Introduction: Navigating the Global Market for Discharge Rubber Hose

In the dynamic landscape of global trade, sourcing high-quality discharge rubber hoses poses a significant challenge for B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. The need for reliable and durable hoses is paramount in industries ranging from agriculture to construction, where the efficient transfer of water and other fluids is crucial. This guide offers a comprehensive exploration of discharge rubber hoses, detailing various types, applications, and essential factors to consider when making purchasing decisions.

Buyers will gain insights into the specific requirements for different applications, helping them identify the right product for their operational needs. We delve into supplier vetting processes, ensuring that businesses can confidently select manufacturers who meet stringent quality and performance standards. Furthermore, an analysis of cost factors will empower buyers to navigate pricing structures effectively, allowing for informed negotiations that align with budgetary constraints.

By equipping B2B buyers with actionable insights and practical knowledge, this guide aims to streamline the sourcing process and enhance decision-making capabilities. Whether you are in Saudi Arabia, Brazil, or any other global market, understanding the nuances of discharge rubber hoses will enable you to secure the best products that drive operational efficiency and reliability in your business endeavors.

Obsah

- Top 7 Discharge Rubber Hose Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for Discharge Rubber Hose

- Understanding Discharge Rubber Hose Types and Variations

- Key Industrial Applications of Discharge Rubber Hose

- 3 Common User Pain Points for ‘Discharge Rubber Hose’ & Their Solutions

- Strategic Material Selection Guide for Discharge Rubber Hose

- In-depth Look: Manufacturing Processes and Quality Assurance for Discharge Rubber Hose

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘Discharge Rubber Hose’

- Comprehensive Cost and Pricing Analysis for Discharge Rubber Hose Sourcing

- Alternatives Analysis: Comparing Discharge Rubber Hose With Other Solutions

- Essential Technical Properties and Trade Terminology for Discharge Rubber Hose

- Navigating Market Dynamics and Sourcing Trends in the Discharge Rubber Hose Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of Discharge Rubber Hose

- Strategic Sourcing Conclusion and Outlook for Discharge Rubber Hose

- Důležité prohlášení o vyloučení odpovědnosti a podmínky používání

Understanding Discharge Rubber Hose Types and Variations

| Název typu | Klíčové rozlišovací znaky | Primární aplikace B2B | Stručné výhody a nevýhody pro kupující |

|---|---|---|---|

| EPDM Rubber Discharge Hose | High abrasion and weather resistance, soft wall | Industrial construction, water management | Klady: Durable, versatile, suitable for various chemicals. Nevýhody: May be more expensive than PVC options. |

| Lay-Flat Discharge Hose | Lightweight, easy to store, partially flattens | Agriculture, irrigation, dewatering | Klady: Portable, cost-effective, easy to transport. Nevýhody: Less durable under harsh conditions. |

| Heavy-Duty Rubber Hose | Thick walls, high pressure tolerance | Mining, oil and gas, heavy-duty applications | Klady: High strength, can handle high pressures. Nevýhody: Heavier and less flexible than standard hoses. |

| PVC Discharge Hose | Cost-effective, good for light applications | Residential, light industrial, drainage | Klady: Affordable, lightweight, easy to handle. Nevýhody: Limited temperature and chemical resistance. |

| Chemical-Resistant Hose | Specialized for specific chemicals | Chemical processing, waste management | Klady: Tailored for specific applications, protects against corrosion. Nevýhody: May require specialized fittings. |

What Are the Key Characteristics of EPDM Rubber Discharge Hoses?

EPDM rubber discharge hoses are designed for rugged industrial and construction applications. Their high abrasion and weather resistance make them suitable for environments where durability is paramount. These hoses are typically soft-walled, allowing for flexibility while maintaining strength. Buyers should consider the pressure ratings, which often range from 150 to 250 psi, depending on the specific model. When purchasing, ensure compatibility with the chemicals and materials being transported, as some formulations may not be suitable for all applications.

How Do Lay-Flat Discharge Hoses Stand Out?

Lay-flat discharge hoses are characterized by their lightweight and flexible design, allowing them to be easily rolled up for storage and transport. This makes them particularly popular in agriculture and irrigation settings where space and weight are considerations. While they are cost-effective and easy to handle, buyers should note that their durability may be compromised in extremely harsh conditions or heavy-duty applications. It’s essential to assess the operating environment and potential exposure to abrasive materials when selecting this type of hose.

What Makes Heavy-Duty Rubber Hoses Ideal for Tough Applications?

Heavy-duty rubber hoses are built with thicker walls and are engineered to withstand high pressures, making them suitable for applications in mining, oil and gas, and other heavy-duty industries. Their construction provides excellent tensile strength and resistance to wear and tear. However, the increased thickness can result in greater weight and reduced flexibility, which may be a consideration for handling and installation. Buyers should evaluate the specific pressure and temperature requirements of their applications to ensure they select an appropriate model.

Why Choose PVC Discharge Hoses for Light Applications?

PVC discharge hoses are often favored for their affordability and lightweight characteristics, making them suitable for residential and light industrial applications. They are easy to handle and transport, which can be advantageous in situations where mobility is essential. However, buyers should be aware of their limitations, particularly regarding temperature and chemical resistance. It’s advisable to assess the specific requirements of the intended use to ensure that a PVC hose will meet performance expectations.

What Are the Benefits of Chemical-Resistant Hoses?

Chemical-resistant hoses are specifically designed to handle various chemicals safely, making them essential in industries like chemical processing and waste management. These hoses are constructed from materials that protect against corrosion and degradation, ensuring longevity and reliability. When purchasing, buyers should carefully consider the specific chemicals being transported, as compatibility is crucial. Additionally, specialized fittings may be necessary, adding to the overall cost and complexity of the setup.

Key Industrial Applications of Discharge Rubber Hose

| Průmysl/odvětví | Specific Application of Discharge Rubber Hose | Hodnota/přínos pro podnik | Klíčové aspekty získávání zdrojů pro tuto aplikaci |

|---|---|---|---|

| Zemědělství | Irrigation and Drainage Systems | Efficient water transport, reducing waste | Consider hose durability, temperature resistance, and length options. |

| Stavebnictví | Site Dewatering and Water Management | Prevents flooding and maintains site safety | Look for hoses with high abrasion resistance and pressure ratings. |

| Těžba | Slurry and Waste Material Discharge | Facilitates effective waste management | Ensure compatibility with specific materials and environmental regulations. |

| Ropa a zemní plyn | Fluid Transfer in Drilling Operations | Ensures safe and efficient transfer of fluids | Focus on chemical resistance and temperature tolerance. |

| Chemické zpracování | Discharge of Mild Chemicals and Wastewater | Safe disposal and handling of hazardous materials | Verify compliance with industry standards and chemical compatibility. |

How is Discharge Rubber Hose Used in Agriculture and What Problems Does it Solve?

In agriculture, discharge rubber hoses are essential for irrigation and drainage systems. They transport water efficiently from sources to fields, minimizing waste and ensuring crops receive adequate moisture. Buyers must consider factors such as durability against environmental elements, flexibility for various terrains, and length options to suit large fields. In regions like Africa and South America, where water scarcity is prevalent, these hoses can significantly enhance agricultural productivity.

What Role Does Discharge Rubber Hose Play in Construction?

Discharge rubber hoses are crucial for site dewatering and water management in construction. They help remove excess water from excavation sites, preventing flooding and ensuring worker safety. When sourcing these hoses, construction companies should prioritize high abrasion resistance and pressure ratings, as construction sites can be harsh environments. In the Middle East, where heavy rainfall can occur unexpectedly, having reliable discharge hoses is vital for maintaining project timelines.

How is Discharge Rubber Hose Utilized in Mining Operations?

In the mining sector, discharge rubber hoses are used to manage slurry and waste materials effectively. They facilitate the safe and efficient transfer of waste products, helping to maintain operational efficiency and environmental compliance. Buyers in this sector need to ensure that the hoses are compatible with the specific materials being transported and meet local environmental regulations. In South America, where mining operations are extensive, these hoses play a critical role in waste management strategies.

What are the Applications of Discharge Rubber Hose in Oil and Gas Industries?

In the oil and gas industry, discharge rubber hoses are utilized for fluid transfer during drilling operations. They ensure the safe and efficient movement of drilling fluids, which is essential for maintaining operational flow and safety. Buyers should focus on the hoses’ chemical resistance and temperature tolerance, as drilling fluids can be harsh. In regions like Saudi Arabia, where oil extraction is a primary industry, having reliable hoses can significantly impact operational success.

How Do Chemical Processing Industries Benefit from Discharge Rubber Hoses?

Discharge rubber hoses are vital in the chemical processing sector for the safe disposal and handling of mild chemicals and wastewater. They provide a secure method for transferring potentially hazardous materials, mitigating risks associated with spills or leaks. When sourcing hoses for this application, buyers must verify compliance with industry standards and ensure chemical compatibility to prevent degradation. In Europe, where stringent regulations govern chemical handling, these considerations are critical for operational compliance.

3 Common User Pain Points for ‘Discharge Rubber Hose’ & Their Solutions

Scenario 1: Struggling with Hose Durability in Harsh Environments

Problém: B2B buyers in sectors such as construction, agriculture, and mining often face the challenge of hose durability, especially when operating in extreme weather conditions or abrasive environments. Discharge rubber hoses can easily deteriorate when exposed to UV rays, ozone, or chemical agents, leading to unexpected failures and costly downtime. Buyers may find themselves frequently replacing hoses, which not only increases operational costs but also impacts productivity.

Řešení: To combat durability issues, it is essential to select discharge rubber hoses made from high-quality materials such as EPDM (Ethylene Propylene Diene Monomer) rubber, which offers superior resistance to UV rays and ozone. When sourcing hoses, buyers should specifically inquire about the material specifications and look for hoses designed for the intended application, such as those rated for high abrasion resistance. Additionally, consider investing in protective accessories like hose covers or sleeves that can provide an extra layer of defense against environmental factors. Regular maintenance and inspections can also prolong the lifespan of the hoses, ensuring they remain functional in demanding conditions.

Scenario 2: Difficulty in Sizing and Compatibility with Existing Equipment

Problém: Another common issue faced by B2B buyers is the challenge of ensuring the right sizing and compatibility of discharge rubber hoses with existing equipment. Incorrect sizing can lead to inefficiencies, such as reduced flow rates, increased pressure loss, or even equipment damage. Buyers may find themselves overwhelmed by the array of sizes and fittings available, leading to costly mistakes in procurement.

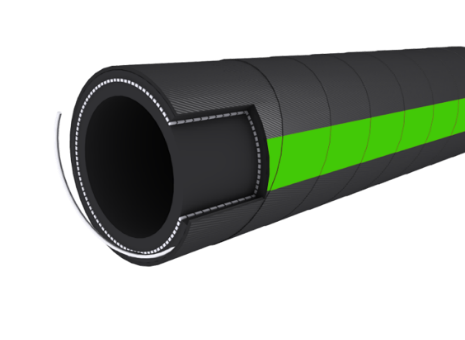

Illustrative image related to Discharge Rubber Hose

Řešení: To address sizing challenges, it is crucial for buyers to conduct a thorough assessment of their equipment specifications and operational requirements. Start by measuring the diameter of the existing fittings and the length of hose needed for the intended application. When purchasing, opt for hoses that come with a range of fitting options, and don’t hesitate to consult with manufacturers or suppliers who can provide expertise in matching the right hose size with equipment. Additionally, consider using adjustable fittings or hose clamps that allow for minor variations in size, providing flexibility while maintaining a secure connection.

Scenario 3: Navigating Supply Chain Issues and Delivery Delays

Problém: In today’s global market, B2B buyers often encounter supply chain disruptions that can lead to extended delivery times for discharge rubber hoses. Delays can stem from various factors, including geopolitical issues, natural disasters, or logistical challenges. Such interruptions can severely impact project timelines and operational efficiency, forcing companies to delay critical processes or seek alternative (and often more expensive) solutions.

Řešení: To mitigate supply chain issues, B2B buyers should develop strong relationships with multiple suppliers to diversify their sourcing options. This approach not only provides backup suppliers in case of delays but also enables buyers to negotiate better terms and prices. Additionally, implementing a just-in-time inventory strategy can help manage stock levels more effectively and reduce the risk of over-reliance on a single supplier. When placing orders, consider requesting expedited shipping options, and maintain open communication with suppliers regarding lead times and inventory availability to stay informed and prepared for any potential disruptions.

Strategic Material Selection Guide for Discharge Rubber Hose

When selecting materials for discharge rubber hoses, it is crucial to consider their performance characteristics, compatibility with various media, and the specific requirements of international markets. Here, we analyze four common materials used in discharge rubber hoses: EPDM, Nitrile, Neoprene, and PVC. Each material has distinct properties that influence its suitability for various applications.

What are the Key Properties of EPDM Rubber for Discharge Hoses?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber known for its excellent resistance to heat, ozone, and weathering. It can withstand temperatures ranging from -40°F to 180°F and has a maximum working pressure of 150 psi. This makes EPDM particularly suitable for outdoor applications and environments where exposure to UV rays is common.

Pros and Cons of EPDM:

The primary advantage of EPDM is its durability and resistance to environmental factors, making it ideal for agricultural and construction applications. However, it has limited compatibility with petroleum-based products, which can restrict its use in certain industrial settings. Additionally, while EPDM is generally cost-effective, its manufacturing process can be more complex due to the need for specialized compounds.

Dopad na aplikaci:

EPDM hoses are often used in water discharge applications, irrigation, and industrial processes where chemical compatibility is not a primary concern. For international buyers, compliance with standards such as ASTM and DIN is essential, especially in regions like Europe and the Middle East.

How Does Nitrile Rubber Perform in Discharge Hose Applications?

Nitrile rubber, also known as Buna-N, is recognized for its excellent resistance to oils and fuels, making it a preferred choice for applications involving petroleum products. It typically operates effectively at temperatures between -30°F and 180°F, with pressure ratings similar to EPDM.

Pros and Cons of Nitrile:

The key advantage of nitrile is its superior oil resistance, which allows it to handle a wide range of industrial applications. However, nitrile is less resistant to ozone and UV radiation, which may limit its outdoor usability. While nitrile hoses can be slightly more expensive than EPDM, their longevity in oil-related applications often justifies the cost.

Dopad na aplikaci:

Nitrile hoses are commonly used in the automotive and industrial sectors for fuel and oil transfer. Buyers in oil-rich regions such as the Middle East or South America should ensure that the hoses meet local compliance standards, as regulations can vary significantly.

What are the Advantages of Neoprene Rubber in Discharge Hoses?

Neoprene rubber is a versatile material that offers good chemical resistance and flexibility. It can handle temperatures from -20°F to 200°F and has a maximum working pressure of 150 psi, making it suitable for various discharge applications.

Pros and Cons of Neoprene:

Neoprene’s main advantage is its balanced resistance to oils, chemicals, and environmental factors, making it suitable for both indoor and outdoor applications. However, it is generally more expensive than EPDM and nitrile, which can be a consideration for budget-conscious buyers.

Dopad na aplikaci:

Neoprene hoses are often utilized in chemical processing and food-grade applications due to their versatility. International buyers should check for compliance with food safety standards, especially in Europe and North America.

Illustrative image related to Discharge Rubber Hose

Why is PVC a Popular Choice for Discharge Hoses?

PVC (Polyvinyl Chloride) is a cost-effective alternative to rubber hoses, known for its lightweight and flexible properties. It can operate within a temperature range of -10°F to 150°F and is typically rated for pressures up to 150 psi.

Pros and Cons of PVC:

The primary advantage of PVC is its affordability and ease of manufacturing, making it accessible for various applications. However, it lacks the durability of rubber and can become brittle over time, particularly in extreme temperatures. Additionally, PVC hoses may not be suitable for high-temperature applications.

Dopad na aplikaci:

PVC hoses are widely used in agricultural irrigation, construction, and general-purpose water discharge applications. Buyers should be aware of local regulations regarding PVC materials, especially in regions where environmental concerns are paramount.

Summary Table of Material Selection for Discharge Rubber Hose

| Materiál | Typical Use Case for Discharge Rubber Hose | Klíčová výhoda | Hlavní nevýhoda/omezení | Relativní náklady (nízké/střední/vysoké) |

|---|---|---|---|---|

| EPDM | Water discharge, irrigation | Excellent weather resistance | Limited oil compatibility | Střední |

| Nitrile | Oil and fuel transfer | Superior oil resistance | Less ozone resistance | Medium to High |

| Neoprene | Chemical processing, food-grade | Balanced chemical resistance | Higher cost | Vysoká |

| PVC | Agricultural irrigation, general discharge | Nákladově efektivní a flexibilní | Less durable than rubber | Nízká |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in discharge rubber hoses, equipping international B2B buyers with the necessary insights to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for Discharge Rubber Hose

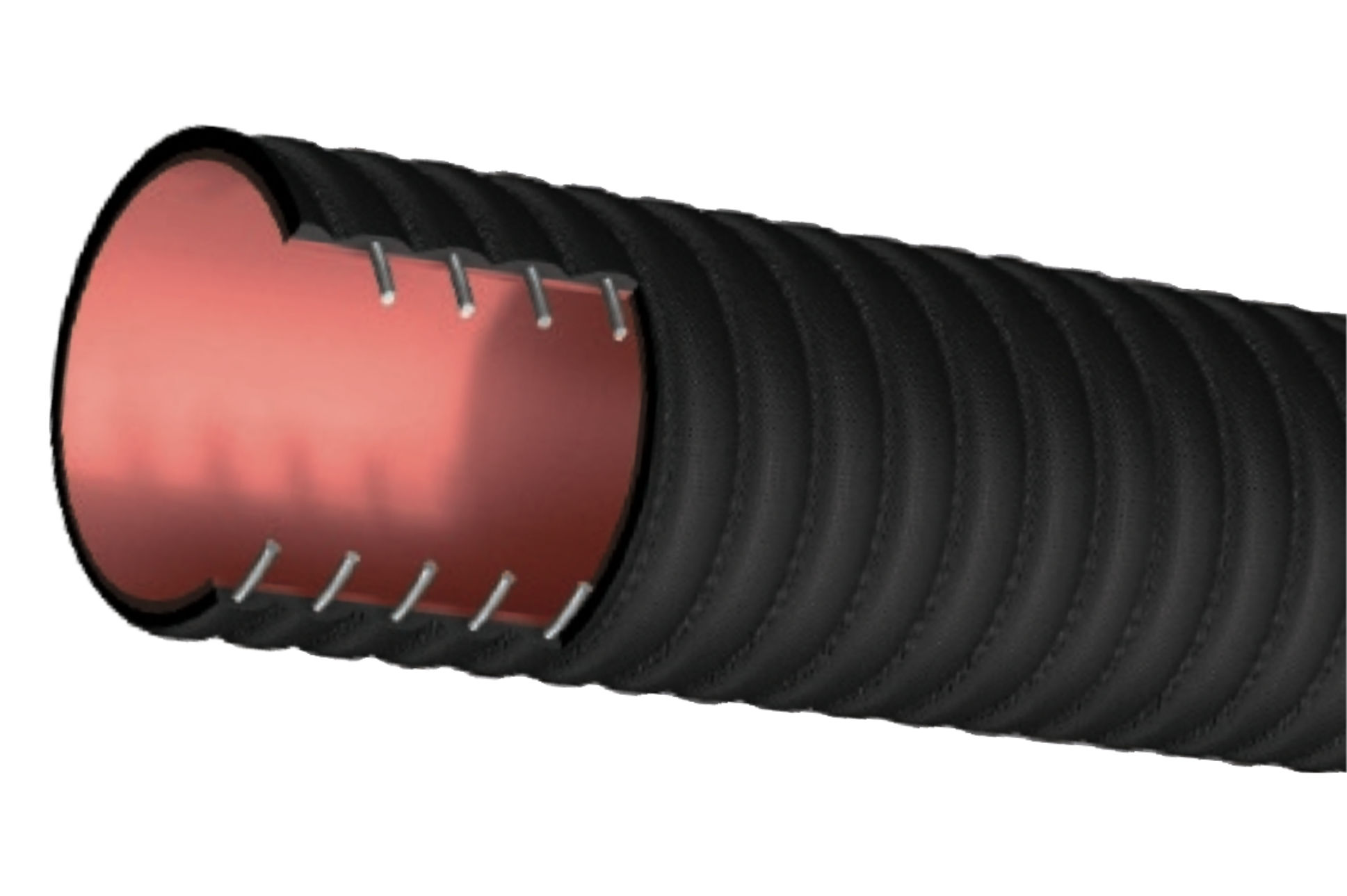

What Are the Key Stages in the Manufacturing Process of Discharge Rubber Hose?

The manufacturing process for discharge rubber hoses typically involves several critical stages: material preparation, forming, assembly, and finishing.

Illustrative image related to Discharge Rubber Hose

-

Příprava materiálu: This initial stage involves sourcing high-quality raw materials, primarily rubber compounds like EPDM (Ethylene Propylene Diene Monomer) and SBR (Styrene-Butadiene Rubber). These materials are selected based on their resistance to abrasion, weather, and various chemicals, ensuring they meet the specific needs of industrial applications. The raw materials are then mixed in precise ratios to create a compound that will exhibit the desired properties.

-

Forming: After preparing the rubber compound, the next step is forming the hose. This typically involves extrusion, where the rubber is forced through a die to create a continuous length of hose. The hose may be reinforced with textile or steel wire to enhance its strength and pressure resistance. The forming stage is crucial, as it determines the hose’s diameter, wall thickness, and overall structural integrity.

-

Montáž: Once the hose has been formed, it may require assembly with fittings or couplings. This is done using techniques such as crimping or bonding, depending on the design specifications. The selection of fittings is essential, as they must match the intended application and pressure requirements.

-

Finishing: The final stage involves curing or vulcanizing the rubber. This process enhances the rubber’s elasticity and durability, making it suitable for demanding environments. After curing, the hoses undergo cutting to specific lengths and may receive surface treatments to improve resistance to environmental factors.

What Quality Control Measures Are Essential for Discharge Rubber Hose Production?

Quality control (QC) is vital to ensure that discharge rubber hoses meet international standards and customer expectations.

-

International Standards: Compliance with standards such as ISO 9001 is crucial for manufacturers. This standard focuses on quality management systems and emphasizes continuous improvement, customer satisfaction, and regulatory compliance. Other relevant certifications include CE marking for products sold within the European Economic Area and API specifications for hoses used in petroleum and petrochemical industries.

-

QC Checkpoints: Effective QC is implemented at various checkpoints throughout the manufacturing process:

– Vstupní kontrola kvality (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– Kontrola kvality v procesu (IPQC): Regular checks are performed during the manufacturing stages to monitor processes such as mixing, forming, and curing. This proactive approach helps identify defects early.

– Konečná kontrola kvality (FQC): After assembly and finishing, the hoses undergo thorough testing for pressure, flexibility, and resistance to abrasion and chemicals. -

Common Testing Methods: Various tests are employed to ensure the hoses meet performance standards. These may include:

– Pressure Testing: To verify that hoses can withstand specified pressures without failure.

– Abrasion Resistance Testing: To assess the durability of the hose surface against wear and tear.

– Chemical Resistance Testing: To ensure compatibility with different fluids and environments, critical for industrial applications.

Jak mohou B2B odběratelé ověřit postupy kontroly kvality u dodavatelů?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to mitigate risks.

-

Audity dodavatelů: Conducting supplier audits is one of the most effective ways to assess QC practices. This involves visiting the manufacturing facility to review processes, equipment, and compliance with international standards. Buyers should look for certifications and detailed documentation of QC practices during the audit.

-

Zprávy o kvalitě: Requesting quality assurance reports can provide insights into the supplier’s QC performance. These reports should detail testing methods, results, and any corrective actions taken for past issues. Regular updates on QC metrics can also indicate a supplier’s commitment to maintaining high standards.

-

Kontroly třetí stranou: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can perform random inspections at various stages of the production process, ensuring compliance with specified standards.

Jaké jsou nuance kontroly kvality pro mezinárodní kupující?

International buyers must be aware of specific nuances when it comes to quality control in the context of discharge rubber hoses.

Illustrative image related to Discharge Rubber Hose

-

Cultural and Regulatory Differences: Different regions may have varying regulatory requirements and cultural attitudes towards quality. For instance, standards in Europe might differ significantly from those in Africa or South America. Understanding these differences is crucial for compliance and quality assurance.

-

Logistics and Supply Chain Considerations: International logistics can impact the quality of the hoses during transportation. Buyers should ensure that suppliers use appropriate packaging and handling methods to prevent damage during shipping. Additionally, establishing clear communication regarding quality expectations and delivery timelines can help mitigate potential issues.

-

Building Long-Term Relationships: Developing a long-term relationship with suppliers can enhance quality assurance efforts. Regular communication, feedback on product performance, and collaborative problem-solving can lead to improved quality standards over time. This relationship-building is particularly important in regions where personal connections can influence business operations.

By understanding the manufacturing processes and quality assurance measures for discharge rubber hoses, B2B buyers can make informed decisions, ensuring they procure products that meet their operational needs and international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Discharge Rubber Hose’

Úvod

When sourcing discharge rubber hoses for industrial applications, having a structured approach is essential. This guide provides a step-by-step checklist to help B2B buyers effectively navigate the procurement process. By following these actionable steps, you can ensure that you select the right products and suppliers to meet your operational needs.

Krok 1: Definujte své technické specifikace

Before initiating the sourcing process, clearly outline the technical requirements for the discharge rubber hoses. Consider factors such as hose diameter, length, pressure ratings, and material compatibility.

– Why it matters: Accurate specifications help prevent procurement errors and ensure the hoses will perform effectively in your specific applications.

– Look for: Industry standards that the hoses must comply with, such as ISO or ASTM certifications.

Krok 2: Research Reliable Suppliers

Take the time to identify and research potential suppliers. Look for manufacturers and distributors with a proven track record in the industry.

– Why it matters: Partnering with reputable suppliers reduces the risk of quality issues and supply chain disruptions.

– Look for: Supplier reviews, testimonials, and case studies from other businesses in your region or industry.

Krok 3: Evaluate Product Quality and Compliance

Assess the quality of the discharge rubber hoses being offered. Request samples if possible, and inquire about material certifications.

– Why it matters: High-quality hoses are crucial for safety and efficiency, especially in rugged environments.

– Look for: Certifications that indicate compliance with relevant safety and performance standards, such as FDA approval for food-grade applications.

Krok 4: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare them based on pricing, payment terms, and delivery schedules.

– Why it matters: Understanding the pricing landscape helps you negotiate better deals and manage your budget effectively.

– Look for: Any hidden costs, such as shipping fees or minimum order quantities that might affect the total procurement cost.

Illustrative image related to Discharge Rubber Hose

Krok 5: Ověření certifikace dodavatele

Ensure that your selected suppliers hold the necessary certifications and licenses to operate in your region.

– Why it matters: Compliance with local regulations is essential, particularly in international transactions, to avoid legal issues and ensure product safety.

– Look for: Certifications such as ISO 9001 for quality management systems or specific regional certifications relevant to your market.

Krok 6: Assess Customer Support and After-Sales Service

Evaluate the level of customer support and after-sales service offered by the supplier.

– Why it matters: Good customer service can significantly ease the procurement process and provide assistance in case of issues with the hoses.

– Look for: Availability of technical support, warranty terms, and responsiveness to inquiries.

Krok 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier, finalize your order and establish clear communication regarding delivery timelines and logistics.

– Why it matters: Keeping track of your order helps ensure timely delivery and allows for contingency planning in case of delays.

– Look for: A detailed order confirmation that outlines product specifications, expected delivery dates, and contact information for any follow-up needs.

By following this practical checklist, you can streamline your procurement process for discharge rubber hoses, ensuring that you make informed decisions that support your operational goals.

Comprehensive Cost and Pricing Analysis for Discharge Rubber Hose Sourcing

Understanding the cost structure and pricing dynamics of discharge rubber hoses is essential for international B2B buyers. This analysis delves into the various cost components, pricing influencers, and valuable tips for effective sourcing in diverse markets, including Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Discharge Rubber Hose Manufacturing?

The cost structure of discharge rubber hoses comprises several critical components:

-

Materiály: The type of rubber used, such as EPDM or other synthetic materials, significantly impacts the cost. High-grade materials offer better durability and resistance to abrasion and weather, but they also come with a higher price tag.

-

Práce: Labor costs vary by region and can influence the overall manufacturing cost. Regions with lower labor costs may provide competitive pricing, but this could affect quality standards.

-

Výrobní režie: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize overhead costs.

-

Nástroje: The initial investment in molds and tools for hose manufacturing can be substantial, especially for custom sizes or specifications. This cost is amortized over the production volume.

-

Kontrola kvality (QC): Ensuring compliance with international quality standards adds to the cost. Certification processes, such as ISO or other industry-specific standards, may also incur additional fees.

-

Logistika: Transportation costs, including shipping, insurance, and tariffs, can vary widely based on the destination and shipping method. Understanding Incoterms is crucial for determining who bears these costs.

-

Marže: Suppliers typically add a profit margin on top of their costs, which can vary based on the competitive landscape and customer negotiations.

How Do Price Influencers Affect Discharge Rubber Hose Costs?

Several factors influence the pricing of discharge rubber hoses:

-

Objem a minimální objednací množství (MOQ): Larger orders often qualify for bulk pricing, reducing the per-unit cost. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifikace a přizpůsobení: Customized hoses that meet specific industry requirements may cost more due to additional manufacturing processes. Standardized products typically offer lower prices.

-

Kvalita a certifikace: Hoses that meet stringent quality certifications or are made from superior materials will carry a premium price. Buyers should assess whether these certifications align with their operational needs.

-

Faktory dodavatele: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often offer better quality assurance and service.

-

Incoterms: Understanding the shipping terms is vital. Different Incoterms (e.g., FOB, CIF) dictate responsibilities regarding shipping costs, insurance, and risk, impacting the total cost of ownership.

What Tips Can Help Buyers Achieve Cost Efficiency in Sourcing?

For international B2B buyers, particularly those in emerging markets, several strategies can enhance cost efficiency:

-

Vyjednávání: Engage in discussions with suppliers to secure better pricing. Emphasizing long-term partnerships or larger volumes can yield favorable terms.

-

Celkové náklady na vlastnictví (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, replacement, and operational efficiency. A slightly higher upfront cost may result in lower overall expenses.

-

Market Research: Conduct thorough research on regional pricing and supplier capabilities. Understanding market conditions in countries like Brazil, Saudi Arabia, or across Africa can help in making informed decisions.

-

Quality vs. Cost: Balance the need for quality with budget constraints. Sometimes, opting for a slightly more expensive product can lead to lower maintenance costs and longer service life.

-

Leverage Technology: Use digital platforms for sourcing and comparing prices. Many suppliers offer online configurations and quotes, streamlining the procurement process.

Závěr

Navigating the complexities of sourcing discharge rubber hoses requires an understanding of the cost structure and various influencing factors. By applying strategic negotiation techniques and considering the total cost of ownership, B2B buyers can enhance their purchasing decisions, ultimately leading to more cost-effective operations. As always, be mindful that prices can fluctuate based on market conditions and supplier policies, so continuous engagement and research are key to successful sourcing.

Alternatives Analysis: Comparing Discharge Rubber Hose With Other Solutions

When evaluating solutions for fluid discharge applications, it is essential to consider various alternatives to discharge rubber hoses. Each option presents unique advantages and disadvantages, making it crucial for international B2B buyers to understand these differences to make informed purchasing decisions.

| Srovnávací hledisko | Výtoková gumová hadice | PVC Lay Flat Hose | Metal Hose |

|---|---|---|---|

| Výkon | High flexibility, suitable for rugged use | Lightweight, good for low-pressure applications | Durable, high pressure handling |

| Náklady | Moderate pricing, varying by diameter | Generally lower cost | Vyšší počáteční investice |

| Snadnost implementace | Requires fittings, somewhat heavy | Easy to transport and store | Requires specialized installation |

| Údržba | Low maintenance, but susceptible to abrasion | Low maintenance, can be punctured | Higher maintenance, corrosion potential |

| Nejlepší případ použití | Industrial and construction environments | Agricultural and irrigation applications | High-pressure industrial applications |

What Are the Advantages and Disadvantages of PVC Lay Flat Hose?

PVC lay flat hoses are an attractive alternative for buyers seeking a lightweight and cost-effective solution. They are typically less expensive than discharge rubber hoses, making them suitable for applications where budget constraints are a priority. Their design allows for easy transportation and storage, as they can be rolled flat. However, they may not withstand high-pressure situations as effectively as rubber hoses and can be more susceptible to punctures and damage from sharp objects.

Illustrative image related to Discharge Rubber Hose

How Do Metal Hoses Compare in Terms of Performance and Durability?

Metal hoses, often made from stainless steel or other alloys, provide excellent durability and can handle high-pressure applications, making them ideal for industrial settings. They are resistant to abrasion and can withstand a range of temperatures and chemicals. However, their higher cost and the need for specialized fittings can make them less accessible for some businesses. Additionally, their installation requires more expertise, which may lead to increased labor costs.

Conclusion: How Can B2B Buyers Select the Right Discharge Solution?

In choosing the right discharge solution, B2B buyers should carefully assess their specific needs, including budget constraints, performance requirements, and the nature of the fluids being handled. Discharge rubber hoses are versatile and durable, making them suitable for a variety of applications, particularly in rugged environments. Conversely, PVC lay flat hoses may be a better choice for budget-conscious projects requiring lighter solutions, while metal hoses excel in high-pressure scenarios. Ultimately, understanding the pros and cons of each alternative will empower buyers to make the best decision for their operational requirements.

Essential Technical Properties and Trade Terminology for Discharge Rubber Hose

Discharge rubber hoses are essential components in various industrial applications, particularly for transferring fluids in construction, agricultural, and manufacturing settings. Understanding the technical specifications and trade terminology associated with these hoses is critical for making informed purchasing decisions.

Illustrative image related to Discharge Rubber Hose

What Are the Key Technical Properties of Discharge Rubber Hose?

-

Stupeň materiálu

The most commonly used material for discharge hoses is EPDM (Ethylene Propylene Diene Monomer) rubber, known for its excellent weather resistance and flexibility. The choice of material affects the hose’s durability and performance in different environmental conditions. For B2B buyers, selecting the right material grade ensures the hose will withstand the specific demands of their applications, reducing the risk of premature failure. -

Working Pressure

This specification indicates the maximum pressure that the hose can handle during operation, typically measured in psi (pounds per square inch). Common ratings for discharge hoses range from 150 psi to 250 psi. Understanding the working pressure is crucial for buyers to ensure that the hose will safely accommodate the pressure requirements of their fluid transfer tasks, preventing leaks and potential safety hazards. -

Teplotní rozsah

The operational temperature range specifies the minimum and maximum temperatures the hose can tolerate, often spanning from -40°F to 180°F. This property is vital for applications involving hot liquids or extreme weather conditions. Buyers must assess their operational environment to select hoses that will maintain performance and integrity without degrading. -

Průměr a délka

Discharge hoses come in various diameters, typically ranging from 1.5 inches to 6 inches, and standard lengths of 50 feet or 100 feet. The diameter and length will significantly impact flow rates and the overall efficiency of fluid transfer. B2B buyers should choose sizes that align with their specific equipment and application needs to optimize performance. -

Vacuum Rating

Vacuum ratings denote the ability of the hose to withstand negative pressure, often measured in inches of mercury (inHg). This property is particularly important in applications where the hose may be used for suction. Understanding vacuum ratings helps buyers select hoses that can handle both suction and discharge applications, ensuring versatility and reliability.

What Are Common Trade Terms Used in the Discharge Hose Industry?

-

OEM (výrobce originálního vybavení)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs ensures compatibility and quality, as these manufacturers adhere to industry standards. -

MOQ (minimální objednací množství)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage their inventory levels effectively and negotiate better pricing terms without overcommitting to large quantities. -

RFQ (žádost o cenovou nabídku)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products or services. This process allows buyers to compare offers and select the best supplier based on price and quality. -

Incoterms (mezinárodní obchodní podmínky)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother transactions and logistics. -

Doba realizace

Lead time refers to the duration between placing an order and receiving the product. For B2B buyers, knowing the lead time is critical for planning and ensuring that projects remain on schedule, especially in time-sensitive industries. -

Fittings

Fittings are components that connect hoses to other equipment or hoses. Understanding the types of fittings available (such as cam and groove or NPSH) is important for buyers to ensure proper compatibility and secure connections in their fluid transfer systems.

In summary, comprehending the essential technical properties and industry terminology for discharge rubber hoses empowers B2B buyers to make informed decisions, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the Discharge Rubber Hose Sector

What Are the Key Market Dynamics and Trends Influencing the Discharge Rubber Hose Sector?

The discharge rubber hose market is experiencing significant growth driven by several global factors. Increasing industrialization across Africa, South America, the Middle East, and Europe is propelling demand for efficient water management solutions. Key sectors such as agriculture, construction, and mining are heavily reliant on discharge hoses for various applications, including water transfer and drainage. As these sectors evolve, so too does the technology behind discharge hoses, with innovations focusing on durability, flexibility, and pressure capabilities.

Emerging B2B trends include the integration of digital platforms for sourcing and procurement, allowing buyers to easily compare products and suppliers. Online marketplaces and e-commerce solutions are becoming essential tools for international buyers, facilitating direct interactions with manufacturers and reducing lead times. Furthermore, there is a growing emphasis on customization, where buyers seek hoses tailored to specific industrial needs, pushing manufacturers to adopt more agile production methods.

Another dynamic to consider is the increasing competition in the market. As new entrants emerge, established players are compelled to innovate and offer competitive pricing while maintaining quality. This competitive landscape encourages manufacturers to adopt advanced materials and production techniques, ensuring that products can withstand harsh environmental conditions and meet diverse application requirements.

How Can Sustainability and Ethical Sourcing Impact the Discharge Rubber Hose Sector?

Sustainability is becoming a critical consideration for B2B buyers in the discharge rubber hose sector. The environmental impact of rubber production, particularly in terms of carbon emissions and resource depletion, has led to a heightened awareness of the need for sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to eco-friendly manufacturing processes, including the use of recycled materials and sustainable sourcing practices.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are not only environmentally responsible but also socially conscious. This involves verifying that suppliers adhere to fair labor practices and provide safe working conditions. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the demand for ‘green’ materials is on the rise. Buyers are looking for discharge hoses made from environmentally friendly compounds that do not compromise on performance. As awareness of climate change and environmental degradation grows, suppliers who can provide sustainable options may gain a competitive advantage in the market.

Illustrative image related to Discharge Rubber Hose

What Is the Historical Context of the Discharge Rubber Hose Sector?

The discharge rubber hose sector has evolved significantly over the decades, shaped by technological advancements and changing market needs. Initially, hoses were predominantly made from natural rubber, which provided limited durability and resistance to environmental factors. However, the introduction of synthetic materials, such as EPDM and PVC, revolutionized the industry by enhancing the performance characteristics of hoses, including temperature resistance and flexibility.

As industries expanded globally, so did the applications of discharge hoses. They became integral to various sectors, including agriculture for irrigation, construction for water removal, and even in the oil and gas industry for fluid transport. The shift towards high-performance materials has allowed manufacturers to cater to increasingly demanding operational environments, making discharge rubber hoses a critical component in modern industrial applications.

This historical evolution highlights the importance of continuous innovation and adaptation in meeting the needs of diverse industries, ensuring that discharge rubber hoses remain relevant in an ever-changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of Discharge Rubber Hose

1. How do I choose the right discharge rubber hose for my application?

Selecting the appropriate discharge rubber hose involves considering several factors: the hose’s diameter, length, working pressure, and the specific materials being transported. Assess the application environment—whether it involves rugged industrial tasks or lighter-duty uses. Additionally, evaluate compatibility with chemicals and temperature ranges. Consult product specifications and seek advice from suppliers to ensure you select a hose that meets your operational needs while adhering to industry standards.

2. What are the key features to look for in a discharge rubber hose?

Key features to consider include the hose material, flexibility, and pressure rating. Rubber hoses with EPDM covers are excellent for abrasion and weather resistance, making them ideal for industrial applications. Look for options that provide high tensile strength and can withstand varying temperatures. Additionally, check for customization options like fittings and lengths that suit your specific requirements, ensuring optimal performance in your operational context.

3. What is the minimum order quantity (MOQ) for discharge rubber hoses?

Minimum order quantities can vary significantly between suppliers and regions. Typically, MOQs for discharge rubber hoses may range from 50 to 100 meters, depending on the manufacturer and specific product line. It’s essential to clarify these details with potential suppliers, especially if you are sourcing from international markets. Some manufacturers may offer flexibility on MOQs for first-time buyers or bulk orders, so don’t hesitate to negotiate.

Illustrative image related to Discharge Rubber Hose

4. How can I ensure the quality of discharge rubber hoses before purchasing?

To ensure quality, request certifications and test reports from suppliers that demonstrate compliance with industry standards. Look for hoses that have undergone rigorous quality assurance testing, including pressure tests and material compatibility assessments. Additionally, consider purchasing samples for testing before placing larger orders. Engaging with reputable suppliers with positive reviews and established track records can further assure you of the product quality.

5. What payment terms should I expect when sourcing discharge rubber hoses internationally?

Payment terms can vary widely by supplier and region, but common practices include advance payments, letters of credit, and net payment terms (e.g., net 30 or net 60 days). Ensure clarity on payment methods accepted, including wire transfers or credit cards. It’s advisable to negotiate terms that provide security for both parties, especially when dealing with new suppliers. Understanding the local currency and potential exchange rate fluctuations is also crucial.

6. What logistics considerations should I keep in mind when importing discharge rubber hoses?

When importing hoses, consider shipping methods, lead times, and customs regulations in your country. Evaluate the total landed cost, including shipping, tariffs, and insurance. Partnering with a reliable freight forwarder can streamline logistics and help navigate complex customs processes. Ensure that all necessary documentation is in order to prevent delays and additional costs. Planning for contingencies like delays or damages during transit is also wise.

7. How can I vet suppliers for discharge rubber hoses?

Vetting suppliers involves researching their reputation and capabilities. Look for suppliers with industry certifications, positive customer testimonials, and a solid track record in your specific market. Utilize platforms like Alibaba or global trade shows to find reputable manufacturers. It’s also beneficial to request references and conduct site visits if possible. Establishing clear communication and discussing terms upfront can help gauge their reliability and professionalism.

8. Are there options for customizing discharge rubber hoses?

Yes, many manufacturers offer customization options for discharge rubber hoses. You can often specify the diameter, length, fittings, and even the hose material based on your operational needs. Discuss your requirements with potential suppliers to explore available customization options, including color coding or branding. Custom hoses can enhance operational efficiency and ensure compatibility with existing equipment, making it worthwhile to invest in tailored solutions.

Top 7 Discharge Rubber Hose Manufacturers & Suppliers List

1. HoseShop – Water Suction & Discharge Hose

Doména: hoseshop.com

Registrován: 2003 (22 let)

Úvod: {“part_number”:”WS300″,”hose_type”:”Water Suction & Discharge Hose”,”price_per_inch”:”$0.84″,”available_sizes”:[“1-1/4 inch”,”1-1/2 inch”,”2 inch”,”2-1/2 inch”,”3 inch”,”4 inch”,”5 inch”,”6 inch”],”application”:”suction, discharge or gravity flow of water in construction, mining, oil exploration, agriculture and equipment rental”,”construction”:”black EPDM tube, EPDM blend cover reinforced by eith…

2. Amazon Hose – Kuriyama PVC Discharge Hose

Doména: shop.amazonhose.com

Registrace: 1998 (27 let)

Úvod: Water Suction and Discharge Hoses from Amazon Hose and Rubber Company include various products such as: 1. Kuriyama PVC Discharge Food and Beverage Hose – Clearbraid K3150 Series RF Standard Wall – Price: $1.54 (from $1.15) 2. Continental Frontier Water Hose – Heavy Duty Black with Couplings – Price: $152.45 3. Suction Strainers – Galvanized Steel and Long Style Strainers – Price: $17.65 4. Kuriya…

3. Texcel – TEX-AQUA Water Suction Hose

Doména: texcelrubber.com

Registrován: 1996 (29 let)

Úvod: Water Suction & Discharge Hose

– Product Types: TEX-AQUA Water Suction Hose

– Available Sizes: 1.5 in, 2 in, 3 in, 4 in, 6 in, 8 in

– Standard Lengths: 20 ft, 100 ft, 200 ft

– Max Working Pressure: 50 psi, 150 psi

– Vacuum Ratings: 20 in/Hg, 25 in/Hg, 29 in/Hg

– Units of Measure: FT, PIECE

4. Hosecraft USA – RM1 Multipurpose Rubber Nitrile Hose

Doména: hosecraftusa.com

Registrováno: 2005 (20 let)

Úvod: Hosecraft USA offers a variety of rubber hoses suitable for different applications. Key products include:

1. RM1 MULTIPURPOSE RUBBER NITRILE HOSE: Premium quality, oil resistant, suitable for compressed air, water, and many chemicals, with a temperature range of -20F to 180F.

2. RM2 MULTIPURPOSE RUBBER EPDM HOSE: Economical, recommended for water and compressed air, with excellent weather and ab…

5. Kuriyama – Discharge Hoses

Doména: products.kuriyama.com

Registrace: 1997 (28 let)

Úvod: Discharge Hose products from Kuriyama of America, Inc. include various types of hoses and assemblies such as Mill Discharge Hoses, Nitrile/PVC Oil & Weather Resistant Rubber Discharge Hose, Polyurethane Discharge Hoses, and PVC Layflat Discharge Hoses. The product line also features EZ-Seal™ Leak Resistant Couplings and Aluminum Pin Lug Couplings in male and female configurations, as well as Alumi…

6. Kuriyama – 150 PSI EPDM Layflat Water Discharge Hose

Doména: industrialhose.com

Registrace: 1998 (27 let)

Úvod: Water – Discharge (Rubber) hoses include various models such as Kuriyama 150 PSI EPDM Layflat Water Discharge Hose (T253AA), Kuriyama 150 PSI SBR Water Discharge Hose (T254AA), Novaflex Heavy Duty Water Discharge Hose (2226), Parker EPDM Water Discharge Hose (Series 7306E), Parker Lightweight High Pressure Water Jetting Hose (Series SS122), ContiTech Plicord® HD Water Discharge, ContiTech Plicord®…

7. Unisource – Rubber Water Suction and Discharge Hose

Doména: unisource-mfg.com

Registrován: 1996 (29 let)

Úvod: Unisource offers rubber water suction and discharge hose in a variety of rugged and durable specifications made from different rubber blends. The hoses are designed for cold-weather applications with low-temp ratings to maintain flexibility. Advantages over PVC hoses include an abrasion-resistant rubber cover that is also resistant to ozone and weathering, longer lifespan, better bend radius in co…

Strategic Sourcing Conclusion and Outlook for Discharge Rubber Hose

In conclusion, the strategic sourcing of discharge rubber hoses is pivotal for international B2B buyers aiming to optimize operational efficiency and reduce costs. Understanding the various specifications—such as pressure ratings, materials, and compatibility with different applications—enables buyers to select the most suitable products for their needs. Additionally, leveraging suppliers that offer comprehensive product ranges and tailored solutions can significantly enhance supply chain resilience, particularly in regions like Africa, South America, the Middle East, and Europe.

As the demand for high-quality discharge rubber hoses continues to rise, international buyers are encouraged to cultivate strong partnerships with reliable manufacturers. This not only ensures access to innovative products but also fosters collaboration for future developments.

Looking ahead, the integration of advanced materials and sustainable practices in manufacturing will likely shape the landscape of discharge rubber hoses. To stay competitive, it is essential for businesses to keep abreast of these trends and proactively adjust their sourcing strategies. Engage with your suppliers today to explore how these innovations can benefit your operations and position your business for success in the evolving marketplace.

Illustrative image related to Discharge Rubber Hose

Důležité prohlášení o vyloučení odpovědnosti a podmínky používání

⚠️ Důležité prohlášení o vyloučení odpovědnosti

Informace uvedené v této příručce, včetně obsahu týkajícího se výrobců, technických specifikací a analýzy trhu, mají pouze informativní a vzdělávací charakter. Nepředstavují odborné poradenství v oblasti nákupu, finanční poradenství ani právní poradenství.

Přestože jsme vynaložili veškeré úsilí, abychom zajistili přesnost a aktuálnost informací, neneseme odpovědnost za případné chyby, opomenutí nebo neaktuální informace. Podmínky na trhu, údaje o společnosti a technické normy se mohou změnit.

B2B kupující musí provést vlastní nezávislé a důkladné due diligence. před jakýmkoli rozhodnutím o nákupu. To zahrnuje přímé kontaktování dodavatelů, ověření certifikací, vyžádání vzorků a odborné konzultace. Riziko spoléhání se na jakékoli informace v této příručce nese výhradně čtenář.