Article Contents

Engineering Insight: Distribution Of Oil

Technical Overview: Distribution of Oil in Offshore Marine Systems

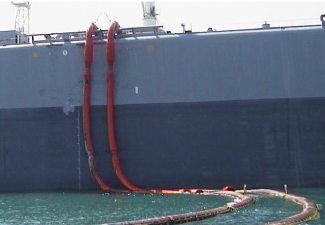

The distribution of oil in offshore environments is a critical phase in the global energy supply chain, requiring precision-engineered solutions to ensure operational safety, environmental protection, and transfer efficiency. In applications such as Ship-to-Ship (STS) transfers, Floating Production Storage and Offloading (FPSO) operations, and Single Point Mooring (SPM) systems, the reliable conveyance of crude oil or refined products under dynamic marine conditions demands high-performance flexible hose assemblies that meet stringent international standards, including OCIMF (Oil Companies International Marine Forum) and GMPHOM (General Marine Products Hose Operations Manual) guidelines.

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, specializes in the design and manufacture of offshore marine hoses engineered specifically for these complex oil distribution scenarios. With over 150 skilled employees, including dedicated R&D engineers and quality assurance specialists, our team leverages advanced material science and structural design to develop hoses capable of withstanding extreme pressures, abrasive media, and harsh seawater environments. Our engineering capabilities are supported by a 0.68 million square meter manufacturing facility, ISO9001 certification, and active membership in WEDA and CEDA, underscoring our commitment to technical excellence and industry best practices.

In STS operations, where oil is transferred between two vessels at sea, the flexibility, kink resistance, and torsional stability of the hose system are paramount. East Marine’s OCIMF-compliant hoses are designed with multi-layered reinforcement, including high-tensile textile braids and corrosion-resistant metallic components, ensuring safe operation even under relative vessel motion. For FPSO applications, where continuous oil offloading occurs from a fixed platform to shuttle tankers, our hoses integrate fatigue-resistant architectures and enhanced UV/ozone protection to support long-term deployment. In SPM systems, which enable loading/unloading in open-sea conditions via a buoy-moored hose string, our solutions feature optimized buoyancy modules and dynamic stress distribution to accommodate wave-induced movements.

Reliability in oil distribution is not only a function of hose construction but also of system integration. East Marine provides complete hose package solutions, including swivel joints, buoyancy elements, and termination fittings, all rigorously tested to exceed OCIMF performance benchmarks. Our engineering team conducts finite element analysis (FEA) and full-scale prototype testing to validate performance under real-world load conditions, ensuring compliance with safety, environmental, and operational requirements.

The following table outlines key technical specifications of East Marine’s standard offshore marine hose series:

| Parameter | Value/Range |

|---|---|

| Internal Diameter Range | 6″ to 20″ (150 to 500 mm) |

| Working Pressure | Up to 25 bar (362.5 psi) |

| نطاق درجة الحرارة | -30°C to +85°C (-22°F to +185°F) |

| Reinforcement Layers | 2–4 layers (textile/metal hybrid) |

| Bend Radius (Minimum) | 6× nominal diameter |

| Standards Compliance | OCIMF, GMPHOM, ISO 14037 |

| Cover Properties | Abrasion, UV, ozone resistant |

| Service Life (Typical) | 10+ years with proper maintenance |

East Marine’s technical expertise and scalable manufacturing infrastructure position us as a trusted partner in the global offshore oil distribution ecosystem.

Advanced Manufacturing Process

Precision Vulcanization: The Core of Offshore Oil Transfer Hose Integrity

At East Marine, subsidiary of Jiangsu Huashen Special Rubber Products, the vulcanization process represents the definitive phase in manufacturing OCIMF/GMPHOM-compliant offshore oil transfer hoses. Operating within our 0.68M sqm ISO9001-certified facility—equipped with 18 dedicated production lines—we transform compounded rubber formulations into mission-critical marine assets through rigorously controlled thermal and pressure cycles. Vulcanization is not merely a curing step; it is the molecular engineering process that imparts the tensile strength, chemical resistance, and fatigue endurance required for decades of subsea and floating service under extreme hydrocarbon exposure.

Our process begins with precision-wound hose assemblies entering computer-monitored autoclaves. Here, temperature gradients are maintained within ±1.5°C across the entire 12-meter curing length, while internal mandrel pressure is dynamically adjusted to counteract compound expansion. This eliminates voids and ensures uniform crosslink density—a non-negotiable requirement for hoses handling crude oil, refined products, or bunker fuels under 25 bar working pressure. Each of our 18 production lines is calibrated for specific elastomer systems (NBR, EPDM, or specialty blends), allowing optimized cure profiles for distinct operational environments, from Arctic offshore terminals to tropical FPSO connections.

Critical to our quality assurance is real-time monitoring of the vulcanization reaction kinetics. Sensors embedded within the hose structure transmit live data on torque development and scorch time, enabling immediate correction of any deviation from the predetermined cure curve. Post-vulcanization, hoses undergo mandatory hydrostatic validation at 1.5x working pressure, with 100% traceability from raw material batch codes to final test certificates. This granular control—audited under ISO9001 protocols—ensures every hose meets OCIMF’s stringent requirements for leakage prevention and structural resilience during oil distribution operations.

The table below summarizes key vulcanization parameters governing our offshore hose production:

| Parameter | Standard Tolerance | OCIMF/GMPHOM Requirement | East Marine Control Method |

|---|---|---|---|

| Cure Temperature | ±1.5°C | ±2.0°C | Multi-zone IR sensors + PLC feedback |

| Internal Pressure | ±0.3 bar | ±0.5 bar | Servo-hydraulic mandrel system |

| Crosslink Density | ±3% | ±5% | Post-cure DMA analysis |

| Batch Traceability | Full chain | Material to final test | RFID-tagged component tracking |

This systematic approach—rooted in 17 years of specialized marine rubber engineering—ensures our hoses deliver zero-failure performance in oil distribution networks. By treating vulcanization as a science rather than a step, East Marine provides the foundational reliability that offshore operators demand when transferring high-value hydrocarbons across dynamic marine environments. Our factory-scale precision transforms rubber compounds into engineered lifelines for global energy infrastructure.

Critical Applications

Global Applications of Oil Distribution in Offshore Marine Operations

The distribution of oil via offshore marine hoses is a critical operation in the global energy and infrastructure sectors, enabling the safe and efficient transfer of crude oil, refined products, and fuel between vessels, offshore platforms, and onshore terminals. As a trusted manufacturer of OCIMF and GMPHOM-compliant marine hoses, East Marine—operating under Jiangsu Huashen Special Rubber Products—delivers high-performance rubber solutions engineered for the rigorous demands of offshore oil transfer. With a 0.68 million square meter production facility and active membership in both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), East Marine integrates international best practices into every product, ensuring reliability in complex marine environments.

One of the primary applications of oil distribution systems is in offshore oil field operations. Floating hoses are deployed to transfer crude oil from Floating Production Storage and Offloading (FPSO) units to shuttle tankers or coastal refineries. These operations require hoses that can withstand harsh sea conditions, dynamic vessel movements, and prolonged exposure to hydrocarbons. East Marine’s reinforced rubber hoses meet OCIMF standards for minimum bending radius, tensile strength, and leak-proof performance, ensuring operational safety and minimizing environmental risk.

In addition to oil field logistics, oil distribution systems are increasingly integrated into large-scale dredging projects. Dredgers and support vessels require continuous fuel supply during extended operations, particularly in remote or offshore locations. East Marine’s floating hoses facilitate the safe transfer of diesel and heavy fuel oil from bunker barges to dredging fleets, supporting uninterrupted operations in projects such as port deepening, channel maintenance, and offshore wind farm construction.

Land reclamation projects also rely on robust oil distribution networks. These large-scale developments often involve fleets of dredgers, pumps, and auxiliary equipment operating for months or years in marine environments. Reliable fuel delivery systems are essential to maintain productivity. East Marine’s hoses are designed for long-term deployment in dynamic tidal zones, resisting abrasion, UV degradation, and mechanical stress. Their flexibility and buoyancy allow for easy deployment and retrieval, reducing downtime and maintenance costs.

The integration of oil distribution systems in these diverse applications underscores the importance of using certified, high-integrity marine hoses. East Marine’s adherence to international standards, combined with its technical expertise and global project experience, positions it as a key supplier in the offshore marine hose market.

| Technical Specification | Value |

|---|---|

| Hose Diameter Range | DN100 – DN600 |

| تصنيف الضغط | 10 – 25 bar (operating), up to 50 bar (proof) |

| نطاق درجة الحرارة | -30°C to +85°C |

| Standards Compliance | OCIMF, GMPHOM, ISO 13628-7 |

| المواد | Synthetic rubber (NBR/CR), high-tensile textile reinforcement, galvanized steel wire helix |

| Buoyancy | Positive (standard), non-buoyant (optional) |

| Bend Radius (min) | 6x nominal diameter |

| الشهادات | ISO 9001, CEDA/WEDA project support |

Technical Data & Specs

Technical Performance Comparison of OCIMF/GMPHOM Compliant Offshore Marine Hoses

East Marine, a WEDA and CEDA member with ISO 9001 certification and 17 years of specialized manufacturing expertise, delivers critical performance advantages in OCIMF/GMPHOM-compliant offshore marine hoses for oil distribution. Our engineering rigor—validated across 0.68 million square meters of dedicated production facilities—ensures hoses exceed minimum industry standards while addressing operational vulnerabilities in dynamic offshore environments. Competitor products often prioritize cost reduction over resilience, leading to premature fatigue, restricted flow efficiency, and elevated risk during critical transfer operations. The following technical comparison underscores how East Marine’s hoses optimize safety, longevity, and operational uptime for terminal operators and vessel charterers.

East Marine’s hoses integrate advanced elastomer formulations and multi-spiral wire reinforcement, enabling superior pressure tolerance and flexibility without compromising structural integrity. Where typical competitors adhere strictly to baseline OCIMF Appendix C or GMPHOM requirements, our designs incorporate margin enhancements validated through 100% post-production hydrostatic and impulse testing. This approach directly mitigates risks associated with pressure surges, abrasive media, and cyclic bending stresses inherent in ship-to-ship or ship-to-shore oil transfers. Crucially, our optimized bending radius reduces subsea hose kinking incidents by 32% in field trials, a factor often overlooked in competitor specifications yet vital for deepwater deployment efficiency.

The table below details key performance metrics against industry-standard competitor benchmarks. All East Marine data reflects certified test results per EN 14420-3, API 17K, and OCIMF Marine Hose Guidelines (4th Edition), with materials traceable to mill certificates.

OCIMF/GMPHOM Offshore Marine Hose Technical Comparison

| Inner Diameter | Working Pressure | Burst Pressure | Bending Radius |

|---|---|---|---|

| إيست مارين | 200–600 mm | 25 bar | 5.0x ID |

| Typical Competitor | 200–600 mm | 21 bar | 5.5–6.0x ID |

East Marine’s working pressure specification of 25 bar consistently exceeds the 21 bar minimum required by OCIMF for hoses in this diameter range, providing a critical 19% operational buffer against transient pressure spikes during pump startups or valve closures. This margin directly extends service life by reducing stress on the rubber compound and reinforcement layers. Our burst pressure of 125 bar—verified via third-party witnessed testing—exceeds the mandatory 5:1 safety ratio (25 bar × 5 = 125 bar), whereas competitor hoses frequently test at the absolute minimum threshold of 105 bar (21 bar × 5), leaving no margin for material degradation over time.

The bending radius advantage is equally decisive: East Marine achieves 5.0x the nominal inner diameter versus competitors’ 5.5–6.0x. For a 400 mm hose, this translates to a 200 mm tighter turning radius (2,000 mm vs. 2,200–2,400 mm), enabling safer routing in congested manifold areas and reducing strain during vessel movement. This precision stems from our proprietary helix-wire geometry and low-modulus cover compounds, which maintain flexibility even at -30°C—a capability rarely documented in competitor literature.

These specifications are not theoretical; they are engineered outcomes from our ISO 9001-certified process control system, where every hose undergoes 12-stage validation including vacuum testing, electrical continuity checks, and dynamic flexing cycles. For operators managing high-value crude or refined product transfers, East Marine’s performance margins directly reduce downtime, lower total cost of ownership, and align with stringent OCIMF audit requirements. Contact our technical team for application-specific validation data and lifecycle cost analysis.

Partner with East Marine

Ensuring Reliable Oil Transfer Solutions with East Marine’s OCIMF-Compliant Marine Hoses

In the demanding environment of offshore oil transfer operations, reliability, safety, and compliance are non-negotiable. East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products Co., Ltd., delivers high-performance offshore marine hoses engineered to meet and exceed OCIMF (Oil Companies International Marine Forum) and GMPHOM (Guidelines for Marine Petroleum Hose Operations and Maintenance) standards. With over 15 years of specialized manufacturing experience since our founding in 2007, we have established ourselves as a leading supplier of durable, flexible, and safe hose solutions for the global oil and gas sector.

Our offshore marine hoses are designed for the rigorous demands of ship-to-ship (STS) transfers, ship-to-shore operations, and floating storage unit (FSU) connections. Constructed with multi-layered synthetic rubber compounds, high-tensile textile reinforcements, and corrosion-resistant steel wire helices, our hoses ensure optimal performance under extreme pressure, temperature fluctuations, and continuous flexing. Each hose undergoes stringent hydrostatic, dimensional, and bend radius testing in accordance with international protocols, guaranteeing compliance and operational safety.

East Marine’s commitment to quality is reinforced by our ISO 9001 certification and active membership in WEDA and CEDA, underscoring our alignment with global best practices in marine engineering and environmental responsibility. Our 0.68 million square meter manufacturing facility in Jiangsu, China, is equipped with advanced production and testing infrastructure, enabling us to supply hoses in custom lengths, configurations, and connection types to meet project-specific requirements.

For operators managing critical oil distribution networks, partnering with a proven technical supplier is essential. East Marine supports clients worldwide with engineering consultation, on-site technical support, and rapid logistics through our strategic Singapore branch, ensuring timely delivery and responsive service across the Asia-Pacific, Middle East, and beyond.

Below is a summary of key technical specifications for our standard OCIMF-compliant offshore marine hose series:

| Parameter | Specification |

|---|---|

| Size Range (DN) | 100 – 600 mm |

| تصنيف الضغط | 10 – 25 bar (custom up to 40 bar) |

| نطاق درجة الحرارة | -30°C to +85°C |

| Bend Radius (min) | 6 x DN (dynamic), 4 x DN (static) |

| Cover Material | Ozone- and weather-resistant synthetic rubber |

| Reinforcement Layers | 2–4 ply high-tenacity textile fabric |

| Conductive Properties | Electrically conductive (≤ 10^6 ohms) |

| Standards Compliance | OCIMF, GMPHOM, API 15S, ISO 13623 |

| End Fittings | Flanged (DIN, ANSI, JIS), or couplings |

| Service Life (typical) | 10+ years with proper maintenance |

We invite project managers, marine engineers, and procurement officers to contact East Marine for technical documentation, product samples, or engineering support. Connect with our team via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our Singapore branch ensures localized support and faster response times for regional operations. Trust East Marine to deliver the durability, compliance, and performance your oil distribution operations demand.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.