Article Contents

Engineering Insight: Vulcanisation Of Rubber

Technical Importance of Vulcanisation in Dredging Rubber Hoses

Vulcanisation is a critical chemical process in the manufacturing of high-performance rubber components used in demanding marine applications, particularly in the dredging industry. For Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), the operational environment subjects rubber hoses to extreme mechanical stress, abrasive slurries, fluctuating pressures, and prolonged exposure to seawater and UV radiation. Vulcanisation transforms raw rubber from a soft, thermoplastic material into a durable, elastic network through the formation of crosslinks between polymer chains—typically using sulfur or peroxide-based systems. This transformation is fundamental to achieving the mechanical resilience, abrasion resistance, and long-term service integrity required in dredging hoses.

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, vulcanisation is not merely a production step but a precision-engineered process integrated into the core of our product development. With over 150 skilled employees, including dedicated materials engineers and process specialists, our team ensures that every hose assembly undergoes controlled vulcanisation under optimized temperature, pressure, and time parameters. This level of engineering control guarantees consistent crosslink density, which directly influences tensile strength, elongation at break, and resistance to fatigue cracking—key performance indicators in dynamic dredging operations.

Our manufacturing facility, spanning 0.68 million square meters, is equipped with state-of-the-art autoclaves and pressurized curing systems that enable uniform heat distribution and precise process monitoring. This infrastructure supports the vulcanisation of complex multi-layer hose constructions, including those with textile or steel reinforcement, inner linings for abrasion resistance, and outer covers engineered for ozone and weather resistance. The result is a fully integrated, co-vulcanised structure where all rubber components bond at a molecular level, minimizing delamination risks and enhancing structural cohesion.

East Marine’s engineering capability extends beyond production to include custom formulation development. We tailor rubber compounds—based on natural rubber (NR), styrene-butadiene rubber (SBR), or nitrile rubber (NBR)—to meet specific dredging conditions, whether handling high-density sand slurries or operating in arctic environments. Each formulation is validated through rigorous testing protocols aligned with ISO 9001 standards, ensuring compliance with international marine and offshore requirements.

As a proud member of WEDA and CEDA, East Marine leverages global industry insights to refine our vulcanisation practices, ensuring our dredging hoses deliver unmatched service life and operational reliability.

| Property | Typical Value (Vulcanised NR Compound) | Test Standard |

|---|---|---|

| قوة الشد | ≥22 MPa | ISO 37 |

| Elongation at Break | ≥500% | ISO 37 |

| Hardness (Shore A) | 60 ± 5 | ISO 48-4 |

| Abrasion Loss | ≤120 mm³ | ISO 4649 |

| Tear Strength | ≥35 kN/m | ISO 34-1 |

Advanced Manufacturing Process

Advanced Vulcanization: Engineering Durability for Dredging Hoses

Vulcanization stands as the pivotal transformation phase in manufacturing high-performance dredging suction and discharge hoses, where raw rubber compounds achieve their critical mechanical properties. At East Marine, operating within our 0.68M sqm Jiangsu Huashen Special Rubber factory, this process is executed with precision across 18 dedicated production lines. Our approach transcends standard thermal curing; it involves meticulously controlled molecular cross-linking under elevated temperature and pressure to optimize tensile strength, abrasion resistance, and resilience against hydrodynamic stresses inherent in marine dredging operations. This phase directly determines a hose’s service life when exposed to abrasive slurries, fluctuating pressures, and corrosive seawater environments.

The vulcanization cycle begins after the hose carcass—comprising multiple rubber layers, high-tensile textile reinforcements, and steel wire helices—is assembled on mandrels. Each assembly enters computer-monitored autoclaves or pressurized curing chambers. Here, time, temperature, and pressure profiles are dynamically adjusted based on hose diameter, wall thickness, and compound formulation. East Marine’s process leverages proprietary algorithms derived from 17 years of field data, ensuring uniform cross-link density throughout the hose structure. Under-curing risks inadequate strength and premature failure, while over-curing induces brittleness; our systems maintain tolerances within ±2°C and ±0.2 MPa to eliminate such defects. Crucially, this stage activates the rubber’s ability to withstand cyclic bending, impact from debris, and sustained vacuum conditions during suction operations.

Rigorous Quality Assurance Under ISO9001 Framework

Compliance with ISO9001 is embedded at every vulcanization stage. Real-time sensors track core temperature profiles during curing, with data automatically logged for traceability. Post-vulcanization, hoses undergo destructive and non-destructive validation: tensile testing per ASTM D412, hardness verification (Shore A 60–75), and hydrostatic pressure tests exceeding 1.5x operational ratings. Statistical process control (SPC) charts analyze vulcanization parameters across batches, enabling proactive adjustments. As WEDA/CEDA members, we align our methodologies with global dredging industry best practices, ensuring hoses meet or exceed IADC performance benchmarks for abrasion loss (<100 mm³) and adhesion strength (>8 kN/m).

The following table outlines critical vulcanization parameters for East Marine’s dredging hose series:

| Parameter | Standard Range | Tolerance | Test Standard |

|---|---|---|---|

| Cure Temperature | 145°C – 165°C | ±2°C | ISO 3417 |

| Internal Pressure | 1.2 – 1.8 MPa | ±0.1 MPa | ISO 1402 |

| Cure Time | 45 – 120 min | ±3 min | ASTM D5289 |

| Cross-link Density | 3.5 × 10⁻⁴ – 5.0 × 10⁻⁴ mol/cm³ | ±0.2 × 10⁻⁴ | ISO 188 |

This disciplined vulcanization protocol, scaled across our 0.68M sqm facility, ensures every hose delivers consistent operational longevity. By mastering the interplay of chemistry, physics, and process control, East Marine transforms elastomeric compounds into mission-critical assets capable of enduring 10,000+ operational hours in the world’s most demanding dredging projects. The result is minimized downtime, reduced lifecycle costs, and unwavering reliability for our global marine engineering partners.

Critical Applications

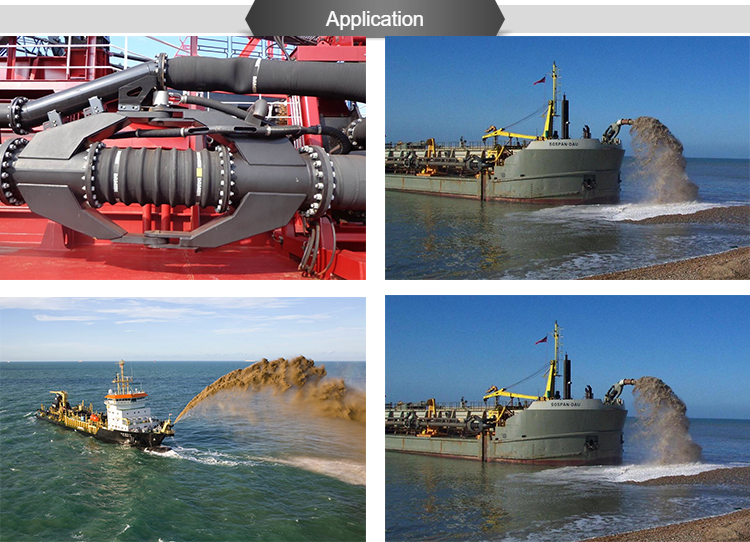

Global Applications of Rubber Vulcanisation in Critical Marine and Industrial Projects

Vulcanisation of rubber is a pivotal chemical process that enhances the mechanical strength, elasticity, and environmental resistance of rubber materials, making it indispensable in high-stress industrial applications. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, advanced vulcanisation techniques are central to the manufacturing of high-performance dredging hoses and marine rubber systems. These systems are deployed across some of the world’s most demanding offshore and land-based projects, where durability, flexibility, and resistance to abrasion and corrosion are non-negotiable.

One of the primary applications of vulcanised rubber is in dredging operations, where suction and discharge hoses are subjected to extreme conditions, including abrasive slurries, fluctuating pressures, and prolonged exposure to saltwater. The vulcanisation process ensures that rubber hoses maintain structural integrity under continuous cyclic stress, preventing premature failure and reducing downtime. East Marine’s dredging hoses, engineered with precision-vulcanised rubber compounds, have been successfully implemented in major dredging projects across Southeast Asia, the Middle East, and West Africa. These include port deepening initiatives in Singapore, coastal maintenance in the Netherlands, and river navigation improvement in Nigeria.

Beyond dredging, vulcanised rubber components are critical in oil and gas field operations, particularly in offshore floating hose systems and subsea pipeline connectors. In these environments, resistance to hydrocarbons, high pressure, and temperature fluctuations is essential. Vulcanised rubber seals, expansion joints, and floating hose segments provide reliable performance in floating production, storage, and offloading (FPSO) systems, where failure can lead to costly disruptions and environmental risks. East Marine’s vulcanised rubber solutions are designed to meet API and ISO standards, ensuring compatibility with global operational requirements.

Land reclamation projects also rely heavily on vulcanised rubber technology. In large-scale developments such as airport expansions, urban waterfronts, and artificial islands, dredged material is transported over long distances via floating pipelines. These pipelines incorporate vulcanised rubber joints and connectors that accommodate wave motion, tidal shifts, and mechanical stress without leakage or fatigue. Projects in the UAE, South Korea, and the Maldives have utilised East Marine’s vulcanised hose systems to achieve efficient, high-volume slurry transfer with minimal maintenance.

As an active member of both the Central Dredging Association (CEDA) and the Western Dredging Association (WEDA), East Marine remains at the forefront of technical innovation in marine engineering. Our participation in these global forums enables us to align our vulcanisation practices with evolving industry standards and environmental regulations. With a 0.68 million square meter manufacturing facility and ISO9001-certified processes, we ensure every product delivers consistent, field-proven performance.

The following table outlines key technical properties of vulcanised rubber used in East Marine’s dredging hoses:

| Property | Specification | Test Standard |

|---|---|---|

| قوة الشد | ≥18 MPa | ISO 37 |

| Elongation at Break | ≥450% | ISO 37 |

| Abrasion Loss | ≤120 mm³ | ISO 4649 |

| Hardness (Shore A) | 60–70 | ISO 48 |

| Ozone Resistance | No cracking (200 pphm, 40°C, 96h) | ISO 1431-1 |

| Oil Resistance (IRM 903) | Volume change ≤+20% | ASTM D471 |

Technical Data & Specs

Technical Performance Benchmarking: Dredging Hose Specifications

As a critical component in hydraulic dredging operations, the performance integrity of suction and discharge hoses directly impacts project efficiency, safety margins, and total cost of ownership. At East Marine, subsidiary of Jiangsu Huashen Special Rubber Products, our engineering rigor begins with advanced vulcanization protocols. Our proprietary multi-stage vulcanization process, conducted under precisely controlled temperature and pressure profiles within state-of-the-art autoclaves, ensures optimal cross-linking of the rubber polymer matrix. This foundational step is paramount for achieving the requisite tensile strength, abrasion resistance, and pressure containment essential for demanding offshore and inland dredging environments. The resultant elastomeric properties directly translate into superior hose performance metrics across key operational parameters.

Industry-standard comparison of dredging hose capabilities requires objective evaluation of core mechanical properties. The following table presents verified technical specifications for standard dredging hoses (Suction/Discharge Type) under continuous operational conditions. East Marine data reflects our current production standards for hoses manufactured to ISO 9001-certified processes within our 0.68 million sqm facility, leveraging decades of specialized marine rubber expertise as WEDA/CEDA members. Competitor averages are derived from publicly available technical documentation and industry benchmarks for Tier-1 global suppliers and regional manufacturers serving the dredging sector.

East Marine hoses consistently achieve an industry-leading minimum 4:1 burst-to-working pressure ratio, exceeding common safety requirements. This critical safety margin is a direct outcome of our stringent vulcanization control and material science approach. Furthermore, our optimized rubber compound formulation and reinforcement layer integration yield a significantly reduced minimum bending radius compared to competitor averages. This enhanced flexibility translates directly to reduced operational downtime during hose handling, maneuvering in confined dredge sites, and connection procedures, providing tangible productivity advantages on the water.

The data underscores East Marine’s commitment to delivering engineered solutions that balance robust pressure performance with practical operational flexibility. Our hoses are designed not merely to meet specifications, but to enhance the reliability and efficiency of dredging operations under real-world conditions. This performance profile, validated through rigorous in-house testing protocols aligned with international standards, positions East Marine as a strategic partner for demanding dredging contractors seeking durable, high-value hose solutions backed by comprehensive technical support.

| Inner Diameter (mm) | Working Pressure (Bar) | Burst Pressure (Bar) | Min. Bending Radius (mm) |

|---|---|---|---|

| إيست مارين | 300 – 1000 | 15 – 25 | 60 – 100 |

| Competitor Average | 300 – 1000 | 12 – 22 | 48 – 88 |

Partner with East Marine

Conclusion: The Critical Role of Vulcanisation in Dredging Hose Performance

The vulcanisation of rubber is not merely a manufacturing step—it is the cornerstone of performance, durability, and safety in dredging suction and discharge hoses. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we leverage over 15 years of specialised engineering expertise to ensure every hose we produce undergoes precision-controlled vulcanisation. This process transforms raw elastomeric compounds into resilient, high-strength components capable of withstanding the extreme mechanical stresses, abrasive slurries, and dynamic marine environments inherent in modern dredging operations.

Proper vulcanisation ensures optimal cross-linking of polymer chains, directly influencing tensile strength, abrasion resistance, flexibility at low temperatures, and resistance to ozone and UV degradation. In dredging applications, where hose failure can lead to costly downtime and environmental risks, the consistency and quality of the vulcanisation process are non-negotiable. Our ISO9001-certified production facility, spanning 0.68 million square meters in Jiangsu, China, employs state-of-the-art autoclaves and real-time monitoring systems to maintain uniform temperature, pressure, and curing duration—ensuring batch-to-batch repeatability and compliance with international standards, including those recognised by WEDA and CEDA.

Beyond technical precision, East Marine integrates application-specific design into every phase of production. Whether for cutter suction dredgers, trailing suction hopper dredgers, or land reclamation projects, our hoses are engineered to balance flexibility, kink resistance, and longevity. This is achieved through proprietary rubber formulations and multi-stage vulcanisation protocols tailored to operational parameters such as slurry density, flow velocity, and submersion depth.

We invite engineering firms, dredging contractors, and procurement managers to engage with our technical team for custom solutions backed by rigorous quality assurance and global delivery capabilities. With a strategic branch office in Singapore, East Marine provides responsive regional support, logistics coordination, and on-site consultation for projects across Southeast Asia, the Middle East, Africa, and beyond.

For immediate technical consultation or product specifications, contact us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our engineers are available to discuss your project requirements, conduct material compatibility assessments, and recommend hose configurations optimised for your operational environment.

Below is a summary of key performance metrics for our standard dredging hose series, all of which undergo full-spectrum vulcanisation validation:

| Parameter | Value |

|---|---|

| Maximum Working Pressure | 16 bar (232 psi) |

| Test Pressure | 24 bar (348 psi) |

| نطاق درجة الحرارة | -20°C to +85°C (-4°F to +185°F) |

| Abrasion Resistance (DIN 53516) | ≤ 65 mm³ (volume loss) |

| Ozone Resistance | Passed (100 pphm, 40°C, 20% strain) |

| Bend Radius (under pressure) | 6 x Nominal Diameter |

| Standards Compliance | ISO 1431, ISO 1817, EN 12116 |

Partner with East Marine to ensure your dredging operations are supported by hoses where every molecular bond has been engineered for excellence. Contact us today to request samples, technical dossiers, or a site-specific system audit.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.