Introduction: Navigating the Global Market for hose water jet

In the fast-evolving landscape of industrial cleaning and maintenance, sourcing the right hose water jet solutions presents a significant challenge for B2B buyers across diverse markets. Whether you are operating in Africa, South America, the Middle East, or Europe, the need for efficient, high-performance water jetting systems to enhance productivity and reduce operational costs cannot be overstated. This comprehensive guide delves into the various types of hose water jets available, their specific applications across industries, and critical factors to consider when evaluating suppliers.

From ultra-high-pressure hoses designed for heavy-duty applications to versatile nozzles suitable for routine cleaning tasks, the spectrum of hose water jet products is vast. Understanding the nuances of each type, alongside insights into supplier vetting processes and pricing structures, will empower you to make informed purchasing decisions.

This guide is specifically tailored for international B2B buyers, providing you with actionable insights that address local market needs and global standards. By leveraging this information, you will be better equipped to navigate the complexities of sourcing hose water jet solutions, ensuring that you select products that not only meet your operational requirements but also align with your budgetary constraints. Equip yourself with the knowledge to optimize your procurement strategy and enhance your business’s cleaning capabilities.

جدول المحتويات

- A Look at Hose Water Jet Manufacturers & Suppliers

- Introduction: Navigating the Global Market for hose water jet

- Understanding hose water jet Types and Variations

- Key Industrial Applications of hose water jet

- 3 Common User Pain Points for ‘hose water jet’ & Their Solutions

- Strategic Material Selection Guide for hose water jet

- In-depth Look: Manufacturing Processes and Quality Assurance for hose water jet

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose water jet’

- Comprehensive Cost and Pricing Analysis for hose water jet Sourcing

- Alternatives Analysis: Comparing hose water jet With Other Solutions

- Essential Technical Properties and Trade Terminology for hose water jet

- Navigating Market Dynamics and Sourcing Trends in the hose water jet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hose water jet

- Strategic Sourcing Conclusion and Outlook for hose water jet

- تنويه هام وشروط الاستخدام

Understanding hose water jet Types and Variations

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Turbo Jet Nozzle | High spray capability, adjustable spray patterns | Lawn care, vehicle washing, general cleaning | الإيجابيات: Versatile and easy to use. السلبيات: Limited pressure compared to UHP options. |

| Ultra High Pressure (UHP) Hose | Rated for 40,000 – 55,000 psi, durable materials | Industrial cleaning, surface preparation | الإيجابيات: Extremely effective for tough jobs. السلبيات: Higher cost and requires specialized equipment. |

| Mini-Jet Water Jetter | Compact design, 1500 psi, portable | Drain cleaning, maintenance of plumbing systems | الإيجابيات: Lightweight and efficient. السلبيات: Limited to smaller diameter pipes. |

| High-Pressure Water Blaster | High flow rates, robust build | Heavy-duty cleaning, construction sites | الإيجابيات: High efficiency and effectiveness. السلبيات: Requires more maintenance and can be expensive. |

| Hydrodemolition Systems | Precision cutting, minimal collateral damage | Concrete removal, surface restoration | الإيجابيات: Safe and precise. السلبيات: Requires skilled operation and specialized training. |

What Are the Characteristics of Turbo Jet Nozzles?

Turbo Jet nozzles are designed for versatility, featuring adjustable spray patterns that allow for high spray capabilities. These nozzles are particularly suitable for B2B applications like lawn care, vehicle washing, and general cleaning tasks. Buyers should consider the ease of use and adaptability of Turbo Jet nozzles, although they may lack the pressure needed for more demanding industrial applications.

How Do Ultra High Pressure Hoses Benefit Industrial Cleaning?

Ultra High Pressure (UHP) hoses are engineered to handle pressures ranging from 40,000 to 55,000 psi, making them ideal for industrial cleaning and surface preparation tasks. They are constructed from durable materials that resist wear and tear, ensuring longevity in demanding environments. B2B buyers should weigh the high initial investment against the efficiency and effectiveness these hoses provide for heavy-duty cleaning tasks.

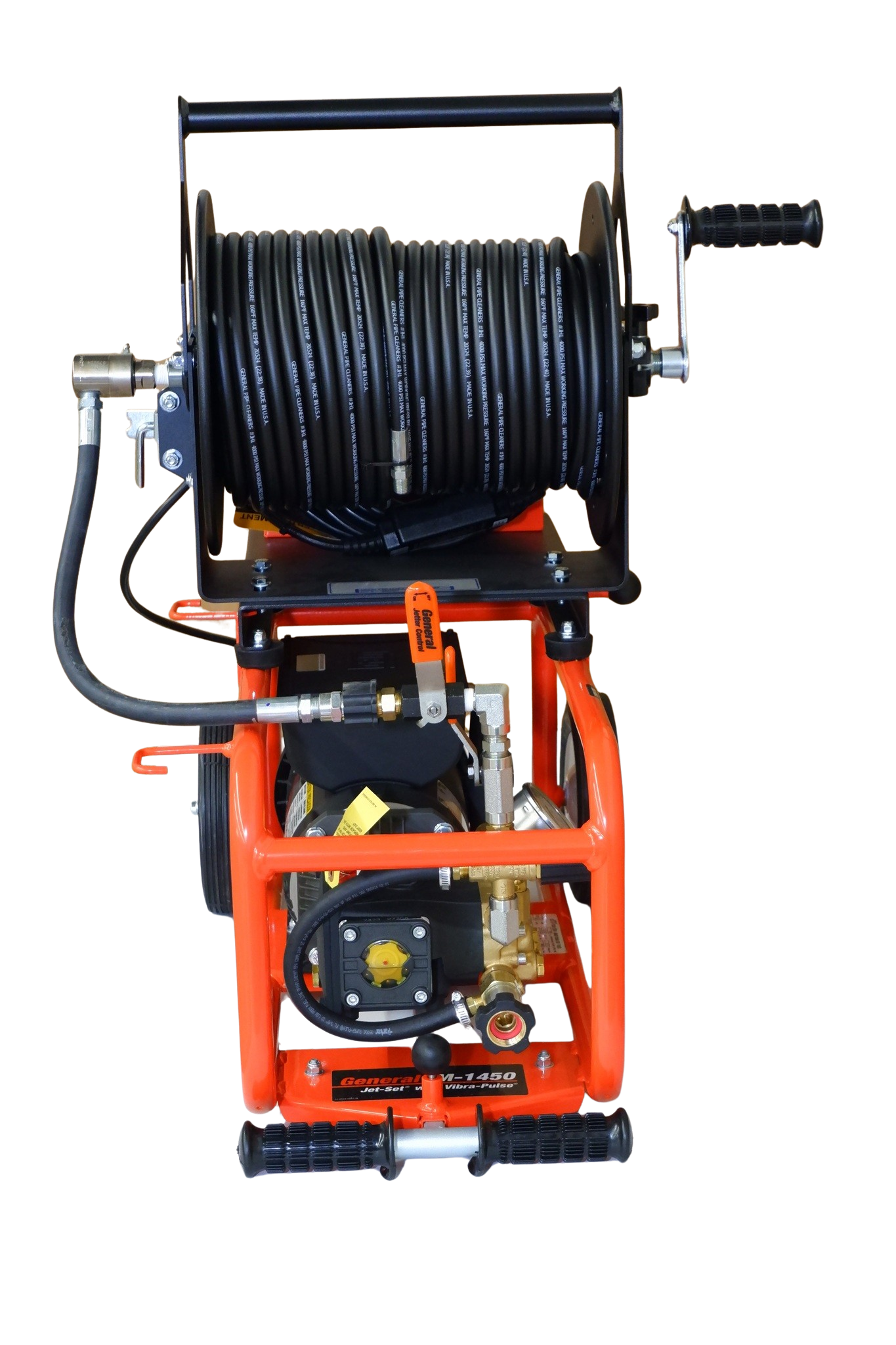

Why Choose Mini-Jet Water Jetters for Plumbing Maintenance?

The Mini-Jet water jetter offers a compact design and operates at 1500 psi, making it perfect for clearing clogged drains and maintaining plumbing systems. Its lightweight and portable nature allow for easy transport to job sites, enhancing operational efficiency. However, buyers should note that its use is limited to smaller diameter pipes, which may restrict its applicability in larger plumbing systems.

What Advantages Do High-Pressure Water Blasters Offer?

High-pressure water blasters are built for heavy-duty cleaning applications, featuring robust designs that allow for high flow rates. They are commonly used in construction sites and for deep cleaning tasks. While these systems are highly effective, buyers must consider the increased maintenance requirements and higher costs associated with such powerful machinery.

How Do Hydrodemolition Systems Ensure Precision in Concrete Removal?

Hydrodemolition systems utilize high-pressure water jets for precise cutting and surface restoration, minimizing collateral damage to surrounding structures. This technology is particularly beneficial in construction and renovation projects where precision is paramount. B2B buyers should evaluate the need for skilled operation and specialized training, which may add to overall project costs, but ultimately provide a safer and more efficient solution for concrete removal.

Key Industrial Applications of hose water jet

| الصناعة/القطاع | Specific Application of hose water jet | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| التصنيع | Surface preparation for painting and coating | Enhanced adhesion and finish quality | Durability of hoses under high pressure; compatibility with existing equipment. |

| الإنشاءات | Hydro-demolition and concrete removal | Efficient material removal with minimal dust and debris | Hose length and pressure rating; availability of fittings and adaptors. |

| النفط والغاز | Pipeline cleaning and descaling | Improved flow efficiency and reduced maintenance costs | Resistance to chemicals; high-pressure ratings for effective cleaning. |

| Marine | Hull cleaning and maintenance | Extended lifespan of vessels and reduced maintenance costs | Corrosion resistance; adaptability to various marine environments. |

| إدارة النفايات | Clearing clogged drains and sewer lines | Reduced downtime and increased operational efficiency | Compact design for portability; compatibility with various drain sizes. |

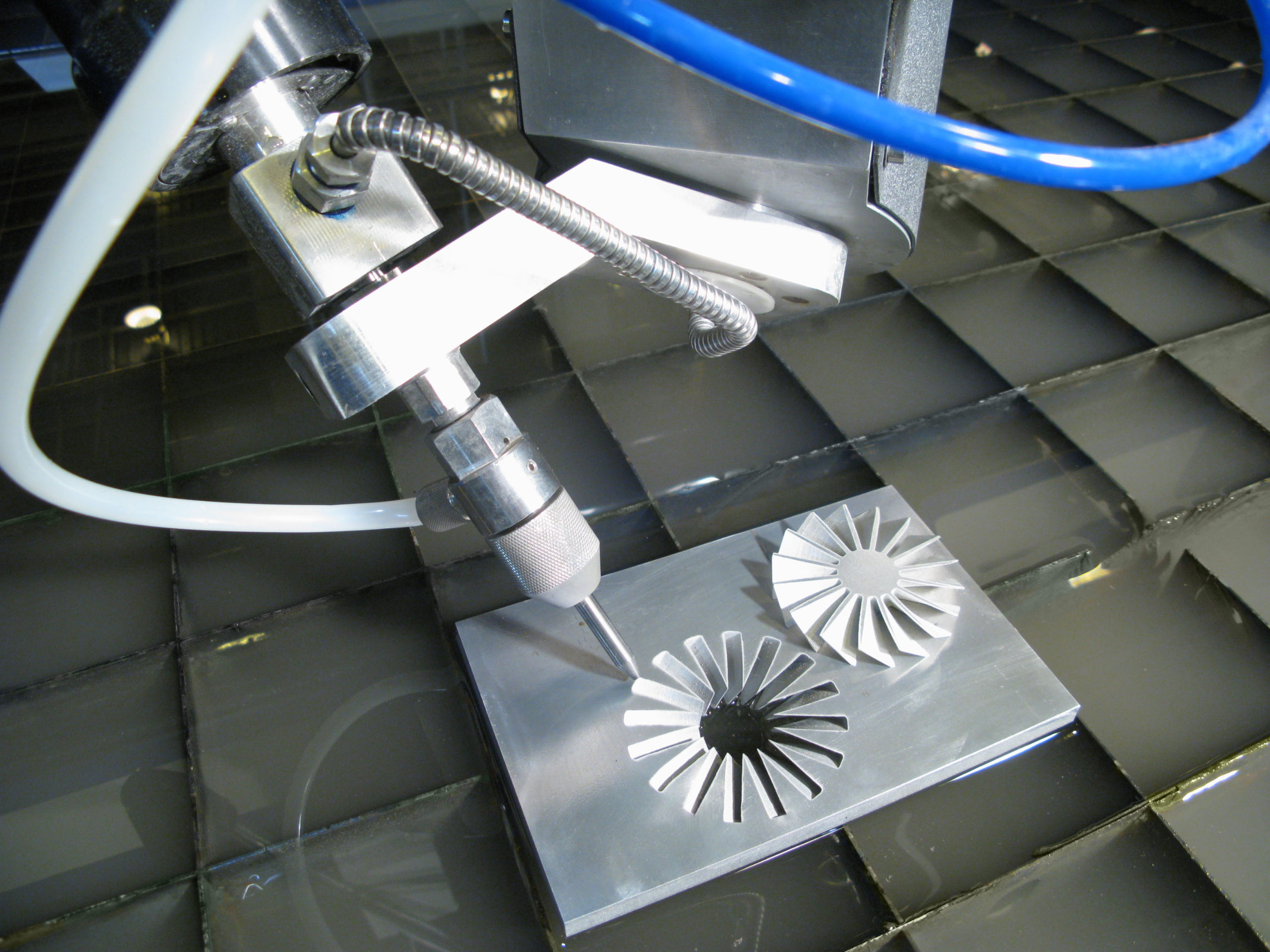

How is Hose Water Jet Used in Manufacturing Applications?

In the manufacturing sector, hose water jets are primarily employed for surface preparation prior to painting or coating. This process ensures that surfaces are free of contaminants like rust, grease, and old paint, thereby enhancing adhesion and finish quality. For international buyers, particularly in regions like Africa and South America, sourcing high-quality hoses that can withstand rigorous cleaning processes is vital. They should look for hoses with high-pressure ratings and durability to ensure long-term use.

Illustrative image related to hose water jet

What Role Does Hose Water Jet Play in Construction?

In construction, hose water jets are invaluable for hydro-demolition and concrete removal tasks. This method allows for the efficient removal of concrete without causing damage to underlying structures, minimizing dust and debris. Buyers in the Middle East and Europe need to consider the hose length and pressure ratings suitable for their specific projects, ensuring that the equipment can handle the demands of heavy-duty applications.

How is Hose Water Jet Essential in the Oil & Gas Industry?

The oil and gas industry utilizes hose water jets for cleaning and descaling pipelines. This process enhances flow efficiency and significantly reduces maintenance costs by preventing blockages and corrosion. Buyers from regions with extensive oil fields, such as Africa and the Middle East, should prioritize sourcing hoses that are resistant to harsh chemicals and capable of operating under high-pressure conditions to ensure effective cleaning.

What Benefits Does Hose Water Jet Provide in Marine Maintenance?

In the marine sector, hose water jets are used for hull cleaning and maintenance, which is crucial for extending the lifespan of vessels. Regular cleaning prevents the accumulation of marine growth, which can impact fuel efficiency. Buyers in Europe and South America should focus on sourcing hoses that are corrosion-resistant and can adapt to various marine environments, ensuring they meet the specific needs of maritime operations.

How Does Hose Water Jet Improve Waste Management Processes?

Hose water jets are effective in waste management for clearing clogged drains and sewer lines. This application reduces downtime and increases operational efficiency by quickly resolving blockages. For B2B buyers, especially in urban regions in Africa and South America, the compact design of these systems is essential for portability and ease of use in tight spaces. Compatibility with various drain sizes is another critical consideration when sourcing this equipment.

3 Common User Pain Points for ‘hose water jet’ & Their Solutions

Scenario 1: High Pressure Failures in Hose Water Jet Applications

المشكلة One of the most significant challenges faced by B2B buyers in the hose water jet industry is the frequent failure of high-pressure hoses during operation. This issue can lead to costly downtime, safety hazards, and damage to equipment. For instance, a contractor using a high-pressure water jet for cleaning heavy machinery may experience a burst in the hose, resulting in not just repair costs but also project delays. Such failures often stem from inadequate selection of hoses that do not meet the required pressure ratings or from improper maintenance practices.

الحل: To mitigate the risk of high-pressure failures, it is essential to source hoses that are specifically rated for the operational pressures required by your equipment. Buyers should look for hoses with a smooth inner core to minimize pressure drop and high-tensile spiraled wire for added strength and kink resistance. Partnering with reputable manufacturers that provide certification for their products, such as those compliant with DIN EN 1829-2, ensures the quality and reliability of the hoses. Additionally, implementing a regular maintenance schedule, including visual inspections for wear and tear, can prevent unexpected failures. It’s also advisable to train operators on proper handling techniques to extend the lifespan of the hoses.

Scenario 2: Inadequate Cleaning Performance Due to Wrong Nozzle Selection

المشكلة B2B buyers often struggle with inadequate cleaning performance when using hose water jets, which can be attributed to the incorrect selection of nozzles. For example, a facility manager tasked with maintaining large industrial tanks may find that the nozzle being used does not provide sufficient pressure or spray pattern for effective cleaning, leading to unsatisfactory results and increased labor costs. This scenario can be frustrating, especially when projects are time-sensitive and require efficient cleaning solutions.

الحل: To enhance cleaning performance, it is crucial to choose the right nozzle based on the specific application. Nozzles come in various designs, including rotating, fan, and pinpoint, each suited for different types of cleaning tasks. Conducting a thorough assessment of the surfaces being cleaned and the contaminants involved can guide nozzle selection. For instance, a rotating nozzle is ideal for heavy-duty cleaning, while a fan nozzle might be more suitable for delicate surfaces. Additionally, suppliers should provide detailed specifications and recommendations for nozzle types based on the hose system being used. Regular training for staff on how to switch nozzles according to cleaning requirements can significantly improve efficiency and effectiveness.

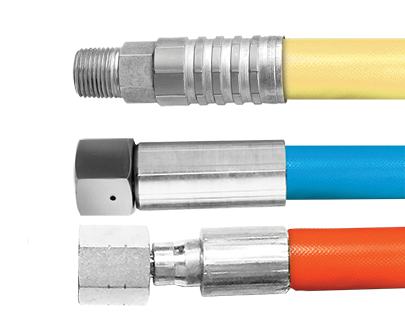

Scenario 3: Lack of Compatibility Between Hose and Equipment

المشكلة Another prevalent issue in the hose water jet sector is the lack of compatibility between hoses and the associated equipment, such as pumps or fittings. B2B buyers may face challenges when trying to connect a newly purchased hose to existing equipment, leading to leaks or inefficient performance. This compatibility issue often arises when buyers neglect to verify the specifications of both the hose and the equipment, resulting in unnecessary expenditures and project delays.

Illustrative image related to hose water jet

الحل: To avoid compatibility issues, it is essential to ensure that all components of the water jet system are compatible before making a purchase. Buyers should consult product datasheets and technical specifications for hoses, pumps, and fittings to confirm that they match in terms of pressure ratings, diameters, and connection types. Engaging with suppliers who offer comprehensive solutions—including custom fittings or hoses tailored to specific equipment—can streamline this process. Additionally, maintaining a database of existing equipment specifications can aid in future purchasing decisions, reducing the risk of mismatches and ensuring operational efficiency. Regular communication with suppliers for updates on new products and compatibility features can also help in making informed decisions.

Strategic Material Selection Guide for hose water jet

What Are the Key Materials Used in Hose Water Jet Applications?

When selecting materials for hose water jet applications, it is crucial to consider the specific properties that will impact performance, durability, and compatibility with various media. Below, we analyze four common materials used in hose water jet construction, highlighting their key properties, pros and cons, and considerations for international B2B buyers.

How Does Rubber Perform in Hose Water Jet Applications?

Rubber is a versatile material commonly used in hose manufacturing due to its flexibility and resilience. Key properties include excellent abrasion resistance and a temperature rating typically between -40°F to 212°F (-40°C to 100°C). Rubber hoses can handle pressures up to 300 psi, making them suitable for low to medium-pressure applications.

الإيجابيات: Rubber hoses are lightweight, cost-effective, and offer high elasticity, which allows them to bend easily around obstacles. They are also resistant to many chemicals, enhancing their versatility.

Illustrative image related to hose water jet

السلبيات: However, rubber is less durable than other materials when exposed to extreme temperatures or UV light, leading to potential degradation over time. Additionally, they may not be suitable for high-pressure applications exceeding 300 psi.

التأثير على التطبيق: Rubber hoses are ideal for cleaning tasks in agriculture and light industrial settings. They are compatible with various media, including water and mild chemicals.

اعتبارات للمشترين الدوليين: Buyers in regions like Africa and South America should ensure compliance with local standards, as rubber may not meet certain temperature or pressure specifications in harsher climates.

What Are the Advantages of PVC in Hose Water Jet Systems?

Polyvinyl chloride (PVC) is another popular material for hose water jets, particularly in applications requiring lightweight and cost-effective solutions. PVC hoses typically have a temperature rating of 32°F to 140°F (0°C to 60°C) and can handle pressures up to 150 psi.

الإيجابيات: PVC hoses are resistant to corrosion and have a smooth inner surface that minimizes friction loss. They are also less expensive than rubber and can be manufactured in various colors for easy identification.

Illustrative image related to hose water jet

السلبيات: The rigidity of PVC can limit its flexibility, making it less suitable for tight bends. Additionally, prolonged exposure to UV light can lead to brittleness and cracking.

التأثير على التطبيق: PVC hoses are commonly used in agricultural irrigation and light-duty cleaning applications. They are compatible with water and some chemicals but may not be suitable for high-pressure scenarios.

اعتبارات للمشترين الدوليين: In Europe, PVC hoses must comply with REACH regulations, and buyers should verify that their suppliers meet these compliance standards.

Why Choose Stainless Steel for High-Pressure Water Jet Applications?

Stainless steel is often the material of choice for high-pressure water jet hoses due to its exceptional strength and corrosion resistance. Stainless steel hoses can handle pressures exceeding 10,000 psi and have a temperature rating that can reach up to 1,200°F (650°C).

Illustrative image related to hose water jet

الإيجابيات: The durability of stainless steel makes it ideal for harsh environments, and it is highly resistant to corrosion, making it suitable for various media, including abrasive substances.

السلبيات: The primary disadvantage is the higher cost associated with stainless steel hoses. Additionally, their weight can make them less manageable compared to rubber or PVC options.

التأثير على التطبيق: Stainless steel hoses are commonly used in industrial applications, including oil and gas extraction and heavy-duty cleaning tasks. They are particularly effective for abrasive media and high-pressure requirements.

Illustrative image related to hose water jet

اعتبارات للمشترين الدوليين: Buyers from the Middle East and Europe should ensure that stainless steel hoses comply with relevant standards like ASTM or DIN for safety and performance.

What Role Does Polyurethane Play in Hose Water Jet Applications?

Polyurethane is increasingly being used in hose manufacturing due to its excellent abrasion resistance and flexibility. These hoses typically have a temperature rating of -40°F to 160°F (-40°C to 71°C) and can handle pressures up to 500 psi.

الإيجابيات: Polyurethane hoses are lightweight and flexible, making them easy to maneuver. They also exhibit excellent resistance to wear and tear, extending their lifespan in demanding applications.

السلبيات: However, polyurethane can be more expensive than rubber or PVC and may not perform well in extreme temperature conditions.

التأثير على التطبيق: These hoses are suitable for a variety of applications, including high-pressure cleaning and industrial processes. They are compatible with water and various chemicals.

Illustrative image related to hose water jet

اعتبارات للمشترين الدوليين: In regions like Europe, compliance with EU regulations regarding material safety and environmental impact is essential for polyurethane hoses.

Summary Table of Material Selection for Hose Water Jet Applications

| المواد | Typical Use Case for hose water jet | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Light industrial cleaning | Lightweight and flexible | Degrades under UV exposure | منخفضة |

| بولي كلوريد الفينيل | Agricultural irrigation | Cost-effective and corrosion-resistant | Limited flexibility | منخفضة |

| الفولاذ المقاوم للصدأ | التطبيقات الصناعية الثقيلة | High pressure and temperature resistance | Higher cost and heavier weight | عالية |

| البولي يوريثين | High-pressure cleaning | Excellent abrasion resistance | More expensive and temperature sensitive | متوسط |

This strategic material selection guide provides valuable insights for B2B buyers in various international markets, helping them make informed decisions based on their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hose water jet

What Are the Main Stages in the Manufacturing Process of Hose Water Jets?

The manufacturing process for hose water jets involves several critical stages that ensure the final product meets the necessary performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

-

إعداد المواد

The first step involves sourcing high-quality raw materials, typically including high-tensile steel for the hose and durable plastics or rubber for the fittings. Suppliers should ensure that these materials comply with international standards, such as ASTM or ISO specifications, to guarantee durability and reliability. Advanced techniques like material testing for tensile strength and flexibility are often conducted at this stage to ensure that the materials can withstand high-pressure applications. -

التشكيل

The forming process can include methods such as extrusion or molding, depending on the design of the hose and its components. For instance, hoses are often extruded to create a seamless, uniform wall that enhances pressure resistance. During this stage, quality checks are crucial to confirm that the dimensions and thickness of the hoses meet design specifications. -

التجميع

Once the individual components are formed, they are assembled. This may involve attaching fittings to the hose ends, which are often made from corrosion-resistant materials like stainless steel to ensure longevity. Automated assembly lines are commonly used to increase efficiency and consistency. Quality control measures, such as torque testing of fittings, are implemented to ensure secure connections that can withstand high-pressure conditions. -

التشطيب

The finishing stage includes applying protective coatings or treatments to enhance the durability of the hose. This might involve abrasion-resistant covers or UV protection, which are particularly important for hoses that will be used outdoors. Final inspections are conducted to check for any surface defects, ensuring that the hose not only performs well but also looks professional.

How Is Quality Assurance Managed in Hose Water Jet Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for hose water jets, ensuring that products meet both customer expectations and regulatory requirements.

-

International Standards and Certifications

Many manufacturers adhere to international quality management standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Additionally, industry-specific certifications, such as CE marking for compliance with European safety standards or API standards for oil and gas applications, are vital for B2B buyers. These certifications not only facilitate market access but also assure buyers of the product’s quality and safety. -

نقاط التحقق من الجودة

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

– مراقبة الجودة الواردة (IQC): Verification of raw materials upon arrival, ensuring they meet specified standards.

– مراقبة الجودة أثناء العملية (IPQC): Continuous monitoring during manufacturing to detect defects early, such as dimensional checks during forming.

– مراقبة الجودة النهائية (FQC): Comprehensive testing of finished products, which may include pressure testing, burst testing, and flow rate measurement to ensure the hoses meet performance specifications. -

Common Testing Methods for Hose Water Jets

Various testing methods are employed to validate the performance and safety of hose water jets. These may include:

– الاختبار الهيدروستاتيكي: Used to test the strength and leak resistance of hoses under high-pressure conditions.

– Visual Inspection: Conducted to detect surface defects, such as kinks or abrasions.

– Material Testing: Assessing the tensile strength and flexibility of the hose material to ensure it meets operational requirements.

كيف يمكن لمشتري B2B التحقق من مراقبة جودة الموردين؟

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several actionable steps:

Illustrative image related to hose water jet

-

Conduct Supplier Audits

Buyers should perform regular audits of their suppliers’ facilities. This includes reviewing their manufacturing processes, quality control measures, and certifications. An audit can help identify any discrepancies in the supplier’s claimed quality assurance practices and their actual operations. -

Request Quality Assurance Reports

Suppliers should provide documentation detailing their quality assurance processes, including results from testing and inspections. Buyers can evaluate these reports to ensure compliance with international standards and assess the reliability of the supplier’s products. -

Utilize Third-Party Inspections

Engaging independent third-party inspection services can provide unbiased evaluations of the supplier’s quality control. These inspections can be especially valuable for new suppliers or when entering new markets, offering an additional layer of assurance for buyers.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين بين الشركات؟

Understanding the nuances of quality control can significantly impact purchasing decisions for international B2B buyers. Here are some key considerations:

-

الامتثال التنظيمي

Buyers must be aware of the specific regulations and standards that apply in their respective markets. For example, products sold in Europe may require CE marking, while those in the U.S. may need to comply with ANSI standards. Failing to meet these regulations can lead to legal issues and product recalls. -

Cultural and Regional Differences

Quality expectations can vary across different regions. For example, European buyers may prioritize stringent environmental standards, while Middle Eastern buyers may focus more on durability and performance under extreme conditions. Understanding these regional preferences can help buyers communicate effectively with suppliers and ensure their products meet local expectations. -

Traceability and Documentation

Buyers should ensure that suppliers maintain detailed records of their quality control processes, including testing results and material certifications. This documentation is essential for traceability and can be crucial in case of disputes or product recalls.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing hose water jets, ensuring they receive reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose water jet’

مقدمة

Sourcing a hose water jet can be a complex task, especially for international B2B buyers. This guide provides a structured checklist to help you navigate the procurement process efficiently. By following these steps, you can ensure that you acquire the right equipment tailored to your operational needs while mitigating risks associated with supplier selection.

الخطوة 1: تحديد المواصفات الفنية الخاصة بك

Understanding your specific requirements is the first crucial step in sourcing a hose water jet. Identify the key parameters such as pressure rating, flow rate, and intended applications (e.g., cleaning, cutting, or surface preparation).

– Pressure Rating: Ensure the hose can withstand the maximum pressure your operations will require.

– Flow Rate: Consider the volume of water needed for effective performance.

Illustrative image related to hose water jet

الخطوة 2: Research Market Trends and Innovations

Staying informed about the latest developments in hose water jet technology can enhance your purchasing decisions.

– Emerging Technologies: Look for advancements such as lightweight materials or enhanced safety features.

– Industry Standards: Familiarize yourself with international standards like ISO or DIN that may apply to your equipment.

الخطوة 3: تقييم الموردين المحتملين

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Reputation: Investigate the supplier’s market presence and customer feedback.

– Certifications: Ensure they comply with relevant industry certifications and safety standards.

الخطوة 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. This will help you compare not just prices but also the specifications and warranties offered.

– Breakdown of Costs: Look for clarity in pricing, including shipping and handling.

– الضمان والدعم: Assess the warranty terms and the availability of after-sales support.

الخطوة 5: Assess Delivery and Lead Times

Understanding delivery timelines is critical, especially if you have project deadlines. Confirm lead times with your suppliers to avoid delays in your operations.

– Shipping Options: Evaluate different shipping methods and their associated costs.

– Flexibility: Inquire about the supplier’s ability to accommodate urgent requests or changes in order size.

الخطوة 6: التفاوض على الشروط والأحكام

Negotiation is a vital part of the sourcing process. Aim for favorable terms that protect your interests while fostering a good relationship with your supplier.

– Payment Terms: Discuss options such as upfront payments, installment plans, or credit terms.

– Return Policy: Ensure there is a clear return policy in case the products do not meet your specifications.

الخطوة 7: Finalize the Purchase and Confirm Specifications

After negotiations, finalize the purchase by confirming all technical specifications and terms in writing. This documentation will serve as a reference for both parties.

– Contract Review: Have legal counsel review the contract to safeguard against potential disputes.

– Documentation: Keep all correspondence and documents related to the purchase for future reference.

By following this checklist, B2B buyers can streamline the procurement process for hose water jets, ensuring they make informed and strategic purchasing decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for hose water jet Sourcing

What Are the Key Cost Components in Hose Water Jet Sourcing?

When sourcing hose water jets, a comprehensive understanding of the cost structure is crucial for international B2B buyers. The primary cost components include:

-

المواد: The quality and type of materials used, such as high-tensile steel for hoses or specialized plastics for nozzles, significantly impact costs. Premium materials enhance durability and performance but come at a higher price.

-

العمالة: Labor costs can vary based on the region of production. In countries with lower labor costs, such as some in South America and Africa, manufacturers can offer more competitive pricing. However, skilled labor for quality assurance may be necessary, affecting overall labor costs.

-

نفقات التصنيع الزائدة: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer better pricing.

-

الأدوات: Custom tooling for specialized products can be a significant upfront cost. Buyers should consider whether the tooling costs are amortized over large production runs or remain a fixed cost for smaller orders.

-

مراقبة الجودة (QC): Rigorous QC processes are essential for ensuring the reliability and safety of hose water jets. Suppliers may pass these costs onto buyers, but they can save significant costs in the long run by reducing returns and warranty claims.

-

الخدمات اللوجستية: Transportation and shipping costs can vary widely, especially for international buyers. Factors such as shipping mode (air vs. sea), distance, and import/export tariffs will influence overall costs.

-

الهامش: Supplier margins typically range from 10% to 30%, depending on the supplier’s market position and the competitive landscape. Understanding these margins can provide insight into potential negotiation points.

What Influences Pricing for Hose Water Jets?

Several factors influence the pricing of hose water jets, making it essential for buyers to be aware of these elements:

-

الحجم/معدل العرض/الطلب: Bulk purchasing often results in lower per-unit costs. Understanding the minimum order quantity (MOQ) can help buyers negotiate better deals, especially when sourcing for large projects.

-

المواصفات والتخصيص: Customized hoses and nozzles designed for specific applications may incur additional costs. Clear communication of specifications can help avoid unexpected expenses during production.

-

الجودة والشهادات: Products that meet international standards or possess certifications such as ISO may command higher prices. Buyers should assess whether these certifications align with their operational needs.

-

عوامل الموردين: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

المصطلحات التجارية الدولية: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can significantly affect total costs.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

To achieve cost-efficiency in sourcing hose water jets, buyers should consider the following strategies:

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Consistent orders may result in volume discounts.

-

Leverage Total Cost of Ownership (TCO): When negotiating prices, consider the TCO, including maintenance, operational efficiency, and longevity. A higher initial investment in quality products can lead to lower TCO over time.

-

أبحاث السوق: Conduct thorough market research to understand pricing trends and competitor offerings. This knowledge can strengthen your negotiation position.

-

Flexibility in Specifications: Being open to alternative materials or designs may allow for cost savings without compromising performance.

-

Timing of Purchases: Timing can affect pricing; purchasing during off-peak seasons may yield better deals due to lower demand.

Conclusion: Understanding Pricing Nuances for International Buyers

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the intricacies of cost and pricing analysis is vital. By considering the outlined cost components and pricing influencers, buyers can make informed decisions that not only meet their immediate needs but also align with their long-term operational goals. Always remember that the prices provided are indicative and can vary based on the factors discussed.

Alternatives Analysis: Comparing hose water jet With Other Solutions

Exploring Alternatives to Hose Water Jets in Industrial Applications

When considering the best solution for high-pressure cleaning or surface preparation, it’s crucial to evaluate various technologies available in the market. While hose water jets are popular for their effectiveness and versatility, several alternatives can also meet similar needs. This analysis will compare hose water jets with two viable alternatives: pressure washers and ultra-high pressure (UHP) water jetting systems.

Comparison Table

| جانب المقارنة | Hose Water Jet | Pressure Washer | Ultra-High Pressure Water Jetting |

|---|---|---|---|

| الأداء | Effective for a range of surfaces; versatile in application | Good for light to moderate cleaning tasks | Extremely powerful; ideal for heavy-duty applications |

| التكلفة | Moderate initial investment; low operating costs | Lower initial costs; moderate operating costs | High initial investment; higher operating and maintenance costs |

| سهولة التنفيذ | Requires minimal setup; portable units available | Very user-friendly; quick setup | More complex setup; requires skilled operators |

| الصيانة | Low maintenance; regular inspections recommended | Moderate maintenance; check for clogs and leaks | High maintenance; specialized parts and periodic servicing needed |

| أفضل حالة استخدام | General cleaning, surface preparation | Home use, vehicle washing, light commercial tasks | Industrial cleaning, surface prep for coatings, demolition |

التقسيم التفصيلي للبدائل

Pressure Washers

Pressure washers are commonly used for various cleaning tasks, from washing cars to cleaning decks and patios. They operate by forcing water through a nozzle at high pressure, effectively removing dirt and grime.

الإيجابيات: Pressure washers are generally less expensive than hose water jets and are easy to operate, making them accessible for both residential and light commercial use. Their portability and ease of setup enhance their appeal for quick cleaning tasks.

السلبيات: However, they may not be as effective for heavy-duty applications, and their cleaning power can be limited compared to hose water jets and UHP systems. Regular maintenance is necessary to ensure optimal performance, and they may struggle with stubborn stains or debris.

Illustrative image related to hose water jet

Ultra-High Pressure Water Jetting

Ultra-high pressure water jetting systems utilize extremely high pressures (typically 20,000 psi or more) to achieve effective cleaning and material removal. These systems are used in specialized industrial applications, such as pipeline cleaning, concrete demolition, and surface preparation for coatings.

الإيجابيات: The primary advantage of UHP systems is their unmatched cleaning power, allowing them to remove tough contaminants and coatings. They can be used in a variety of demanding applications, making them suitable for industries like construction, marine, and manufacturing.

السلبيات: On the downside, UHP systems come with a higher initial investment and require skilled operators to handle safely and effectively. Maintenance can also be more intensive, as specialized components may need regular replacement or servicing, which can increase operational costs.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a cleaning solution, B2B buyers should assess their specific needs, including the types of surfaces to be cleaned, the level of cleaning required, and budget constraints. Hose water jets offer a balanced solution for various applications, providing versatility and performance without excessive costs. For lighter tasks, pressure washers may suffice, while ultra-high pressure systems are ideal for heavy-duty industrial applications. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for hose water jet

What Are the Key Technical Properties of Hose Water Jets?

Understanding the technical properties of hose water jets is essential for B2B buyers to ensure the right selection for specific applications. Here are some critical specifications to consider:

Illustrative image related to hose water jet

1. درجة المادة

Hose water jets are often made from materials like reinforced rubber, thermoplastics, or polyurethane. The material grade affects durability, flexibility, and resistance to abrasion and chemicals. For high-pressure applications, hoses made from high-grade materials are crucial to prevent failures that could lead to downtime or safety hazards. Buyers should prioritize hoses with materials designed for their specific working conditions, especially in harsh environments.

2. Pressure Rating

The pressure rating indicates the maximum pressure a hose can withstand during operation, typically expressed in PSI (pounds per square inch) or bar. For instance, ultra-high pressure (UHP) hoses can handle pressures exceeding 40,000 PSI. Selecting a hose with the appropriate pressure rating is vital for ensuring operational efficiency and safety, as using a hose beyond its rated capacity can result in catastrophic failure.

3. Hose Diameter

The diameter of the hose affects both the flow rate and the pressure drop. A larger diameter can provide a higher flow rate, suitable for extensive cleaning tasks, while a smaller diameter is often more maneuverable for detailed work. It is essential to match the hose diameter to the required application to optimize performance and reduce wear on the hose and equipment.

4. Length and Flexibility

Hose length varies, with common options ranging from 15 to 100 feet. Flexibility is also a key factor, as hoses must navigate tight corners and reach various locations. A hose that is too rigid may become difficult to handle, while one that is too flexible may not maintain its shape under pressure. Buyers should consider the balance between length and flexibility based on their operational requirements.

5. Burst Pressure

Burst pressure is the maximum pressure a hose can withstand before failing. This is typically significantly higher than the working pressure. A higher burst pressure provides an additional safety margin, which is particularly important in high-risk applications where hose failure can lead to injury or damage. Buyers should ensure that the hoses they select have a burst pressure well above their operational pressures.

What Are Common Trade Terms in the Hose Water Jet Industry?

Familiarizing oneself with industry terminology can facilitate smoother transactions and negotiations. Here are some common terms:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the hose water jet industry, understanding OEM relationships can help buyers identify reliable suppliers and ensure they are sourcing high-quality components that meet their specifications.

2. موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, particularly those looking to procure hoses in bulk. Understanding MOQ can help buyers plan their inventory and manage costs effectively.

3. طلب عرض الأسعار (RFQ)

An RFQ is a formal document that buyers send to suppliers requesting pricing and terms for specific products or services. Using RFQs can lead to better pricing and terms, as suppliers are encouraged to provide competitive offers.

4. الشروط التجارية الدولية (الشروط التجارية الدولية)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border transactions to avoid misunderstandings and ensure smooth logistics.

5. المهلة الزمنية

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the hose water jet industry, understanding lead times can help buyers plan their projects effectively, ensuring they have the necessary equipment when needed.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the right hose water jets for their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the hose water jet Sector

What Are the Current Market Dynamics and Key Trends in the Hose Water Jet Sector?

The hose water jet sector is experiencing significant growth driven by increasing demand across various industries, including construction, manufacturing, and municipal services. One of the primary global drivers is the push for more efficient cleaning and maintenance solutions. With advancements in technology, water jet systems are becoming more effective, offering higher pressure capabilities and versatility in applications ranging from surface cleaning to material removal. Notably, high-pressure hoses are being integrated with smart technologies, enabling remote monitoring and real-time performance analytics, which are particularly appealing to B2B buyers looking for efficiency and cost-effectiveness.

International buyers from regions such as Africa, South America, the Middle East, and Europe are particularly keen on sourcing products that align with their operational needs. The rise of e-commerce platforms has facilitated easier access to suppliers, allowing businesses to compare prices and features more efficiently. Moreover, buyers are increasingly prioritizing suppliers who offer customization options and after-sales support, reflecting a trend towards tailored solutions that meet specific operational requirements.

Emerging technologies, such as improved hose materials that enhance durability and reduce weight, are also shaping the market. These innovations not only extend the lifespan of products but also improve user handling and safety. As businesses globally seek to enhance their operational efficiencies, the hose water jet sector is poised to benefit significantly from these technological advancements.

How Is Sustainability and Ethical Sourcing Impacting the Hose Water Jet Industry?

As environmental concerns become more pronounced, sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the hose water jet sector. The production and disposal of traditional hoses often involve materials and processes that can have detrimental environmental impacts. Consequently, suppliers are increasingly adopting ‘green’ certifications and utilizing eco-friendly materials, such as recycled plastics and biodegradable compounds, to meet the demands of environmentally conscious buyers.

In addition to materials, ethical supply chains are gaining importance. Buyers are looking for suppliers who adhere to responsible sourcing practices, ensuring fair labor conditions and minimal environmental impact throughout the manufacturing process. This trend is particularly relevant for international buyers who are navigating diverse regulatory landscapes and consumer expectations across regions.

Furthermore, the integration of sustainability into product design, such as the development of hoses that require less water or energy for operation, is becoming a key differentiator in the market. By prioritizing sustainability, businesses not only enhance their brand reputation but also comply with increasingly stringent regulations, making ethical sourcing a strategic imperative for long-term success.

How Has the Hose Water Jet Sector Evolved Over Time?

The hose water jet sector has evolved significantly from its early days of basic pressure cleaning systems. Initially, water jets were primarily used in industrial settings for simple cleaning tasks. However, as technology advanced, the applications of water jet systems expanded dramatically, encompassing a wide range of uses including hydro-demolition, surface preparation, and even intricate cutting processes.

The introduction of high-pressure and ultra-high-pressure hoses has transformed the market, enabling more efficient and effective cleaning methods. Innovations in hose design, such as the development of lightweight and durable materials, have further enhanced usability and safety. Today, the sector is characterized by a blend of traditional practices and cutting-edge technology, catering to an increasingly diverse array of industry needs. This evolution reflects a broader trend in the B2B landscape, where companies are continuously seeking innovative solutions to improve operational efficiency and reduce environmental impact.

Frequently Asked Questions (FAQs) for B2B Buyers of hose water jet

1. How do I choose the right hose water jet for my industrial application?

Choosing the right hose water jet involves assessing your specific cleaning needs, pressure requirements, and the types of surfaces you will be working with. Consider factors such as the PSI rating, hose length, and nozzle type. For heavy-duty applications, opt for ultra-high-pressure hoses that can handle 40,000 to 55,000 PSI. Additionally, evaluate the material durability, as some hoses are designed with tough jackets for enhanced abrasion resistance. Consulting with suppliers who specialize in your industry can also provide insights tailored to your unique requirements.

2. What is the best nozzle type for different cleaning tasks?

The best nozzle type largely depends on the cleaning task at hand. For general cleaning and surface preparation, fan nozzles are effective, while rotary nozzles are ideal for tougher jobs like removing paint or rust. If you are working with delicate surfaces, consider using adjustable nozzles that allow you to control the spray pattern. It’s crucial to match the nozzle type with the pressure output of your hose water jet to ensure optimal performance and avoid damage to the surfaces being cleaned.

3. How can I ensure the quality of hose water jets from suppliers?

To ensure the quality of hose water jets, conduct thorough vetting of suppliers. Request certifications and quality assurance documentation, such as ISO standards, to verify compliance with industry norms. Consider visiting manufacturing facilities or seeking testimonials from other businesses that have purchased similar products. Additionally, inquire about warranty terms and after-sales support, as reliable suppliers often provide robust customer service to address any quality issues that may arise.

4. What are the typical minimum order quantities (MOQ) for hose water jets?

Minimum order quantities (MOQ) for hose water jets can vary significantly between suppliers. Typically, MOQs range from 10 to 100 units, depending on the type and customization of the products. It’s advisable to communicate your needs directly with suppliers to explore flexibility in MOQs, especially if you are a small or medium-sized business. Some suppliers may offer lower MOQs for trial orders or initial purchases, which can help you assess the quality before committing to larger orders.

5. What payment terms should I expect when sourcing hose water jets internationally?

Payment terms for international transactions can vary widely based on the supplier’s policies and your negotiation. Common terms include 30% upfront payment with the balance due before shipment or upon receipt. For larger orders, suppliers might offer more favorable terms such as net 30 or net 60 days. Always clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal, and ensure you understand any applicable fees or currency conversion costs to avoid surprises.

6. How do logistics and shipping impact the sourcing of hose water jets?

Logistics and shipping are critical factors in sourcing hose water jets, particularly for international buyers. Consider lead times, shipping methods, and freight costs when planning your order. Opt for suppliers who can provide transparent shipping options and track shipments to ensure timely delivery. Additionally, familiarize yourself with customs regulations and potential tariffs in your country to avoid unexpected delays and costs. Engaging a freight forwarder can also simplify the logistics process.

Illustrative image related to hose water jet

7. Can hose water jets be customized for specific applications?

Yes, many suppliers offer customization options for hose water jets to meet specific application needs. Customizations can include variations in hose length, pressure ratings, nozzle types, and fittings. When requesting customization, be clear about your operational requirements and any industry standards that must be met. Collaborating with the supplier during the design phase can result in a more effective product tailored to your unique cleaning tasks.

8. What are the common applications for hose water jets in various industries?

Hose water jets are versatile tools used across multiple industries, including construction, manufacturing, and maritime. Common applications include surface preparation, cleaning of machinery and equipment, pipeline descaling, and removal of coatings like rust or paint. In the construction industry, they are effective for hydro-demolition and concrete cleaning. Understanding the specific needs of your industry can help you select the right hose water jet configurations to enhance operational efficiency and effectiveness.

A Look at Hose Water Jet Manufacturers & Suppliers

Could not verify enough suppliers for hose water jet to create a list at this time.

Strategic Sourcing Conclusion and Outlook for hose water jet

As the global market for hose water jets continues to expand, strategic sourcing emerges as a critical element for B2B buyers looking to optimize their procurement processes. Understanding the diverse applications of hose water jets—ranging from industrial cleaning to agricultural irrigation—enables buyers to select the right products that meet their specific needs. By prioritizing high-quality materials and innovative designs, such as those offered by leading manufacturers, businesses can enhance operational efficiency and reduce downtime.

Illustrative image related to hose water jet

Furthermore, engaging with suppliers that provide comprehensive technical support and customization options can significantly improve the purchasing experience. Buyers in regions like Africa, South America, the Middle East, and Europe should leverage their unique market dynamics to negotiate favorable terms and ensure a steady supply chain.

Looking ahead, the demand for efficient and eco-friendly solutions will shape the hose water jet landscape. We encourage international buyers to actively explore partnerships with reputable suppliers, invest in advanced technologies, and remain agile in their sourcing strategies. By doing so, they can stay ahead of industry trends and secure a competitive edge in their markets.

تنويه هام وشروط الاستخدام

⚠️ إخلاء مسؤولية مهم ⚠️

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.