Article Contents

Engineering Insight: Suction Rubber Hose

Technical Imperatives of Suction Rubber Hoses in Modern Dredging Operations

Suction rubber hoses represent a critical engineering component in the operational integrity and efficiency of Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs). Unlike standard discharge hoses, suction hoses operate under severe negative pressure conditions while simultaneously conveying highly abrasive sand-water slurries, often containing sharp aggregate particles exceeding 30% solids by volume. In TSHDs, the hose must maintain structural stability during dynamic trailing operations where it interfaces directly with the seabed, enduring cyclic bending stresses and potential impact loads. For CSDs, the suction hose forms the vital connection between the cutter head ladder and the pump inlet, requiring exceptional resistance to localized abrasion and vacuum-induced collapse during high-solids excavation. Failure in suction hose performance directly translates to costly vessel downtime, reduced production rates, and compromised project timelines, making material science and reinforcement architecture non-negotiable factors in dredging system design.

East Marine leverages its 150+ strong engineering team and 0.68 million square meter manufacturing facility to address these extreme operational demands. Our suction hoses employ a proprietary multi-layer construction: a specialized abrasion-resistant synthetic rubber compound for the inner tube ensures minimal wear against slurries, while multiple high-tensile textile and steel wire reinforcement layers provide precise vacuum stability and burst resistance. The outer cover utilizes ozone- and UV-resistant EPDM rubber, critical for prolonged marine exposure. Crucially, our engineering team optimizes the reinforcement angle and density to balance flexibility for vessel maneuverability with rigidity to prevent kinking under full vacuum – a common failure point in inferior designs. This precision engineering, validated through rigorous ISO 9001-certified processes and WEDA-aligned testing protocols, ensures hydrodynamic stability and maximizes operational lifespan even in the most challenging dredging environments, from coastal reclamation to deep-sea mining support.

The following table outlines the core technical specifications for East Marine’s standard dredging suction hose series, engineered for TSHD and CSD applications:

| Parameter | Value Range | Test Standard |

|---|---|---|

| Internal Diameter (ID) | 300 mm – 1200 mm | ISO 1307 |

| Working Vacuum | ≤ -0.95 bar (abs) | ISO 14310 |

| Max. Working Pressure | 16 bar (static) | ISO 1402 |

| Bend Radius (min) | 8 x ID (unloaded) | Internal Procedure |

| Cover Thickness | 8 mm – 12 mm | ASTM D2240 |

| Temp. Range | -30°C to +80°C | ISO 188 |

| مقاومة التآكل | ≤ 120 mm³ (DIN 53516) | ISO 4649 |

East Marine’s commitment to dredging infrastructure is underscored by our engineering-led approach and scalable production capacity. Each hose assembly undergoes full-length vacuum testing and ultrasonic wall-thickness verification, ensuring compliance with CEDA best practices and client-specific project requirements. This technical rigor, combined with our extensive manufacturing footprint, positions East Marine as a strategic partner capable of delivering mission-critical suction hose solutions for global dredging projects of any scale, directly contributing to vessel uptime and project profitability.

Advanced Manufacturing Process

Advanced Manufacturing and Precision Vulcanization of Suction Rubber Hoses at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance suction rubber hoses is driven by advanced engineering, stringent quality protocols, and a vertically integrated manufacturing ecosystem. Operating from a state-of-the-art 0.68 million square meter facility, our production infrastructure supports 18 dedicated manufacturing lines, each optimized for the precise fabrication of dredging hoses tailored to demanding marine and industrial applications.

The manufacturing journey begins with the selection of premium-grade synthetic and natural rubber compounds, engineered for abrasion resistance, flexibility, and resilience under dynamic hydraulic conditions. These raw materials are compounded using computer-controlled mixing systems to ensure batch-to-batch consistency and optimal physical properties. The compounded rubber is then processed through extrusion and calendaring stages, where it is formed into inner tubes, reinforcement layers, and outer covers with exact dimensional tolerances.

Reinforcement is a critical phase in suction hose production. High-tensile textile or wire helix reinforcements are precisely wound using automated braiding and spiraling machines, ensuring uniform stress distribution and collapse resistance under full vacuum conditions. This structural integrity is vital for maintaining hose performance during continuous dredging operations, where negative pressure and abrasive slurries are routine.

The defining stage of the process is vulcanization—a precisely controlled thermal curing method that transforms the assembled hose components into a durable, monolithic structure. At East Marine, vulcanization is conducted in high-pressure autoclaves and continuous vulcanization (CV) tunnels, where time, temperature, and pressure are meticulously monitored. This ensures complete cross-linking of rubber polymers, resulting in enhanced mechanical strength, ozone resistance, and long-term service life. Each hose undergoes a full vulcanization cycle validated by real-time data logging and thermal profiling to guarantee uniform curing throughout the wall thickness.

Quality assurance is embedded at every stage of production, aligned with our ISO 9001-certified quality management system. In-process inspections, including thickness gauging, visual checks, and dimensional verification, are conducted alongside final performance testing. Every suction hose is subjected to rigorous hydrostatic pressure tests, vacuum integrity checks, and flexibility assessments before release.

Our membership in industry-leading organizations such as WEDA and CEDA underscores our commitment to technical excellence and adherence to international dredging standards. With 18 synchronized production lines and deep materials expertise, East Marine delivers suction hoses that meet the highest benchmarks in reliability and operational efficiency.

| Parameter | Specification |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 dedicated lines |

| Vulcanization Method | Autoclave and Continuous Vulcanization (CV) |

| Quality Standard | ISO 9001:2015 |

| Test Pressure | 1.5x working pressure (min. 30 sec hold) |

| Vacuum Resistance | Full vacuum (up to 0.98 bar) |

| Reinforcement Types | Spiral wire, textile braid, or hybrid |

| Temperature Range (Standard) | -20°C to +80°C |

Critical Applications

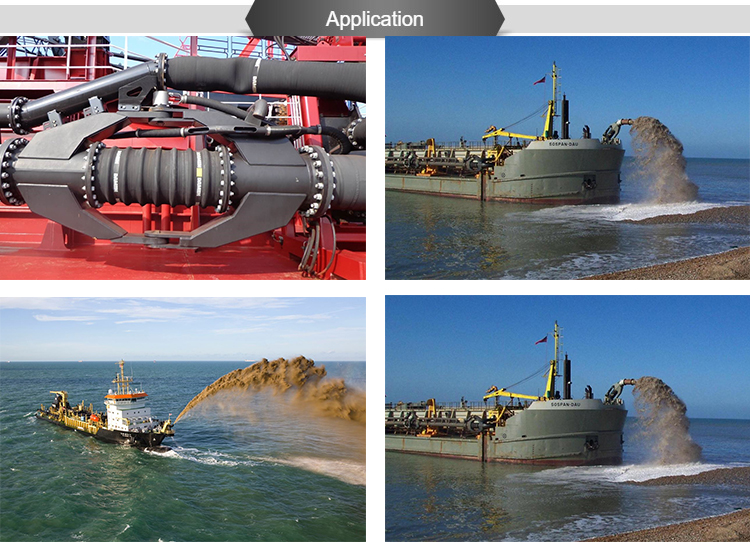

Global Project Applications of Industrial Suction Rubber Hoses

Suction rubber hoses serve as critical components across demanding global infrastructure and resource extraction projects, where reliability under extreme hydraulic and environmental conditions is non-negotiable. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), we engineer hoses specifically for high-abrasion, high-pressure suction applications. Our solutions are deployed worldwide in sectors where failure is not an option, including capital and maintenance dredging, offshore energy operations, and large-scale land reclamation initiatives.

In dredging operations, suction hoses form the lifeline of cutter suction dredgers (CSDs) and trailing suction hopper dredgers (TSHDs), enduring continuous abrasion from sand, gravel, and debris-laden slurries. Projects such as the Port of Rotterdam expansion and the maintenance of Singapore’s strategic waterways rely on hoses capable of sustaining vacuum pressures while resisting internal wear. Similarly, in offshore oil and gas fields, our hoses facilitate the transfer of drilling muds, produced water, and crude oil during exploration and production phases. Their resistance to hydrocarbons, seawater corrosion, and dynamic vessel motion ensures uninterrupted operations in challenging marine environments, from the North Sea to the Gulf of Mexico. Land reclamation projects—particularly prevalent in Southeast Asia and the Middle East—leverage our suction hoses to transport vast volumes of fill material. These hoses withstand sharp-edged sediments and prolonged submersion during island creation or coastal protection works, such as the Palm Jumeirah developments or Jakarta Bay reclamation.

The operational integrity of these projects hinges on precise technical specifications. East Marine’s suction hoses integrate advanced rubber compounds and multi-layer reinforcement to exceed industry standards. Below are representative performance parameters for our flagship dredging-grade suction hose series:

| Parameter | Specification Range | Standard Compliance |

|---|---|---|

| Internal Diameter (ID) | 200 mm – 1200 mm | ISO 1436, DIN 2822 |

| Working Pressure | -0.9 bar (Vacuum) to 16 bar | EN 12117 |

| نطاق درجة الحرارة | -30°C to +85°C | ASTM D2000 |

| Cover Material | Abrasion-Resistant NBR/SBR Blend | Customizable for Oil Resistance |

| Reinforcement | High-Tensile Steel Wire Spiral + Polyester Fabric | ISO 1307 |

Backed by a 0.68 million square meter manufacturing facility and ISO 9001-certified processes since our founding in 2007, East Marine delivers hoses validated through rigorous field testing in over 50 countries. Our CEDA/WEDA membership underscores our commitment to advancing dredging technology and adhering to global best practices. Whether enabling deeper port channels, supporting energy security, or reclaiming land for urban development, our suction rubber hoses provide the durability and performance demanded by the world’s most ambitious marine projects. This technical expertise, rooted in 17 years of specialized production, ensures clients mitigate downtime risks while optimizing operational efficiency in fluid transfer systems.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: Suction and Discharge Performance

In the demanding environment of dredging operations, the performance of suction and discharge rubber hoses is critical to project efficiency, safety, and long-term cost management. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted member of WEDA and CEDA, delivers high-performance dredging hoses engineered for durability, flexibility, and resistance to abrasion and high-pressure conditions. With over 15 years of industry experience and an expansive 0.68 million square meter manufacturing facility, East Marine applies stringent ISO9001-certified quality controls to ensure every hose meets or exceeds international standards.

To provide clarity on performance differentials, the following comparison evaluates key technical parameters of East Marine’s dredging rubber hoses against typical competitor offerings in the global market. The focus is on four critical specifications: inner diameter tolerance, working pressure, burst pressure ratio, and minimum bending radius—factors that directly influence flow efficiency, safety margins, and operational adaptability in complex marine environments.

East Marine’s hoses are constructed using premium synthetic rubber compounds and high-tensile textile-reinforced layers, often incorporating helical steel wire for structural integrity and kink resistance. This advanced construction enables tighter control over dimensional tolerances and enhanced pressure handling. In contrast, many standard competitor hoses utilize lower-grade elastomers and less optimized reinforcement, leading to higher variability in performance, especially under prolonged stress.

The data below reflects average values across common sizes (ranging from 200 mm to 600 mm inner diameter) used in medium to large-scale dredging applications. East Marine consistently achieves a burst pressure rating of 4:1 relative to working pressure—exceeding the industry’s recommended safety factor of 3:1. Additionally, the optimized layline design and material flexibility result in a reduced minimum bending radius, enabling easier deployment in confined or dynamic offshore setups.

This technical edge translates into real-world advantages: fewer pressure-related failures, lower maintenance costs, and improved operational uptime. For engineering teams and procurement managers in dredging firms, selecting a hose with superior technical specifications directly impacts project ROI and safety compliance.

| Inner Diameter (mm) | Working Pressure (bar) – East Marine | Working Pressure (bar) – Competitors | Burst Pressure (bar) – East Marine | Burst Pressure (bar) – Competitors | Bending Radius (mm) – East Marine | Bending Radius (mm) – Competitors |

|---|---|---|---|---|---|---|

| 200 | 16 | 12 | 64 | 36 | 900 | 1100 |

| 300 | 15 | 11 | 60 | 33 | 1350 | 1650 |

| 400 | 14 | 10 | 56 | 30 | 1800 | 2200 |

| 500 | 13 | 9 | 52 | 27 | 2250 | 2750 |

| 600 | 12 | 8 | 48 | 24 | 2700 | 3300 |

East Marine’s technical superiority in dredging hose performance is validated through third-party testing and field deployment across Asia, Africa, and the Middle East. By maintaining tighter tolerances and higher safety margins, East Marine ensures reliable, long-term service in the most challenging hydraulic excavation environments.

Partner with East Marine

Conclusion: Engineered Reliability for Demanding Dredging Operations

Selecting the optimal suction rubber hose is not merely a procurement decision; it is a critical investment in operational continuity, safety, and project profitability within the demanding dredging environment. East Marine, operating as a core subsidiary of Jiangsu Huashen Special Rubber Products Co. Ltd., delivers this essential reliability through decades of specialized engineering focus and rigorous manufacturing discipline. Our commitment transcends standard production; we engineer solutions grounded in deep material science expertise and a thorough understanding of the abrasive, high-pressure, and corrosive realities faced daily in suction applications worldwide. Since our founding in 2007, we have consistently met and exceeded the stringent requirements of major international dredging contractors and port authorities, underpinned by our ISO 9001 certified quality management system and active membership in leading industry bodies WEDA and CEDA. Our 0.68 million square meter integrated manufacturing facility in Jiangsu represents one of the largest dedicated capacities for specialized marine rubber products globally, ensuring not only scale but also unparalleled process control and material traceability for every hose assembly.

The technical specifications detailed below represent the baseline capabilities of our standard dredging suction hose range, engineered for maximum abrasion resistance, kink prevention, and structural integrity under full vacuum and high-pressure discharge conditions. This foundation is merely the starting point; East Marine excels in tailoring solutions to meet unique project challenges, whether requiring enhanced chemical resistance, specific flange configurations, integrated buoyancy, or compliance with niche regulatory frameworks. Our engineering team collaborates directly with clients to translate operational parameters into optimized hose system designs, minimizing lifecycle costs through extended service life and reduced downtime.

| Technical Parameter | Standard Suction Hose Specification | Notes |

|---|---|---|

| Internal Diameter (ID) | 200 mm – 1200 mm | Custom sizes available beyond range |

| Working Pressure | -0.9 bar (Full Vacuum) to +16 bar | Specific rating varies by ID & design |

| نطاق درجة الحرارة | -30°C to +80°C | Special compounds for extreme temps |

| Cover Type | Abrasion-Resistant Synthetic Rubber | Oil/Fuel resistant options available |

| Reinforcement | High-Tensile Steel Wire Spiral(s) | Multiple layers for higher pressures |

| Liner Material | Specialized Wear-Resistant Rubber | Tailored for sand, gravel, slurry types |

| Standards Compliance | ISO 14313, API 17K, Project Specific | Certifications provided per project |

Initiate Your Project with Confirmed Expertise

Do not compromise your dredging operation’s efficiency and safety on substandard hose performance. Partner with East Marine for suction hose solutions engineered for the long haul in the world’s most challenging marine environments. Our global engineering support team is prepared to provide immediate technical consultation, detailed product specifications, and competitive commercial proposals tailored precisely to your project scope. Leverage our Singapore branch for responsive regional coordination, technical support, and streamlined logistics management across the Asia-Pacific region, ensuring minimal lead times and localized expertise. Contact us today to discuss your specific suction hose requirements and discover how our engineered reliability translates directly to your bottom line. Reach our dedicated dredging solutions team via WhatsApp at +86-13806109365 for urgent inquiries or email hsdredging@eastmarine.tech to initiate a comprehensive technical review. Let East Marine be the assured link in your critical dredging infrastructure.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.