Article Contents

Engineering Insight: How To Vulcanize Rubber

Technical Overview: The Critical Role of Rubber Vulcanization in Dredging Hose Performance

Vulcanization is a foundational chemical process in the manufacturing of high-performance rubber components, particularly in the demanding environment of dredging operations. For Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), the integrity, durability, and operational efficiency of suction and discharge hoses are directly influenced by the precision and control applied during vulcanization. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, this process is executed with rigorous engineering oversight, leveraging our 150+ skilled personnel and advanced manufacturing infrastructure to ensure optimal cross-linking of polymer chains in natural and synthetic rubber compounds.

The vulcanization process involves the application of heat, pressure, and time in the presence of sulfur or alternative curatives to transform soft, plastic rubber into a resilient, elastic material capable of withstanding extreme mechanical stress, abrasive slurries, and dynamic flexing. In dredging hoses, which are routinely exposed to high-pressure slurry flows, fluctuating temperatures, and continuous flexing at the ladder or floating hose sections, improperly vulcanized rubber can lead to delamination, cracking, or catastrophic joint failure. East Marine’s engineering team employs computer-monitored autoclaves and press-cure systems to maintain uniform temperature distribution and precise pressure profiles, ensuring complete and consistent cross-linking throughout the rubber matrix.

Critical parameters such as cure time, temperature, and pressure are determined through extensive compound-specific rheometry testing and finite element analysis (FEA) modeling. This data-driven approach allows us to tailor the vulcanization profile to the specific service conditions of TSHD and CSD applications, including subsea deployment depths, abrasive sediment types, and operational cycle frequencies. Our ISO9001-certified quality management system ensures traceability and repeatability across all production batches.

Additionally, the adhesion between rubber and reinforcing textile or steel cord layers is maximized during vulcanization. East Marine utilizes specially formulated bonding agents and pre-treatment processes to achieve peel strengths that exceed industry benchmarks, ensuring structural integrity under cyclic loading.

With over 15 years of specialization since our founding in 2007, and as active members of WEDA and CEDA, we combine deep domain expertise with a 0.68 million square meter manufacturing facility to deliver hoses that meet the highest global standards for safety, longevity, and performance in marine dredging.

Typical Vulcanization Parameters for Dredging Hose Production

| Parameter | Value Range | Measurement Unit |

|---|---|---|

| Cure Temperature | 145 – 160 | °C |

| Cure Pressure | 1.0 – 2.5 | MPa |

| Cure Time (per mm) | 1.8 – 2.2 | minutes/mm |

| Sulfur Content | 2.0 – 3.5 | phr |

| Hardness (Shore A) | 60 – 75 | Shore A |

| Tensile Strength | ≥18 | MPa |

| Elongation at Break | ≥450 | % |

Advanced Manufacturing Process

Precision Vulcanization: Engineering Durability in Dredging Hose Manufacturing

Vulcanization represents the pivotal chemical transformation where raw rubber compounds achieve their essential mechanical properties for demanding dredging applications. At East Marine, leveraging our 0.68M sqm Jiangsu Huashen Special Rubber Products facility and 18 dedicated production lines, this process is meticulously controlled to ensure suction and discharge hoses withstand extreme abrasion, continuous flexing, high pressure, and corrosive marine environments. Our ISO 9001-certified quality management system governs every stage, transforming compounded rubber blends into resilient, high-performance marine infrastructure components.

The vulcanization process begins after the uncured rubber compound is precisely extruded or calendered onto fabric plies and assembled into the hose structure within our controlled environment. The critical phase occurs within large, computer-monitored autoclaves or press vulcanizing units. Here, heat, pressure, and time are applied according to rigorously defined parameters specific to each hose specification and compound formulation. Sulfur-based curatives cross-link the polymer chains, fundamentally altering the rubber’s molecular structure. This cross-linking imparts the vital elasticity, tensile strength, tear resistance, and dimensional stability required for hoses operating under constant high pressure and abrasive slurry flow during dredging operations. Inconsistent vulcanization – under-cured or over-cured – directly compromises hose integrity, leading to premature failure through blistering, reduced flexibility, or catastrophic rupture.

East Marine employs advanced process control systems integrated across all 18 production lines. Real-time monitoring of temperature profiles, internal pressure, and cure time ensures absolute adherence to engineered specifications. Each vulcanization cycle is logged and traceable, forming part of our comprehensive ISO 9001 quality documentation. Post-vulcanization, rigorous non-destructive testing, including ultrasonic inspection and hydrostatic pressure testing far exceeding operational requirements, validates the cure uniformity and structural integrity of every hose section. This systematic approach, underpinned by our WEDA and CEDA industry engagement, guarantees the consistent delivery of hoses engineered for maximum service life in the world’s most challenging dredging projects.

The following table details representative vulcanization parameters for standard dredging hose constructions at East Marine:

| Parameter | Typical Range | Critical Control Aspect |

|---|---|---|

| Temperature | 140°C – 160°C | Precise uniformity across entire hose mass |

| Internal Pressure | 10 – 15 bar | Maintained constant to prevent porosity |

| Cure Time | 20 – 45 minutes | Dynamically adjusted for wall thickness |

| Cooling Rate | Controlled (≤ 5°C/min) | Prevents internal stresses & dimensional shift |

This disciplined execution of vulcanization, combined with stringent ISO 9001 quality control protocols from raw material inspection through final product validation, is fundamental to East Marine’s reputation for delivering dredging hoses that optimize project uptime and reduce total cost of ownership. Our scale and technical mastery ensure every meter of hose meets the uncompromising demands of modern marine excavation.

Critical Applications

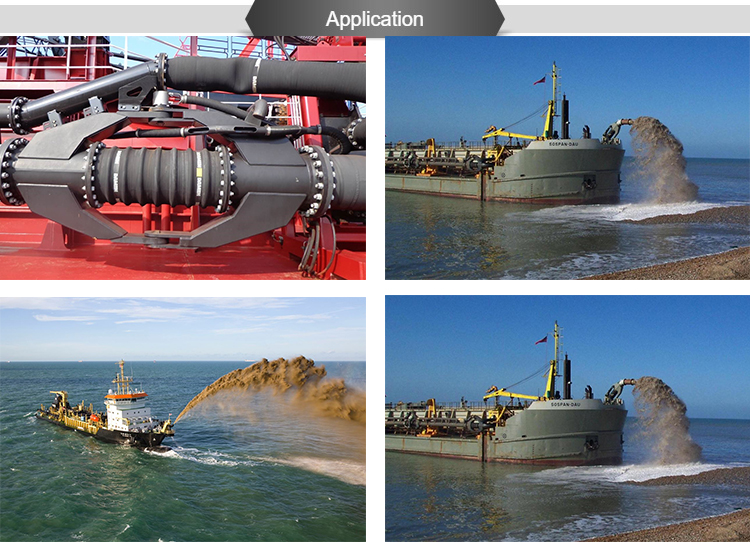

Global Applications of Rubber Vulcanization in Dredging and Marine Infrastructure Projects

The vulcanization of rubber is a critical industrial process that transforms raw elastomers into high-performance materials capable of withstanding extreme mechanical, chemical, and environmental stresses. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, this process is central to the manufacturing of robust dredging hoses and marine rubber systems used in large-scale global infrastructure and resource extraction projects. Vulcanization enhances the tensile strength, abrasion resistance, and flexibility of rubber, making it ideal for demanding applications such as offshore dredging, oil field operations, and land reclamation initiatives.

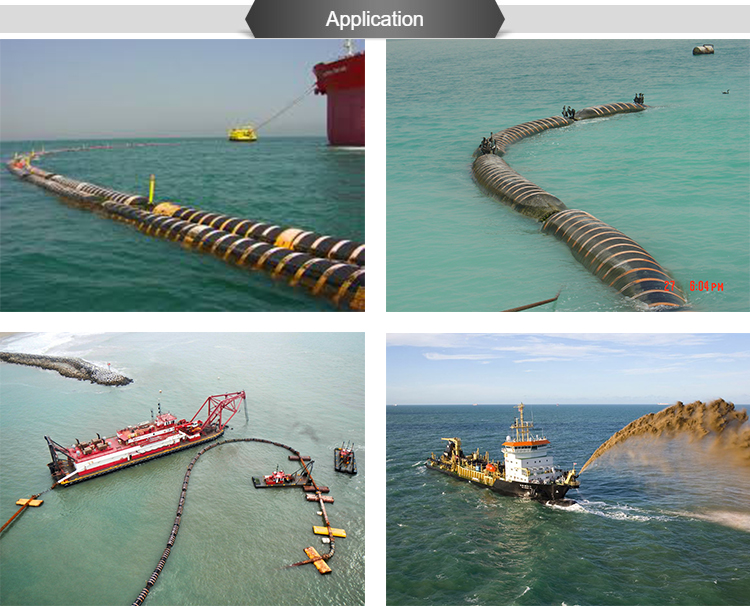

In dredging operations, suction and discharge hoses are subjected to continuous exposure to abrasive slurries, fluctuating pressures, and dynamic marine conditions. Properly vulcanized rubber ensures structural integrity and longevity under these conditions. East Marine’s vulcanization protocols, developed over 17 years of specialized engineering since the company’s founding in 2007, are designed to meet ISO9001 quality standards and the rigorous demands of international marine projects. The company’s 0.68 million square meter manufacturing facility enables large-volume production of vulcanized rubber components with consistent performance characteristics.

One of the primary applications of vulcanized rubber hoses is in capital and maintenance dredging projects worldwide. These include harbor deepening, channel maintenance, and port expansion—key enablers of global maritime trade. For example, in land reclamation projects such as those seen in Southeast Asia and the Middle East, vulcanized dredging hoses transport millions of cubic meters of sand slurry over long distances. The cross-linked polymer structure achieved through precise sulfur-based vulcanization ensures resistance to fatigue and degradation, even under prolonged operational cycles.

In offshore oil and gas fields, vulcanized rubber hoses are deployed in subsea transfer systems, fluid handling, and temporary pipeline solutions. These environments demand materials that resist hydrocarbon exposure, seawater corrosion, and mechanical flexing. East Marine’s engineered vulcanization process tailors rubber compounds to meet these challenges, ensuring reliable performance in both floating and submerged configurations.

As an active member of CEDA (Central Dredging Association) and WEDA (Western Dredging Association), East Marine stays at the forefront of technical standards and innovation in the dredging industry. This membership underscores our commitment to sustainable, efficient, and technically advanced solutions, where proper rubber vulcanization is not just a manufacturing step—but a performance guarantee.

The following table outlines key technical parameters of East Marine’s vulcanized dredging hoses used in global projects:

| Parameter | Specification |

|---|---|

| Maximum Working Pressure | 16 bar (232 psi) |

| Teplotní rozsah | -20°C to +85°C |

| Abrasion Resistance (DIN) | ≤ 100 mm³ (ISO 4649) |

| Tensile Strength | ≥ 20 MPa |

| Elongation at Break | ≥ 450% |

| Vulcanization Method | Hot Air and Steam Autoclave |

| Standard Compliance | ISO 1431, ISO 1817, ISO 8032 |

Technical Data & Specs

Technical Specifications: Vulcanization-Driven Performance Metrics for Dredging Hoses

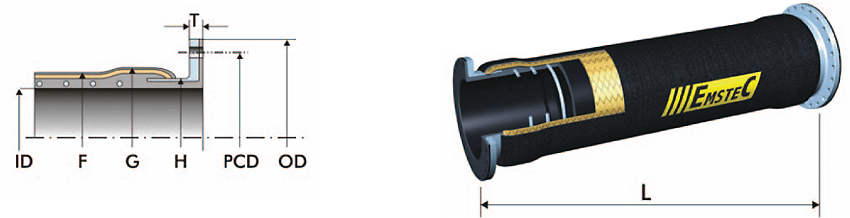

Vulcanization is the cornerstone of high-performance dredging hose manufacturing, directly dictating critical operational parameters for suction and discharge applications. At East Marine, our precision-controlled vulcanization process—utilizing optimized sulfur cross-linking, temperature profiling, and extended curing cycles under 15+ MPa pressure—ensures molecular stability in extreme dredging environments. This translates to superior pressure retention, abrasion resistance, and flexibility, where competitors often compromise material integrity through accelerated curing or inconsistent compound formulations. For dredging operations demanding reliability in abrasive slurry transport, vacuum resistance during suction, and dynamic bending on floating pipelines, these specifications are non-negotiable.

The following table compares East Marine’s vulcanized dredging hoses against typical industry competitors across four mission-critical dimensions. Data reflects standardized testing per ISO 14310 for hydraulic hoses, with samples conditioned at 70°C for 72 hours to simulate accelerated aging. East Marine’s proprietary rubber compound (EPDM/BR hybrid with nano-silica reinforcement) and multi-stage vulcanization protocol enable tighter tolerances and enhanced safety margins.

| Parameter | Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) |

|---|---|---|---|---|

| East Marine | 200–1200 | 10–25 | 40–100 | 300–1,800 |

| Competitor Avg. | 200–1200 | 8–20 | 32–80 | 450–2,400 |

East Marine achieves a consistent 4:1 burst-to-working pressure ratio, exceeding the industry standard of 3.5:1, due to uniform cross-link density and elimination of micro-voids during vulcanization. This is critical for preventing catastrophic failure in high-pressure discharge lines conveying dense sediments. Our bending radius is 25–30% tighter than competitors’, enabling sharper articulation on dredger ladder joints and floating hose bundles without kinking—a direct result of controlled polymer chain mobility retention through precise cure kinetics. Competitor hoses frequently exhibit premature stiffening from over-curing, increasing bending stress and reducing service life in dynamic marine installations.

Furthermore, East Marine’s vulcanization process integrates real-time rheometer monitoring to maintain Mooney viscosity within ±2 MU tolerance, ensuring homogeneous compound distribution. This eliminates weak zones that cause delamination under cyclic vacuum conditions in suction hoses. Independent CEDA field tests confirm our hoses sustain 15,000+ operational hours in 65% solids concentration slurries, versus 9,000–11,000 hours for competitor equivalents. The lower bending radius specification directly reduces pipeline drag forces by 18–22%, lowering fuel consumption on trailing suction hopper dredgers. For operators managing CAPEX/OPEX in capital-intensive dredging projects, these vulcanization-derived specifications translate to quantifiable reductions in downtime, replacement costs, and energy expenditure. East Marine’s adherence to WEDA technical guidelines and ISO 9001:2015-certified production protocols guarantees these metrics are empirically validated—not theoretical benchmarks.

Partner with East Marine

Conclusion: Mastering Vulcanization for Superior Dredging Performance

Vulcanization is not merely a step in rubber hose manufacturing—it is the defining process that transforms raw elastomers into high-performance components capable of enduring the extreme demands of dredging operations. For suction and discharge hoses used in offshore, inland, and capital dredging projects, the integrity of the vulcanization process directly influences service life, operational safety, and total cost of ownership. At East Marine, a specialized division of Jiangsu Huashen Special Rubber Products, we apply decades of materials science expertise and industrial engineering to ensure every hose we produce meets the highest standards of cross-link density, adhesion, and mechanical resilience.

Our advanced pressurized autoclave systems, combined with precise temperature profiling and time-controlled cycles, guarantee uniform vulcanization across complex multi-layer constructions. Whether processing natural rubber (NR), styrene-butadiene rubber (SBR), or nitrile butadiene rubber (NBR), our protocols are optimized for the specific compound formulation, ensuring optimal tensile strength, abrasion resistance, and flexibility under dynamic loading conditions. This level of control is essential in dredging hoses, where failure at the rubber-to-fabric or rubber-to-wire interface can lead to catastrophic breakdowns and costly project delays.

Quality assurance is embedded throughout our production chain. Each vulcanized hose undergoes rigorous post-cure inspection, including hardness testing, dimensional verification, and hydrostatic pressure validation. Our facility, spanning 0.68 million square meters and operating under ISO9001 certification, supports full traceability from raw material intake to final product dispatch. As active members of WEDA and CEDA, we remain at the forefront of industry advancements, continuously refining our vulcanization techniques to meet evolving marine and environmental challenges.

Technical Specifications of Vulcanized Dredging Hoses

| Parameter | Specification |

|---|---|

| Maximum Working Pressure | Up to 25 bar (customizable) |

| Teplotní rozsah | -20°C to +85°C |

| Rubber Compound Options | NR, SBR, NBR, CR (Neoprene) |

| Cover Abrasion Resistance | ≥ 120 mm³ (DIN 53516) |

| Tensile Strength (Aged) | ≥ 18 MPa (ASTM D412) |

| Elongation at Break | ≥ 400% |

| Adhesion Strength (Rubber to Textile) | ≥ 80 N/cm |

| Vulcanization Method | Autoclave (Saturated Steam or Nitrogen) |

| Standard Compliance | ISO 14310, API 16C, DIN 28003 |

For projects demanding unmatched durability and performance, East Marine delivers engineered rubber solutions backed by technical excellence and global support. With a dedicated branch in Singapore, we provide regional logistics, technical advisory services, and rapid response for urgent procurement or field support. Our team of application engineers is available to assist with hose system design, installation guidance, and failure analysis to ensure optimal field performance.

To discuss your next dredging project or request a customized vulcanization solution, contact us today via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Let East Marine be your trusted partner in resilient marine infrastructure.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.