Introduction: Navigating the Global Market for hose pipe for high pressure supplier

In the rapidly evolving landscape of international trade, sourcing high-pressure hose pipes poses significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With applications ranging from hydraulic systems in manufacturing to specialized equipment in construction, the demand for reliable and durable hoses is paramount. This comprehensive guide is designed to navigate the complexities of sourcing high-pressure hose pipes, providing insights into various types, applications, and the critical factors that influence supplier selection.

Buyers will discover the importance of understanding pressure ratings, material compatibility, and industry-specific standards to ensure optimal performance and safety in their operations. Furthermore, we delve into effective strategies for vetting suppliers, considering aspects such as product certifications, service quality, and logistical capabilities. Cost considerations, including pricing structures and potential bulk discounts, are also addressed to help buyers make informed financial decisions.

By equipping international B2B buyers with actionable insights and a thorough understanding of the high-pressure hose market, this guide empowers them to make confident purchasing decisions that meet their operational needs. Whether you are in Nigeria, Brazil, or elsewhere, the knowledge gained here will facilitate better supplier relationships and enhance your procurement processes in this critical sector.

جدول المحتويات

- Top 10 Hose Pipe For High Pressure Supplier Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hose pipe for high pressure supplier

- Understanding hose pipe for high pressure supplier Types and Variations

- Key Industrial Applications of hose pipe for high pressure supplier

- 3 Common User Pain Points for ‘hose pipe for high pressure supplier’ & Their Solutions

- Strategic Material Selection Guide for hose pipe for high pressure supplier

- In-depth Look: Manufacturing Processes and Quality Assurance for hose pipe for high pressure supplier

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose pipe for high pressure supplier’

- Comprehensive Cost and Pricing Analysis for hose pipe for high pressure supplier Sourcing

- Alternatives Analysis: Comparing hose pipe for high pressure supplier With Other Solutions

- Essential Technical Properties and Trade Terminology for hose pipe for high pressure supplier

- Navigating Market Dynamics and Sourcing Trends in the hose pipe for high pressure supplier Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hose pipe for high pressure supplier

- Strategic Sourcing Conclusion and Outlook for hose pipe for high pressure supplier

- تنويه هام وشروط الاستخدام

Understanding hose pipe for high pressure supplier Types and Variations

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| High Pressure Hydraulic Hoses | Rated for up to 10,000 psi; durable with multi-layer reinforcement | Construction, manufacturing, and mining | الإيجابيات: High durability; versatile applications. السلبيات: تكلفة أولية أعلى. |

| Stainless Steel Braided Hoses | Flexible, corrosion-resistant; available in various lengths | Aviation, chemical processing, and oil & gas | الإيجابيات: Excellent chemical resistance; lightweight. السلبيات: Can be more expensive than rubber. |

| Ultra High Pressure Hoses | Designed for pressures exceeding 10,000 psi; robust construction | Industrial cleaning and specialized machinery | الإيجابيات: Exceptional pressure handling; long service life. السلبيات: Requires careful handling and installation. |

| Specialty Hoses (e.g., Fuel, Water) | Tailored for specific fluids; various connection types available | Automotive, agriculture, and HVAC | الإيجابيات: Customizable for specific needs; optimized for fluid types. السلبيات: Limited to specific applications. |

| Abrasion-Resistant Hoses | Reinforced outer layer; designed for harsh environments | Mining, construction, and agricultural use | الإيجابيات: Enhanced durability against wear; longer lifespan. السلبيات: Heavier than standard hoses. |

What Are High Pressure Hydraulic Hoses and Their Applications?

High pressure hydraulic hoses are engineered to handle extreme pressures, often rated up to 10,000 psi. They are constructed with multiple layers of reinforcement, ensuring durability and resistance to wear and tear. These hoses are widely used in construction, manufacturing, and mining industries, where reliable performance under high pressure is critical. When purchasing, consider the hose’s pressure rating, compatibility with fluids, and length to ensure it meets the specific demands of your application.

How Do Stainless Steel Braided Hoses Stand Out?

Stainless steel braided hoses offer flexibility and corrosion resistance, making them ideal for industries such as aviation, chemical processing, and oil and gas. Their construction allows for a lightweight design without compromising strength. B2B buyers should evaluate the specific chemical compatibility and pressure requirements when selecting these hoses, as they can be more costly than rubber alternatives but offer superior longevity and performance.

What Are the Benefits of Ultra High Pressure Hoses?

Ultra high pressure hoses are designed for extreme applications, often exceeding pressures of 10,000 psi. Their robust construction makes them suitable for industrial cleaning and specialized machinery. While they provide exceptional pressure handling and extended service life, they require careful installation and maintenance to ensure safety and reliability. Buyers should assess the specific pressure requirements and environmental conditions to select the most suitable hose.

Why Choose Specialty Hoses for Specific Applications?

Specialty hoses, such as those designed for fuel or water, are tailored to handle specific fluids and come with various connection types. They are commonly used in automotive, agricultural, and HVAC applications. Buyers should consider the specific requirements of their operations, including fluid type and connection compatibility, to ensure optimal performance. While these hoses can offer excellent customization, they may be limited to particular applications.

What Advantages Do Abrasion-Resistant Hoses Offer?

Abrasion-resistant hoses are designed with reinforced outer layers to withstand harsh environments, making them ideal for mining, construction, and agricultural use. Their enhanced durability against wear extends the hose’s lifespan, providing a cost-effective solution in the long run. However, they tend to be heavier than standard hoses, which may impact handling and installation. Buyers should weigh the benefits of durability against potential handling challenges when making a purchasing decision.

Key Industrial Applications of hose pipe for high pressure supplier

| الصناعة/القطاع | Specific Application of hose pipe for high pressure supplier | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| النفط والغاز | High-pressure fluid transfer in drilling and extraction | Ensures safe and efficient transport of fluids | Compliance with industry standards, temperature resistance, and material compatibility |

| التصنيع | Hydraulic systems for machinery operation | Increases productivity and reduces downtime | Durability under extreme conditions, flexibility, and compatibility with existing systems |

| الزراعة | High-pressure irrigation systems | Maximizes water efficiency and crop yield | Resistance to wear and tear, UV stability, and proper fitting options |

| الإنشاءات | Concrete pumping and spraying | Enhances operational efficiency and project speed | High abrasion resistance, pressure ratings, and custom lengths |

| Industrial Cleaning and Maintenance | High-pressure cleaning for equipment and surfaces | Improves maintenance efficiency and equipment lifespan | Chemical resistance, flexibility, and ease of handling |

How Are Hose Pipes Used in the Oil and Gas Sector?

In the oil and gas industry, hose pipes for high pressure are vital for the safe and efficient transfer of drilling fluids and hydrocarbons during extraction processes. These hoses must withstand extreme pressures, often exceeding 10,000 psi, while maintaining integrity to prevent leaks and environmental hazards. International buyers from regions like Africa and the Middle East must prioritize sourcing hoses that comply with industry standards and are designed to handle the specific chemical compositions of the fluids being transported.

What Role Do High-Pressure Hoses Play in Manufacturing?

High-pressure hoses are crucial in manufacturing settings, where they are integrated into hydraulic systems that operate machinery. These hoses facilitate the transmission of hydraulic fluids that power equipment, ensuring seamless operations. Buyers should consider hoses with high durability and flexibility to accommodate various manufacturing processes. Additionally, sourcing hoses that meet international safety standards is essential for minimizing workplace accidents and maximizing productivity.

How Are High-Pressure Hoses Applied in Agriculture?

In agriculture, high-pressure hoses are utilized in irrigation systems to deliver water efficiently across large areas. By employing high-pressure technology, farmers can enhance water distribution, ensuring optimal moisture levels for crops. Buyers in regions like South America should look for hoses that offer UV stability and resistance to abrasion, ensuring longevity in outdoor environments. Furthermore, compatibility with existing irrigation systems is a critical consideration for effective implementation.

What Benefits Do High-Pressure Hoses Provide in Construction?

High-pressure hoses are integral in construction for tasks such as concrete pumping and spraying. They enable the quick and efficient transfer of concrete mixtures to various site locations, facilitating faster project completion. Construction firms must focus on sourcing hoses that provide high abrasion resistance and can withstand the rigors of construction environments. Custom lengths and fittings are also essential for maximizing versatility and ensuring compatibility with construction equipment.

How Are High-Pressure Hoses Used in Industrial Cleaning?

In industrial cleaning, high-pressure hoses are employed for the effective cleaning of machinery and surfaces, utilizing water or specialized cleaning solutions. These hoses help maintain equipment efficiency and prolong lifespan by removing dirt, grease, and other contaminants. Buyers should ensure that the hoses are resistant to chemicals and easy to handle, as this will enhance operational efficiency. Flexibility and compatibility with cleaning equipment are also important factors to consider during sourcing.

Illustrative image related to hose pipe for high pressure supplier

3 Common User Pain Points for ‘hose pipe for high pressure supplier’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compatibility with Existing Equipment

المشكلة B2B buyers often face the challenge of sourcing high-pressure hoses that are compatible with their existing equipment. This issue can stem from a lack of standardization in hose fittings and materials across different manufacturers. A buyer may purchase a hose that seems suitable but later discovers that the fittings do not match their hydraulic systems or that the hose material is not suitable for the fluids being transported, leading to leaks or equipment damage. This misalignment can result in costly downtime and the need for additional purchases, compounding frustrations.

الحل: To ensure compatibility, buyers should conduct thorough research before making a purchase. This includes consulting product specifications and compatibility charts provided by suppliers. It’s essential to verify the pressure ratings, material compatibility (such as rubber, thermoplastic, or stainless steel), and fitting types (NPT, JIC, etc.) of the hoses. Engaging directly with suppliers to discuss specific application needs can also provide valuable insights. Additionally, consider opting for suppliers that offer custom hose solutions, allowing you to specify lengths, fittings, and materials tailored to your operational requirements.

Scenario 2: Concerns About Durability and Reliability Under Pressure

المشكلة High-pressure applications demand hoses that can withstand extreme conditions without failing. Buyers may worry about the longevity and reliability of the hoses, especially in demanding environments such as construction sites or industrial settings. A hose that ruptures or leaks not only poses safety risks but also leads to operational delays and financial losses. Ensuring that the chosen hose can handle the intended pressure and environmental factors is crucial yet often difficult for buyers to assess.

Illustrative image related to hose pipe for high pressure supplier

الحل: To address durability concerns, buyers should prioritize hoses with proven performance metrics and certifications. Look for hoses that have undergone rigorous testing and meet industry standards, such as those outlined by the Material Handling Institute or other relevant organizations. Suppliers that provide detailed information on the hose’s construction, including multiple layers of reinforcement and abrasion-resistant coatings, can offer peace of mind. It is also advisable to seek warranties or guarantees from suppliers, as these can indicate the manufacturer’s confidence in their product’s reliability. Regular maintenance and inspections should be implemented to identify potential wear and tear before they lead to failure.

Scenario 3: Navigating the Complexities of International Shipping and Sourcing

المشكلة For international buyers, particularly in regions like Africa or South America, sourcing high-pressure hoses can involve navigating complex shipping logistics and import regulations. There may be additional costs related to customs duties, shipping delays, or finding reliable freight forwarders. These complexities can deter buyers from accessing the best products available globally, leading to reliance on local suppliers who may not offer optimal solutions.

الحل: To successfully navigate international sourcing, buyers should partner with suppliers who have experience in global logistics and can provide comprehensive shipping solutions. Engaging with suppliers that have a robust international presence can simplify the purchasing process. They can assist in understanding local regulations and help with documentation to ensure compliance. Additionally, buyers should consider leveraging freight forwarders who specialize in industrial equipment, as they can offer insights into the most efficient shipping routes and costs. Establishing a clear communication channel with the supplier regarding lead times and shipping options will also help manage expectations and streamline the procurement process.

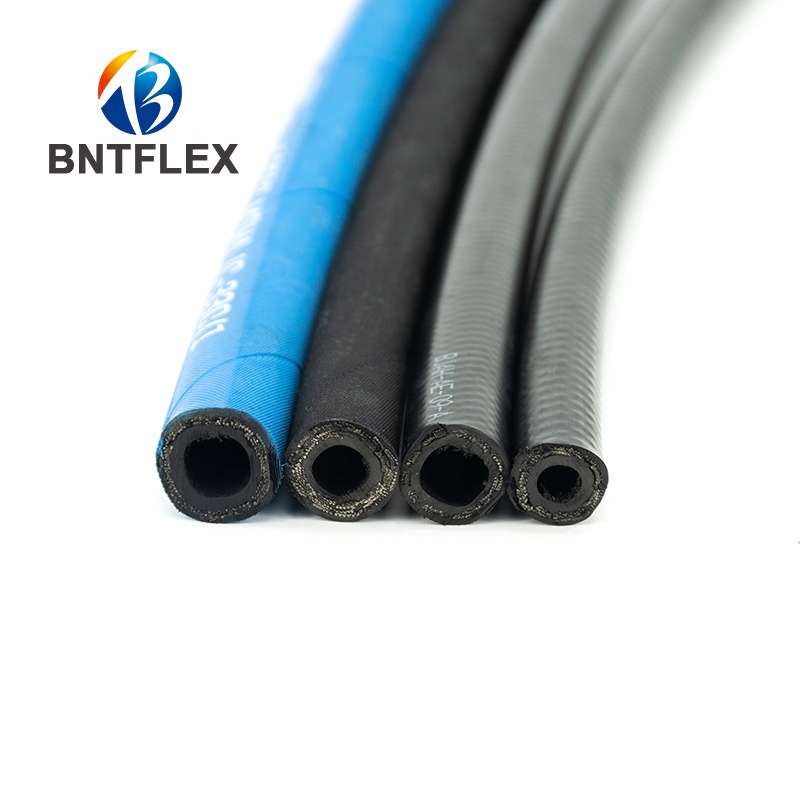

Strategic Material Selection Guide for hose pipe for high pressure supplier

When selecting materials for high-pressure hoses, it is crucial for B2B buyers to consider various factors such as performance characteristics, application compatibility, and regional standards. The following analysis explores four common materials used in high-pressure hoses, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Rubber in High-Pressure Hoses?

Rubber hoses, particularly those reinforced with synthetic fibers, are widely used in high-pressure applications. They offer excellent flexibility and can handle pressures up to 3000 psi (206 bar). Rubber is also relatively resistant to abrasion and has good temperature tolerance, typically ranging from -40°F to 212°F (-40°C to 100°C).

الإيجابيات والسلبيات: Rubber hoses are generally cost-effective and easy to manufacture, making them a popular choice. However, they may not be suitable for all media, particularly those that are highly corrosive or involve extreme temperatures. The longevity of rubber hoses can also be affected by exposure to UV light and ozone.

التأثير على التطبيق: Rubber hoses are ideal for hydraulic systems and general-purpose applications. However, international buyers should ensure that the rubber used complies with regional standards such as ASTM or ISO specifications for safety and performance.

How Does Stainless Steel Compare for High-Pressure Hoses?

Stainless steel hoses are known for their exceptional durability and corrosion resistance. They can withstand high pressures, often exceeding 5000 psi (345 bar), and are suitable for a wide range of temperatures. The multi-layer braided design enhances their strength and flexibility.

الإيجابيات والسلبيات: The primary advantage of stainless steel hoses is their resistance to corrosion and high temperatures, making them suitable for harsh environments. However, they are generally more expensive and can be more complex to manufacture compared to rubber hoses. Their rigidity may also limit flexibility in certain applications.

التأثير على التطبيق: Stainless steel hoses are commonly used in chemical processing and oil and gas applications. Buyers in regions with stringent environmental regulations should consider stainless steel hoses for their compliance with safety standards.

What Are the Advantages of Thermoplastic Hoses?

Thermoplastic hoses are engineered for high-pressure applications, often rated up to 6000 psi (413 bar). They are lightweight, flexible, and resistant to a variety of chemicals, making them suitable for diverse applications.

الإيجابيات والسلبيات: One of the key advantages of thermoplastic hoses is their versatility and lower weight, which can reduce overall system weight. However, they may not offer the same level of heat resistance as rubber or stainless steel hoses. Additionally, their performance can be affected by UV exposure.

التأثير على التطبيق: Thermoplastic hoses are frequently used in industries such as agriculture and construction. International buyers should verify that these hoses meet local standards for chemical compatibility and pressure ratings.

What Role Do Composite Hoses Play in High-Pressure Applications?

Composite hoses are constructed from multiple materials, often combining layers of thermoplastic and metal. They can handle pressures up to 5000 psi (345 bar) and are highly resistant to chemicals and temperature variations.

Illustrative image related to hose pipe for high pressure supplier

الإيجابيات والسلبيات: The composite design allows for excellent flexibility and chemical resistance, making them suitable for a wide range of applications. However, they can be more expensive and may require specialized fittings, complicating installation.

التأثير على التطبيق: Composite hoses are ideal for transporting chemicals and fuels. B2B buyers should ensure compliance with international standards, particularly in regions with strict regulations on hazardous materials.

Summary Table of Material Properties

| المواد | Typical Use Case for hose pipe for high pressure supplier | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Hydraulic systems, general-purpose applications | فعالة من حيث التكلفة ومرنة | Limited chemical compatibility | منخفضة |

| الفولاذ المقاوم للصدأ | Chemical processing, oil and gas applications | High durability and corrosion resistance | Higher cost, less flexible | عالية |

| بلاستيك حراري | Agriculture, construction | Lightweight and versatile | Lower heat resistance | متوسط |

| مركب | Transporting chemicals and fuels | Excellent flexibility and chemical resistance | Higher cost, installation complexity | عالية |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hose pipe for high pressure supplier

What Are the Key Stages in the Manufacturing Process of High-Pressure Hose Pipes?

The manufacturing of high-pressure hose pipes involves several critical stages, each designed to ensure that the final product meets stringent performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to hose pipe for high pressure supplier

Material Preparation: Which Materials Are Used for High-Pressure Hoses?

The first step in the manufacturing process is material preparation. High-pressure hoses are typically made from a combination of rubber, thermoplastics, and reinforced materials such as steel or synthetic fibers. The choice of materials is crucial, as they must withstand extreme pressures, temperatures, and environmental conditions. For instance, stainless steel braiding is often used for its strength and corrosion resistance, while high-grade rubber compounds provide flexibility and durability.

Forming: How Are High-Pressure Hoses Shaped?

After material preparation, the forming stage begins. This involves shaping the hose into its desired dimensions and structure. Advanced techniques such as extrusion and molding are commonly used. During extrusion, heated material is forced through a die to create a continuous length of hose. This process is particularly effective for producing hoses of varying diameters and lengths.

Assembly: What Techniques Are Used to Assemble Hose Pipes?

Once the individual components are formed, the assembly process takes place. This includes attaching fittings and connectors, which must be securely fastened to prevent leaks under high pressure. Techniques such as crimping and welding are employed to ensure that connections are robust. Additionally, quality checks are often integrated into this stage to identify any issues before proceeding to finishing.

Finishing: What Final Treatments Are Applied?

The finishing stage involves applying protective coatings and conducting final inspections. Hoses may receive abrasion-resistant outer layers to enhance durability. This stage also includes testing for flexibility, pressure endurance, and other performance metrics to ensure compliance with industry standards.

What Quality Assurance Measures Are Essential for High-Pressure Hose Suppliers?

Quality assurance (QA) is a crucial aspect of the manufacturing process for high-pressure hoses. It ensures that the products meet international safety standards and customer specifications.

Illustrative image related to hose pipe for high pressure supplier

ما هي المعايير الدولية التي يجب على المشترين بين الشركات أخذها في الاعتبار؟

For B2B buyers, understanding the relevant international standards is essential. ISO 9001 is a widely recognized standard that outlines quality management principles, focusing on customer satisfaction and continuous improvement. Additionally, industry-specific certifications such as CE marking (for European markets) and API standards (for oil and gas applications) are important indicators of product quality and safety.

What Are the QC Checkpoints in the Manufacturing Process?

Quality Control (QC) checkpoints are integral to the manufacturing process. These typically include:

- مراقبة الجودة الواردة (IQC): Raw materials are inspected upon receipt to ensure they meet specified standards.

- مراقبة الجودة أثناء المعالجة (IPQC): Ongoing inspections are conducted during manufacturing to identify defects early.

- مراقبة الجودة النهائية (FQC): The finished product undergoes rigorous testing to verify compliance with performance specifications before shipping.

What Common Testing Methods Are Used for High-Pressure Hoses?

Several testing methods are employed to ensure the reliability and safety of high-pressure hoses:

- الاختبار الهيدروستاتيكي: This method involves filling the hose with water and pressurizing it to check for leaks and structural integrity.

- Burst Testing: Hoses are subjected to pressures beyond their rated capacity to determine the maximum pressure they can withstand before failure.

- Flexibility Testing: Assessing how well the hose maintains its integrity under bending and twisting conditions.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers need to have confidence in their suppliers’ quality assurance processes. Here are several ways to verify supplier QC:

What Documentation Should Buyers Request?

Buyers should request documentation that includes:

- Quality Management System (QMS) Certifications: Proof of compliance with ISO 9001 or relevant certifications.

- Test Reports: Detailed results from hydrostatic and burst tests, along with any other relevant performance evaluations.

- Traceability Documents: Information on the sourcing of materials and the manufacturing process to ensure accountability.

How Can Buyers Conduct Audits and Inspections?

Conducting audits is a proactive way to assess a supplier’s quality assurance practices. Buyers can:

Illustrative image related to hose pipe for high pressure supplier

- Schedule On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes and QC measures firsthand.

- Engage Third-Party Inspectors: Independent inspections can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the Nuances of Quality Certification for International Buyers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is vital. Different markets may have unique regulations and compliance requirements.

How Do Regional Standards Affect Supplier Selection?

Buyers should consider local regulations and standards that may influence supplier selection. For example, the CE marking is essential for products sold in the European Union, while different certifications may be required in African or South American markets. Understanding these requirements helps buyers mitigate risks related to compliance and product safety.

What Role Does Supply Chain Transparency Play?

Supply chain transparency is increasingly important in global trade. Buyers should look for suppliers who provide clear information about their sourcing, manufacturing processes, and quality control measures. This transparency not only builds trust but also ensures that the products meet the buyers’ specific needs and regional regulations.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting high-pressure hose suppliers, ensuring that they receive reliable and compliant products tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose pipe for high pressure supplier’

This guide provides a comprehensive checklist for B2B buyers looking to procure high-pressure hose pipes from suppliers. The process can be intricate, given the critical nature of these products in various applications, including industrial cleaning, hydraulic systems, and more. By following this step-by-step approach, buyers can ensure they make informed decisions that meet their operational needs.

الخطوة 1: تحديد المواصفات الفنية الخاصة بك

Understanding the specific requirements for your high-pressure hose is essential. This includes pressure ratings, material types, and length specifications. High-pressure hoses often come with various features such as multi-layer reinforcement and abrasion resistance, which are critical for durability and safety in demanding applications.

- Pressure Rating: Ensure the hose can handle the maximum pressure of your application.

- توافق المواد: Choose materials that are resistant to the fluids they will convey, such as hydraulic oil or water.

الخطوة 2: البحث عن الموردين المحتملين

Thorough research is necessary to compile a list of potential suppliers. Look for companies with a proven track record in manufacturing high-pressure hoses. Utilize online directories, trade shows, and industry forums to gather names of reputable suppliers.

- تحقق من الخبرة في المجال: Suppliers with extensive experience in your industry can better understand your unique needs.

- Explore Product Range: A supplier offering a diverse range of hoses may provide better options tailored to your specifications.

الخطوة 3: تقييم شهادات الموردين

Before making a commitment, verify that potential suppliers have the necessary certifications. Compliance with international standards, such as ISO 9001, indicates a commitment to quality and safety.

- Quality Assurance: Certifications ensure that the supplier follows strict quality control measures.

- Safety Standards: Look for compliance with safety standards relevant to your industry, such as those set by the Material Handling Institute.

الخطوة 4: Request Samples and Specifications

Always request product samples and detailed specifications from shortlisted suppliers. This allows you to assess the quality and suitability of the hoses for your specific applications.

- Physical Assessment: Inspect the samples for construction quality, flexibility, and durability.

- Technical Documentation: Review specifications to ensure they align with your defined requirements.

الخطوة 5: Compare Pricing and Payment Terms

Cost is a critical factor in supplier selection. Compare pricing across different suppliers while considering the total cost of ownership, which includes shipping, installation, and maintenance.

- Transparent Pricing: Ensure there are no hidden costs in the pricing structure.

- Payment Flexibility: Understand payment terms and conditions to avoid cash flow issues.

الخطوة 6: Check References and Customer Feedback

Request references from previous clients to gauge the supplier’s reliability and service quality. Additionally, look for online reviews or testimonials to gather insights into the experiences of other buyers.

- Reputation in the Market: A supplier with a solid reputation is more likely to deliver quality products and services.

- After-Sales Support: Assess their commitment to customer service and support post-purchase.

الخطوة 7: Finalize the Agreement and Terms

Once you have evaluated all aspects, finalize the agreement with your selected supplier. Ensure all terms are clearly outlined, including delivery timelines, warranties, and service agreements.

- Legal Protection: A well-drafted contract protects both parties and outlines expectations.

- Flexibility for Future Needs: Discuss terms for future orders or adjustments to the supply agreement to accommodate your evolving needs.

By following this checklist, B2B buyers can confidently navigate the sourcing process for high-pressure hose pipes, ensuring they select a supplier that meets their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for hose pipe for high pressure supplier Sourcing

What Are the Key Cost Components in High-Pressure Hose Manufacturing?

When sourcing high-pressure hoses, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

المواد: High-pressure hoses are typically made from specialized materials such as synthetic rubber, thermoplastics, or stainless steel braiding. The choice of material significantly impacts the durability and pressure rating of the hose, thereby influencing cost.

-

العمالة: Skilled labor is often required for manufacturing high-pressure hoses, especially in processes like assembly and quality control. Labor costs can vary based on the region and the complexity of the hose design.

-

نفقات التصنيع الزائدة: This includes utilities, facility costs, and equipment depreciation. Efficient manufacturing processes can help minimize overhead, thus affecting the overall pricing.

-

الأدوات: Initial tooling costs can be substantial, especially for custom or specialized hoses. This one-time investment is spread over the production volume, impacting per-unit costs.

-

مراقبة الجودة (QC): Ensuring that hoses meet safety and performance standards requires rigorous testing, which can add to the production cost. Certifications like ISO or specific industry standards also necessitate additional QC processes.

-

الخدمات اللوجستية: Transportation costs are particularly important for international buyers. These can fluctuate based on shipping methods, distances, and the Incoterms agreed upon.

-

الهامش: Finally, suppliers will add a margin to cover their operational costs and profit. This can vary widely depending on the supplier’s market position and the competitive landscape.

How Do Volume and Customization Influence Pricing?

Volume and customization are two critical factors that can significantly influence the pricing of high-pressure hoses.

-

الحجم/معدل العرض/الطلب: Suppliers often offer discounts for bulk purchases. Understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing. For instance, buying in larger quantities can lead to lower per-unit costs, which is advantageous for businesses with ongoing needs.

-

المواصفات والتخصيص: Custom hoses tailored to specific applications or industries may come at a premium. Buyers should clearly define their requirements, as this can help suppliers provide more accurate quotes and lead times.

What Role Do Quality and Certifications Play in Pricing?

The quality of high-pressure hoses is paramount, especially in industries where safety is a concern. Higher-quality materials and manufacturing processes typically lead to increased costs. Additionally, certifications like ISO 9001 or industry-specific standards can add to the price but also ensure reliability and compliance with safety regulations. Buyers should weigh the cost against the long-term benefits of investing in high-quality hoses.

What Are the Important Buyer Tips for Negotiating Prices?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several strategies when negotiating prices:

-

التكلفة الإجمالية للملكية (TCO): Evaluate not only the purchase price but also the long-term costs associated with maintenance, durability, and potential downtime. A lower initial cost may not always be the best option if the hose requires frequent replacements.

-

Understanding Pricing Nuances: Be aware of the factors that influence pricing, such as currency fluctuations, import duties, and local regulations. These can significantly affect the total landed cost of the hoses.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better terms and pricing. Regular communication and feedback can help establish trust, which may result in more favorable negotiations.

-

Leverage Incoterms: Familiarize yourself with Incoterms to understand the responsibilities of buyers and sellers in shipping. This can help avoid unexpected costs and delays.

Disclaimer on Indicative Pricing

It’s essential to note that prices for high-pressure hoses can vary widely based on the factors mentioned above. Always seek detailed quotes from multiple suppliers to ensure competitive pricing and the best value for your investment.

Illustrative image related to hose pipe for high pressure supplier

Alternatives Analysis: Comparing hose pipe for high pressure supplier With Other Solutions

Introduction: Understanding Alternatives in High-Pressure Solutions

When selecting a high-pressure hose supplier, it is essential to consider not only the hose pipes themselves but also viable alternative solutions that can meet similar operational needs. The right choice can depend on various factors, including performance requirements, cost considerations, and the specific applications involved. This analysis will compare traditional high-pressure hose suppliers with alternative solutions such as high-pressure piping systems and hydraulic pumps, providing insights that will help international B2B buyers make informed decisions.

Comparison Table

| جانب المقارنة | Hose Pipe For High Pressure Supplier | High-Pressure Piping System | Hydraulic Pumps |

|---|---|---|---|

| الأداء | Handles up to 10,000 psi; flexible and durable | Rigid; can handle higher pressures over long distances | Varies widely; typically high flow rates |

| التكلفة | Moderate initial investment; ongoing maintenance costs | Higher upfront costs; lower long-term operational costs | Variable; depends on capacity and application |

| سهولة التنفيذ | Generally straightforward installation; requires fittings | More complex; requires planning and installation expertise | Requires proper setup and calibration |

| الصيانة | Regular inspection and replacement necessary | Lower maintenance; less frequent inspections needed | Routine maintenance and checks needed |

| أفضل حالة استخدام | Ideal for mobile applications and short runs | Best for fixed installations with long runs | Suitable for high flow and pressure applications |

التقسيم التفصيلي للبدائل

High-Pressure Piping Systems

High-pressure piping systems provide a rigid alternative to hose pipes, allowing for the transport of fluids under high pressure over longer distances. These systems are typically constructed from metals such as steel or high-grade plastics, making them robust and suitable for various industrial applications. The primary advantage is their ability to maintain structural integrity under extreme pressure, which can exceed that of standard hoses. However, the installation process can be complex and costly, requiring specialized knowledge and tools.

Hydraulic Pumps

Hydraulic pumps serve as an alternative solution by generating high-pressure hydraulic fluid flow. They can be integrated into systems requiring significant power output, such as machinery in manufacturing or construction. The flexibility of hydraulic pumps allows them to be used in various applications, from powering hydraulic lifts to facilitating automated processes. While they provide high flow rates and can achieve significant pressure, the initial investment and ongoing maintenance can be substantial, which may be a deterrent for some businesses.

الخاتمة: اختيار الحل المناسب لاحتياجاتك

For B2B buyers considering high-pressure solutions, the choice between a hose pipe supplier and alternative methods hinges on specific operational requirements. High-pressure hose suppliers offer flexibility and ease of use, making them ideal for mobile and varied applications. In contrast, high-pressure piping systems may be more suitable for fixed installations requiring long-distance fluid transport. Hydraulic pumps, while powerful, require careful consideration of costs and maintenance. Ultimately, assessing the unique demands of your operations will guide you in selecting the most appropriate solution for your business needs.

Essential Technical Properties and Trade Terminology for hose pipe for high pressure supplier

What Are the Key Technical Properties of High-Pressure Hose Pipes?

When considering high-pressure hose pipes, several critical specifications must be understood to ensure the right choice for your application. Here are some essential properties:

-

درجة المادة

High-pressure hoses are typically constructed from materials such as thermoplastic, rubber, or stainless steel. The choice of material affects durability, flexibility, and resistance to environmental factors. For instance, stainless steel braided hoses offer superior abrasion resistance and high-temperature tolerance, making them suitable for demanding industrial environments. -

تصنيف الضغط

This specification indicates the maximum pressure the hose can safely handle, typically measured in psi (pounds per square inch) or bar. For example, hoses designed for hydraulic applications may have ratings as high as 10,000 psi (700 bar). Understanding the pressure rating is crucial for ensuring safety and performance, as using a hose beyond its rated pressure can lead to catastrophic failures. -

نطاق درجة الحرارة

The operating temperature range defines the extremes the hose can withstand without degrading. High-pressure hoses often have specific temperature ratings, which are vital for applications involving hot fluids or gases. A hose that cannot handle the required temperature may become brittle or lose integrity, posing risks to operations. -

Burst Pressure

This metric refers to the maximum pressure the hose can withstand before bursting. It is usually significantly higher than the working pressure and is vital for safety considerations. A high burst pressure provides a safety margin, allowing for unexpected pressure spikes during operation. -

Flexibility and Bend Radius

Flexibility indicates how easily the hose can be maneuvered in tight spaces, while the bend radius is the minimum curve a hose can be bent without damage. These properties are particularly important in applications where space is limited, such as in machinery or vehicles. A hose with a smaller bend radius can facilitate easier installation and routing. -

Safety Factor

The safety factor is a ratio that indicates how much stronger a hose is compared to the maximum pressure it will experience during normal use. A common safety factor for hydraulic hoses is 4:1, meaning the hose can handle four times the maximum working pressure. This factor is critical for ensuring long-term reliability and safety in high-pressure systems.

ما هي المصطلحات التجارية الشائعة التي يجب أن يعرفها المشترون بين الشركات؟

Understanding industry jargon can significantly enhance communication and negotiation with suppliers. Here are some essential terms:

-

OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of high-pressure hoses, OEMs often provide hoses that meet specific standards required by machinery or vehicles, ensuring compatibility and quality. -

موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For high-pressure hoses, understanding MOQ is essential for budgeting and inventory management. Suppliers may set MOQ to optimize production and minimize costs. -

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. When seeking high-pressure hoses, issuing an RFQ helps buyers compare prices and terms, facilitating informed purchasing decisions. -

إنكوترمز (الشروط التجارية الدولية)

These are pre-defined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps prevent disputes and misunderstandings in international transactions. -

توافق السوائل الهيدروليكية

This term refers to the ability of the hose material to withstand various hydraulic fluids without degrading. It is crucial for ensuring the longevity and safety of the hose in hydraulic applications, as using incompatible fluids can lead to hose failure. -

المهلة الزمنية

Lead time is the duration between placing an order and receiving the product. Understanding lead times is vital for project planning, especially in industries where timely delivery of high-pressure hoses can affect operational efficiency.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing high-pressure hose pipes, ensuring they meet their specific operational needs while optimizing safety and performance.

Navigating Market Dynamics and Sourcing Trends in the hose pipe for high pressure supplier Sector

What are the Current Market Dynamics and Key Trends Affecting High-Pressure Hose Pipe Suppliers?

The high-pressure hose pipe market is witnessing significant growth driven by various global factors. Increasing demand across industries such as construction, oil and gas, agriculture, and manufacturing is propelling the need for durable and reliable hose solutions. Emerging economies in Africa, South America, and the Middle East are investing heavily in infrastructure, which is a major driver for high-pressure hose suppliers. Additionally, advancements in materials technology, such as the use of synthetic fibers and advanced composite materials, are enhancing product performance and safety ratings, making hoses more resistant to extreme conditions.

Illustrative image related to hose pipe for high pressure supplier

B2B buyers are increasingly focusing on technological innovations that improve operational efficiency. The integration of IoT (Internet of Things) in hose monitoring systems allows for real-time tracking of performance metrics, thus enabling predictive maintenance and reducing downtime. Furthermore, the rise of e-commerce platforms is transforming the sourcing landscape, allowing international buyers to access a wider range of products and suppliers at competitive prices. With the shift towards digitalization, suppliers that leverage data analytics for inventory management and customer insights are better positioned to meet the evolving demands of the market.

How is Sustainability and Ethical Sourcing Influencing High-Pressure Hose Pipe Supply Chains?

The focus on sustainability is reshaping the sourcing strategies of high-pressure hose suppliers. As businesses become more conscious of their environmental impact, the demand for eco-friendly materials and manufacturing processes is on the rise. Suppliers are increasingly adopting ‘green’ certifications and sourcing from manufacturers that prioritize sustainability. This includes utilizing recyclable materials and reducing waste during production.

Ethical sourcing is also gaining importance, particularly among international buyers who prioritize supply chain transparency. This trend is especially relevant for regions like Africa and South America, where ethical labor practices are critical for maintaining brand reputation and customer loyalty. Suppliers that can demonstrate compliance with environmental regulations and ethical standards will likely gain a competitive edge in the global marketplace. Buyers are advised to seek partnerships with suppliers who have verifiable sustainability credentials and a commitment to social responsibility.

What is the Historical Context of High-Pressure Hose Pipe Development?

The evolution of high-pressure hose pipes can be traced back to the industrial revolution, where the need for reliable fluid transfer in hydraulic systems became paramount. Initial designs were rudimentary, often made from rubber and lacking the safety features seen today. Over the decades, advancements in materials science led to the development of synthetic hoses capable of withstanding much higher pressures and temperatures.

By the late 20th century, the introduction of reinforced composite materials and braided steel hoses revolutionized the market, enhancing durability and safety. The modern high-pressure hose market now offers a wide range of specialized products tailored for various applications, including hydraulic systems, industrial cleaning, and even aerospace. This historical context highlights the ongoing innovation in the sector, driven by the need for greater efficiency, safety, and environmental responsibility.

In conclusion, understanding the dynamics, sustainability trends, and historical context of the high-pressure hose market equips international B2B buyers with the insights necessary to make informed sourcing decisions. By aligning with suppliers who prioritize innovation and ethical practices, businesses can enhance their operational efficiency while contributing to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of hose pipe for high pressure supplier

-

1. How do I choose the right high-pressure hose for my application?

Choosing the right high-pressure hose involves considering several factors, including the type of fluid being transported, pressure ratings, temperature ranges, and the hose’s material compatibility. Ensure that the hose can withstand the maximum pressure of your system, typically rated higher than your operating pressure for safety. Additionally, assess the hose length, diameter, and connection types needed for your specific equipment. Consulting with suppliers who offer expert guidance can also help you make an informed decision based on your unique operational requirements. -

2. What are the key specifications to look for in high-pressure hoses?

Key specifications to consider include the hose’s pressure rating (often measured in psi or bar), temperature tolerance, and material composition. Look for hoses with multi-layer reinforcement for durability and safety, as well as resistance to abrasion, chemicals, and environmental factors. Additionally, check the connection types and ensure they match your equipment. Compliance with industry standards and certifications is also crucial for ensuring reliability and safety in demanding applications. -

3. What is the typical lead time for ordering high-pressure hoses?

Lead times can vary significantly based on several factors such as customization, order volume, and supplier location. Standard orders may ship within a few days, while custom hoses could take several weeks to manufacture. It’s advisable to discuss timelines with your supplier during the ordering process. For international buyers, factor in additional time for customs clearance and shipping, which can further affect delivery schedules. -

4. How can I verify the quality of high-pressure hoses from suppliers?

To verify quality, request certifications and compliance documentation that demonstrate adherence to industry standards. Conducting supplier audits and checking references from other buyers can also provide insights into the supplier’s reliability. Additionally, consider ordering samples for testing before committing to larger orders. Quality assurance processes, including pressure testing and material inspections, should be a part of the supplier’s manufacturing protocol. -

5. What are the minimum order quantities (MOQ) for high-pressure hoses?

Minimum order quantities can vary widely among suppliers, often depending on the hose type, material, and customization requirements. Some suppliers may offer flexible MOQs for standard products, while custom hoses may require larger quantities. It’s important to discuss your needs with potential suppliers and negotiate terms that work for your business. Always consider the cost-effectiveness of larger orders against your inventory capabilities. -

6. What payment terms should I expect when sourcing high-pressure hoses internationally?

Payment terms can differ based on supplier policies, geographic locations, and the nature of the transaction. Common terms include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60 days). It’s essential to discuss and agree on payment methods that provide security for both parties. International transactions may also involve currency considerations, so be sure to clarify exchange rates and potential fees. -

7. How do I handle logistics and shipping for high-pressure hoses?

Logistics for high-pressure hoses involve coordinating with your supplier to determine the best shipping methods based on your location and urgency. Consider factors like freight costs, customs clearance, and potential delays. Working with freight forwarders experienced in international shipping can streamline the process. Ensure you have the necessary import/export documentation to avoid issues at customs. -

8. Can I customize high-pressure hoses to meet specific requirements?

Yes, many suppliers offer customization options for high-pressure hoses, including length, diameter, material, and connection types. Custom solutions can help you better meet the specific needs of your application. When discussing customization, provide detailed specifications to your supplier to ensure the final product meets your operational requirements. Always confirm lead times and costs associated with custom orders to avoid unexpected delays or expenses.

Top 10 Hose Pipe For High Pressure Supplier Manufacturers & Suppliers List

1. MH Oxygen – High-Pressure Flex Hoses

المجال: mhoxygen.com

مسجل: 2000 (25 سنة)

مقدمة: High-pressure Hoses: 1/8NPT (M-M) Flex Hose – 2 braided flex hose with 1/8 NPT (pipe threads) male on both ends, available in lengths from 18-inch to 8-foot, priced at $95.00 – $199.00. 1/4 NPT F-F Flex Hose – 4 braided flex hose with 1/4 NPT (pipe threads, female on both ends), available in lengths from 18-inch to 10-foot, priced at $95.00 – $299.00. 1/4 NPT M-F Flex Hose – 4 braided flex hose wi…

2. Enerpac – Hydraulic Hoses

المجال: enerpac.com

Registered: 1995 (30 years)

مقدمة: {“product_type”:”Hydraulic Hoses”,”pressure_rating”:”10,000 psi (700 bar)”,”diameters”:”two diameters available”,”connection_types”:”various connection types”,”lengths”:”up to 50 ft (15m)”,”H700_series”:”4:1 safety factor”,”H900_series”:”complies with Material Handling Institute IJ100 hose specification”,”bonus_savings”:”3%, 5%, or 8%”,”offer_end_date”:”29th August 2025″}

3. RMI Order – High Pressure Hoses

المجال: rmiorder.com

Registered: 2007 (18 years)

مقدمة: High Pressure Hoses available for purchase. Custom hose builder site for ordering hoses with specific fittings. Customer support available at 800-264-7793 for inquiries. Warning about exposure to chemicals including Lead, which may cause cancer and reproductive harm.

4. Dultmeier – High Pressure Hose

المجال: dultmeier.com

مسجل: 1996 (29 سنة)

مقدمة: High Pressure Hose designed for demanding applications including power washer hose and sewer jetting hose. Features include multi-layer reinforcement for maximum pressure handling, abrasion-resistant outer coating, high-temperature resistance, and burst-resistant design. Offers a wide range of pressure ratings, extended service life, and flexible handling. Suitable for industrial cleaning, manufac…

5. NLB Corp – Ultra High Pressure Hose

المجال: nlbcorp.com

مسجل: 1996 (29 سنة)

مقدمة: Ultra High Pressure Hose, designed for extreme pressure applications, suitable for hydraulic systems, high-pressure cleaning, and industrial use. Features include high tensile strength, excellent flexibility, and resistance to abrasion and weathering. Available in various lengths and diameters to meet specific requirements. Compatible with a range of couplings and fittings for versatile use.

6. Titeflex – Ultra High Pressure Hoses

المجال: titeflex.com

Registered: 1995 (30 years)

مقدمة: {“Ultra High Pressure Hoses”: {“402X Series High Pressure Annular Hose”: {“Material”: “Series 300 stainless steel”, “Layers”: “Up to 4 layers of braid”, “Types”: [“Double (402X)”, “Triple (403X)”, “Quad (404X)”], “Diameter”: “1/4″ – 4” (4-100mm)”}, “403XM/404XM Series High Pressure Annular Hose”: {“Material”: “Series 300 stainless steel”, “Layers”: “Up to 4 layers of braid”, “Types”: [“Double (402…

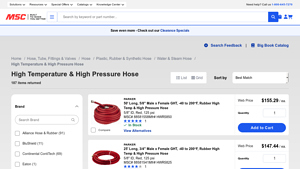

7. MSC Direct – High Temperature & Pressure Hoses

المجال: mscdirect.com

مسجل: 1996 (29 سنة)

مقدمة: This company, MSC Direct – High Temperature & Pressure Hoses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. High Pressure Hose – Rubber Hoses for Air, Oil, and Water

المجال: highpressure-hose.com

مسجل: 2012 (13 سنة)

مقدمة: High Pressure Rubber Hose for Air, Oils and Water; suitable for hydraulic systems, gas and water supply; made from various materials depending on operating environment; includes steel wire reinforced hoses (SAE 100 R1/R2/R5, EN 853 1SN/2SN), steel wire spiraled hoses (EN 856 4SH/4SP, SAE 100 R12/R13/R15), textile reinforced hoses (EN 854 1TE/2TE/3TE, SAE 100 R3/R4/R6), thermoplastic hoses (SAE 100…

9. The Hydraulic Hose – High Pressure Hydraulic Hoses

المجال: thehydraulichose.com

مسجل: 2012 (13 سنة)

مقدمة: High Pressure Hydraulic Hose types: EN 853 1SN, 2SN, 4SP, 4SH, SAE 100R13, R15. Applications: hydraulic systems for mineral and hydraulic oil, fuel oil, water-oil emulsions; used in logging, road-construction, agriculture, mining, oil and gas industries. EN 853 1SN specifications: Tube – synthetic rubber, Reinforcement – one-braid high tensile steel wire, Cover – abrasion/weather resistant synthet…

10. Swagelok – Industrial Hoses and Flexible Tubing

المجال: products.swagelok.com

مسجل: 1996 (29 سنة)

مقدمة: Industrial Hoses and Flexible Tubing from Swagelok include various types such as Flexible Tubing, Metal Core Hose, and PTFE and PFA Core Hose. Key offerings include:

– Flexible Tubing: Available in PFA and Vinyl options.

– Metal Core Hose: Includes Flexible Metal Hose (FJ, FL, FM, FX, AH Series) and High-Pressure Metal Hose.

– Vacuum-Insulated Metal Hose (FV Series).

– PTFE and PFA Core Hose: Opti…

Strategic Sourcing Conclusion and Outlook for hose pipe for high pressure supplier

In the evolving landscape of high-pressure hose supply, strategic sourcing emerges as a critical pillar for international B2B buyers. Understanding the diverse range of high-pressure hoses—ranging from hydraulic to ultra-high-pressure options—ensures that businesses can select products that meet rigorous operational demands while adhering to safety standards. Buyers must prioritize suppliers who not only offer a comprehensive selection but also demonstrate a commitment to quality, compliance, and innovation.

Illustrative image related to hose pipe for high pressure supplier

As markets in Africa, South America, the Middle East, and Europe continue to grow, so does the necessity for reliable partnerships that facilitate seamless procurement processes. By leveraging strategic sourcing, organizations can enhance their supply chain resilience, mitigate risks associated with quality and delivery, and ultimately drive cost efficiencies.

Looking ahead, the global demand for high-pressure hoses is poised to expand, fueled by advancements in technology and increasing industrial applications. Now is the time for B2B buyers to engage with reputable suppliers and invest in high-quality solutions that not only fulfill current needs but also position them for future growth. Start exploring your options today to secure the best value for your high-pressure hose requirements.

تنويه هام وشروط الاستخدام

⚠️ إخلاء مسؤولية مهم ⚠️

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.

Illustrative image related to hose pipe for high pressure supplier