Úvod: Navigace na globálním trhu pro přepravu z lodi na loď

Ve složitém prostředí globální lodní dopravy může hledání účinných řešení pro přepravu z lodi na loď (STS) představovat pro B2B kupující, zejména pro ty, kteří působí v regionech, jako je Afrika, Jižní Amerika, Střední východ a Evropa, značnou výzvu. Přesuny STS, které zahrnují přesun nákladu mezi plavidly bez nutnosti dokování v přístavu, představují nákladově efektivní alternativu pro velké tankery, které čelí omezením ponoru. Složitost této operace však vyžaduje komplexní porozumění regulačním požadavkům, environmentálním aspektům a logistické koordinaci s cílem zmírnit rizika, jako je nebezpečí úniku a požáru.

Tento průvodce slouží jako základní zdroj informací pro mezinárodní B2B nákupčí a poskytuje podrobný přehled o různých typech operací STS a jejich využití na různých trzích. Čtenáři zde naleznou cenné informace o tom, jak účinně prověřit dodavatele, posoudit provozní náklady a dodržovat přísné předpisy, včetně směrnic MARPOL a MEPC. Tím, že tato příručka demystifikuje proces STS, poskytuje osobám s rozhodovacími pravomocemi znalosti potřebné k informovanému rozhodování o nákupu, které je v souladu s jejich provozními cíli a odpovědností za životní prostředí.

Orientace na globálním trhu přepravy z lodi na loď vyžaduje strategickou předvídavost a pečlivé plánování. S touto příručkou budou kupující vybaveni tak, aby mohli zefektivnit své operace, snížit náklady a zvýšit svou konkurenceschopnost v námořním průmyslu.

Obsah

- Top 5 Ship To Ship Transfer Výrobci a dodavatelé Seznam

- Úvod: Navigace na globálním trhu pro přepravu z lodi na loď

- Porozumění typům a variantám přenosu z lodi na loď

- Klíčové průmyslové aplikace přenosu z lodi na loď

- 3 nejčastější problémy uživatelů při přenosu z lodi do lodi a jejich řešení

- Průvodce strategickým výběrem materiálu pro přepravu z lodi na loď

- Podrobný pohled: Výrobní procesy a zajištění kvality pro přenos z lodi na loď

- Praktická příručka pro vyhledávání zdrojů: Kontrolní seznam krok za krokem pro převod z lodi na loď

- Komplexní analýza nákladů a cen pro transfer z lodi na loď Sourcing

- Analýza alternativ: Srovnání přepravy z lodi na loď s jinými řešeními

- Základní technické vlastnosti a obchodní terminologie pro přepravu z lodi na loď

- Orientace v dynamice trhu a trendech v oblasti získávání zdrojů v odvětví přepravy z lodí na lodě

- Často kladené otázky (FAQ) pro B2B kupující při převodu z lodi na loď

- Závěr a výhled strategického zásobování pro převod z lodi na loď

- Důležité prohlášení o vyloučení odpovědnosti a podmínky používání

Porozumění typům a variantám přenosu z lodi na loď

| Název typu | Klíčové rozlišovací znaky | Primární aplikace B2B | Stručné výhody a nevýhody pro kupující |

|---|---|---|---|

| Konvenční STS | Překládka nákladu mezi dvěma plavidly kotvícími nebo stojícími vedle sebe. | Přeprava ropy a zemního plynu | Klady: Nákladově efektivní, snižuje přístavní poplatky. Nevýhody: Vyšší riziko pro životní prostředí v důsledku možných úniků. |

| Probíhá STS | K přenosu dochází za pohybu obou nádob. | Efektivní pro časově náročné zásilky | Klady: Šetří čas, udržuje provozní tok. Nevýhody: Vyžaduje pokročilou koordinaci a bezpečnostní opatření. |

| Bunkrování STS | Specifické pro přečerpávání paliva mezi cisternami nebo z cisterny na plavidlo. | Zásobování palivem pro námořní operace | Klady: Rychlé doplňování paliva, zkrácení prostojů. Nevýhody: Mohou vzniknout složité právní předpisy. |

| Nákladní STS | Překládání volně ložených nákladů (např. LNG, chemikálií) mezi plavidly. | Hromadné obchodování s komoditami | Klady: Flexibilita logistiky a distribuce. Nevýhody: Vysoké riziko kontaminace nákladu. |

| Pohotovostní služba STS | Provádí se v reakci na nepředvídané okolnosti (např. úniky). | Krizové řízení v lodní dopravě | Klady: Rychlá reakce na mimořádné události. Nevýhody: Potenciálně chaotické, může chybět řádné plánování. |

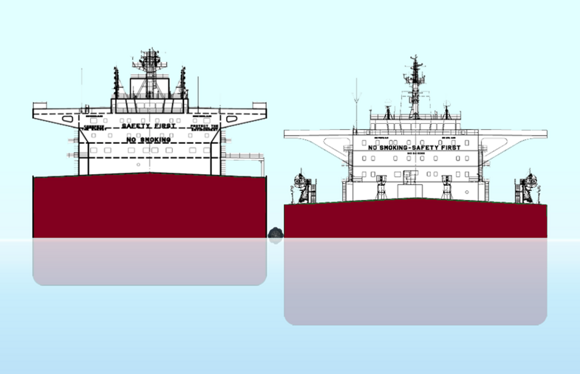

Jaké jsou vlastnosti a vhodnost konvenční STS?

Konvenční přeprava z lodi na loď (STS) je charakterizována přímou přepravou nákladu mezi dvěma plavidly, která jsou buď zakotvena, nebo umístěna vedle sebe. Tato metoda se používá převážně pro přepravu ropy a plynu a je základem námořní logistiky. Je vhodná zejména pro velké ropné tankery, které nemusí být schopny zakotvit kvůli omezením ponoru. Kupující B2B by měli zvážit ekonomické výhody plynoucí z toho, že se vyhnou přístavním poplatkům, a provozní efektivitu získanou zkrácením doby kotvení, musí však také zvážit potenciální environmentální rizika spojená s touto metodou.

Jak zvyšuje STS pod vodou efektivitu provozu?

Operace STS pod hladinou zahrnují překládání nákladu za pohybu obou plavidel, což může výrazně zvýšit efektivitu provozu. Tato metoda je výhodná zejména pro časově citlivé zásilky, protože umožňuje plynulý tok nákladu bez zpoždění spojeného s dokováním. Vyžaduje však pečlivou koordinaci a pokročilá bezpečnostní opatření ke zmírnění rizik. Odběratelé B2B musí vyhodnotit své provozní kapacity a bezpečnostní protokoly, aby se ujistili, že jsou schopni efektivně zvládnout složitost tohoto typu přepravy.

Ilustrační obrázek týkající se přepravy z lodi na loď

V čem je společnost Bunkering STS jedinečná?

Bunkrování STS je specializovaná forma přepravy zaměřená na doplňování paliva do plavidel. Tato metoda je klíčová pro udržení provozní připravenosti námořních flotil a často se provádí rychle, aby se minimalizovaly prostoje. Přestože nabízí výhodu rychlého doplňování paliva, musí si kupující B2B být vědomi regulačních složitostí, které mohou nastat, zejména v různých jurisdikcích. Zajištění souladu s místními a mezinárodními předpisy je pro hladký provoz nezbytné.

Proč si vybrat Cargo STS pro přepravu sypkých komodit?

Cargo STS se používá k přepravě volně ložených komodit, jako je zkapalněný zemní plyn (LNG) nebo chemikálie, mezi plavidly. Tato metoda poskytuje flexibilitu v logistice a distribuci, což z ní činí atraktivní možnost pro podniky zabývající se obchodováním s volně loženými komoditami. Významným problémem je však riziko kontaminace nákladu během procesu přepravy. Kupující by měli upřednostňovat plavidla s prokazatelnou historií a spolehlivými bezpečnostními protokoly, aby se tato rizika zmírnila.

Jak funguje nouzová STS v krizovém řízení?

Nouzové operace STS se provádějí v reakci na nepředvídané okolnosti, jako je únik nákladu nebo porucha plavidla. Tyto operace mají zásadní význam pro krizové řízení v lodním průmyslu, protože umožňují rychlou reakci a zmírnění následků případných katastrof. Tato metoda sice může poskytnout okamžitá řešení, ale může postrádat strukturované plánování typické pro ostatní operace STS, což vede k chaotickým podmínkám. Nákupčí B2B musí připravit pohotovostní plány a zajistit, aby jejich týmy byly vyškoleny k efektivnímu zvládání krizových situací.

Klíčové průmyslové aplikace přenosu z lodi na loď

| Průmysl/odvětví | Specifické použití převodu z lodi na loď | Hodnota/přínos pro podnik | Klíčové aspekty získávání zdrojů pro tuto aplikaci |

|---|---|---|---|

| Ropa a zemní plyn | Přeprava ropy mezi tankery | Snižuje přístavní poplatky a minimalizuje čekací dobu pro plavidla. | Dodržování předpisů MARPOL; specializované vybavení STS |

| Chemická výroba | Přečerpávání kapalných chemikálií mezi nádobami | Zvyšuje flexibilitu logistiky a dodavatelského řetězce | Bezpečnostní opatření pro nebezpečné materiály; vyškolený personál |

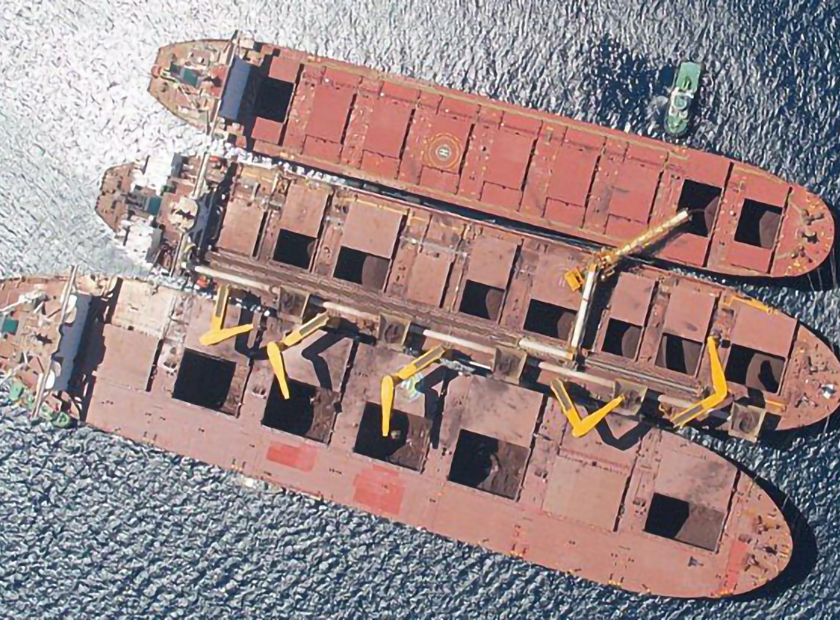

| Hromadná přeprava | Přeprava volně ložených komodit, jako je uhlí nebo železná ruda. | Zvyšuje provozní efektivitu a zkracuje dobu obratu | Kvalita zařízení STS; posouzení dopadů na životní prostředí |

| Námořní logistika | Bunkrování topného oleje | Nákladově efektivní dodávky paliva bez zdržení v přístavu | Udělování licencí a schvalování přístavními orgány; řízení rizik |

| Přeprava LNG a LPG | Přeprava zkapalněného zemního plynu nebo propanu | Umožňuje efektivní distribuci na vzdálených místech | Specializované ochranné systémy; dodržování mezinárodních norem |

Jak se v ropném a plynárenském průmyslu používá "přenos z lodi na loď"?

V odvětví těžby ropy a zemního plynu se přeprava z lodi na loď (STS) využívá převážně pro přepravu ropy mezi tankery. Tato metoda je nezbytná pro velmi velké lodě na přepravu ropy (VLCC), které nemohou kotvit v docích kvůli omezením ponoru. Využitím operací STS mohou společnosti výrazně snížit přístavní poplatky a minimalizovat čekací doby, čímž optimalizují svou logistiku. Kupující v tomto odvětví musí zajistit soulad s předpisy MARPOL a mít k dispozici potřebné vybavení STS a vyškolený personál připravený bezpečně zvládnout operace.

Jakou roli hraje přenos z lodi na loď v chemické výrobě?

V chemickém průmyslu se při přepravě kapalných chemikálií mezi nádobami často využívá přeprava STS. Tato aplikace má zásadní význam pro společnosti, které chtějí zvýšit svou logistickou flexibilitu a zefektivnit své dodavatelské řetězce. Operace STS umožňují rychlý přesun chemikálií bez nutnosti dokování v přístavu, které může být časově náročné. Odběratelé musí upřednostňovat bezpečnostní opatření a zajistit, aby byl personál vyškolen pro manipulaci s nebezpečnými materiály a aby veškeré vybavení splňovalo průmyslové normy.

Jak je přenos z lodi na loď výhodný pro hromadnou přepravu?

Při přepravě volně loženého zboží se používá přeprava STS pro komodity, jako je uhlí, železná ruda a další sypké materiály. Tato metoda zvyšuje efektivitu provozu tím, že umožňuje rychlejší nakládku a vykládku, což se projevuje zkrácením doby obratu plavidel. Kupující musí zvážit kvalitu zařízení STS a provést posouzení dopadu na životní prostředí, aby zmírnili případná rizika spojená s přesuny sypkých materiálů.

Jak přenos z lodi na loď usnadňuje námořní logistiku?

V námořní logistice se přeprava STS běžně používá při tankování, kdy se palivový olej převáží mezi plavidly. Tato metoda umožňuje lodním společnostem pořizovat palivo bez zdržení spojeného s dokováním v přístavu, což představuje nákladově efektivní řešení pro zásobování palivem. Odběratelé by měli zajistit, aby měli potřebné licence a povolení od přístavních orgánů, a vypracovat důkladné strategie řízení rizik, které budou řešit případná provozní rizika.

Jaký význam má přeprava z lodi na loď při přepravě LNG a LPG?

Při přepravě zkapalněného zemního plynu (LNG) a zkapalněného ropného plynu (LPG) je pro účinnou distribuci zásadní přeprava z lodi na loď, zejména v odlehlých oblastech, kde nemusí být k dispozici tradiční přístavní zařízení. Tato metoda umožňuje přímou přepravu LNG nebo LPG mezi plavidly a optimalizuje tak dodavatelský řetězec. Odběratelé musí investovat do specializovaných záchytných systémů a zajistit dodržování mezinárodních bezpečnostních norem, aby zvládli jedinečná rizika spojená s přepravou těchto plynů.

Ilustrační obrázek týkající se přepravy z lodi na loď

3 nejčastější problémy uživatelů při přenosu z lodi do lodi a jejich řešení

Scénář 1: Dodržování předpisů při převodech z lodi na loď

Problém: B2B kupující často čelí značným výzvám při zajišťování souladu s nesčetnými předpisy, které upravují převody mezi loděmi (STS). Předpisy jako MARPOL a MEPC 59 vyžadují pečlivou dokumentaci a schválení, což může být zejména pro společnosti působící ve více jurisdikcích zdrcující. Kupující mohou mít potíže s pochopením specifických požadavků na oznamování přístavním orgánům, vedení řádných záznamů a zajištění toho, aby veškeré vybavení splňovalo bezpečnostní normy. Nedodržení požadavků může vést k vysokým pokutám, provozním zpožděním a poškození pověsti společnosti.

Řešení: Aby se B2B odběratelé mohli efektivně orientovat v oblasti dodržování předpisů, měli by investovat do komplexního systému řízení dodržování předpisů, který je přizpůsoben operacím STS. Tento systém by měl zahrnovat podrobný kontrolní seznam veškeré potřebné dokumentace a schválení vyžadovaných pro každý převod, jako je plán provozu STS, kniha ropných záznamů a oznámení pobřežním orgánům. Spolupráce s námořním právním poradcem, který se specializuje na předpisy STS, může navíc poskytnout neocenitelné poznatky a pomoci zefektivnit proces dodržování předpisů. Pravidelná školení členů posádky o nejnovějších změnách předpisů také zajistí, že všichni účastníci provozu budou dobře informováni a připraveni dodržovat právní normy.

Scénář 2: Zmírnění environmentálních a bezpečnostních rizik během přepravy

Problém: Znečištění životního prostředí a bezpečnostní rizika jsou hlavními problémy při přepravě z lodi na loď, zejména pokud se jedná o nebezpečný náklad, jako je ropa nebo plyn. Kupující B2B se často potýkají s rizikem úniků, rozlití a požárů, které nejenže ohrožují mořské ekosystémy, ale představují také vážné hrozby pro bezpečnost posádky. Možnost nehod při operacích STS může vést ke značným finančním ztrátám, právním závazkům a poškození pověsti.

Řešení: Pro zmírnění těchto rizik by kupující měli zavést důkladnou strategii řízení rizik, která zahrnuje důkladné posouzení rizik před každou operací STS. To by mělo zahrnovat identifikaci potenciálních rizik souvisejících s konkrétním nákladem a také s podmínkami prostředí v místě přepravy. Kupující by také měli zajistit, aby obě plavidla byla vybavena nejmodernějším zařízením pro zadržování úniků a hašení požárů a aby posádka byla dobře vyškolena v postupech pro případ nouze. Vytvoření jasných komunikačních kanálů mezi plavidly a používání technologií, jako jsou monitorovací systémy v reálném čase, může zvýšit koordinaci a bezpečnost během procesu přepravy.

Scénář 3: Zajištění účinné koordinace a komunikace mezi plavidly

Problém: Jedním z nejvýznamnějších problémů, s nimiž se B2B nákupčí setkávají při přesunech z lodi na loď, je koordinace operací mezi dvěma plavidly, zejména pokud nejsou zakotvena. Špatná komunikace může vést ke zpoždění, provozní neefektivitě a zvýšeným nákladům. Pro nákupčí může být obtížné zvládnout logistiku umístění plavidel, plánování operací a zajistit, aby všichni členové posádky byli na stejné vlně, zejména pokud jednají s více zúčastněnými stranami.

Řešení: Pro zlepšení koordinace a komunikace by měli B2B nákupčí investovat do pokročilých komunikačních technologií, které usnadňují aktualizace mezi plavidly v reálném čase. Využití digitálních platforem, které umožňují sdílení provozních panelů, může pomoci sledovat pokrok a efektivně koordinovat činnosti. Je také nezbytné zavést dobře definovaný komunikační protokol, který zahrnuje pravidelné aktualizace a kontroly před a během operace přesunu. Provedení instruktáže před přesunem s oběma posádkami, na které se projednají role, odpovědnosti a nouzové postupy, dále zajistí, že všechny strany budou sladěny a připraveny na hladké provedení přesunu.

Průvodce strategickým výběrem materiálu pro přepravu z lodi na loď

Jaké materiály se běžně používají při převozu z lodi na loď?

V oblasti přepravy z lodi na loď (STS) je výběr správných materiálů pro zařízení a součásti zásadní pro zajištění bezpečnosti, účinnosti a souladu s mezinárodními normami. Níže analyzujeme čtyři běžné materiály používané v operacích STS, přičemž zdůrazňujeme jejich klíčové vlastnosti, výhody a nevýhody a úvahy pro mezinárodní B2B kupující.

1. Nerezová ocel

Klíčové vlastnosti:

Nerezová ocel vykazuje vynikající odolnost proti korozi, vysokou pevnost a dobrou teplotní toleranci, takže je vhodná pro manipulaci s různými náklady, včetně ropy a plynu. Její schopnost odolávat drsnému mořskému prostředí bez výrazné degradace je rozhodujícím faktorem.

Výhody a nevýhody:

Významnou výhodou je odolnost nerezové oceli, která může vydržet mnoho let s minimální údržbou. Ve srovnání s jinými materiály je však relativně drahá, což může zvýšit celkové náklady na projekt. Kromě toho může být složitější výroba kvůli potřebě specializovaných svařovacích technik.

Dopad na aplikaci:

Nerezová ocel je kompatibilní se širokou škálou médií, včetně uhlovodíků, což ji činí ideální pro operace STS. Její odolnost proti důlkové a štěrbinové korozi je důležitá zejména při přepravě citlivých nákladů.

Úvahy pro zahraniční kupující:

Kupující z regionů, jako je Evropa a Blízký východ, by měli zajistit shodu s normami, jako je ASTM A240 nebo EN 10088 pro třídy nerezové oceli. Zásadní je také porozumět místním předpisům týkajícím se získávání materiálu a dopadu na životní prostředí.

Ilustrační obrázek týkající se přepravy z lodi na loď

2. Polyvinylchlorid (PVC)

Klíčové vlastnosti:

PVC je univerzální plast známý svou chemickou odolností, lehkostí a pružností. Odolává různým teplotám, i když ve srovnání s kovy je méně účinný při vysokých teplotách.

Výhody a nevýhody:

Hlavní výhodou PVC je jeho cenová výhodnost a snadná výroba, což může snížit počáteční náklady na projekt. Nemusí však být vhodné pro vysokotlaké aplikace a ve srovnání s kovy má nižší životnost, což může časem vést k vyšším nákladům na výměnu.

Dopad na aplikaci:

PVC je kompatibilní s mnoha chemikáliemi, takže je vhodné pro přenos jiných než nebezpečných kapalin. Jeho omezení ve vysokotlakých scénářích však mohou omezit jeho použití v některých operacích STS.

Úvahy pro zahraniční kupující:

Kupující by měli hledat výrobky z PVC, které splňují příslušné normy, například ASTM D1784. Klíčové je také povědomí o místních ekologických předpisech týkajících se používání plastů, zejména v regionech s přísnou politikou nakládání s odpady.

3. Guma

Klíčové vlastnosti:

Pryž je známá svou vynikající pružností, odolností a schopností absorbovat nárazy a vibrace. V závislosti na konkrétním typu použité pryže snese různé teploty a tlaky.

Výhody a nevýhody:

Flexibilita pryže umožňuje snadnou instalaci a přizpůsobivost v různých aplikacích, což je významná výhoda v provozu STS. Ve srovnání s kovy však může mít kratší životnost a při působení některých chemických látek nebo UV záření může časem degradovat.

Dopad na aplikaci:

Pryž se často používá v hadicích a těsněních pro přenos kapalin, které zajišťují těsnost. Díky své kompatibilitě s různými chemikáliemi je oblíbenou volbou, ale kupující se musí ujistit, že konkrétní typ pryže je vhodný pro přenášený náklad.

Úvahy pro zahraniční kupující:

Mezinárodní kupující by se měli ujistit, že pryžové výrobky splňují normy, jako je ASTM D2000 pro pryžové materiály. Pro výběr správného typu pryže je nezbytné porozumět specifickým podmínkám prostředí v jejich provozních oblastech.

4. Hliník

Klíčové vlastnosti:

Hliník je lehký, odolný proti korozi a má dobrou tepelnou a elektrickou vodivost. Odolává středním teplotám a tlakům, takže je vhodný pro různé aplikace STS.

Výhody a nevýhody:

Lehkost hliníku je významnou výhodou, protože snižuje celkovou hmotnost zařízení, čímž zlepšuje spotřebu paliva. Je však obecně méně odolný než nerezová ocel a může vyžadovat ochranné nátěry, které zvýší jeho životnost.

Dopad na aplikaci:

Hliník je vhodný pro aplikace, kde je rozhodujícím faktorem hmotnost, například u přenosných zařízení STS. Díky své odolnosti proti korozi je kompatibilní s mnoha mořskými prostředími, ale je třeba dbát na opatrnost při použití některých agresivních chemikálií.

Úvahy pro zahraniční kupující:

Kupující by si měli ověřit, zda hliníkové výrobky splňují normy, jako je ASTM B221. Pro zajištění souladu s regionálními předpisy je také důležité porozumět místnímu trhu pro získávání a výrobu hliníku.

Souhrnná tabulka výběru materiálu pro přepravu z lodi na loď

| Materiál | Typický případ použití pro přenos z lodi na loď | Klíčová výhoda | Hlavní nevýhoda/omezení | Relativní náklady (nízké/střední/vysoké) |

|---|---|---|---|---|

| Nerezová ocel | Nákladní nádrže a potrubní systémy | Vysoká trvanlivost a odolnost proti korozi | Vyšší náklady a složitost výroby | Vysoká |

| Polyvinylchlorid (PVC) | Hadice pro jiné než nebezpečné kapaliny | Nákladově efektivní a snadná výroba | Omezená tolerance tlaku a životnost | Nízká |

| Guma | Těsnění a ohebné hadice | Pružnost a tlumení nárazů | Kratší životnost a citlivost na chemické látky | Med |

| Hliník | Lehká zařízení a konstrukce | Snížená hmotnost zlepšuje spotřebu paliva | Méně odolné než nerezová ocel | Med |

Tento strategický průvodce výběrem materiálu poskytuje cenné informace pro mezinárodní B2B nákupčí zapojené do operací přenosu z lodi na loď a pomáhá jim činit informovaná rozhodnutí na základě výkonnosti, nákladů a souladu s předpisy.

Podrobný pohled: Výrobní procesy a zajištění kvality pro přenos z lodi na loď

Jaké jsou hlavní fáze výrobních procesů zařízení pro přenos z lodi na loď?

Výrobní proces zařízení používaného při přepravě z lodi na loď (STS) obvykle zahrnuje několik kritických fází: přípravu materiálu, tváření, montáž a konečnou úpravu. Každá z těchto fází má zásadní význam pro zajištění toho, aby zařízení splňovalo přísné požadavky námořních operací.

Jak se připravuje materiál pro zařízení pro přepravu z lodi na loď?

Příprava materiálů začíná výběrem vysoce kvalitních surovin, jako jsou specializované slitiny a kompozitní materiály, které musí odolávat drsnému mořskému prostředí. Dodavatelé často poskytují materiály, které splňují mezinárodní normy, jako je ASTM nebo ISO. Fáze přípravy zahrnuje řezání, tvarování a povrchovou úpravu pro zvýšení odolnosti proti korozi a opotřebení.

Jaké techniky tváření se používají při výrobě zařízení STS?

Techniky tváření se liší v závislosti na konkrétní vyráběné součásti. Mezi běžné metody patří:

- Obsazení: Používá se pro složité tvary, jako jsou příruby a tvarovky.

- Kování: Ideální pro součásti vyžadující vysokou pevnost, jako jsou kotevní součásti a konektory.

- Svařování: Je nezbytný pro montáž různých částí zařízení, zajišťuje konstrukční celistvost a trvanlivost.

Každá technika musí být provedena přesně, aby byla zachována kvalita a výkonnost konečného výrobku.

Ilustrační obrázek týkající se přepravy z lodi na loď

Jak probíhá montáž při výrobě zařízení pro přenos z lodi na loď?

Proces montáže zahrnuje integraci různých součástí, které tvoří kompletní systém, jako jsou nakládací ramena, hadice a přečerpávací čerpadla. Kvalifikovaní technici postupují podle podrobných montážních pokynů, které často vycházejí z osvědčených mezinárodních postupů a specifikací výrobce. Prostor pro montáž by měl být uspořádán tak, aby se minimalizovala kontaminace a zajistila bezpečnost během operace.

Jaká opatření pro kontrolu kvality jsou nezbytná pro zařízení pro přenos z lodi na loď?

Kontrola kvality (QC) je při výrobě zařízení STS zásadní pro zajištění shody s bezpečnostními a výkonnostními normami. Tento proces se řídí různými mezinárodními a oborovými normami.

Které mezinárodní normy by měli znát B2B nákupčí?

Mezinárodní normy, jako je ISO 9001, která se zaměřuje na systémy řízení kvality, jsou pro výrobce zařízení STS zásadní. Kromě toho jsou klíčové i specifické oborové certifikace, jako je označení CE pro evropské trhy a specifikace API pro zařízení pro těžbu ropy a zemního plynu. Dodržování těchto norem prokazuje závazek ke kvalitě a bezpečnosti.

Jaké jsou klíčové kontrolní body kontroly kvality ve výrobě?

V různých fázích výrobního procesu se provádějí kontrolní body kontroly kvality:

- Vstupní kontrola kvality (IQC): Materiály a součásti jsou po příchodu zkontrolovány, aby bylo zajištěno, že splňují stanovené požadavky.

- Kontrola kvality v procesu (IPQC): Průběžné kontroly během výroby pomáhají včas odhalit závady a umožňují okamžitá nápravná opatření.

- Konečná kontrola kvality (FQC): Hotový výrobek prochází přísným testováním, které potvrzuje, že splňuje všechny konstrukční specifikace a regulační požadavky.

Tyto kontrolní body pomáhají udržovat vysoký standard kvality v průběhu celého výrobního procesu.

Jaké běžné zkušební metody se používají pro zařízení STS?

Zkušební metody se liší v závislosti na konkrétním zařízení a jeho zamýšleném použití. Mezi běžné zkušební metody patří:

- Hydrostatická zkouška: Používá se k ověření integrity součástí obsahujících tlak, zda nedochází k únikům.

- Nedestruktivní zkoušení (NDT): Techniky, jako je ultrazvukové testování a radiografie, hodnotí strukturální integritu materiálů, aniž by došlo k jejich poškození.

- Funkční testování: Zajišťuje správnou funkci všech součástí za očekávaných podmínek.

Tyto testy jsou nezbytné pro zajištění bezpečné a efektivní funkce zařízení v reálných podmínkách.

Jak mohou B2B odběratelé ověřit postupy kontroly kvality u dodavatelů?

B2B kupující by měli podniknout proaktivní kroky k ověření postupů kontroly kvality dodavatelů zapojených do výroby STS zařízení. Zde je několik účinných strategií:

Jaké audity a zprávy by měli kupující požadovat?

Kupující by si měli vyžádat dokumentaci o systémech řízení kvality, včetně:

- Certifikace ISO: Důkaz o splnění příslušných norem ISO.

- Zprávy o zajištění kvality: Podrobné zprávy o minulých výkonech a případných problémech s kvalitou.

- Výsledky auditu: Výsledky interních a externích auditů by měly být k dispozici k nahlédnutí.

Provádění auditů dodavatelů může poskytnout hlubší vhled do výrobních postupů a dodržování mezinárodních norem.

Ilustrační obrázek týkající se přepravy z lodi na loď

Jakou roli hrají při zajišťování kvality inspekce třetích stran?

Zapojení inspekčních agentur třetích stran může proces ověřování dále zkvalitnit. Tyto nezávislé organizace mohou poskytnout nestranné posouzení výrobních procesů, opatření pro kontrolu kvality a dodržování průmyslových předpisů. To je důležité zejména pro mezinárodní odběratele, kteří nemusí mít možnost provádět kontroly na místě.

Jaké jsou nuance kontroly kvality pro mezinárodní B2B odběratele?

Mezinárodní kupující B2B, zejména z regionů, jako je Afrika, Jižní Amerika, Blízký východ a Evropa, se musí při nákupu zařízení STS orientovat v různých nuancích kontroly kvality.

Jak ovlivňují rozdíly v právních předpisech zajištění kvality?

Různé regiony mohou mít různé regulační požadavky na námořní operace. Kupující by se měli seznámit s místními předpisy na svých trzích, jako je MARPOL pro dodržování ekologických norem nebo SOLAS pro bezpečnostní normy. Zajištění toho, aby dodavatelé tyto předpisy dodržovali, je zásadní pro předcházení právním komplikacím.

Co by měli kupující zvážit v souvislosti s dokumentací a certifikací?

Dokumentace je při dovozu zařízení STS velmi důležitá. Kupující by měli zajistit, aby zásilky doprovázely všechny potřebné certifikáty, jako jsou protokoly o zkouškách a osvědčení o shodě. Tato dokumentace nejen usnadňuje hladké celní odbavení, ale také ujišťuje kupující o kvalitě a bezpečnosti zařízení.

Závěrem lze říci, že pochopení výrobních procesů a postupů zajištění kvality zařízení pro přenos z lodi na loď je pro kupující B2B zásadní. Zaměřením se na opatření pro kontrolu kvality, důkladným hodnocením dodavatelů a zajištěním souladu s mezinárodními normami si mohou podniky zajistit spolehlivá a účinná řešení STS, která splňují jejich provozní potřeby.

Praktická příručka pro vyhledávání zdrojů: Kontrolní seznam krok za krokem pro převod z lodi na loď

Úvod

Tato praktická příručka je navržena tak, aby pomohla mezinárodním B2B nákupčím zorientovat se ve složitých otázkách zadávání zakázek na služby přepravy z lodi na loď (STS). Vzhledem k jedinečným provozním a regulačním požadavkům spojeným s STS tento kontrolní seznam popisuje kritické kroky k zajištění úspěšné a vyhovující operace transferu.

Ilustrační obrázek týkající se přepravy z lodi na loď

Krok 1: Porozumění regulačním požadavkům

Před zahájením jakýchkoli operací STS se seznamte s příslušnými předpisy, jako je příloha I úmluvy MARPOL a pokyny MEPC. Dodržování těchto předpisů je zásadní pro zamezení právních následků a zajištění bezpečného provozu. Navíc znalost místních námořních zákonů v regionu, kde působíte, může zabránit nákladným zpožděním a pokutám.

Krok 2: Definujte specifikace nákladu

Jasně formulujte typ a množství přepravovaného nákladu. To zahrnuje znalost vlastností nákladu, jako je jeho UN číslo a bezpečnostní listy materiálu (MSDS). Přesné specifikace nákladu jsou zásadní pro zajištění vhodného vybavení a bezpečnostních opatření, což v konečném důsledku chrání provoz a životní prostředí.

Krok 3: Vyhodnocení potenciálních dodavatelů

Důkladně prověřte potenciální dodavatele a poskytovatele služeb zapojené do provozu STS. Vyžádejte si podrobné profily společností, včetně jejich zkušeností s podobnými operacemi, certifikací a bezpečnostních záznamů. Zvažte možnost oslovit stávající klienty s žádostí o reference, protože výpovědi z první ruky mohou poskytnout cenné informace o spolehlivosti a kvalitě služeb.

Krok 4: Posouzení standardů vybavení a školení

Zajistěte, aby obě plavidla zapojená do přepravy STS byla vybavena potřebným vybavením STS a aby bylo udržováno v dobrém stavu. Dále ověřte, zda členové posádky absolvovali odpovídající školení specifické pro operace STS. Dobře vyškolený personál a spolehlivé vybavení minimalizují rizika a zvyšují účinnost procesu přepravy.

Krok 5: Vypracování komplexního provozního plánu STS

Spolupracujte se svým dodavatelem na vytvoření podrobného provozního plánu STS, který je v souladu se všemi regulačními pokyny. Tento plán by měl zahrnovat aspekty, jako jsou přípravy před převozem, komunikační protokoly mezi plavidly a strategie reakce na mimořádné události. Důkladný provozní plán pomáhá zmírnit rizika a zajišťuje, že všechny strany jsou v souladu s provozním procesem.

Krok 6: Zavedení komunikačních protokolů

Vytvořit spolehlivý komunikační kanál mezi oběma plavidly zapojenými do přepravy. Efektivní komunikace je pro koordinaci operace klíčová, zejména při řešení problémů v reálném čase nebo při mimořádných událostech. Zajistěte, aby si všichni členové posádky byli vědomi svých rolí a měli přístup ke komunikačním nástrojům nezbytným pro hladký průběh operace.

Krok 7: Příprava na environmentální a bezpečnostní problémy

Upřednostněte ochranu životního prostředí a bezpečnost tím, že zajistíte, aby na palubě bylo veškeré potřebné vybavení pro hašení požárů a likvidaci úniků a aby posádka byla vyškolena k jeho používání. Vzhledem k neodmyslitelným rizikům spojeným s operacemi STS je zavedení přísných bezpečnostních opatření nejen zákonným požadavkem, ale také zásadní pro ochranu posádky, nákladu a mořského prostředí.

Dodržováním tohoto kontrolního seznamu mohou kupující B2B zvýšit svou připravenost a jistotu při efektivním a bezpečném provádění převodů z lodi na loď.

Ilustrační obrázek týkající se přepravy z lodi na loď

Komplexní analýza nákladů a cen pro transfer z lodi na loď Sourcing

Jaké jsou klíčové složky nákladů na přepravu z lodi na loď?

Pochopení struktury nákladů na přepravu z lodi na loď (STS) je pro mezinárodní odběratele B2B, zejména v Africe, Jižní Americe, na Středním východě a v Evropě, zásadní. Mezi hlavní složky nákladů patří:

-

Materiály: Patří sem vybavení potřebné pro přepravu, jako jsou hadice, blatníky a přípojná místa. Kvalita a specifikace těchto materiálů může výrazně ovlivnit cenu. Například vysoce kvalitní certifikované materiály, které splňují mezinárodní normy, mohou mít vyšší počáteční náklady, ale mohou snížit rizika během provozu.

-

Práce: Pro dohled nad provozem STS je zapotřebí kvalifikovaný personál. Patří sem členové posádek na obou plavidlech a další pomocný personál. Náklady na pracovní sílu se mohou značně lišit v závislosti na regionálních mzdových standardech a na konkrétních požadovaných odborných znalostech.

-

Výrobní režie: Tato položka zahrnuje náklady spojené s výrobou a údržbou zařízení používaného při operacích STS. Pravidelná údržba a dodržování bezpečnostních předpisů mohou tyto režijní náklady zvýšit.

-

Nástroje: K bezpečnému připojení a přemístění nákladu jsou zapotřebí specializované nástroje. Investice do spolehlivého nářadí jsou rozhodující pro minimalizaci provozních rizik a zajištění souladu s námořními předpisy.

-

Kontrola kvality (QC): Klíčové je zajistit, aby veškeré vybavení a postupy splňovaly bezpečnostní a environmentální normy. Procesy kontroly kvality mohou zvyšovat náklady, ale jsou nezbytné pro předcházení nehodám a škodám na životním prostředí, které mohou vést ke značným závazkům.

-

Logistika: Zahrnuje náklady na přepravu zařízení do přístavu a z přístavu, jakož i veškeré náklady spojené s umístěním plavidel pro přepravu. Efektivní plánování logistiky může pomoci snížit celkové náklady.

-

Marže: Dodavatelé obvykle zahrnují do svých cen ziskové rozpětí, které se může lišit v závislosti na poptávce na trhu, konkurenci a vnímaném riziku spojeném s danou operací.

Jak ovlivňují cenotvorbu náklady na přepravu z lodi na loď?

Tvorbu cen při převozu z lodi na loď mohou ovlivnit různé faktory:

-

Objem/MOQ: Rozsah operace často určuje cenu. Větší objemy mohou umožnit slevy z důvodu úspor z rozsahu. Kupující by měli zvážit sjednání minimálního objednacího množství (MOQ), aby maximalizovali efektivitu nákladů.

-

Specifikace a přizpůsobení: Specifické provozní požadavky mohou vést k rozdílům v cenách. Vlastní řešení mohou být spojena s vyššími náklady, ale mohou zvýšit bezpečnost a efektivitu provozu.

-

Kvalita materiálu a certifikace: Úroveň certifikace a zajištění kvality materiálů může významně ovlivnit náklady. Kvalitnější materiály často vedou k menšímu počtu incidentů a snížení dlouhodobých nákladů.

-

Faktory dodavatele: Pověst a spolehlivost dodavatele může ovlivnit cenu. Zavedení dodavatelé s prokazatelnou historií si mohou účtovat vyšší ceny, ale často poskytují lepší služby a podporu.

-

Incoterms: Zvolené Incoterms mohou ovlivnit celkové náklady. Kupující by si měli uvědomit, kdo nese odpovědnost za dopravu, pojištění a cla, protože tyto faktory mohou zvýšit celkové výdaje.

Jaké jsou tipy pro kupující pro efektivní využití nákladů při převodu z lodi na loď?

-

Efektivní vyjednávání: Kupující by měli využít svou kupní sílu, zejména pokud se jedná o větší objemy. Navázání dlouhodobých vztahů s dodavateli může vést k lepším podmínkám a cenám.

-

Zvažte celkové náklady na vlastnictví (TCO): Zhodnoťte nejen počáteční náklady, ale také dlouhodobé důsledky výběru zařízení a služeb. Nižší počáteční cena může vést k vyšším nákladům na údržbu nebo provoz.

-

Porozumění cenovým nuancím: Zahraniční kupující by si měli být vědomi kolísání měny, regionálních cenových rozdílů a možných cel, které by mohly ovlivnit konečnou cenu.

-

Investujte do kvality: Počáteční náklady na vysoce kvalitní zařízení mohou být sice vyšší, ale často vedou k nižším rizikům a nákladům spojeným s nehodami nebo nedodržením předpisů.

-

Provádění průzkumu trhu: Pochopení situace na trhu může kupujícím pomoci identifikovat konkurenční ceny a vyjednat lepší nabídky. To zahrnuje i povědomí o regionálních rozdílech ve struktuře nákladů.

Odmítnutí odpovědnosti

Ceny a složky nákladů zde uvedené jsou orientační a mohou se lišit v závislosti na mnoha faktorech, včetně zeměpisné polohy, tržních podmínek a specifických provozních požadavků. Kupujícím se doporučuje, aby provedli důkladný průzkum a vyžádali si více nabídek, aby se ujistili, že získají nejlepší možné ceny pro své operace převodu z lodi na loď.

Analýza alternativ: Srovnání přepravy z lodi na loď s jinými řešeními

Úvod

Při hodnocení metod přepravy nákladu v námořní dopravě je nezbytné zvážit alternativy k přepravě z lodi na loď (STS). Každá metoda má své jedinečné výhody a omezení v závislosti na různých faktorech, jako je typ nákladu, provozní účinnost, bezpečnost a náklady. Tato analýza porovná přepravu STS se dvěma schůdnými alternativami: převozem z lodi na břeh (STS) a převozem pomocí lighterů.

Ilustrační obrázek týkající se přepravy z lodi na loď

| Srovnávací hledisko | Převod z lodi na loď | Transfer z lodi na břeh | Zapalovací operace |

|---|---|---|---|

| Výkon | Vysoká účinnost při velkých hromadných přesunech; provozní flexibilita | Omezeno možnostmi portu; vhodné pro menší objemy | Efektivní pro mělké vody; flexibilita při manipulaci s nákladem |

| Náklady | Úsporné díky absenci přístavních poplatků; potenciální náklady na životní prostředí | Vyšší přístavní poplatky; náklady spojené s nakládkou/vykládkou | Mírné náklady; provozní efektivita může snížit celkové výdaje |

| Snadnost implementace | Vyžaduje rozsáhlé plánování, povolení a školení posádky. | Relativně jednoduché, ale závisí na přístavní infrastruktuře. | Středně složité; vyžaduje koordinaci se zapalovacím plavidlem |

| Údržba | Náročné na vybavení; vyžaduje pravidelné kontroly | Minimální potřeba údržby v pobřežních zařízeních | Údržba plavidel pro přepravu světla je nezbytná pro zajištění bezpečnosti. |

| Nejlepší případ použití | Ideální pro velké přepravy ropy a plynu v hlubokých vodách. | Vhodné pro různé druhy nákladu, které potřebují dokovací zařízení. | Účinné v oblastech s omezením ponoru nebo omezeným přístupem do přístavu. |

Podrobný rozpis alternativ

Transfer z lodi na břeh

Přeprava z lodi na břeh (STS) zahrnuje vyložení nákladu z plavidla přímo do zařízení na břehu, jako je terminál nebo rafinerie. Tato metoda je obecně jednoduchá a široce používaná pro různé druhy nákladu, včetně volně ložených kapalin, kontejnerů a obecného nákladu. Často je však omezena možnostmi přístavu, včetně velikosti plavidla, které může být umístěno, a účinnosti procesů nakládky a vykládky. Tato metoda sice přináší vyšší přístavní poplatky, ale eliminuje rizika spojená s operacemi STS, jako je ohrožení životního prostředí a riziko požáru.

Zapalovací operace

V rámci odlehčovacích operací dochází k překládání nákladu z většího plavidla na menší plavidla, která mohou plout v mělčích vodách nebo v přístavech s omezeným ponorem. Tato metoda je zvláště výhodná v oblastech, kde nemají lodě s hlubokým ponorem přístup do doků. Lightering umožňuje efektivní manipulaci s nákladem bez nutnosti rozsáhlých přístavních zařízení, což z něj činí flexibilní řešení pro přepravu ropy a zemního plynu. Může však být středně složitá, protože vyžaduje přesnou koordinaci mezi plavidly a dodržování bezpečnostních předpisů. Náklady mohou být sice přiměřené, ale mohou se lišit v závislosti na efektivitě provozu a povaze převáženého nákladu.

Závěr

Při výběru správného řešení pro přepravu nákladu by měli zákazníci B2B vyhodnotit své specifické provozní potřeby a omezení. Přesuny z lodi na loď nabízejí vysokou efektivitu a úsporu nákladů u velkých hromadných zásilek, zejména v hlubokých vodách. Je však třeba zvážit dopady na životní prostředí a provozní složitost. Alternativou jsou operace přepravy z lodi na břeh a přepravy na lighteru, které představují životaschopné možnosti v závislosti na možnostech přístavu a omezeních hloubky. Posouzením výkonnosti, nákladů, snadnosti implementace, údržby a nejlepšího případu použití každé metody mohou kupující učinit informovaná rozhodnutí, která odpovídají jejich logistickým požadavkům a bezpečnostním standardům.

Základní technické vlastnosti a obchodní terminologie pro přepravu z lodi na loď

Jaké jsou základní technické vlastnosti přenosu z lodi na loď?

Při převozu z lodi na loď (STS) je pro zajištění bezpečnosti, efektivity a souladu s mezinárodními předpisy rozhodujících několik technických vlastností. Porozumění těmto vlastnostem může kupujícím B2B pomoci činit informovaná rozhodnutí a podpořit efektivní partnerství.

1. Kompatibilita nákladu

Kompatibilita nákladu se týká chemických a fyzikálních vlastností přepravovaných materiálů, jako jsou druhy ropy nebo složení plynu. Znalost kompatibility pomáhá předcházet nebezpečným reakcím během přepravy, které mohou vést k únikům nebo výbuchům. Kupující se musí ujistit, že zúčastněná plavidla jsou vybavena pro manipulaci s konkrétními typy nákladu, včetně znalosti bezpečnostních listů (MSDS) a příslušných UN čísel.

Ilustrační obrázek týkající se přepravy z lodi na loď

2. Specifikace zařízení

Zařízení používané při operacích STS musí splňovat zvláštní normy. Patří sem hadice, čerpadla a spojky, které by měly být navrženy pro daný typ přepravovaného nákladu. Zařízení musí být také pravidelně udržováno a certifikováno, aby se předešlo mechanickým poruchám během operací. Kupující by měli hledat dodavatele, kteří poskytují podrobné specifikace a záznamy o údržbě, aby byla zajištěna spolehlivost.

3. Rozdíl volné desky

Rozdíl volných boků je svislá vzdálenost mezi čárou ponoru a horní palubou plavidla. Při operacích STS mohou mít plavidla různé úrovně volného pásu, což může komplikovat proces přepravy. Pochopení rozdílu volných boků je zásadní pro zajištění bezpečného překládání nákladu a prevenci úniku. Nákupčí by měli upřednostnit školení posádek, aby tyto rozdíly účinně zvládaly.

4. Bezpečnostní prvky pro životní prostředí

Vzhledem k rizikům spojeným s provozem STS musí být plavidla vybavena bezpečnostními prvky pro ochranu životního prostředí, jako jsou soupravy pro likvidaci úniku ropy a hasicí zařízení. Tyto prvky mají zásadní význam pro zmírnění možných dopadů na životní prostředí. B2B kupující by měli hodnotit dodavatele na základě dodržování předpisů MARPOL a přítomnosti odpovídajících bezpečnostních opatření.

5. Školení a certifikace

Řádný výcvik členů posádky zapojených do provozu STS je zásadní vlastností, která ovlivňuje bezpečnost a efektivitu. Členové posádky musí být vyškoleni v reakci na mimořádné události, manipulaci s vybavením a komunikačních protokolech. Kupující by si měli ověřit, zda jejich partneři poskytují komplexní školicí programy a certifikace, aby zajistili, že všichni pracovníci jsou kompetentní.

Ilustrační obrázek týkající se přepravy z lodi na loď

Jaké jsou běžné obchodní podmínky při převodu z lodi na loď?

Porozumění oborovému žargonu je nezbytné pro efektivní komunikaci a vyjednávání v B2B transakcích souvisejících s operacemi STS. Zde je několik klíčových pojmů:

1. OEM (Original Equipment Manufacturer)

OEM označuje společnost, která vyrábí zařízení nebo součásti používané v procesu STS. Znalost OEM může kupujícím pomoci posoudit kvalitu a spolehlivost pořizovaného zařízení.

2. MOQ (minimální objednací množství)

MOQ je nejmenší množství výrobku, které je dodavatel ochoten prodat. V operacích STS může pochopení MOQ pomoci kupujícím řídit úroveň zásob a vyhnout se nadměrným nákladům.

3. RFQ (žádost o cenovou nabídku)

RFQ je formální žádost zaslaná dodavatelům za účelem získání cenových nabídek na konkrétní výrobky nebo služby. V kontextu STS může RFQ obsahovat specifikace vybavení, školení a bezpečnostních opatření, což kupujícím umožňuje efektivní porovnání nabídek.

4. Incoterms (mezinárodní obchodní podmínky)

Incoterms jsou mezinárodně uznávaná pravidla, která definují povinnosti kupujících a prodávajících v celosvětovém obchodě. Objasňují aspekty, jako jsou přepravní náklady, pojištění a přenos rizik při operacích STS. Znalost Incoterms pomáhá kupujícím vyjednávat lepší podmínky a efektivněji řídit logistiku.

Ilustrační obrázek týkající se přepravy z lodi na loď

5. Operační plán STS

Operační plán STS je zdokumentovaná strategie, která popisuje postupy, bezpečnostní opatření a vybavení, které se má během přepravy použít. Tento plán musí být schválen příslušnými orgány a je nezbytný pro dodržování předpisů. Kupující by měli zajistit, aby jejich partneři vypracovali a udržovali spolehlivé operační plány STS.

Pochopením těchto technických vlastností a obchodních podmínek mohou B2B kupující zlepšit své rozhodovací procesy, navázat jasnou komunikaci a zmírnit rizika spojená s převody mezi loděmi.

Orientace v dynamice trhu a trendech v oblasti získávání zdrojů v odvětví přepravy z lodí na lodě

Jaké jsou klíčové tržní faktory ovlivňující přenos z lodi na loď?

Sektor přepravy z lodi na loď (STS) zažívá významný růst, který je způsoben rostoucí poptávkou po efektivní přepravě nákladu v ropném a plynárenském průmyslu. Vzhledem k tomu, že lodě, jako jsou VLCC (Very Large Crude Carrier) a ULCC (Ultra Large Crude Carrier), často čelí omezením ponoru v přístavech, představují operace STS praktickou alternativu, která minimalizuje náklady na kotvení a zkracuje dobu obratu. Rozšiřování ropných polí na moři v regionech, jako je Afrika a Jižní Amerika, navíc vytváří nové příležitosti pro operace STS, protože v těchto oblastech často chybí přístavní infrastruktura pro přijímání velkých tankerů.

Nově vznikající technologie rovněž mění podobu STS. Digitální platformy, které umožňují sledování a komunikaci mezi plavidly v reálném čase, získávají na popularitě a zvyšují efektivitu a bezpečnost provozu. Kromě toho se do provozu STS začleňují automatizované systémy pro sledování dodržování předpisů v oblasti životního prostředí, které pomáhají zmírňovat rizika spojená s úniky a emisemi. Pro mezinárodní odběratele B2B v regionech, jako je Saúdská Arábie a Německo, je udržení kroku s tímto technologickým pokrokem klíčové pro zajištění bezproblémového provozu a dodržování regulačních norem.

Ilustrační obrázek týkající se přepravy z lodi na loď

Navíc s tím, jak se mění struktura globálního obchodu, roste důraz na strategické zásobování. Kupující stále více vyhledávají partnerství se spolehlivými poskytovateli služeb, kteří mohou prokázat odborné znalosti v oblasti STS operací a dodržování environmentálních předpisů. Tento trend podtrhuje význam vytváření robustních dodavatelských řetězců, které se dokáží přizpůsobit proměnlivým požadavkům trhu a regulačnímu prostředí.

Jak lze integrovat udržitelnost a etické získávání zdrojů do operací přepravy z lodi na loď?

Nelze přehlížet dopad přepravy z lodi na loď na životní prostředí. Přestože operace STS nabízejí logistické výhody, představují také riziko znečištění a nehod, pokud nejsou řádně řízeny. Proto je v sektoru B2B stále důležitější zavádění postupů udržitelnosti. Kupující jsou vyzýváni, aby upřednostňovali dodavatele, kteří zavádějí přísné systémy environmentálního řízení a dodržují mezinárodní normy, jako je MARPOL.

V odvětví se stále více prosazuje také etické získávání zdrojů. B2B kupující by měli vyhledávat partnery, kteří se zavázali k iniciativám v oblasti udržitelnosti, jako je používání ekologicky šetrných materiálů a technologií, které snižují emise během provozu STS. Jako měřítko pro posouzení závazku dodavatele k udržitelnosti mohou sloužit certifikace, jako je ISO 14001 pro environmentální řízení a certifikace Green Marine.

Ilustrační obrázek týkající se přepravy z lodi na loď

Vzhledem k tomu, že globální trh je stále ohleduplnější k životnímu prostředí, mohou společnosti, které ve svých provozovnách STS upřednostňují udržitelné postupy, zlepšit pověst své značky a oslovit širší okruh zákazníků. Tento soulad s etickým získáváním zdrojů nejen podporuje dodržování právních předpisů, ale také příznivě ovlivňuje postavení podniků na konkurenčním trhu.

Jaký je historický kontext přenosu z lodi na loď?

Koncepce překládky z lodi na loď vznikla před několika desetiletími v reakci na rostoucí potřebu efektivní manipulace s nákladem v námořním průmyslu. Původně se v polovině 20. století používala pro přepravu ropy mezi plavidly, ale od té doby se operace STS rozšířily na širokou škálu druhů nákladu, včetně zkapalněného zemního plynu (LNG) a chemických látek.

V průběhu let se díky technologickému pokroku výrazně zvýšila bezpečnost a efektivita provozu STS. Byly také vytvořeny regulační rámce, například rámce stanovené Mezinárodní námořní organizací (IMO), které se zabývají otázkami životního prostředí a zajišťují, aby se při STS operacích dodržovaly osvědčené postupy. Tento historický vývoj formoval současnou situaci, díky níž se STS stala důležitou součástí globální logistiky lodní dopravy, zejména pro mezinárodní B2B odběratele, kteří hledají nákladově efektivní a flexibilní řešení na různých trzích.

Vzhledem k tomu, že se odvětví přepravy z lodi na loď nadále vyvíjí, musí zúčastněné strany i nadále bedlivě sledovat nové trendy a změny právních předpisů, aby mohly využít nových příležitostí a zároveň minimalizovat rizika spojená s dopadem na životní prostředí a bezpečnost provozu.

Ilustrační obrázek týkající se přepravy z lodi na loď

Často kladené otázky (FAQ) pro B2B kupující při převodu z lodi na loď

-

Jak zajistit bezpečný přenos z lodi na loď?

Pro zajištění bezpečné přepravy z lodi na loď (STS) je nezbytné provést důkladné předběžné plánování, včetně posouzení rizik a podrobného plánu přepravy STS schváleného příslušnými orgány. Obě plavidla musí mít vhodné vybavení STS v dobrém provozním stavu a vyškolený personál na palubě. Komunikace mezi loděmi by měla být jasná a stálá a měla by se týkat specifik nákladu, možných nebezpečí a nouzových postupů. Kromě toho je pro ochranu životního prostředí a bezpečnost nezbytné dodržování mezinárodních předpisů, jako je MARPOL a směrnice Mezinárodní námořní organizace (IMO). -

Jaké jsou regulační požadavky na přepravu z lodi na loď?

Regulační požadavky na přepravu STS se v jednotlivých regionech liší, ale obecně zahrnují získání povolení od místních přístavních orgánů a dodržování pokynů přílohy I úmluvy MARPOL. Provozovatelé musí vypracovat podrobný plán provozu STS, který zahrnuje aspekty, jako je typ a množství nákladu, bezpečnostní opatření a opatření na ochranu životního prostředí. Veškeré operace musí být zaznamenány v knize záznamů o ropě a v knize záznamů o provozu STS. Je také nezbytné oznámit pobřežním orgánům nejméně 48 hodin před operací a uvést podrobně názvy plavidel, typ nákladu a další důležité informace. -

Jaké faktory bych měl zvážit při výběru dodavatele služeb přepravy z lodi na loď?

Při výběru dodavatele služeb přepravy STS zvažte jeho zkušenosti a pověst v oboru, zejména v konkrétních regionech, kde působíte, jako je Afrika, Jižní Amerika nebo Evropa. Prověřte jejich bezpečnostní protokoly, kvalitu vybavení a dodržování regulačních norem. Je také přínosné posoudit jejich provozní kapacitu, včetně schopnosti spravovat různé druhy nákladu. Nakonec si vyžádejte reference nebo posudky od jiných B2B odběratelů, kteří využili jejich služeb, abyste posoudili spolehlivost a výkonnost. -

Jaké platební podmínky jsou obvykle nabízeny pro služby převodu z lodi na loď?

Platební podmínky za služby převodu STS se mohou značně lišit v závislosti na dodavateli a konkrétní smlouvě o poskytování služeb. Mezi běžné postupy patří platby předem, zálohy nebo platby po dokončení služeb. Někteří dodavatelé mohou nabízet flexibilní podmínky, například 30 nebo 60 dní netto, zejména u větších smluv. Doporučuje se vyjednat podmínky, které odpovídají vašemu peněžnímu toku a časovému plánu projektu, a zároveň zajistit, aby byly všechny podmínky jasně popsány ve smlouvě o poskytování služeb, aby se předešlo sporům. -

Jaké je minimální objednací množství (MOQ) pro služby přenosu z lodi na loď?

Minimální objednací množství (MOQ) pro služby přepravy STS je často určeno typem nákladu a související provozní logistikou. Zatímco někteří poskytovatelé služeb nemusí mít striktní MOQ, jiní mohou vyžadovat určitý objem nákladu, aby ospravedlnili provozní náklady. Je nezbytné projednat s potenciálními poskytovateli vaše konkrétní potřeby a vyjasnit si jejich podmínky týkající se MOQ, zejména pokud se jedná o vysoce hodnotné nebo nebezpečné materiály. -

Jak si mohu ověřit postupy zajištění kvality poskytovatele služeb STS?

Chcete-li si ověřit postupy zajištění kvality poskytovatele služeb STS, vyžádejte si dokumentaci o jeho certifikacích a dodržování mezinárodních norem, jako je ISO 9001. Zajímejte se o programy školení členů posádky a protokoly o údržbě vybavení a bezpečnostních kontrolách. Kromě toho zvažte možnost návštěvy nebo auditu na místě, pokud je to možné, a vyžádejte si případové studie nebo reference od předchozích klientů, abyste posoudili jejich provozní výsledky a závazek ke kvalitě. -

Jaké logistické aspekty bych měl mít na paměti při převozu z lodi na loď?

Logistika přepravy STS zahrnuje řadu aspektů, včetně místa přepravy, povětrnostních podmínek a dostupnosti vhodného kotviště. Zajistěte, aby načasování operace bylo koordinováno s harmonogramem plavidel, aby se minimalizovala zpoždění. Dále je třeba posoudit logistické schopnosti poskytovatele služeb, včetně jeho schopnosti zvládnout celní a regulační odbavení, a také jeho pohotovostní plány pro případ mimořádných událostí, jako jsou úniky nebo poruchy zařízení. -

S jakými běžnými problémy se setkáváte při převozu z lodi na loď?

Mezi běžné problémy při operacích STS patří nepříznivé povětrnostní podmínky, poruchy komunikace mezi plavidly a neočekávaná zpoždění v plánování. Kromě toho existují rizika spojená s manipulací s nákladem, jako je rozlití nebo únik, což může mít dopad na životní prostředí a právní předpisy. Pro zmírnění těchto rizik je nezbytné důkladné plánování, účinná komunikace a dodržování bezpečnostních protokolů. K účinnému řešení těchto problémů může přispět také zapojení zkušeného personálu a využití vysoce kvalitního vybavení.

Top 5 Ship To Ship Transfer Výrobci a dodavatelé Seznam

1. Marine Insight - Přeprava z lodi na loď

Doména: marineinsight.com

Registrováno: 2010 (15 let)

Úvod: Tato společnost, Marine Insight - Ship to Ship Transfer, je významným subjektem na trhu. Konkrétní informace o produktech doporučujeme navštívit přímo na jejich webových stránkách.

2. Britannia Pandi - Příručka k operacím STS Transfer

Doména: britanniapandi.com

Registrován: 1999 (26 let)

Úvod: Pokyny pro přepravu z lodi na loď (STS) zahrnují protokoly pro bezpečnou přepravu nákladu mezi dvěma loděmi a zdůrazňují význam dovedností a zkušeností. Mezi klíčové aspekty operací STS patří:

- Rozměry lodi a interakční efekty

- Dozorci kotviště a metody komunikace

- Označení lodí s konstantním kurzem a manévrujících lodí

- Dostupnost denního světla pro některé tran...

3. Odpojovací spojky - STS Transfer Solutions

Doména: breakawaycouplings.com

Registrováno: 2015 (10 let)

Úvod: Překládka z lodi na loď (STS), známá také jako lightering, spočívá v tom, že dva skladovací tankery kotví vedle sebe a překládají náklad, obvykle ropu a zkapalněný plyn, na otevřeném moři nebo na vnější hranici přístavu. Klíčové postupy zahrnují spouštění fenderů, kotvení lodí, spojování hadic a překládání nákladu. Bezpečnost se řídí mezinárodními směrnicemi, včetně předpisů MARPOL, a vyžaduje se, aby STS ...

4. North Standard - STS Loss Prevention Insights

Doména: north-standard.com

Registrováno: 2022 (3 roky)

Úvod: Přeprava nákladu z lodi na loď (STS) poskytuje vlastníkům nákladu flexibilitu při relativně nízkých nákladech. Zvýšená četnost operací STS vedla k nárůstu případů poškození konstrukce během manévrování před operacemi STS. Cílem briefingu o prevenci ztrát je poradit členům, jak minimalizovat rizika spojená s operacemi STS.

5. Fendercare - STS Transfer Solutions

Doména: fendercare.com

Registrován: 1996 (29 let)

Úvod: Společnost James Fisher Fendercare je světovým lídrem v oblasti přepravy z lodi na loď (STS) a nabízí kompletní řešení s rychlou reakcí na potřeby zákazníků. Klíčové údaje o produktu zahrnují:

- Více než 60 provozních základen STS po celém světě

- Plně vybavené základny s hadicemi, blatníky a pomocným vybavením

- Více než 100 zkušených superintendantů STS k dispozici 24 hodin denně, 7 dní v týdnu.

- Technická podpora námořního zabezpečení

- Podpora řemesel...

Závěr a výhled strategického zásobování pro převod z lodi na loď

Vzhledem k tomu, že celosvětová poptávka po efektivní přepravě nákladu stále roste, představují operace přepravy z lodi na loď (STS) strategickou výhodu pro mezinárodní odběratele B2B. Ekonomické výhody STS, jako jsou nižší přístavní poplatky a lepší doba obratu, jsou významné, zejména pro velké lodě, které čelí omezením ponoru. Je však nezbytné vyvážit tyto výhody s potenciálními environmentálními riziky a požadavky na dodržování právních předpisů.

Investice do strategického zajištění služeb STS může zvýšit efektivitu provozu a zároveň zajistit dodržování bezpečnostních a environmentálních norem. Řádné školení posádek, používání certifikovaného vybavení a důkladné plánování před zahájením provozu jsou základními prvky, které mohou zmírnit rizika spojená s operacemi STS.

Do budoucna by mezinárodní B2B kupující, zejména z Afriky, Jižní Ameriky, Blízkého východu a Evropy, měli využívat inovace v oblasti technologií a logistiky k optimalizaci procesů STS. Upřednostňováním partnerství se zkušenými poskytovateli služeb mohou společnosti nejen zefektivnit své dodavatelské řetězce, ale také zaujmout pozici lídrů v oblasti udržitelných a odpovědných námořních postupů. Nyní je čas jednat - vyhodnoťte své strategie STS a prozkoumejte nové možnosti zvýšení efektivity a dodržování předpisů ve svých operacích.

Důležité prohlášení o vyloučení odpovědnosti a podmínky používání

⚠️ Důležité prohlášení o vyloučení odpovědnosti

Informace uvedené v této příručce, včetně obsahu týkajícího se výrobců, technických specifikací a analýzy trhu, mají pouze informativní a vzdělávací charakter. Nepředstavují odborné poradenství v oblasti nákupu, finanční poradenství ani právní poradenství.

Přestože jsme vynaložili veškeré úsilí, abychom zajistili přesnost a aktuálnost informací, neneseme odpovědnost za případné chyby, opomenutí nebo neaktuální informace. Podmínky na trhu, údaje o společnosti a technické normy se mohou změnit.

Ilustrační obrázek týkající se přepravy z lodi na loď

B2B kupující musí provést vlastní nezávislé a důkladné due diligence. před jakýmkoli rozhodnutím o nákupu. To zahrnuje přímé kontaktování dodavatelů, ověření certifikací, vyžádání vzorků a odborné konzultace. Riziko spoléhání se na jakékoli informace v této příručce nese výhradně čtenář.