Introduction: Navigating the Global Market for floating hoses

In the ever-evolving landscape of global trade, sourcing reliable floating hoses poses a significant challenge for B2B buyers across diverse sectors. Whether you’re managing petroleum transfers in the Middle East or facilitating potable water delivery in South America, the need for durable, high-performance floating hoses is paramount. This guide serves as a comprehensive resource, detailing various types of floating hoses, their applications, and the critical factors to consider during supplier vetting.

International buyers, particularly from regions like Africa, Europe, and Asia, will find actionable insights on cost considerations, industry standards, and technological advancements in hose manufacturing. By understanding the specifications that influence durability—such as resistance to extreme weather, UV radiation, and mechanical loads—decision-makers can make informed choices that enhance operational efficiency and safety.

Furthermore, this guide empowers businesses to navigate the complexities of the floating hose market by providing expert recommendations on sourcing strategies and supplier relationships. With a focus on quality and reliability, it equips B2B buyers with the knowledge necessary to select the right floating hoses for their unique needs, ultimately driving better procurement outcomes and fostering sustainable partnerships in the global market.

Obsah

- Top 9 Floating Hoses Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for floating hoses

- Understanding floating hoses Types and Variations

- Key Industrial Applications of floating hoses

- 3 Common User Pain Points for ‘floating hoses’ & Their Solutions

- Strategic Material Selection Guide for floating hoses

- In-depth Look: Manufacturing Processes and Quality Assurance for floating hoses

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘floating hoses’

- Comprehensive Cost and Pricing Analysis for floating hoses Sourcing

- Alternatives Analysis: Comparing floating hoses With Other Solutions

- Essential Technical Properties and Trade Terminology for floating hoses

- Navigating Market Dynamics and Sourcing Trends in the floating hoses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of floating hoses

- Strategic Sourcing Conclusion and Outlook for floating hoses

- Důležité prohlášení o vyloučení odpovědnosti a podmínky používání

Understanding floating hoses Types and Variations

| Název typu | Klíčové rozlišovací znaky | Primární aplikace B2B | Stručné výhody a nevýhody pro kupující |

|---|---|---|---|

| Standard Floating Hose | Designed for general use; buoyancy provided by external floats. | Oil transfer, dredging, potable water transport. | Klady: Versatile, cost-effective. Nevýhody: May lack durability in extreme conditions. |

| Double Carcass Floating Hose | Features an inner and outer layer for added protection. | High-pressure oil and chemical transfer, heavy-duty dredging. | Klady: Enhanced durability, resistant to damage. Nevýhody: Higher cost, requires careful handling. |

| Flexible Floating Hose | High flexibility allows for easy maneuvering in tight spaces. | Vessel refueling, dynamic marine applications. | Klady: Excellent adaptability, reduces risk of kinking. Nevýhody: Potentially less robust than standard types. |

| Bunkering Floating Hose | Specifically designed for fuel transfer in marine environments. | Fuel bunkering at ports, offshore refueling operations. | Klady: Tailored for fuel, high visibility. Nevýhody: Limited to specific applications. |

| Water Reclamation Floating Hose | Equipped with wear-resistant liners for water reclamation tasks. | Water reclamation, environmental protection projects. | Klady: Durable, suitable for harsh conditions. Nevýhody: May require specialized fittings. |

What are the Characteristics of Standard Floating Hoses?

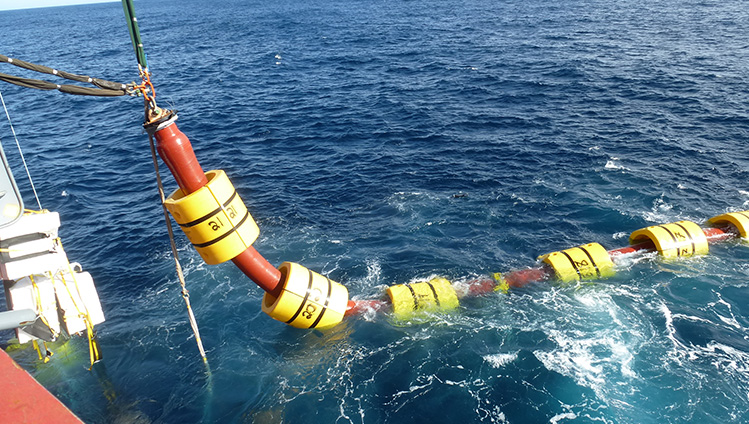

Standard floating hoses are the most commonly used type in various applications. They are characterized by their buoyancy, which is achieved through external floats attached to the hose. This design keeps the hose afloat, preventing damage from ship propellers and ensuring visibility. They are ideal for oil transfer, dredging operations, and potable water transport. Buyers should consider their versatility and cost-effectiveness, but they may not perform well under extreme conditions, which could lead to increased maintenance costs.

How Do Double Carcass Floating Hoses Enhance Durability?

Double carcass floating hoses are engineered with both an inner and outer layer, providing superior protection against punctures and abrasions. This design is particularly beneficial for high-pressure applications involving oil and chemicals, making them suitable for heavy-duty dredging and offshore operations. While these hoses offer enhanced durability and resistance to damage, buyers should be prepared for a higher initial investment and ensure that their handling and installation practices align with the hose’s specifications.

Why Choose Flexible Floating Hoses for Dynamic Applications?

Flexible floating hoses are designed for high maneuverability, making them an excellent choice for dynamic marine applications such as vessel refueling. Their flexibility reduces the risk of kinking and allows for easier handling in confined spaces. While they offer great adaptability, buyers must weigh the benefits against the potential trade-off in robustness compared to standard floating hoses, especially in harsher environments.

What Makes Bunkering Floating Hoses Unique?

Bunkering floating hoses are specifically tailored for fuel transfer in marine environments, featuring designs that enhance visibility and safety during operations. They are commonly used in ports for fuel bunkering and offshore refueling operations. While they excel in their designated applications, buyers should note that their specialized nature may limit versatility compared to other hose types.

How Do Water Reclamation Floating Hoses Contribute to Environmental Projects?

Water reclamation floating hoses are equipped with wear-resistant liners, making them suitable for environmental protection and water reclamation tasks. Their robust construction allows them to withstand harsh conditions, which is essential for maintaining operational efficiency in demanding environments. Buyers should consider their durability and suitability for reclamation projects, though they may require specialized fittings that could add to overall costs.

Key Industrial Applications of floating hoses

| Průmysl/odvětví | Specific Application of Floating Hoses | Hodnota/přínos pro podnik | Klíčové aspekty získávání zdrojů pro tuto aplikaci |

|---|---|---|---|

| Ropa a zemní plyn | Loading and unloading of crude oil at ports | Ensures safe and efficient transfer, minimizing spill risks. | Compliance with GMPHOM2009 standards; durability against harsh marine conditions. |

| Marine Transport | Refueling vessels at sea | Streamlines operations, reducing downtime and improving logistics. | Customization options for specific vessel types; buoyancy and visibility features. |

| Bagrování a těžba | Transport of dredge spoil (sand and gravel) | Enhances operational efficiency in material handling processes. | Resistance to mechanical stress; ability to handle heavy loads. |

| Hospodaření s vodou | Transfer of potable water for humanitarian projects | Supports clean water access in remote areas, crucial for health. | Certification for potable water standards; flexibility for varying water conditions. |

| Stavebnictví | Dewatering applications in construction sites | Prevents water accumulation, maintaining site safety and efficiency. | Adaptability to various site conditions; resistance to abrasion and UV exposure. |

How Are Floating Hoses Utilized in the Oil and Gas Sector?

In the oil and gas industry, floating hoses are primarily employed for loading and unloading crude oil at ports and offshore platforms. These hoses are designed to withstand extreme marine conditions, ensuring safe and efficient transfer operations while minimizing the risk of spills. For international buyers, particularly from regions like Africa and the Middle East, it is crucial to source hoses that comply with the GMPHOM2009 standards, ensuring reliability and safety. Buyers should also consider the durability and wear resistance of the hoses, as they must endure harsh environments and mechanical stress during operations.

What Role Do Floating Hoses Play in Marine Transport?

Floating hoses are vital for refueling vessels at sea, facilitating the efficient transfer of fuel between ships and supply vessels. This application is essential for maintaining the operational readiness of marine fleets, as it significantly reduces downtime associated with refueling. International buyers, especially from Europe and South America, should prioritize sourcing hoses that can be customized to fit specific vessel types and sizes. Key features to look for include buoyancy for visibility and protection against vessel propellers, as well as robust construction to withstand the rigors of ocean conditions.

How Are Floating Hoses Applied in Dredging and Mining?

In dredging and mining operations, floating hoses are used to transport dredge spoil, such as sand and gravel, from the dredging site to processing areas. This application enhances the efficiency of material handling processes, allowing for quicker project completion. Buyers in this sector must ensure that the hoses are resistant to mechanical stress and capable of handling heavy loads, as they will often be subjected to challenging operational conditions. Additionally, sourcing hoses that are designed for easy connection and disconnection can streamline operations further.

Why Are Floating Hoses Important for Water Management?

Floating hoses play a crucial role in water management, particularly for the transfer of potable water in humanitarian projects. These hoses facilitate clean water access in remote and underserved areas, making them essential for health and sanitation efforts. International buyers must ensure that the hoses meet certification standards for potable water, guaranteeing safety for human consumption. Flexibility to adapt to varying water conditions and resistance to environmental factors are also key considerations for sourcing these hoses effectively.

Illustrative image related to floating hoses

How Do Floating Hoses Support Construction Projects?

In construction, floating hoses are utilized for dewatering applications, helping to prevent water accumulation on sites. This is critical for maintaining safety and operational efficiency, as excess water can hinder construction activities and pose hazards. Buyers should look for hoses that are adaptable to various site conditions, with features that enhance resistance to abrasion and UV exposure. Ensuring the durability and reliability of these hoses is vital for minimizing downtime and maintaining project timelines in challenging environments.

3 Common User Pain Points for ‘floating hoses’ & Their Solutions

Scenario 1: Managing Extreme Weather Conditions

Problém:

B2B buyers often face the challenge of ensuring the reliability of floating hoses under extreme weather conditions. Industries operating in regions prone to severe storms, high winds, or extreme temperatures may find their floating hoses susceptible to damage or failure. This can result in costly downtime, disrupted operations, and potential environmental hazards. The impact of such failures can be especially significant in sectors like oil and gas, where the transfer of hazardous materials must be managed with utmost care.

Řešení:

To combat the challenges posed by extreme weather, it is essential to select floating hoses that are specifically designed to withstand harsh conditions. Buyers should look for hoses constructed with durable, wear-resistant materials that meet or exceed industry standards like GMPHOM2009. Additionally, investing in hoses with UV-resistant properties and reinforced structural designs can significantly enhance durability. Regular maintenance checks should also be scheduled, focusing on the integrity of the hose and its connectors. Implementing a proactive inspection regime can identify potential issues before they escalate into major failures.

Scenario 2: Navigating Regulatory Compliance

Problém:

Regulatory compliance is a major concern for B2B buyers in industries dealing with the transfer of hazardous liquids. Floating hoses must adhere to strict safety and environmental regulations, which can vary significantly by region. Non-compliance can lead to heavy fines, legal repercussions, and damage to a company’s reputation. Buyers often struggle to understand the specific requirements applicable to their operations, particularly in international markets.

Řešení:

B2B buyers should prioritize sourcing floating hoses from manufacturers who provide detailed compliance documentation and certifications. Engaging in discussions with suppliers about specific regulatory requirements in the buyer’s operational regions can clarify necessary standards. Additionally, utilizing hoses that are designed with built-in safety features, such as anti-static properties for hazardous materials, will further ensure compliance. Buyers should also consider investing in training for their staff to ensure they understand the regulatory landscape and the importance of using compliant equipment.

Scenario 3: Reducing Operational Downtime

Problém:

Operational downtime due to hose failures can be financially devastating for B2B buyers, particularly in high-stakes industries like shipping and dredging. A single failure can halt operations, lead to delays, and increase operational costs. Buyers may face challenges in predicting hose lifespan and performance under varying operational pressures, contributing to unexpected failures.

Řešení:

To minimize the risk of operational downtime, buyers should adopt a predictive maintenance strategy that involves monitoring the condition of floating hoses regularly. Using condition-monitoring technology, such as pressure sensors and wear indicators, can provide real-time data on hose performance. Additionally, establishing a partnership with a reliable supplier who offers a robust warranty and support for their hoses can provide buyers with peace of mind. Implementing a replacement schedule based on usage patterns rather than waiting for failure will also significantly reduce the risk of unexpected downtime, ensuring continuous operational efficiency.

By addressing these common pain points through strategic sourcing, compliance adherence, and proactive maintenance, B2B buyers can enhance the reliability and performance of their floating hose systems, leading to improved operational outcomes and reduced risks.

Strategic Material Selection Guide for floating hoses

What Are the Key Materials Used in Floating Hoses?

Floating hoses are critical components in various marine applications, including oil transfer, dredging, and potable water transport. The choice of material for these hoses significantly impacts their performance, durability, and suitability for specific applications. Here, we analyze four common materials used in floating hoses: rubber, thermoplastic, polyurethane, and composite materials.

How Does Rubber Perform as a Material for Floating Hoses?

Rubber is a traditional choice for floating hoses due to its excellent flexibility and resilience. Key properties include high abrasion resistance, good temperature tolerance (typically from -20°C to 80°C), and substantial pressure ratings. Rubber hoses can withstand harsh marine environments, including UV exposure and saltwater corrosion.

Klady: Rubber is durable and has a long service life, making it suitable for heavy-duty applications. It is also relatively cost-effective compared to other materials.

Nevýhody: However, rubber can be heavier than alternative materials, which may affect buoyancy. Additionally, it has a limited temperature range, which may restrict its use in extreme environments.

For international buyers, especially in regions like Africa and South America, compliance with local standards (e.g., ASTM or DIN) is crucial. Buyers should also consider the availability of rubber materials in their region to ensure timely procurement.

What Advantages Do Thermoplastics Offer for Floating Hoses?

Thermoplastic materials, such as PVC or polyethylene, are increasingly popular for floating hoses due to their lightweight nature and excellent chemical resistance. These materials typically offer good flexibility and can handle temperatures ranging from -30°C to 60°C.

Klady: The lightweight nature of thermoplastics enhances buoyancy, making them ideal for applications requiring high visibility and maneuverability. Additionally, they are resistant to a wide range of chemicals, making them suitable for various media.

Nevýhody: On the downside, thermoplastics may not offer the same level of durability as rubber in high-abrasion environments. They can also be more expensive to manufacture due to the complexity of processing.

For buyers in Europe and the Middle East, it is essential to ensure that thermoplastic hoses meet relevant safety and environmental standards, such as REACH compliance.

Why Choose Polyurethane for Floating Hoses?

Polyurethane is another advanced material used in floating hoses, known for its exceptional abrasion resistance and flexibility. It can handle temperatures from -40°C to 80°C and is often used in applications involving high mechanical stress.

Klady: Polyurethane hoses are lightweight and have excellent tensile strength, making them suitable for demanding applications. They also exhibit superior resistance to oil and chemicals.

Nevýhody: However, polyurethane can be more expensive than rubber and thermoplastics. Additionally, it may have a shorter lifespan when exposed to UV radiation unless treated.

International buyers should be aware of the specific performance standards for polyurethane hoses, particularly in regions with stringent environmental regulations, such as Germany.

Illustrative image related to floating hoses

What Are the Benefits of Composite Materials in Floating Hoses?

Composite materials, often a blend of rubber, thermoplastics, and other materials, offer unique advantages for floating hoses. They provide excellent strength-to-weight ratios and can be engineered to meet specific application requirements.

Klady: Composites can be designed for enhanced buoyancy and resistance to extreme weather conditions, making them versatile for various marine applications. They can also be tailored for specific media compatibility.

Nevýhody: The manufacturing process for composite hoses can be complex and costly, leading to higher prices. Additionally, their performance can vary significantly based on the specific formulation used.

Illustrative image related to floating hoses

For buyers in regions like Africa and South America, understanding the specific applications and media compatibility of composite hoses is crucial for ensuring optimal performance in local conditions.

Summary of Material Selection for Floating Hoses

| Materiál | Typical Use Case for Floating Hoses | Klíčová výhoda | Hlavní nevýhoda/omezení | Relativní náklady (nízké/střední/vysoké) |

|---|---|---|---|---|

| Guma | Oil transfer, dredging | High durability and abrasion resistance | Heavier, limited temperature range | Nízká |

| Thermoplastic | Potable water transfer, light-duty tasks | Lightweight, good chemical resistance | Less durable in high-abrasion areas | Střední |

| Polyuretan | High-stress applications, oil transfer | Excellent tensile strength, flexibility | Higher cost, UV sensitivity | Vysoká |

| Kompozitní | Specialized marine applications | Tailored for specific needs | Complex manufacturing, variable performance | Vysoká |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of different materials used in floating hoses. Understanding these factors will assist in making informed purchasing decisions tailored to specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for floating hoses

Floating hoses are critical components in various industrial applications, particularly in the maritime and oil and gas sectors. Understanding the manufacturing processes and quality assurance measures that underpin these products is essential for B2B buyers looking to invest in reliable, high-performance floating hoses. This guide delves into the typical stages of manufacturing, key quality control practices, and relevant international standards.

What Are the Main Stages of Floating Hose Manufacturing?

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing of floating hoses begins with the careful selection of raw materials, primarily rubber compounds and buoyant materials. These materials must possess excellent resistance to abrasion, UV radiation, and harsh environmental conditions, as they are frequently exposed to seawater and extreme weather. Suppliers often utilize specially formulated rubber compounds that meet industry standards for durability and flexibility.

Illustrative image related to floating hoses

Once selected, materials undergo a rigorous preparation process. This includes mixing rubber compounds with additives to enhance properties such as chemical resistance and tensile strength. The mixing phase is crucial, as it determines the quality of the final product. Advanced machinery ensures precise mixing, which is followed by the testing of raw materials to confirm they meet required specifications.

Forming: What Techniques Are Used to Shape Floating Hoses?

The forming stage involves several techniques tailored to produce the specific geometries required for floating hoses. Extrusion is a primary method where the prepared rubber compound is forced through a die to create a long, continuous tube. The extrusion process allows for consistent wall thickness and helps maintain the structural integrity of the hose.

In addition to extrusion, other methods such as molding may be employed for components like fittings or connectors. These components are crucial for the functionality and reliability of the hose system. For floating hoses, the buoyancy is often provided by foam layers that are integrated during the forming process, ensuring that the hose remains afloat and visible in water.

Assembly: How Are Floating Hoses Constructed?

Assembly involves the integration of various components, including the hose body, buoyant materials, and fittings. During this stage, careful attention is paid to the connection points, as these are critical areas that withstand high mechanical loads during operation. Specialized techniques such as vulcanization may be used to bond rubber layers together, enhancing their strength and durability.

Quality checks are performed throughout the assembly process to ensure that each component meets the specified requirements. This may include visual inspections and measurements to confirm that dimensions are within tolerances.

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage involves several processes aimed at enhancing the performance and aesthetic appeal of the floating hoses. This may include surface treatments to improve resistance to UV degradation and other environmental factors. Additionally, hoses may be subjected to final inspections and testing to ensure they meet operational specifications.

Before shipment, hoses are often marked with necessary identification details, including batch numbers and compliance certifications, to facilitate traceability and quality assurance.

What Quality Control Measures Are Essential for Floating Hoses?

What International Standards Should B2B Buyers Be Aware Of?

Quality assurance in the manufacturing of floating hoses is governed by several international standards. ISO 9001 is a key standard that outlines requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) further validate the quality and safety of floating hoses.

Illustrative image related to floating hoses

B2B buyers should prioritize suppliers that are certified under these standards, as they demonstrate a commitment to quality and continuous improvement.

What Are the Key Quality Control Checkpoints in Hose Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that every hose meets established standards. These checkpoints include:

-

Vstupní kontrola kvality (IQC): This phase involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must ensure that all materials comply with specifications and standards.

-

Kontrola kvality v procesu (IPQC): During the manufacturing process, continuous monitoring occurs to identify any deviations from quality standards. This includes checking for dimensional accuracy and material consistency.

-

Konečná kontrola kvality (FQC): Before products are shipped, a thorough inspection is conducted. This includes functional testing and verifying compliance with relevant standards, ensuring that the finished product is ready for operational use.

What Common Testing Methods Are Used to Verify Hose Quality?

Testing methods employed for floating hoses include:

-

Hydrostatické zkoušky: This assesses the hose’s ability to withstand high-pressure conditions without leaking or bursting.

-

Abrasion Testing: This determines the hose’s resistance to wear and tear, simulating the conditions it will face in operational environments.

-

UV and Ozone Testing: These tests evaluate the material’s durability against UV radiation and ozone exposure, critical for hoses that will be used in outdoor applications.

How Can B2B Buyers Verify Supplier Quality Assurance?

What Steps Can Be Taken for Supplier Audits and Inspections?

B2B buyers should conduct thorough due diligence when selecting suppliers. This includes:

-

Audity dodavatelů: Regular audits can assess compliance with quality standards, manufacturing processes, and overall operational efficiency. Buyers may consider engaging third-party inspection services for an unbiased evaluation.

-

Vyžádání zpráv o kvalitě: Suppliers should provide documentation that outlines their quality control processes, test results, and certifications. This transparency is crucial for establishing trust and ensuring product reliability.

-

Kontroly třetí stranou: Engaging independent inspectors can provide additional assurance regarding the quality of the hoses being purchased. These inspections can confirm that products meet specified standards before they are shipped.

What Are the Quality Assurance Nuances for International Buyers?

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe must be aware of the specific requirements and regulations that may affect their purchase decisions. Understanding local standards, import regulations, and environmental considerations is essential for ensuring compliance and successful product integration.

Different regions may have varying expectations regarding quality, leading buyers to prioritize suppliers with relevant certifications and experience in their specific markets. Engaging with suppliers who understand the local landscape can help facilitate smoother transactions and mitigate potential challenges.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for floating hoses is essential for B2B buyers. By prioritizing suppliers with robust quality control measures and relevant certifications, businesses can ensure that they invest in reliable, high-performance hoses that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘floating hoses’

This guide aims to provide international B2B buyers with a clear, actionable checklist for sourcing floating hoses, essential components for various marine and industrial applications. By following these steps, you can ensure that your procurement process is efficient and meets the specific requirements of your operations.

Krok 1: Definujte své technické specifikace

Establishing precise technical specifications is crucial for ensuring the floating hoses meet your operational needs. Consider factors such as the type of fluid being transported, hose diameter, length, and pressure ratings. Additionally, assess the environmental conditions the hoses will face, such as UV exposure and temperature fluctuations, to determine suitable materials and designs.

Illustrative image related to floating hoses

Krok 2: Research Industry Standards and Certifications

Before proceeding with suppliers, familiarize yourself with relevant industry standards, such as GMPHOM 2009 for floating hoses. Understanding these standards will help you evaluate the compliance and quality assurance processes of potential suppliers. Look for certifications that demonstrate adherence to safety and quality benchmarks, which are essential for maintaining operational integrity.

Krok 3: Vyhodnocení potenciálních dodavatelů

Conduct thorough evaluations of potential suppliers to ensure they have the necessary experience and capabilities. Request company profiles, case studies, and references from other clients in similar industries or regions. Pay attention to their history in the industry, particularly in the production of floating hoses, to gauge their reliability and expertise.

Krok 4: Inquire About Customization Options

Floating hoses often need to be tailored to specific applications, so inquire about customization capabilities. Discuss options for varying lengths, diameters, and specialized features such as integrated floats or specific materials designed for harsh conditions. A supplier that can accommodate your unique requirements demonstrates flexibility and commitment to customer satisfaction.

Krok 5: Assess Quality Control Measures

Quality control is paramount in the manufacturing of floating hoses. Inquire about the supplier’s quality assurance processes, including testing methodologies and inspection protocols. Ensure that they conduct rigorous testing for durability, wear resistance, and performance under extreme conditions, which is critical for preventing costly failures in the field.

Krok 6: Verify Delivery and Logistics Capabilities

Timely delivery is vital for maintaining project timelines, so assess the supplier’s logistics and delivery capabilities. Inquire about their shipping options, lead times, and ability to handle international shipments. A supplier with a well-established logistics network can help mitigate potential delays and ensure that you receive your hoses when needed.

Krok 7: Vyjednávání podmínek

Once you have selected a supplier, negotiate terms and conditions that protect your interests. Discuss pricing, payment terms, warranty provisions, and after-sales support. Clear contractual terms help establish expectations and ensure that both parties are aligned on the delivery of quality products and services.

By following these steps, you will be better equipped to source floating hoses that meet your operational needs, ensuring reliability and efficiency in your projects.

Illustrative image related to floating hoses

Comprehensive Cost and Pricing Analysis for floating hoses Sourcing

Understanding the cost structure and pricing dynamics of floating hoses is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Floating hoses are vital components in various industries, including oil and gas, water transfer, and dredging operations. The following analysis outlines the key cost components, pricing influencers, and strategic buyer tips.

What are the Key Cost Components of Floating Hoses?

-

Materiály: The primary cost driver in floating hoses is the raw materials used in their construction. High-quality rubber compounds, wear-resistant liners, and buoyancy materials significantly impact the overall cost. Suppliers often source these materials from specialized manufacturers, and fluctuations in commodity prices can affect pricing.

-

Práce: Labor costs include wages for skilled workers involved in the manufacturing process. The complexity of floating hoses, which often requires specialized skills for assembly and quality control, can lead to higher labor costs. Additionally, labor rates vary significantly by region, influencing the pricing structure for international buyers.

-

Výrobní režie: This encompasses costs associated with factory operations, including utilities, maintenance, and administrative expenses. Efficient manufacturing processes can lower overhead, which can be reflected in the pricing of floating hoses.

-

Nástroje: Custom tooling for specific hose designs or specifications can add to the initial costs. Buyers requiring bespoke solutions should anticipate these costs in their budgeting.

-

Kontrola kvality (QC): Ensuring that floating hoses meet industry standards and certifications—such as GMPHOM 2009—incurs additional costs. Rigorous testing and quality assurance processes are necessary, particularly for hoses used in high-risk environments.

-

Logistika: Shipping costs vary based on the distance from the manufacturing facility to the buyer’s location. Incoterms can also influence logistics costs, as they dictate responsibility for shipping, insurance, and tariffs.

-

Marže: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on supplier competition and market demand.

How Do Price Influencers Impact Floating Hose Costs?

-

Objem/MOQ: Bulk purchases often result in lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to negotiate minimum order quantities (MOQs) that align with their operational needs.

-

Specifikace a přizpůsobení: Customization requirements can significantly affect pricing. Floating hoses designed for specific applications (e.g., high-pressure oil transfer) will generally incur higher costs due to specialized materials and design considerations.

-

Kvalita a certifikace: Hoses that meet stringent quality standards or possess certifications may come at a premium. Buyers must weigh the benefits of these certifications against their budget constraints.

-

Faktory dodavatele: Supplier reputation, reliability, and market presence can impact pricing. Established suppliers may charge more due to perceived value, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the implications of Incoterms is essential for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly alter the total landed cost of floating hoses.

What Strategic Tips Can Help Buyers Optimize Costs?

-

Vyjednávání: Engage in proactive discussions with suppliers to negotiate better pricing based on volume or long-term contracts. Highlighting potential repeat business can leverage better terms.

-

Zaměření na celkové náklady na vlastnictví (TCO): When evaluating suppliers, consider the TCO, which includes not just the purchase price but also maintenance, operational efficiency, and potential downtime costs associated with lower-quality hoses.

-

Cenové nuance pro mezinárodní kupující: Be aware of currency fluctuations, import duties, and local regulations that can influence overall costs when sourcing from international suppliers. This knowledge can aid in making informed purchasing decisions.

-

Supplier Diversification: To avoid dependency on a single source, consider engaging multiple suppliers. This strategy can foster competitive pricing and ensure a steady supply chain.

-

Stay Informed: Keep abreast of market trends, material costs, and technological advancements in floating hose manufacturing. This information can empower buyers to make timely and cost-effective purchasing decisions.

Odmítnutí odpovědnosti

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information tailored to your needs.

Alternatives Analysis: Comparing floating hoses With Other Solutions

Exploring Alternative Solutions to Floating Hoses

In the quest for effective fluid transfer solutions, floating hoses are widely recognized for their versatility and reliability, especially in marine and industrial applications. However, other technologies and methods also exist that can fulfill similar functions. Understanding the strengths and weaknesses of these alternatives is crucial for B2B buyers seeking the most suitable solution for their operations.

Comparison of Floating Hoses and Alternatives

| Srovnávací hledisko | Floating Hoses | Submersible Pumps | Rigid Pipelines |

|---|---|---|---|

| Výkon | High durability, resistant to extreme conditions | Effective for continuous flow and deep water | Excellent for long-term installations and high pressure |

| Náklady | Moderate initial investment, potential high maintenance | High initial cost, but low ongoing costs | High upfront costs, low maintenance, long lifespan |

| Snadnost implementace | Quick setup and relocation in diverse environments | Requires significant installation efforts | Permanent installation, limited relocation flexibility |

| Údržba | Regular inspections and potential repairs needed | Minimal maintenance required | Low maintenance but difficult to repair once installed |

| Nejlepší případ použití | Ideal for temporary or dynamic operations | Best for deep water applications or stationary use | Suited for permanent installations in fixed locations |

In-Depth Analysis of Alternatives

Submersible Pumps

Submersible pumps are designed for fluid transfer in submerged environments, making them a popular choice in various industries. They excel in continuous flow applications, particularly in deep water settings such as reservoirs or wells. The primary advantage is their low operational cost once installed; however, their initial investment can be substantial. Installation can be complex, requiring specialized skills and equipment. While they offer excellent performance, they are not easily relocated, limiting their flexibility compared to floating hoses.

Rigid Pipelines

Rigid pipelines are a traditional solution for transporting liquids over long distances. They are particularly effective in situations where high pressure is required, and they can be designed to withstand significant environmental stress. The longevity of rigid pipelines often results in lower long-term costs, as they require minimal maintenance. However, the initial installation can be costly and labor-intensive. Additionally, once installed, rigid pipelines lack the flexibility for relocation, making them less ideal for dynamic or temporary applications.

Závěr: Výběr správného řešení pro vaše potřeby

When selecting the appropriate fluid transfer solution, B2B buyers must consider their specific operational requirements. Floating hoses offer flexibility and ease of implementation, making them suitable for temporary or dynamic applications. In contrast, submersible pumps provide high efficiency for deep water tasks, while rigid pipelines are ideal for permanent installations where high pressure is necessary. Assessing factors such as performance, cost, ease of implementation, and maintenance will help buyers make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for floating hoses

What Are the Key Technical Properties of Floating Hoses?

Floating hoses are essential in various maritime operations, including the transfer of crude oil, potable water, and dredge spoil. Understanding their technical properties is critical for B2B buyers looking to invest in reliable and efficient solutions. Here are several key specifications that define the performance and suitability of floating hoses:

-

Stupeň materiálu

The material used in the construction of floating hoses significantly impacts their durability and performance. Common materials include rubber compounds and thermoplastics, selected for their resistance to abrasion, UV exposure, and chemical degradation. For B2B buyers, choosing the right material grade ensures the hose can withstand specific operational conditions, such as high temperatures or corrosive environments. -

Working Pressure (WP)

This specification indicates the maximum pressure the hose can handle during operation. Floating hoses are typically designed with varying WP ratings, which should align with the intended application—whether it be for loading and unloading petroleum or transferring water. Understanding WP is crucial for buyers to prevent hose failure and ensure safe operations. -

Teplotní rozsah

The operational temperature range defines the extremes within which a floating hose can function effectively. This includes both minimum and maximum temperatures. Buyers must consider the environmental conditions where the hose will be deployed, as failure to do so can lead to premature wear or catastrophic failure. -

Buoyancy and Floatation Design

Buoyancy is a vital characteristic for floating hoses, enabling them to remain on the water’s surface. This property is typically achieved through the incorporation of floats or specialized foam materials that prevent sinking. Buyers should assess the buoyancy design to ensure visibility and protection from vessel propellers, reducing the risk of damage during operations. -

Wear Resistance

Given the harsh marine environments in which floating hoses are used, wear resistance is a critical property. This is often enhanced through the use of specialized liners or coatings that protect against abrasion and impact. For B2B buyers, selecting hoses with high wear resistance can lead to longer service life and reduced maintenance costs.

What Are Common Trade Terms in the Floating Hose Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several common terms that buyers should know:

Illustrative image related to floating hoses

-

OEM (výrobce originálního vybavení)

This term refers to companies that produce components that are used in another company’s end product. In the context of floating hoses, an OEM may provide hoses that meet specific design and performance standards set by vessel manufacturers. Understanding OEM relationships can help buyers ensure they are sourcing quality products that meet industry standards. -

MOQ (minimální objednací množství)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For floating hoses, MOQs can vary significantly based on the supplier and the type of hose. Being aware of MOQ helps buyers plan their purchasing strategy and manage inventory effectively. -

RFQ (žádost o cenovou nabídku)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products. For floating hoses, submitting an RFQ allows buyers to compare offers and negotiate better deals, ensuring they receive competitive pricing and favorable terms. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for buyers dealing with floating hoses, as they dictate aspects such as shipping costs, insurance, and delivery responsibilities, which can significantly impact the total cost of acquisition. -

Doba realizace

Lead time refers to the duration between placing an order and receiving the product. For floating hoses, lead times can vary based on customization and supplier capabilities. Understanding lead times helps buyers plan their operations and avoid delays in critical projects.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing floating hoses, ultimately enhancing operational efficiency and ensuring compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the floating hoses Sector

What Are the Current Market Dynamics and Key Trends in the Floating Hoses Sector?

The global floating hoses market is experiencing significant growth, driven by the increasing demand for efficient and reliable fluid transfer solutions across various industries, including oil and gas, dredging, and water transportation. Key factors propelling this demand include the rise of offshore oil and gas exploration, environmental regulations requiring safer transfer methods, and the need for enhanced operational efficiency. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking advanced floating hose technologies that comply with international standards such as GMPHOM2009, ensuring reliability even in extreme conditions.

Emerging trends in sourcing floating hoses reflect a shift towards customization and technological innovation. Buyers are prioritizing suppliers that offer tailored solutions, such as hoses designed for specific applications like dredging or potable water transfer. The integration of IoT technology is also becoming prevalent, enabling real-time monitoring and predictive maintenance, which can significantly reduce downtime and operational costs. Furthermore, as environmental concerns grow, buyers are gravitating towards suppliers who can demonstrate a commitment to sustainability and ethical sourcing practices.

How Important Is Sustainability and Ethical Sourcing in the Floating Hoses Market?

In the floating hoses sector, sustainability and ethical sourcing have become paramount. The environmental impact of traditional materials and manufacturing processes has led to increased scrutiny from regulators and consumers alike. B2B buyers are now more conscious of the materials used in floating hoses, with a growing preference for options that minimize ecological footprints, such as hoses made from recycled or eco-friendly materials.

Ethical supply chains are also gaining traction, with buyers seeking suppliers who adhere to responsible sourcing practices. This includes ensuring fair labor practices and transparency in the supply chain, which can enhance brand reputation and foster customer loyalty. Certifications like ISO 14001 for environmental management and various green certifications for materials can serve as important indicators of a supplier’s commitment to sustainability. By prioritizing sustainability, international buyers not only comply with regulations but also align their operations with the values of environmentally conscious consumers.

What Is the Brief Evolution and History of Floating Hoses?

The history of floating hoses can be traced back to the early 20th century when the need for efficient fluid transfer in marine environments became apparent. Initially, these hoses were rudimentary, lacking the durability and flexibility required for modern applications. Over the decades, advancements in materials science and engineering have led to the development of high-performance floating hoses designed to withstand harsh marine conditions, including extreme temperatures, UV radiation, and mechanical stress.

The introduction of synthetic materials, such as high-strength polymers and rubber compounds, has significantly improved the performance and longevity of floating hoses. This evolution has been further accelerated by the growing demand for offshore drilling and marine transportation, prompting manufacturers to innovate continuously. Today, floating hoses are sophisticated products tailored to meet specific industry needs, setting a benchmark for reliability and safety in fluid transfer applications.

By understanding these market dynamics, sustainability considerations, and the historical context, B2B buyers can make informed decisions that align with their operational requirements and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of floating hoses

-

How do I select the right floating hose for my application?

Selecting the appropriate floating hose involves considering several factors, including the type of fluid being transferred, operating conditions, and specific requirements such as pressure and temperature. Evaluate the material compatibility with the fluid, the hose’s buoyancy, and resistance to environmental factors like UV exposure and seawater corrosion. Consult with suppliers to understand their product specifications and ensure they meet industry standards, such as GMPHOM2009 for marine applications. It’s also beneficial to review customer feedback and case studies related to your specific use case. -

What are the typical applications of floating hoses in marine operations?

Floating hoses are primarily used for the transfer of liquids in marine environments, including loading and unloading petroleum products, transferring potable water to vessels, and refueling ships. They are also employed in dredging operations for transporting sediments like sand and gravel. The hoses’ design ensures they remain buoyant and visible, minimizing the risk of damage from vessel propellers and facilitating safe navigation around them. Understanding the application will help you choose the right specifications and features for your operational needs. -

How do I ensure the quality of floating hoses from suppliers?

To ensure quality, verify that the supplier adheres to recognized industry standards and certifications, such as GMPHOM2009 or ISO certifications. Request detailed product specifications, including material composition, testing methods, and performance data. It is also advisable to ask for references or case studies from previous clients to assess the reliability of their products. Conducting a factory visit or third-party inspection can further assure quality before making a purchase. -

What customization options are available for floating hoses?

Most manufacturers offer customization options to meet specific operational needs. This can include varying lengths, diameters, and material compositions to suit different fluids and environmental conditions. Additional features like reinforced linings, specific buoyancy aids, or visibility enhancements (like colored floats or reflective elements) can also be customized. Discuss your specific requirements with the supplier to explore all available options for tailoring the floating hose to your application. -

What is the minimum order quantity (MOQ) for floating hoses?

The MOQ for floating hoses can vary significantly depending on the supplier, product specifications, and customization requirements. Many manufacturers establish an MOQ to ensure cost-effectiveness in production. It’s best to inquire directly with potential suppliers about their MOQ policies. If your needs are below their standard MOQ, some suppliers may offer flexibility or provide alternative solutions, such as combining orders with other customers. -

What payment terms should I expect when purchasing floating hoses internationally?

Payment terms for international purchases can vary widely by supplier and region. Common options include upfront payments, letters of credit, or staggered payments based on production milestones. It is crucial to clarify payment terms during negotiations to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and international transaction fees, which may impact your overall cost. -

How is logistics handled for shipping floating hoses internationally?

Logistics for international shipping of floating hoses involves coordinating with freight forwarders to manage transportation, customs clearance, and delivery timelines. Discuss shipping options with suppliers to determine the best method based on your location and urgency. Consider factors like shipping insurance, tracking capabilities, and potential delays due to customs regulations. Proper logistics planning ensures timely delivery and reduces the risk of damage during transit. -

What should I know about after-sales support for floating hoses?

After-sales support is crucial for maintaining the performance and longevity of floating hoses. Inquire about the supplier’s warranty terms and return policies. Good suppliers offer technical support, maintenance guidelines, and troubleshooting assistance. Additionally, check if they provide training for your team on proper handling and installation of the hoses. Robust after-sales support can significantly enhance the value of your investment and ensure operational efficiency.

Top 9 Floating Hoses Manufacturers & Suppliers List

1. Trelleborg – Flexible Floating Hose

Doména: trelleborg.com

Registrován: 1996 (29 let)

Úvod: Flexible Floating Hose for Water Reclaim, designed according to GMPHOM2009 standard, wear and tear resistant, reliable and safe for extreme working conditions in the tailings process, equipped with a wear resistant liner, extensive history in the dredging industry with over 50 years of expertise in rubber material handling hoses.

2. Tubes International – Floating Hoses

Doména: tubes-international.com

Registrován: 2007 (18 let)

Úvod: Floating hoses are used on various bodies of water (sea, lake, smaller pools) for applications such as loading and unloading petroleum in ports, transferring crude oil from oil rigs to ships, transferring potable water to ships, refueling vessels, and transferring dredge spoil (sand and gravel) from dredgers. They remain afloat and visible to protect against damage from ship propellers and allow f…

3. Continental Industry – Floating Hose

Doména: continental-industry.com

Registrováno: 2018 (7 let)

Úvod: Floating Hose – Standard for material handling in dredge and mining applications. Designed for the storage and transport of liquids, offering flexibility and durability in challenging environments.

4. Yokohama – GMPHOM 2009 Certified Offshore Marine Hoses

Doména: y-yokohama.com

Registrováno: 2014 (11 let)

Úvod: Yokohama offers a complete line of GMPHOM 2009 certified offshore marine hoses. Key design features include superior durability, flexibility, and weight reduction in the double carcass hose. The hoses are manufactured by a highly skilled workforce in state-of-the-art facilities located in Japan and Indonesia.

5. VL Maritime – Floating & Submarine Hoses

Doména: vlmaritime.com

Registrováno: 2015 (10 let)

Úvod: Floating & Submarine hoses for oil loading and discharge operation manufactured to order meeting GMPHOM 2009 Design, Manufacturing and Testing standards. Features include: Type of hose (Floating or Submarine), Amount of each type, Application (Main line, Tail, Tanker rail, Reducer etc), Carcass (Single or double), Primary carcass reinforcement (Polyester or steel wire cord), Pressure options (15 b…

6. Offspring International – Fluid Transfer Hoses

Doména: offspringinternational.com

Registrováno: 2000 (25 let)

Úvod: Offspring International offers a range of hoses for fluid transfer applications including oil suction & discharge, LPG suction & discharge, fuel transfer, and suction & discharge of petroleum products. All hoses are manufactured and tested according to industry standards such as OCIMF GMPHOM 2009, certified by the American Bureau of Shipping (ABS). The range includes:

1. Single Carcass Hoses – Av…

7. Flexomarine – Reeling Floating Hoses

Doména: flexomarine.com

Registered: 2008 (17 years)

Úvod: Flexomarine’s Reeling Floating Hoses are designed for offshore oil industries, featuring robust construction and exceptional performance. Key product details include:

– Types: Reeling Floating Hoses, Monobuoy Floating Hoses, Reeling Submarine Hoses, Monobuoy Submarine Hoses.

– Models: 1610F RT, 1620F RT, 1630F RT, 1640F RT, 1652F RT, 1670BC RT, 1710F RT, 1720F RT, 1730F RT, 1740F RT, 1752F RT, 17…

8. China Rubber Hose – Floating Hoses for Offshore Mooring

Doména: chinarubberhose.com

Registrováno: 2009 (16 let)

Úvod: Floating hoses for offshore mooring systems, including double carcass and single carcass options. Designed for transferring various mediums such as natural gas, LPG, and oil. Features include resistance to abrasion, sunlight, and sea water corrosion. Types of floating hoses include: Tanker Rail Floating Hose, Tail Floating Hose, Reducer Floating Hose, Mainline Floating Hose, and One End Reinforced…

9. Dutch Dredging Components – Custom Floating Hoses

Doména: dutchdredgingcomponents.com

Registered: 2016 (9 years)

Úvod: {“Floating Hoses”: {“Also known as”: [“Mainline Hose”, “Marine Hose”, “Floating Dredge Hose”, “Self Floating Hose”], “Description”: “Custom floating hoses for offshore transport in harsh dredging and mining conditions, available in various diameters and pressure ratings.”}, “Follow Hose”: {“Also known as”: “Follow hoses”, “Description”: “Used to connect the mainline floating hose and the connectio…

Strategic Sourcing Conclusion and Outlook for floating hoses

As international markets continue to evolve, the strategic sourcing of floating hoses emerges as a critical component for operational success across various industries, including oil and gas, marine logistics, and environmental management. With their robust design and adaptability to extreme conditions, floating hoses not only enhance safety but also ensure efficiency in transporting vital resources, such as crude oil and potable water. It is essential for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, to prioritize suppliers who adhere to industry standards such as GMPHOM2009, ensuring reliability and performance.

Illustrative image related to floating hoses

Investing in high-quality floating hoses enables companies to mitigate risks associated with equipment failure and environmental hazards, ultimately leading to cost savings and improved operational continuity. By fostering partnerships with reputable manufacturers, businesses can secure tailored solutions that meet specific project requirements, enhancing their competitive edge.

Looking ahead, the demand for innovative and sustainable solutions in floating hose technology is expected to grow. B2B buyers should seize this opportunity to engage with suppliers who are committed to advancing product quality and environmental stewardship. Take the next step in optimizing your supply chain by exploring strategic partnerships that will empower your operations for the future.

Důležité prohlášení o vyloučení odpovědnosti a podmínky používání

⚠️ Důležité prohlášení o vyloučení odpovědnosti

Informace uvedené v této příručce, včetně obsahu týkajícího se výrobců, technických specifikací a analýzy trhu, mají pouze informativní a vzdělávací charakter. Nepředstavují odborné poradenství v oblasti nákupu, finanční poradenství ani právní poradenství.

Illustrative image related to floating hoses

Přestože jsme vynaložili veškeré úsilí, abychom zajistili přesnost a aktuálnost informací, neneseme odpovědnost za případné chyby, opomenutí nebo neaktuální informace. Podmínky na trhu, údaje o společnosti a technické normy se mohou změnit.

B2B kupující musí provést vlastní nezávislé a důkladné due diligence. před jakýmkoli rozhodnutím o nákupu. To zahrnuje přímé kontaktování dodavatelů, ověření certifikací, vyžádání vzorků a odborné konzultace. Riziko spoléhání se na jakékoli informace v této příručce nese výhradně čtenář.