Sourcing

What Are the Key Cost Components in Vulcanized Rubber Sourcing?

When sourcing vulcanized rubber, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

المواد: The raw materials used in vulcanized rubber production, such as natural and synthetic rubbers, sulfur, accelerators, and other additives, significantly influence costs. The prices of these materials can fluctuate based on market conditions, which may vary by region.

-

العمالة: Labor costs encompass the wages of skilled workers involved in the manufacturing and quality assurance processes. In regions with higher labor costs, such as parts of Europe, sourcing may be more expensive compared to regions with lower labor costs, such as parts of Africa or South America.

-

نفقات التصنيع الزائدة: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead costs, which can be a critical factor in pricing for competitive markets.

-

الأدوات: The initial investment in molds and machinery for producing specific rubber components can be significant. Custom tooling for specialized products can add to the upfront costs but may be amortized over larger production runs.

-

مراقبة الجودة: Ensuring that the vulcanized rubber meets required specifications and certifications involves additional costs. This includes testing materials and finished products to comply with international standards, which is particularly important for markets in Europe and the Middle East.

-

الخدمات اللوجستية: Transporting vulcanized rubber from the manufacturing site to the buyer incurs shipping costs. These costs can vary widely based on distance, shipping method, and local tariffs or duties.

-

الهامش: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market competition, supplier reputation, and the uniqueness of the product.

How Do Price Influencers Affect Vulcanized Rubber Sourcing?

Several factors can influence the pricing of vulcanized rubber, making it essential for buyers to be aware of these when negotiating contracts.

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger orders often qualify for bulk pricing discounts, reducing the unit cost. Buyers should consider their demand and negotiate MOQs that align with their needs.

-

المواصفات والتخصيص: Customized rubber products tailored to specific applications can lead to higher costs due to the need for specialized tooling and testing. Buyers should evaluate whether the added features justify the increased expense.

-

الجودة والشهادات: Products that meet international quality standards or certifications (e.g., ISO, ASTM) may carry a premium price. Buyers should weigh the benefits of certified products against their budget constraints.

-

عوامل الموردين: Supplier reliability, reputation, and production capabilities can influence pricing. Established suppliers may charge more due to their experience and quality assurance processes, while newer suppliers might offer lower prices to enter the market.

-

المصطلحات التجارية الدولية: The terms of shipping and delivery (Incoterms) can significantly impact overall costs. Buyers should clearly understand who bears the responsibility and risk during transportation, as this can affect pricing.

What Are the Best Tips for B2B Buyers Sourcing Vulcanized Rubber?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

-

Negotiate Terms: Engage in negotiations regarding pricing, payment terms, and delivery schedules. Establishing a good relationship with suppliers can lead to better deals over time.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with sourcing vulcanized rubber, including maintenance and disposal. Lower upfront costs may not always translate to lower TCO.

-

Understand Pricing Nuances: Be aware of regional pricing differences, particularly when sourcing from Africa, South America, the Middle East, or Europe. Economic conditions, currency fluctuations, and local market dynamics can all play a role.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide a better understanding of market rates and help identify competitive pricing.

While these insights provide a comprehensive overview of the cost and pricing landscape for vulcanized rubber sourcing, it is essential for buyers to conduct thorough due diligence and remain flexible in their sourcing strategies. Prices can vary significantly based on the aforementioned factors, so always approach negotiations with a clear understanding of your needs and the market conditions.

Alternatives Analysis: Comparing vulcanized ribber With Other Solutions

Exploring Alternative Solutions to Vulcanized Rubber

In the realm of industrial materials, vulcanized rubber is a popular choice due to its enhanced strength and elasticity. However, it’s essential for B2B buyers to consider alternative solutions that may meet specific needs, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This section provides a comparative analysis of vulcanized rubber against two viable alternatives: thermoplastic elastomers (TPE) and polyurethane (PU) elastomers.

| جانب المقارنة | Vulcanized Rubber | Thermoplastic Elastomers (TPE) | Polyurethane (PU) Elastomers |

|---|---|---|---|

| الأداء | High elasticity and durability; excellent abrasion resistance | Good elasticity, moderate durability; can be tailored for specific applications | Very high tensile strength, excellent abrasion resistance; versatile applications |

| التكلفة | Generally higher due to processing and material costs | Typically lower; cost-effective for many applications | Moderate to high; depends on formulation and application |

| سهولة التنفيذ | Requires specialized processing and curing | Easily molded and processed; can be recycled | Requires specific processing techniques; not as straightforward as TPE |

| الصيانة | Low maintenance; high durability prolongs lifespan | Moderate; can degrade under UV exposure or extreme temperatures | Low; but may require protective coatings for longevity |

| أفضل حالة استخدام | Heavy-duty applications like automotive tires and industrial gaskets | Consumer goods, seals, and flexible components | High-performance applications like medical devices and automotive parts |

What Are the Advantages and Disadvantages of Thermoplastic Elastomers (TPE)?

Thermoplastic elastomers (TPE) present a flexible alternative to vulcanized rubber, combining the properties of rubber with the processing advantages of plastics. TPEs are easy to mold and can be recycled, making them a cost-effective option for many applications. They offer good elasticity and can be engineered to suit specific performance requirements. However, TPEs may not perform as well under extreme conditions, such as high temperatures or prolonged UV exposure, which can limit their applicability in certain industrial settings.

How Do Polyurethane (PU) Elastomers Compare?

Polyurethane elastomers are renowned for their exceptional tensile strength and abrasion resistance, making them suitable for high-performance applications. They are often used in industries ranging from automotive to medical devices. While PU elastomers can be more expensive than vulcanized rubber, their versatility and durability can justify the cost in demanding applications. The main drawback is that the processing of PU can be more complex, requiring specialized techniques, and they may also necessitate protective coatings to enhance longevity in harsh environments.

كيف يمكن لمشتري B2B اختيار الحل المناسب؟

Choosing the right material for industrial applications hinges on various factors, including performance requirements, cost constraints, and ease of implementation. For buyers in emerging markets, it is critical to assess local conditions, such as climate and typical usage scenarios, as these can significantly impact material performance. By understanding the specific needs of their applications and comparing the strengths and weaknesses of vulcanized rubber, TPE, and PU elastomers, B2B buyers can make informed decisions that align with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for vulcanized ribber

ما هي الخصائص التقنية الرئيسية للمطاط المفلكن؟

When engaging in the procurement of vulcanized rubber, understanding its essential technical properties is critical for making informed decisions. Here are some of the most relevant specifications:

1. درجة المادة

Material grade refers to the classification of rubber based on its composition and intended use. In vulcanized rubber, common grades include natural rubber (NR), styrene-butadiene rubber (SBR), and ethylene-propylene diene monomer (EPDM). Each grade has unique properties such as tensile strength, elasticity, and resistance to weathering. Selecting the appropriate grade is vital for ensuring the rubber meets the specific demands of its application, whether it’s for automotive parts, industrial seals, or consumer products.

2. Hardness (Shore A)

Hardness is measured on the Shore A scale, which determines the rubber’s resistance to indentation. Typically, vulcanized rubber hardness ranges from 30 to 90 Shore A, with softer rubber being more flexible and harder rubber providing greater durability and wear resistance. Understanding the required hardness is essential for applications where performance under stress is critical, such as in tires or gaskets.

3. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. Vulcanized rubber generally exhibits high tensile strength due to the cross-linking that occurs during vulcanization. This property is particularly important for applications where the rubber will be subjected to stretching or pulling forces, ensuring longevity and reliability.

4. Elongation at Break

This property indicates how much a rubber material can stretch before breaking, expressed as a percentage of its original length. Vulcanized rubber typically exhibits high elongation at break, making it suitable for applications requiring flexibility and resilience, such as seals and flexible hoses. Buyers must consider this specification to ensure the rubber can accommodate movement without failure.

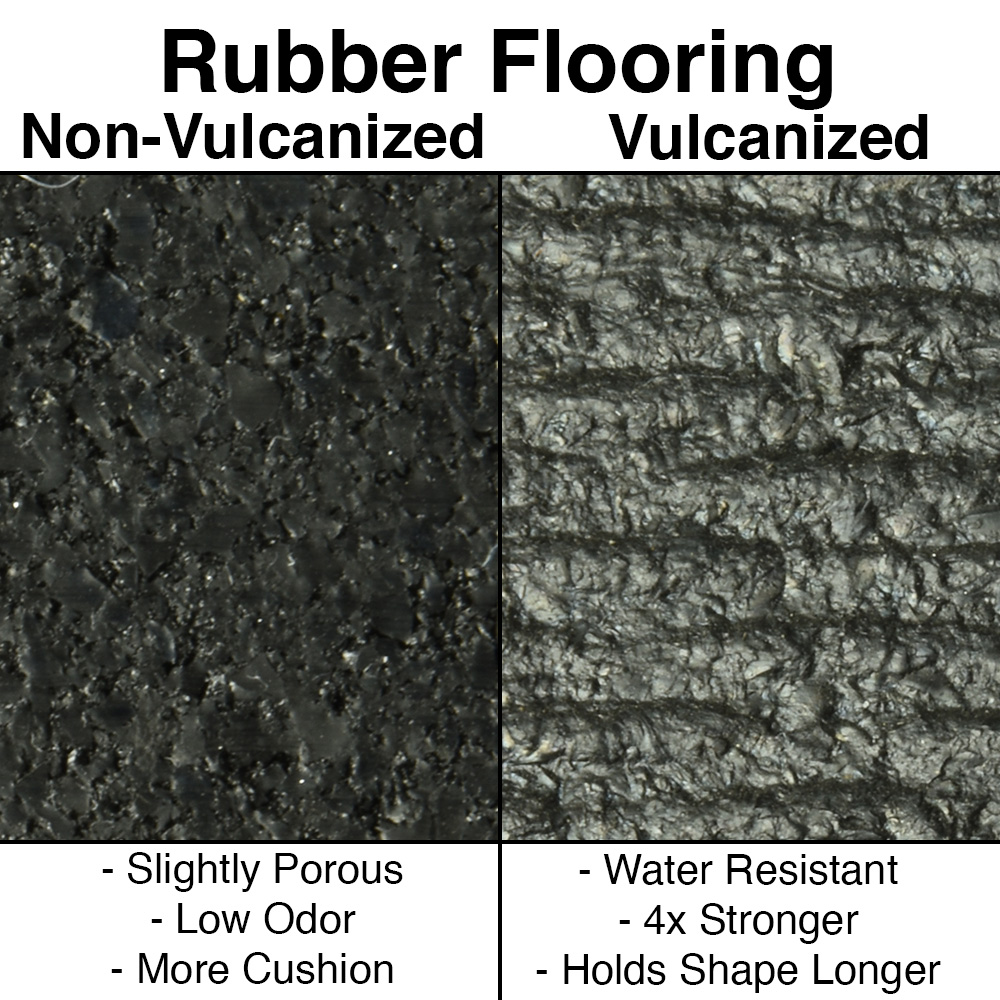

5. Abrasion Resistance

Abrasion resistance refers to the rubber’s ability to withstand surface wear due to friction. Vulcanized rubber is generally more resistant to abrasion compared to non-vulcanized alternatives, making it ideal for products like conveyor belts and flooring materials. Assessing abrasion resistance is crucial for applications exposed to harsh conditions or frequent mechanical wear.

What Are Common Trade Terms Used in Vulcanized Rubber Procurement?

Navigating the procurement process for vulcanized rubber involves familiarizing oneself with industry jargon. Here are some essential terms:

Illustrative image related to vulcanized ribber

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of vulcanized rubber, understanding whether a supplier is an OEM can help buyers ensure that they are sourcing high-quality products that meet specific industry standards.

2. موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand, as it impacts inventory management and initial investment. Knowing the MOQ can help companies determine if a supplier aligns with their production needs.

3. طلب عرض الأسعار (RFQ)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery timelines. By issuing an RFQ, buyers can compare offers from multiple suppliers, ensuring they receive competitive pricing and terms.

4. الشروط التجارية الدولية (الشروط التجارية الدولية)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping agreements. Familiarity with Incoterms is essential for international transactions, as they clarify who is responsible for costs, risks, and logistics during transportation. Understanding these terms can prevent disputes and enhance supply chain efficiency.

5. المهلة الزمنية

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the context of vulcanized rubber, lead times can vary based on the complexity of the order and the supplier’s capabilities. Understanding lead times helps buyers plan their production schedules and manage inventory effectively.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing vulcanized rubber, ensuring that they select the right materials and suppliers for their needs.

Navigating Market Dynamics and Sourcing Trends in the vulcanized ribber Sector

What Are the Key Market Drivers in the Vulcanized Rubber Sector?

The vulcanized rubber market is witnessing significant growth driven by various global factors. The increasing demand from industries such as automotive, aerospace, and manufacturing is propelling the market forward. In regions like Africa and South America, the expansion of infrastructure projects and urbanization is creating a robust demand for durable and resilient materials like vulcanized rubber. Additionally, the Middle East’s growing manufacturing capabilities and Europe’s focus on high-quality automotive components further emphasize the need for reliable vulcanized rubber products.

Emerging technologies, such as automation in manufacturing and advancements in rubber processing techniques, are also shaping the sourcing landscape. B2B buyers are increasingly seeking suppliers who leverage these technologies to enhance product quality and reduce lead times. Furthermore, the integration of digital platforms for sourcing and procurement is becoming prevalent, allowing international buyers to streamline their purchasing processes and access a broader range of suppliers.

How Are Sustainability and Ethical Sourcing Impacting the Vulcanized Rubber Market?

In the context of vulcanized rubber, sustainability and ethical sourcing are gaining prominence among B2B buyers. The environmental impact of rubber production, particularly concerning deforestation and carbon emissions, has led to an increased focus on sourcing from suppliers committed to sustainable practices. Companies are now prioritizing suppliers who can demonstrate compliance with environmental standards and certifications.

The use of ‘green’ materials, such as bio-based or recycled rubber, is becoming a critical consideration for many buyers. Certifications like the Forest Stewardship Council (FSC) and Cradle to Cradle (C2C) are sought after, as they assure buyers of sustainable sourcing practices. By aligning with suppliers who prioritize sustainability, businesses can enhance their brand reputation and meet the growing consumer demand for eco-friendly products.

What Is the Historical Context of Vulcanized Rubber’s Development?

The journey of vulcanized rubber began in the 19th century when Charles Goodyear patented the vulcanization process, which involved heating rubber with sulfur to enhance its strength and elasticity. This innovation transformed rubber from a fragile material into one that could withstand significant stress, opening up vast applications across various industries, including tires, footwear, and industrial components.

Over the decades, the vulcanization process has evolved, incorporating synthetic rubbers and advanced additives that improve performance characteristics. Today, the vulcanized rubber sector stands at the intersection of tradition and innovation, as manufacturers adapt to modern demands for durability, sustainability, and ethical sourcing. As B2B buyers navigate this landscape, understanding the historical evolution of vulcanized rubber can provide valuable insights into current market dynamics and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of vulcanized ribber

-

How do I choose the right supplier for vulcanized rubber?

When selecting a supplier for vulcanized rubber, prioritize those with a proven track record in quality and reliability. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, evaluate their production capacity and lead times to ensure they can meet your demands. Request samples to assess the quality of their products and review customer testimonials or case studies for insights into their performance. Establish open communication to discuss your specific needs and gauge their responsiveness. -

What are the common applications of vulcanized rubber in industry?

Vulcanized rubber is widely used across various industries due to its enhanced strength and elasticity. Common applications include automotive components like tires and seals, industrial machinery parts, gaskets, and consumer goods such as footwear and sporting equipment. Its resistance to abrasion and weathering makes it ideal for outdoor applications. Understanding the specific requirements of your industry can help you select the right type of vulcanized rubber for your products, ensuring optimal performance and durability. -

ما هو الحد الأدنى لكمية الطلب (MOQ) لمنتجات المطاط المفلكن؟

Minimum order quantities for vulcanized rubber products can vary significantly between suppliers. Generally, MOQs may range from a few hundred to several thousand units, depending on the complexity of the product and the supplier’s manufacturing capabilities. It’s important to discuss your specific needs with potential suppliers and see if they offer flexibility for smaller orders, especially for prototypes or custom designs. Understanding the MOQ can help you plan your inventory and budget accordingly. -

What payment terms should I expect when sourcing vulcanized rubber internationally?

Payment terms for international sourcing of vulcanized rubber typically include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit upfront, with the remaining balance due before shipment or upon receipt. It’s advisable to negotiate terms that align with your cash flow and risk tolerance. Additionally, consider using secure payment methods that provide buyer protection, especially when dealing with new suppliers or larger orders. -

How can I ensure quality assurance in vulcanized rubber products?

To guarantee the quality of vulcanized rubber products, establish a robust quality assurance (QA) process with your supplier. This may include requesting certificates of analysis (COA) for raw materials, conducting regular audits of their production processes, and implementing strict inspection protocols for finished products. Collaborate with suppliers to develop quality benchmarks tailored to your specifications, and consider third-party testing for critical applications to validate performance and compliance with industry standards. -

What logistics considerations should I keep in mind when importing vulcanized rubber?

When importing vulcanized rubber, consider factors such as shipping methods, customs regulations, and lead times. Choose a reliable logistics partner experienced in handling rubber products to navigate potential challenges. Ensure compliance with import regulations in your country, including any necessary certifications or inspections. Additionally, plan for potential delays by factoring in buffer time in your supply chain, particularly during peak seasons or geopolitical events that may impact shipping routes. -

How does the vulcanization process affect the performance of rubber products?

The vulcanization process significantly enhances the performance characteristics of rubber products. By introducing heat and sulfur, vulcanization creates cross-links between rubber molecules, resulting in improved strength, elasticity, and resistance to abrasion. This process allows vulcanized rubber to withstand greater stress and deformation without permanent damage, making it ideal for demanding applications. Understanding these properties can help you select the right vulcanized rubber for your specific needs, ensuring better performance and longevity. -

ما هي خيارات التخصيص المتاحة لمنتجات المطاط المفلكن؟

Customization options for vulcanized rubber products can include variations in hardness, color, and specific formulations tailored to unique applications. Suppliers often offer the ability to modify dimensions, shapes, and even the addition of specific additives to enhance properties like UV resistance or chemical compatibility. Discuss your requirements with potential suppliers to explore available customization options that align with your product goals, and request prototypes to evaluate the performance of customized solutions before committing to larger orders.

Top 5 Vulcanized Ribber Manufacturers & Suppliers List

1. ElastoStar – Silicone & Rubber Solutions

المجال: elastostar.com

Registered: 2013 (12 years)

مقدمة: Closed Cell Silicone Sponge Rubber, Metal & X-Ray Detectable Rubber, Silicone Rubber O-Rings, Die Cutting Gaskets, Platinum Cured Rubber Tubing, Rubber U-Channel, Rubber P-Channel, Extruded Rubber Bulb Seal

2. Walker Rubber – Custom Rubber Extrusions

المجال: Walker-rubber.co.uk

مسجل: 1999 (26 سنة)

مقدمة: النتوءات المطاطية، النتوءات المطاطية المخصصة، النتوءات المطاطية المخصصة، النتوءات المطاطية ذات الزوايا، سدادات النوافذ المطاطية للقوارب، سدادات النوافذ المطاطية للقوارب، مسكات الطوب، إطارات الكابينة، حماية الكابلات المطاطية، النتوءات الملونة، نتوءات ختم باب الحاوية، الحواف الجانبية للناقل، سدادات الأبواب المطاطية، نتوءات الأبواب المطاطية، نتوءات EPDM، سدادات التمدد المطاطية، سدادات ختم الواجهات المطاطية، نتوءات مثبطات اللهب، نتوءات درجة الغذاء، سدادات البوابات المطاطية، سدادات التزجيج المطاطية، سدادات التزجيج المطاطية، H Pr...

3. EBSCO – Vulcanized Rubber

المجال: ebsco.com

Registered: 1990 (35 years)

مقدمة: Vulcanized rubber is a durable material created through a chemical process known as vulcanization, which enhances rubber’s elasticity, tensile strength, and resistance to temperature variations. The process involves mixing natural rubber from the Hevea brasiliensis tree with sulfur and applying heat, resulting in chemical cross-links between polymer molecules. Patented by Charles Goodyear in the m…

4. WARE – Boiler Rentals & Services

المجال: wareinc.com

مسجل: 2000 (25 سنة)

مقدمة: WARE is an industrial & commercial boiler rental and service company specializing in sales, service, valve repair, rentals, parts, turn key solutions, and boiler training. They offer a wide range of boiler rentals for various applications and industries, new, used, and remanufactured boiler equipment, industrial boiler room auxiliary equipment like deaerators and heat exchangers, combustion equipm…

5. ScienceDirect – Vulcanization Process

المجال: sciencedirect.com

مسجل: 1997 (28 سنة)

مقدمة: Vulcanization is a chemical process that enhances the elasticity and retractile force of rubbery or elastomeric materials by forming a crosslinked molecular network. This process typically involves the insertion of crosslinks between polymer chains using sulfur or other vulcanizing agents. Key benefits of vulcanization include improved mechanical properties (strength, toughness, elasticity), enhan…

Strategic Sourcing Conclusion and Outlook for vulcanized ribber

In the ever-evolving landscape of industrial materials, the strategic sourcing of vulcanized rubber presents a significant opportunity for international B2B buyers. As highlighted throughout this guide, vulcanized rubber’s superior strength, elasticity, and resistance to abrasion make it an essential component across various industries, from automotive to consumer goods. By understanding the intricacies of the vulcanization process and the benefits it brings, companies can make informed decisions that enhance product durability and performance.

For buyers in regions such as Africa, South America, the Middle East, and Europe, aligning sourcing strategies with reliable suppliers of vulcanized rubber can lead to substantial cost savings and improved supply chain resilience. Establishing partnerships with manufacturers that prioritize quality and innovation will not only ensure access to high-performance materials but also foster long-term business growth.

Looking ahead, the demand for vulcanized rubber is expected to rise as industries increasingly prioritize sustainability and efficiency. Now is the time for international buyers to engage with suppliers, explore innovative applications, and solidify their position in a competitive market. By doing so, businesses can unlock new avenues for success and contribute to a more resilient global supply chain.

تنويه هام وشروط الاستخدام

⚠️ إخلاء مسؤولية مهم ⚠️

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.