Introduction: Navigating the Global Market for water hose manufacturers

In the dynamic landscape of global trade, sourcing high-quality water hoses from manufacturers can pose significant challenges for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The key lies in understanding the varied applications and specifications of water hoses, which range from agricultural use to commercial cleaning and residential gardening. This comprehensive guide serves as an essential resource, equipping international buyers with the knowledge needed to navigate the complexities of sourcing water hoses.

Within these pages, we delve into the different types of water hoses available in the market, their specific applications, and critical factors to consider when vetting suppliers. Additionally, we cover aspects of cost, durability, and performance to ensure that buyers can make informed purchasing decisions. By addressing common pitfalls and offering actionable insights, this guide empowers B2B buyers to confidently select the right products that meet their operational needs while adhering to budget constraints.

With a focus on fostering strong supplier relationships and understanding market trends, this guide is designed to streamline the procurement process, enabling buyers to leverage the best offerings from manufacturers worldwide. Whether you’re in Brazil, Vietnam, or any other region, the insights provided herein will help you optimize your sourcing strategy and enhance your competitive edge in the marketplace.

جدول المحتويات

- Top 9 Water Hose Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water hose manufacturers

- Understanding water hose manufacturers Types and Variations

- Key Industrial Applications of water hose manufacturers

- 3 Common User Pain Points for ‘water hose manufacturers’ & Their Solutions

- Strategic Material Selection Guide for water hose manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for water hose manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water hose manufacturers’

- Comprehensive Cost and Pricing Analysis for water hose manufacturers Sourcing

- Alternatives Analysis: Comparing water hose manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for water hose manufacturers

- Navigating Market Dynamics and Sourcing Trends in the water hose manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water hose manufacturers

- Strategic Sourcing Conclusion and Outlook for water hose manufacturers

- تنويه هام وشروط الاستخدام

Understanding water hose manufacturers Types and Variations

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Commercial Rubber Hoses | High durability, kink-resistant, heavy-duty construction | Agriculture, construction, industrial cleaning | الإيجابيات: Long-lasting, high burst strength. السلبيات: Heavier and less flexible than other types. |

| Polyurethane Hoses | Lightweight, flexible, resistant to abrasion and UV rays | Landscaping, gardening, light industrial use | الإيجابيات: Easy to handle, good for tight spaces. السلبيات: Lower pressure ratings compared to rubber hoses. |

| Soaker Hoses | Designed with porous material for slow, deep watering | Agriculture, horticulture, gardening | الإيجابيات: Efficient water usage, reduces evaporation. السلبيات: Limited to specific applications; may require maintenance. |

| Flat Hoses | Space-saving design, lightweight, easy to store | Irrigation, temporary setups, landscaping | الإيجابيات: Easy to transport, versatile. السلبيات: Less durable, may kink under pressure. |

| RV/Marine Hoses | Drinking water-safe, lightweight, resistant to abrasion | Recreational vehicles, boating | الإيجابيات: Safe for drinking water, compact design. السلبيات: Generally not suitable for high-pressure applications. |

What Are the Key Characteristics of Commercial Rubber Hoses?

Commercial rubber hoses are known for their robust construction and high durability. They typically feature a kink-resistant design and can handle high pressure, making them ideal for demanding environments such as agriculture, construction, and industrial cleaning. Buyers should consider the specific pressure ratings and lengths available, as well as the hose’s weight, which can impact handling during use.

How Do Polyurethane Hoses Compare in Terms of Flexibility and Weight?

Polyurethane hoses stand out for their lightweight and flexible nature, making them easier to maneuver in tight spaces. They are resistant to abrasion and UV rays, making them suitable for landscaping and light industrial applications. When purchasing, B2B buyers should assess the hose’s pressure ratings and ensure it meets the specific needs of their operations, particularly in environments where flexibility is paramount.

What Are the Advantages of Using Soaker Hoses for Agriculture?

Soaker hoses are designed to deliver water directly to the plant roots through tiny pores, promoting efficient water usage and reducing evaporation. This makes them particularly beneficial in agricultural and horticultural settings. Buyers should evaluate the length and material of the soaker hose, as well as its maintenance requirements, to ensure optimal performance and longevity in their watering systems.

Why Choose Flat Hoses for Temporary Irrigation Needs?

Flat hoses are favored for their space-saving design, making them easy to transport and store. They are versatile and can be used for various applications, including irrigation and temporary setups in landscaping. However, B2B buyers should be aware of their lower durability compared to traditional hoses and the potential for kinking under pressure, which may limit their use in high-demand situations.

What Makes RV/Marine Hoses Unique for Recreational Applications?

RV and marine hoses are specifically designed to be drinking water-safe and lightweight, catering to the needs of recreational vehicles and boating. Their compact design allows for easy storage, making them ideal for travel. However, these hoses typically have lower pressure ratings and may not be suitable for heavy-duty applications, so buyers should assess their specific requirements before purchasing.

Key Industrial Applications of water hose manufacturers

| الصناعة/القطاع | Specific Application of water hose manufacturers | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| الزراعة | Irrigation systems for crop cultivation | Ensures consistent water supply, enhancing crop yield | Durability, flexibility, resistance to UV and chemicals, length options |

| الإنشاءات | Water supply for concrete mixing and dust control | Increases efficiency and safety on job sites | Burst strength, kink resistance, compatibility with machinery |

| Landscaping & Gardening | Watering solutions for plants and lawns | Promotes healthy growth and aesthetic appeal | Lightweight design, eco-friendly materials, ease of handling |

| التعدين | Water hoses for dust suppression and equipment cooling | Enhances operational safety and equipment longevity | High-pressure tolerance, abrasion resistance, temperature flexibility |

| المأكولات والمشروبات | Safe water hoses for beverage production | Ensures compliance with health standards and safety | Certification for drinking water safety, material quality, length options |

How Are Water Hoses Used in Agriculture and What Problems Do They Solve?

Water hoses are essential in agriculture, particularly in irrigation systems that facilitate crop cultivation. They enable farmers to maintain consistent moisture levels, critical for seed germination and growth. The challenges in this sector include varying water supply conditions and the need for durable hoses that withstand exposure to sunlight and chemicals. International buyers, especially from regions like Africa and South America, should prioritize hoses that offer UV resistance and flexibility to adapt to diverse terrains.

What Role Do Water Hoses Play in Construction Projects?

In construction, water hoses are pivotal for supplying water during concrete mixing and controlling dust on job sites. Their ability to deliver high-pressure water ensures efficient operations and enhances safety by minimizing dust-related hazards. Buyers in the construction industry should consider hoses with high burst strength and kink resistance to withstand rigorous use. This is particularly important for international buyers in regions with challenging climates, such as the Middle East, where heat can affect material integrity.

How Do Landscaping and Gardening Benefit from Water Hose Solutions?

Water hoses are vital in landscaping and gardening, providing effective watering solutions that promote healthy plant growth. Their lightweight and flexible designs facilitate easy maneuverability, making them ideal for diverse garden layouts. Buyers should focus on eco-friendly options, such as hoses made from recycled materials, which are increasingly important in Europe. Additionally, features like kink resistance and compatibility with various fittings enhance usability and efficiency.

What Are the Applications of Water Hoses in Mining Operations?

In the mining sector, water hoses are used for dust suppression and cooling equipment. These applications are crucial for maintaining safety standards and prolonging the lifespan of machinery. Given the harsh environments, hoses must be robust, with high-pressure tolerance and abrasion resistance. B2B buyers from regions like South America, where mining operations are prevalent, should ensure that hoses can withstand extreme conditions and offer reliable performance.

Why Are Water Hoses Important in the Food and Beverage Industry?

Water hoses in the food and beverage industry must comply with health and safety standards, ensuring that the water used in production is safe for consumption. These hoses are designed to handle various applications, from beverage production to cleaning processes. Buyers should prioritize hoses certified for drinking water safety, focusing on material quality and length options to meet specific operational needs. This is particularly relevant for international buyers in Europe, where regulatory compliance is stringent.

3 Common User Pain Points for ‘water hose manufacturers’ & Their Solutions

Scenario 1: The Challenge of Durability in Harsh Environments

المشكلة B2B buyers often face issues with water hoses that fail under extreme conditions, such as high temperatures or abrasive environments. For instance, agricultural businesses in arid regions or construction companies in desert-like conditions require hoses that can withstand significant wear and tear. Standard hoses might crack or burst, leading to costly downtime and operational inefficiencies. Additionally, the need for reliable products that can endure continuous use adds pressure on procurement teams to select the right hoses.

الحل: To address these challenges, B2B buyers should prioritize sourcing from manufacturers that specialize in heavy-duty, industrial-grade hoses designed for extreme conditions. When evaluating potential suppliers, look for certifications such as burst strength ratings and material specifications that indicate durability, like reinforced rubber or polyurethane. Engage with manufacturers to discuss specific environmental conditions and obtain product samples for testing. Additionally, consider hoses with features such as kink resistance and UV protection to ensure longevity. Implementing a regular maintenance schedule can also help extend the lifespan of the hoses, including checks for wear and tear, which can prevent unexpected failures.

Scenario 2: Sizing and Compatibility Issues with Water Hoses

المشكلة A common pain point for B2B buyers is determining the correct size and compatibility of hoses with existing equipment. Industries such as landscaping or facilities maintenance often utilize various tools and fittings, and mismatches can lead to inefficiencies and wasted resources. For example, a facility may order hoses that do not fit their connectors or are too short for their application, causing delays in operations and increased costs due to the need for replacements.

الحل: Buyers should conduct a thorough assessment of their current equipment and existing hoses before making a purchase. This includes measuring hose lengths, diameters, and checking the types of fittings used. When engaging with water hose manufacturers, provide detailed specifications and inquire about customization options for length and fittings. Look for manufacturers that offer a range of sizes and can provide technical support for compatibility questions. Additionally, establishing a relationship with a trusted supplier can facilitate easier exchanges or returns if products do not meet the specified requirements.

Scenario 3: Environmental Concerns and Sustainability Practices

المشكلة Increasingly, B2B buyers are confronted with the need to align their purchasing decisions with sustainability goals. Water hose manufacturing processes can involve harmful chemicals and materials that are not environmentally friendly. Companies in sectors such as agriculture and landscaping are particularly sensitive to these issues, as they seek to minimize their environmental footprint while maintaining operational efficiency.

Illustrative image related to water hose manufacturers

الحل: To navigate these concerns, buyers should seek out manufacturers committed to sustainable practices, such as using recycled materials in their hoses or adopting eco-friendly production processes. When evaluating suppliers, ask about their sustainability certifications and initiatives. Consider products like soaker hoses made from recycled rubber that not only reduce waste but also promote efficient water usage. Additionally, collaborating with manufacturers who prioritize research and development in eco-friendly products can help businesses meet their sustainability targets while still achieving high performance. Regularly review and assess the environmental impact of purchased products to ensure ongoing alignment with corporate sustainability goals.

Strategic Material Selection Guide for water hose manufacturers

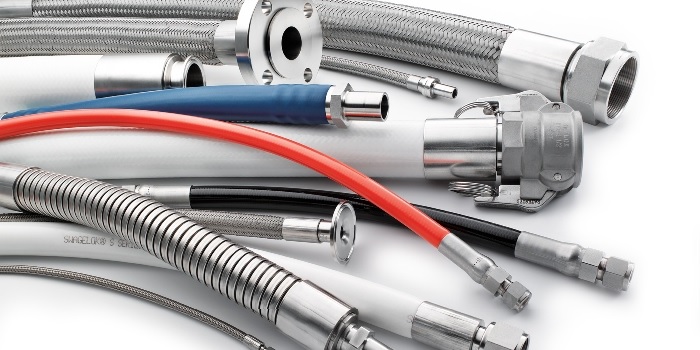

What Are the Common Materials Used in Water Hose Manufacturing?

Water hoses are essential tools across various industries, and their performance largely depends on the materials used in their construction. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, particularly those operating in diverse environments like Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in water hose manufacturing.

How Does PVC Impact Water Hose Performance?

Polyvinyl Chloride (PVC) is a widely used material in the production of water hoses. It offers excellent flexibility and is lightweight, making it easy to handle. PVC hoses typically have a temperature rating of up to 60°C and can withstand moderate pressure, generally around 200 psi.

الإيجابيات: PVC hoses are cost-effective and resistant to corrosion and UV damage, making them suitable for outdoor applications. They are also available in various colors, which can enhance visibility in work environments.

السلبيات: However, PVC hoses can become brittle over time, especially in extreme temperatures, and may not perform well in high-pressure applications. Their flexibility can also lead to kinking, which can impede water flow.

Application Impact: PVC is compatible with water and some chemicals, but it is not suitable for high-temperature or high-pressure applications. Buyers in regions with extreme climates should consider these limitations.

What Advantages Do Rubber Hoses Offer?

Rubber hoses are known for their durability and flexibility, making them a popular choice for both commercial and industrial applications. They typically have a higher temperature rating (up to 100°C) and can withstand pressures of 600 psi or more.

الإيجابيات: The primary advantage of rubber hoses is their resilience; they resist kinking and are less prone to wear and tear. They also maintain their flexibility in cold temperatures, making them suitable for various environments.

السلبيات: On the downside, rubber hoses are generally more expensive than PVC options and can be heavier, which may affect portability. Additionally, they may require more complex manufacturing processes.

Application Impact: Rubber hoses are well-suited for transporting water, chemicals, and other media, making them versatile for various applications. Buyers should ensure compliance with local standards, such as ASTM or DIN, especially when exporting to different regions.

Why Choose Polyurethane for Water Hoses?

Polyurethane (PU) is increasingly being used in water hose manufacturing due to its excellent abrasion resistance and flexibility. PU hoses can handle temperatures ranging from -40°C to 80°C and pressures up to 300 psi.

الإيجابيات: One of the standout features of PU hoses is their lightweight nature, which makes them easy to maneuver. They are also resistant to UV rays and ozone, enhancing their longevity.

السلبيات: However, polyurethane hoses can be more expensive than both PVC and rubber options. They may also have limited compatibility with certain chemicals, which could restrict their use in specific applications.

Application Impact: PU hoses are ideal for applications requiring flexibility and durability, such as in agriculture or industrial cleaning. International buyers should verify chemical compatibility and ensure that the hoses meet relevant standards.

What Role Does Layflat Hose Material Play?

Layflat hoses, often made from PVC or polyurethane, are designed for ease of storage and transport. They typically have a pressure rating of up to 150 psi and can handle temperatures from -10°C to 60°C.

الإيجابيات: Layflat hoses are lightweight and easy to deploy, making them ideal for temporary irrigation or drainage applications. Their flat design allows for compact storage.

السلبيات: The primary limitation of layflat hoses is their susceptibility to punctures and abrasions. They may not be suitable for heavy-duty applications where durability is critical.

Application Impact: Layflat hoses are commonly used in agriculture and construction for transporting water over short distances. Buyers should consider local environmental conditions and ensure that the hoses meet relevant compliance standards.

Summary Table of Material Properties

| المواد | Typical Use Case for water hose manufacturers | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| بولي كلوريد الفينيل | General-purpose watering and light-duty tasks | Cost-effective and lightweight | هش في درجات الحرارة القصوى | منخفضة |

| المطاط | Heavy-duty industrial and agricultural tasks | High durability and flexibility | أغلى ثمناً وأثقل | عالية |

| البولي يوريثين | Flexible applications in agriculture and cleaning | Excellent abrasion resistance | Higher cost and limited chemical compatibility | ميد |

| Layflat | Temporary irrigation and drainage applications | Easy storage and deployment | Susceptible to punctures | ميد |

This guide provides a comprehensive overview of the materials used in water hose manufacturing, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for water hose manufacturers

What Are the Main Stages in the Manufacturing Process of Water Hoses?

The manufacturing process for water hoses involves several critical stages, each designed to ensure the final product meets the necessary durability and performance standards.

-

إعداد المواد: The process begins with the selection and preparation of raw materials, typically comprising rubber, PVC, or a blend of both. Suppliers often utilize high-grade compounds that offer resistance to UV rays, abrasion, and temperature variations. These materials undergo thorough testing for consistency and quality before proceeding to the next stage.

-

التشكيل: In this stage, the prepared materials are shaped into hoses using extrusion or molding techniques. Extrusion involves forcing the material through a die to create a continuous length of hose, while molding shapes the material into specific designs. Advanced techniques, such as the use of multi-layer extrusion, allow manufacturers to produce hoses with varying properties, including reinforced layers for added strength.

-

التجميع: After forming, the hoses are cut to desired lengths and fitted with couplings or connectors. This stage may also involve the addition of other features, such as kink resistance or flexibility enhancements. Some manufacturers employ automated machinery to ensure precision in assembly, which is critical for maintaining product integrity.

-

التشطيب: The final stage involves surface treatment and quality checks. Hoses may be coated or treated to improve UV resistance or to add color. Additionally, they undergo a thorough inspection to ensure they meet specifications regarding dimensions and aesthetics.

How Do Water Hose Manufacturers Ensure Quality Control?

Quality control (QC) is an essential aspect of the manufacturing process, ensuring that the products meet both international standards and customer expectations.

-

International Standards and Certifications: Many water hose manufacturers adhere to international quality management systems, such as ISO 9001. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for oil and gas applications, can further validate a manufacturer’s quality.

-

Quality Checkpoints Throughout the Manufacturing Process:

– مراقبة الجودة الواردة (IQC): Materials are inspected upon arrival at the manufacturing facility. Testing for chemical composition, physical properties, and compliance with specifications is crucial at this stage.

– مراقبة الجودة أثناء المعالجة (IPQC): During production, regular checks are conducted to monitor the extrusion and assembly processes. This includes measuring dimensions, checking for defects, and ensuring consistency in material properties.

– مراقبة الجودة النهائية (FQC): The completed hoses undergo a comprehensive evaluation, including pressure testing and visual inspections. This step is crucial for identifying any potential weaknesses before the product is shipped. -

Common Testing Methods for Water Hoses: Manufacturers employ various testing methods, such as:

– Burst Pressure Testing: Evaluating the hose’s ability to withstand high pressure without failure.

– Kink Resistance Testing: Assessing how well the hose maintains its shape and functionality under stress.

– UV Exposure Testing: Simulating long-term exposure to sunlight to ensure the material’s durability.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is vital. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can help verify their adherence to quality standards. Audits should assess compliance with ISO certifications and evaluate the effectiveness of their QC processes.

-

Request Quality Assurance Reports: Buyers can ask suppliers for detailed quality assurance reports that outline testing methods, results, and any corrective actions taken in response to defects. This transparency can help build trust in the supplier’s capabilities.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control practices. These services can conduct in-factory inspections and testing to ensure compliance with international standards.

-

Understand Certification Nuances: Familiarize yourself with the specific certifications relevant to your market. For example, CE marking is critical for products sold in Europe, while other regions may have different requirements. Understanding these nuances can help ensure compliance and avoid costly regulatory issues.

Why Is Quality Control Critical for International Buyers of Water Hoses?

Quality control is not just a regulatory requirement; it also significantly impacts the performance and longevity of water hoses. For international buyers, ensuring that the hoses meet rigorous quality standards is crucial for several reasons:

- الموثوقية: Quality hoses minimize the risk of leaks and failures, which is particularly important in agricultural and industrial applications where downtime can lead to significant losses.

- Safety: Hoses that do not meet quality standards can pose safety risks, especially in high-pressure applications. Ensuring rigorous QC helps mitigate these risks.

- Reputation: For businesses that rely on high-quality hoses, sourcing from manufacturers with strong QC processes can enhance their reputation and customer satisfaction.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices employed by water hose manufacturers is essential for B2B buyers. By following these guidelines, buyers can make informed decisions, ensuring they partner with suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water hose manufacturers’

مقدمة

Sourcing water hoses for your business requires careful consideration and strategic planning. This guide provides a step-by-step checklist to help B2B buyers efficiently procure from water hose manufacturers. By following these steps, you will ensure that you select a supplier who meets your specific needs, adheres to quality standards, and provides reliable service.

الخطوة 1: تحديد المواصفات الفنية الخاصة بك

Before reaching out to suppliers, clearly outline the technical specifications of the water hoses you require. Consider factors such as hose material, diameter, length, pressure ratings, and intended applications (e.g., agricultural, industrial, or residential use). Defining these parameters will streamline your search and help suppliers provide tailored solutions.

- Material Considerations: Look for hoses made from durable materials such as rubber or polyurethane, which offer longevity and performance.

- Application Needs: Identify if you need hoses for high-pressure environments or specific features like kink-resistance or UV protection.

الخطوة 2: إجراء أبحاث السوق

Research potential manufacturers to understand the landscape of available suppliers. Explore industry reports, online directories, and trade shows relevant to water hose manufacturing. This step is crucial for identifying reputable companies and understanding market trends.

- Identify Key Players: Look for manufacturers with strong market presence and positive reviews from other B2B buyers.

- Check Regional Capabilities: Ensure the manufacturers have the capacity to serve your geographical area, especially if you are sourcing from international markets.

الخطوة 3: تقييم الموردين المحتملين

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; seek out independent reviews and testimonials to gauge reliability.

- Assess Experience and Expertise: Look for suppliers with a proven track record in producing the specific type of hoses you need.

- Request Samples: If possible, obtain product samples to evaluate the quality and performance firsthand.

الخطوة 4: التحقق من شهادات الموردين

Check that potential suppliers hold relevant certifications and comply with industry standards. Certifications such as ISO, CE, or local regulatory approvals are indicative of a manufacturer’s commitment to quality and safety.

- Quality Assurance: Ensure that the manufacturer follows stringent quality control processes.

- المعايير البيئية: Consider suppliers that prioritize sustainability, such as using recycled materials in their products.

الخطوة 5: Analyze Pricing and Terms

Obtain detailed quotations from shortlisted suppliers and analyze their pricing structures. Pay attention not only to the cost per unit but also to shipping, payment terms, and bulk order discounts.

- Transparent Pricing: Ensure the supplier provides clear breakdowns of costs to avoid hidden fees.

- Negotiate Terms: Don’t hesitate to negotiate payment terms and delivery schedules that align with your business needs.

الخطوة 6: Establish Communication Protocols

Effective communication with your supplier is essential for a successful partnership. Discuss and agree upon communication channels, response times, and points of contact.

- Regular Updates: Set expectations for regular updates regarding production and shipping status.

- Feedback Mechanisms: Ensure there are processes in place for addressing any concerns or issues that may arise during the partnership.

الخطوة 7: Finalize Contracts and Agreements

Once you’ve selected a supplier, draft a formal contract that clearly outlines all agreed-upon terms. Include details about pricing, delivery timelines, quality expectations, and dispute resolution procedures.

- Legal Review: It may be prudent to have legal counsel review the contract to ensure all bases are covered.

- Flexibility Clauses: Consider including terms that allow for adjustments based on changing business needs or market conditions.

By following this checklist, B2B buyers can strategically navigate the sourcing process for water hoses, ensuring they partner with a reliable manufacturer that meets their operational needs.

Comprehensive Cost and Pricing Analysis for water hose manufacturers Sourcing

What Are the Key Cost Components for Water Hose Manufacturers?

Understanding the cost structure of water hose manufacturing is crucial for international B2B buyers looking to source effectively. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for water hoses include rubber, PVC, and polyurethane. Higher quality materials may incur higher costs but can lead to better durability and performance.

-

Labor: Labor costs vary by region and can be influenced by local wage standards, skill levels, and the complexity of the manufacturing process. Countries with lower labor costs may provide attractive pricing but could compromise on quality or lead times.

-

Manufacturing Overhead: This includes utilities, maintenance, and indirect labor costs associated with production facilities. Efficient manufacturing processes can help reduce overhead, positively affecting pricing.

-

Tooling: The initial setup costs for molds and manufacturing equipment can be significant, especially for custom hose specifications. Buyers should consider these costs when evaluating quotes.

-

Quality Control (QC): Ensuring that products meet specific standards incurs costs that can vary based on the level of scrutiny required. Certifications (like ISO or ASTM) may add to QC expenses but can enhance product trustworthiness.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and current fuel prices. International buyers must factor in potential tariffs, duties, and local transportation costs.

-

Margin: Manufacturers typically add a margin to cover their costs and achieve profitability. This margin can vary based on market competition and the perceived value of the product.

How Do Price Influencers Affect Water Hose Sourcing?

Several factors influence the pricing of water hoses beyond the basic cost components:

-

Volume/MOQ: Buyers can often negotiate better pricing based on larger orders. Manufacturers may offer tiered pricing models that decrease the cost per unit as the order volume increases.

-

Specifications/Customization: Custom designs or specialized features (like kink-resistance or temperature tolerance) can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected pricing.

-

Material Quality and Certifications: High-quality materials and industry certifications can elevate the price but also enhance the product’s reliability and lifespan, which is critical for long-term use.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may charge a premium for their proven track record and customer service.

-

Incoterms: The terms of trade agreed upon can significantly affect the total cost. Buyers should understand whether prices are quoted FOB (Free on Board), CIF (Cost, Insurance, and Freight), or DDP (Delivered Duty Paid) to assess their total landed costs.

What Are Essential Buyer Tips for Negotiating Water Hose Prices?

When sourcing water hoses, international buyers should consider the following strategies:

-

Negotiate Based on Total Cost of Ownership: Rather than focusing solely on unit price, evaluate the total cost of ownership, including durability, maintenance, and potential downtime costs. A higher initial investment in quality hoses may yield savings over time.

-

Understand Pricing Nuances in International Markets: Be aware that pricing may vary significantly based on local economic conditions, currency fluctuations, and trade policies. Buyers from regions like Africa, South America, the Middle East, and Europe should consider these factors when negotiating.

-

Leverage Volume Discounts: If your business has a consistent need for hoses, consolidating orders can lead to volume discounts. Establishing long-term relationships with suppliers can also yield better pricing and service.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs to identify areas for negotiation. This transparency can reveal opportunities for cost-saving adjustments.

-

Stay Informed About Market Trends: Keeping abreast of market trends and competitor pricing can provide leverage in negotiations, helping you secure better deals.

Disclaimer on Pricing

Pricing for water hoses can vary widely based on the factors discussed above. The figures presented in this analysis are indicative and may not reflect the current market rates. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing for their specific needs.

Alternatives Analysis: Comparing water hose manufacturers With Other Solutions

Exploring Alternative Solutions to Water Hose Manufacturers

In the landscape of irrigation and water transport, water hose manufacturers offer a vital service, but they are not the only option available to businesses. As international B2B buyers evaluate their needs, it is essential to consider alternative solutions that may provide similar benefits. This analysis will compare water hose manufacturers against two viable alternatives: drip irrigation systems and portable water tanks.

Illustrative image related to water hose manufacturers

Comparison Table

| جانب المقارنة | Water Hose Manufacturers | Drip Irrigation Systems | Portable Water Tanks |

|---|---|---|---|

| الأداء | High flexibility and durability; suitable for various applications | Highly efficient water use; minimizes evaporation and runoff | Provides large volume storage; suitable for various terrains |

| التكلفة | Mid-range to high, depending on material and length | Higher initial setup cost; long-term savings on water | Variable costs based on size; often requires additional infrastructure |

| سهولة التنفيذ | Simple to set up and use; minimal training required | Requires professional installation; ongoing management needed | Generally easy to deploy; may need pumps for effective use |

| الصيانة | Moderate; occasional replacement needed for wear and tear | Low; mainly requires periodic checks for clogs | Moderate; requires regular cleaning and monitoring for leaks |

| أفضل حالة استخدام | Residential and commercial watering needs | Agricultural applications needing efficient irrigation | Emergency supply, construction sites, or areas lacking plumbing |

التقسيم التفصيلي للبدائل

Drip Irrigation Systems

Drip irrigation systems are designed to deliver water directly to the plant roots, which significantly reduces water waste. This method is particularly advantageous in arid regions or for businesses aiming to implement sustainable practices. While the initial investment can be higher due to installation costs, the long-term savings on water bills and improved crop yields can justify the expense. However, these systems require regular maintenance to ensure that emitters do not clog, which may necessitate additional training for staff.

Portable Water Tanks

Portable water tanks are versatile solutions for businesses that need to store and transport large volumes of water. They are especially useful in areas without fixed water infrastructure or for emergency situations such as firefighting. The cost of portable tanks can vary widely based on size and materials, and while they may not provide the same immediate convenience as hoses, their ability to supply significant water volumes makes them invaluable in certain scenarios. Maintenance involves checking for leaks and ensuring cleanliness, but they can be more straightforward to manage than complex irrigation systems.

Conclusion: How to Choose the Right Solution for Your Business Needs

Selecting the right water management solution depends on specific business requirements, environmental conditions, and budget constraints. For those needing flexible, immediate access to water for a variety of tasks, water hoses from reputable manufacturers might be the best choice. Conversely, businesses focused on sustainable agricultural practices may find that drip irrigation systems offer superior efficiency and long-term benefits. Portable water tanks provide robust solutions for emergency or remote applications. Ultimately, B2B buyers should carefully assess their operational needs and consider both upfront and long-term costs to make an informed decision that aligns with their strategic goals.

Essential Technical Properties and Trade Terminology for water hose manufacturers

What Are the Key Technical Properties of Water Hoses Important for Manufacturers?

Understanding the essential technical properties of water hoses is crucial for manufacturers and B2B buyers alike. Here are several critical specifications to consider:

-

درجة المادة

Water hoses are typically made from materials such as rubber, PVC, or polyurethane. Each material has its unique properties that affect flexibility, durability, and temperature resistance. For example, rubber hoses are known for their robustness and ability to withstand extreme temperatures, making them ideal for industrial applications. Choosing the right material grade can significantly impact the hose’s lifespan and performance in various environments. -

Burst Strength

This refers to the maximum pressure a hose can withstand before failing. Measured in psi (pounds per square inch), burst strength is a vital indicator of a hose’s durability under high-pressure conditions. For B2B buyers, selecting hoses with higher burst strength ensures reliability in demanding applications, reducing the risk of leaks or ruptures during use. -

Kink Resistance

Kink resistance is a measure of a hose’s ability to maintain water flow even when bent or twisted. Hoses with high kink resistance are essential for commercial users who need to manage complex irrigation systems or cleaning tasks without interruptions. This property is particularly important in regions where water supply is limited, as it enhances efficiency and reduces downtime. -

Temperature Tolerance

This specification indicates the range of temperatures within which a hose can operate without degrading. Hoses designed for extreme conditions must maintain integrity in both high and low temperatures. B2B manufacturers must consider temperature tolerance when developing products for diverse climates, especially in regions prone to heat waves or frost. -

القطر والطول

The diameter of the hose affects the flow rate of water, while the length determines how far water can be transported. Common diameters include 1/2 inch, 5/8 inch, and 3/4 inch. For businesses, selecting the right diameter and length is crucial to ensure adequate water supply for specific applications, whether in agriculture, construction, or landscaping.

What Are Common Trade Terms Used in the Water Hose Industry?

Familiarity with industry jargon can facilitate smoother transactions and better communication among water hose manufacturers and buyers. Here are some essential terms:

Illustrative image related to water hose manufacturers

-

OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For water hose manufacturers, partnering with OEMs can enhance product offerings and streamline the supply chain. -

موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it impacts inventory management and budget planning. Manufacturers often set MOQs to ensure profitability and efficiency in production. -

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For water hose manufacturers, providing detailed RFQs helps buyers understand pricing structures, delivery timelines, and product specifications, ensuring transparency in the procurement process. -

إنكوترمز (الشروط التجارية الدولية)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers, as they clarify shipping costs, risk transfer, and delivery obligations, facilitating smoother cross-border trade. -

المهلة الزمنية

This term indicates the time taken from placing an order to delivery. For manufacturers, managing lead time effectively is crucial for maintaining customer satisfaction and optimizing production schedules. B2B buyers should inquire about lead times to plan their operations accordingly.

By comprehending these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing water hoses, ensuring they meet their specific needs while fostering successful supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the water hose manufacturers Sector

What Are the Current Market Dynamics and Key Trends for Water Hose Manufacturers?

The global market for water hoses is experiencing significant transformation driven by various factors. One of the primary drivers is the increasing demand for durable and efficient irrigation solutions across agriculture, landscaping, and industrial sectors, particularly in regions like Africa and South America where agricultural practices are rapidly evolving. Furthermore, the rise in urbanization in the Middle East and Europe has spurred demand for high-quality hoses for both residential and commercial use.

Technological advancements are also reshaping the landscape. Innovations such as lightweight materials, kink-resistant designs, and eco-friendly manufacturing processes are emerging as key trends. For instance, water hoses made from recycled materials are gaining traction among environmentally conscious buyers. B2B buyers are increasingly seeking suppliers who offer customizable solutions tailored to specific industry needs, such as hoses that can withstand extreme weather conditions or high-pressure applications.

Additionally, the COVID-19 pandemic has prompted a shift towards online sourcing and procurement. International buyers are leveraging digital platforms to compare products, assess supplier reliability, and streamline their purchasing processes. This trend highlights the importance of having a robust online presence and e-commerce capabilities for manufacturers aiming to attract global clientele.

How Is Sustainability Impacting Sourcing Trends in the Water Hose Manufacturing Sector?

Sustainability is becoming a cornerstone of sourcing strategies within the water hose manufacturing sector. The environmental impact of traditional manufacturing processes has led to a significant push for greener alternatives. Manufacturers are increasingly adopting sustainable practices, such as utilizing recycled materials and reducing waste during production. For example, hoses made from recycled rubber and plastics not only minimize landfill contributions but also appeal to buyers looking for eco-friendly options.

The importance of ethical supply chains cannot be overstated. Buyers are now scrutinizing the sourcing of raw materials and the labor practices of manufacturers. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential benchmarks for suppliers aiming to establish credibility in the market. This trend is particularly pronounced among international buyers from regions like Europe, where stringent environmental regulations and consumer preferences for sustainable products are prevalent.

Moreover, incorporating sustainability into product design—such as creating hoses that are biodegradable or have a longer lifespan—can provide a competitive edge. B2B buyers increasingly favor suppliers that demonstrate a commitment to environmental stewardship, aligning their purchasing decisions with their corporate social responsibility (CSR) goals.

What Is the Historical Context of Water Hose Manufacturing?

The water hose manufacturing industry has evolved significantly over the past century. Initially, hoses were primarily made from natural rubber, which offered some durability but lacked the versatility required for various applications. As industrial demands grew, manufacturers began exploring synthetic materials, leading to the development of hoses that could withstand higher pressures and extreme temperatures.

Illustrative image related to water hose manufacturers

In recent decades, the introduction of advanced manufacturing techniques and materials has further transformed the sector. Innovations such as PVC and polyurethane hoses have emerged, offering lightweight, kink-resistant, and durable options that cater to both consumer and industrial needs. This evolution reflects a broader trend toward specialization, with manufacturers now focusing on niche markets such as agricultural, commercial, and recreational hoses, responding to the diverse requirements of global B2B buyers.

The transition towards sustainability in the manufacturing process, along with the integration of technology for improved performance, is shaping the future of water hose production. Understanding this historical context allows B2B buyers to appreciate the advancements and innovations that have led to the current offerings in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of water hose manufacturers

1. How do I choose the right water hose for my business needs?

Selecting the right water hose involves evaluating factors such as the intended application, hose material, diameter, length, and pressure ratings. For industrial purposes, look for heavy-duty options with high burst strength and kink resistance, while agricultural applications may benefit from soaker or sprinkler hoses that optimize water efficiency. Additionally, consider environmental factors like UV exposure and temperature extremes, which can affect hose durability. Engaging with manufacturers for sample testing can also help ensure that the product meets your specific operational requirements.

2. What certifications should I look for in water hose manufacturers?

When sourcing from water hose manufacturers, seek certifications that demonstrate quality and safety standards. Look for ISO certifications, which indicate adherence to international quality management standards. Additionally, check for compliance with regional regulations such as FDA approval for drinking water safety or NSF certifications for materials that contact potable water. These certifications not only ensure product reliability but also build trust in the manufacturer’s commitment to quality and safety.

3. How can I verify the reliability of a water hose manufacturer?

To verify the reliability of a water hose manufacturer, conduct thorough due diligence. Start by reviewing their company history, industry reputation, and customer testimonials. Request references from other businesses in your sector and assess their feedback on product performance and customer service. Additionally, consider visiting their production facilities if possible or review their quality control processes. Engaging with a third-party inspection service can also provide an unbiased evaluation of the manufacturer’s capabilities.

4. What are the typical minimum order quantities (MOQs) for water hoses?

Minimum order quantities (MOQs) for water hoses can vary significantly based on the manufacturer and the specific product. Generally, MOQs can range from a few hundred to several thousand units. It’s essential to discuss your needs directly with manufacturers, as they may offer flexibility based on your business’s order frequency or future purchasing commitments. Be prepared to negotiate terms, especially if you’re a new buyer or exploring a long-term partnership.

5. What customization options are available for water hoses?

Many manufacturers offer customization options to suit specific business needs. Common customizations include variations in length, diameter, material composition, and color. Branding opportunities, such as printing your company logo on the hose, are also frequently available. Discussing your requirements with manufacturers upfront can help them provide tailored solutions that align with your operational needs and branding strategy.

6. What payment terms are standard when dealing with international water hose suppliers?

Standard payment terms for international transactions can vary widely, but common practices include advance payments, letters of credit, and payment upon delivery. Some suppliers may offer net terms, allowing payment within 30 to 90 days post-delivery. It’s crucial to clarify these terms before finalizing your order to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when negotiating payment terms.

7. How do I ensure quality assurance (QA) when sourcing water hoses?

To ensure quality assurance, establish clear QA protocols with your supplier. Request documentation of their quality control processes, including testing methods for durability, pressure resistance, and material safety. Consider implementing regular inspections and audits of the manufacturing process, either through third-party services or in-house teams. Establishing a clear return policy for defective products can also safeguard your interests and ensure you receive hoses that meet your quality standards.

8. What logistics considerations should I keep in mind when importing water hoses?

When importing water hoses, logistics considerations include shipping methods, lead times, and customs regulations. Determine the most efficient shipping route and method, whether by air or sea, based on your timeline and budget. Familiarize yourself with customs duties and import taxes that may apply in your country. Collaborating with a logistics partner experienced in international shipping can streamline the process, ensuring timely delivery while navigating regulatory requirements.

Top 9 Water Hose Manufacturers Manufacturers & Suppliers List

1. Swan Products – Garden Hoses

المجال: swanhose.com

مسجل: 1996 (29 سنة)

مقدمة: Garden Hoses by Swan Products include various types such as Professional Commercial, Agriculture/Farm, Hot Water, Landscaping, Residential Gardening, Drinking Water-Safe, Flexible Cleaning, Light/Medium Duty, WaterCOLORS® Rubber, Commercial Flexible Hot Water Rubber, Premium Rubber, Soaker/Sprinkler Hoses, Foundation Hydration, Sprinkler Hose, RV/Marine Portable Hose, and Flexible/Lightweight Drin…

2. Home by Ames – Heavy Duty and Hot Water Hoses

المجال: homebyames.com

مسجل: 2021 (4 سنوات)

مقدمة: Heavy Duty Professional Hose 100-ft x 5/8-in, Customer Rating: 3.2 out of 5; Hot Water Rubber Hose 100-ft x 3/4-in, Customer Rating: 4.6 out of 5; Heavy Duty Professional Hose 50-ft x 5/8-in, Customer Rating: 5 out of 5; High Visibility Hose 100-ft x 5/8-in, Customer Rating: 4.6 out of 5; Hot Water Rubber Hose 50-ft x 5/8-in, Customer Rating: 5 out of 5; Heavy Duty Professional Hose 100-ft x 3/4-i…

3. A.M. Leonard – Commercial Rubber Hoses

المجال: amleo.com

مسجل: 1996 (29 سنة)

مقدمة: Water Hoses: Commercial-grade, kink-free, heavy-duty options designed for horticultural professionals. Key products include: 1. Commercial Rubber Hoses by A.M. Leonard – $98.95 2. Leonard Polyurethane Hoses – $58.95 3. Pro Series 1-inch Soaker Hose, For Longer Runs – $114.95 4. Pro Series 5/8-inch Soaker Hose – $40.95 5. Polyurethane Premium Water Hose, 5/8in x 100ft – $172.95 6. Leonard Lay Flat …

4. Flexon Industries – Water Hoses

المجال: flexonhose.com

مسجل: 1997 (28 سنة)

مقدمة: Flexon Industries offers a wide selection of water hoses suitable for home gardeners and professional landscapers. Key product categories include: 1. Performance Hoses: Light Duty, Medium Duty, Heavy Duty, Professional Rubber, Hot Water Rubber, Farm & Ranch, Contractor Grade, StreamTech® Supreme Duty. 2. Specialty Hoses: Lightweight H2Zero®, Featherlite®, PureFlo®, Flextreme™, Professional Perform…

5. Apex Hose – Versatile Water Solutions

المجال: apexhose.com

مسجل: 1997 (28 سنة)

مقدمة: Apex Hose offers a variety of commercial and residential water hoses designed for different applications including professional landscaping, farm & ranch, industrial & construction, RV/marine, and food services. Key product features include: 55% lighter weight for easier handling, advanced hose design for kink resistance, and long-lasting performance. Notable brands include zero-G, NeverKink, NexF…

6. Gates – Hybrid Water Hose

المجال: gates.com

Registered: 1994 (31 years)

مقدمة: Gates water system hoses are constructed with high abrasion and chemical resistance, suitable for a range of service, shop, and business applications including sanitation, water transfer, and engine water intake. Two specific products mentioned are the Gates® Hybrid Water Hose, which features premium hybrid polymer material for extreme flexibility, and the Service-Master® Water Hose, a heavy-duty …

7. Parker Hannifin – 7092 General Service

المجال: hoseshop.com

مسجل: 2003 (22 سنة)

مقدمة: Industrial Water Hoses and Pipes available from The Hose Shop include: 7092 – General Service (Manufacturer: Parker Hannifin), REGP – General Service (Manufacturer: Kuriyama of America), 7093 – General Service (Manufacturer: Parker Hannifin), 7107 – Grizzly (Manufacturer: Parker Hannifin), Rubber Water Suction (Manufacturer: Jason Industrial), EPDM Water Suction w/ PE Helix (Manufacturer: Kuriyama…

8. Hanna Rubber Company – Industrial Hoses

المجال: hannarubbercompany.com

مسجل: 2004 (21 سنة)

مقدمة: Industrial Hose Categories: Aquahammer Hoses, Chemical Transfer Hoses, Chem Master Xtreme FEP (Stallion), UHMW-PE Chemical Hose, XLPE (Cross-linked Polyethylene), Composite Hoses, Data Center Cooling Hose, Dredge & Dock Hoses, Ducting Hoses, FlexStat CR PVC Ducting Hose, PVC Light Duty Ducting, Urethane Ducting Hose, Edible Oil Hoses, Fire Protection Hoses, Food & Beverage Hoses, 6X100 Food Master…

9. Metoree – Potable Water Hoses

المجال: us.metoree.com

مسجل: 2020 (5 سنوات)

مقدمة: {‘description’: ‘Potable water hoses are specialized hoses designed for the safe supply of drinking water, focusing on corrosion resistance and durability. They come in two types: flexible hoses made from materials like polyethylene or PVC, and rigid hoses made from materials such as stainless steel or copper. Applications include homes, restaurants, and industrial facilities.’, ‘types’: [‘Flexibl…

Strategic Sourcing Conclusion and Outlook for water hose manufacturers

In conclusion, the strategic sourcing of water hoses is essential for B2B buyers looking to enhance their operations across various sectors, including agriculture, construction, and landscaping. Key takeaways emphasize the importance of selecting high-quality hoses that offer durability, flexibility, and resistance to kinking, which directly impact productivity and cost-effectiveness. Additionally, leveraging sustainable options can align with corporate social responsibility goals, appealing to environmentally conscious consumers and stakeholders.

As international buyers from Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, it is crucial to establish partnerships with reputable manufacturers that prioritize innovation and customer service. Understanding the specific needs of your local market, such as climate conditions and usage scenarios, can guide your sourcing decisions and ensure optimal performance of the products you choose.

Looking ahead, the water hose manufacturing industry is poised for growth, driven by advancements in materials technology and increased demand for eco-friendly solutions. Now is the time to explore new suppliers and invest in high-quality products that will not only meet but exceed your operational needs. Engage with manufacturers today to secure your competitive advantage and build a sustainable future for your business.

تنويه هام وشروط الاستخدام

⚠️ إخلاء مسؤولية مهم ⚠️

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

Illustrative image related to water hose manufacturers

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.