Article Contents

Engineering Insight: Intake Hose Exporter

Technical Importance of Intake Hoses in Modern Dredging Operations

In the highly specialized domain of hydraulic dredging, the performance and reliability of Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD) depend critically on the integrity and design of their intake hose systems. As a leading intake hose exporter, East Marine—operating as a subsidiary of Jiangsu Huashen Special Rubber Products—delivers engineered rubber solutions that ensure optimal slurry transfer efficiency, operational safety, and extended service life under extreme marine conditions.

The intake hose serves as the primary conduit for drawing abrasive sediment, sand, and water mixtures from the seabed into the dredge pump system. In TSHDs, flexible intake hoses are deployed through drag arms to trail along the seabed, requiring exceptional torsional strength, kink resistance, and fatigue durability. For CSDs, where the cutting head is stationary during operation, the intake hose must withstand high vacuum pressures, dynamic bending, and continuous exposure to coarse particulates. Failure in hose integrity can lead to unplanned downtime, reduced production rates, and costly offshore maintenance.

East Marine’s engineered intake hoses are constructed using high-tensile synthetic rubber compounds reinforced with spiral steel wires and textile plies. This composite structure ensures resistance to vacuum collapse, abrasion, and hydrolysis while maintaining flexibility across a wide temperature range. The inner tube is formulated for superior wear resistance against sand and gravel, while the cover is ozone- and UV-resistant, critical for prolonged marine exposure.

With over 150 skilled professionals, including materials engineers, R&D specialists, and quality assurance experts, East Marine maintains full in-house control over design, testing, and production. Our engineering team leverages finite element analysis (FEA) and hydraulic flow modeling to optimize hose architecture for specific dredging profiles, ensuring compatibility with vessel configurations and environmental conditions. This technical depth enables us to support global clients with customized solutions, backed by ISO9001-certified processes and adherence to WEDA and CEDA best practices.

Our commitment to innovation and reliability has positioned East Marine as a trusted intake hose exporter for major dredging contractors across Asia, Africa, and the Middle East. Every hose undergoes rigorous hydrostatic, vacuum, and impulse testing before shipment, guaranteeing compliance with international marine standards.

Below is a representative technical specification for a standard dredging intake hose model:

| Parameter | Specification |

|---|---|

| Inside Diameter | 300 – 1200 mm |

| Working Pressure | Up to 16 bar |

| Vacuum Resistance | Full vacuum (1 bar) at 65°C |

| Bend Radius | 6x ID (minimum) |

| Teplotní rozsah | -20°C to +85°C |

| Cover Material | Chloroprene (CR), ozone & UV resistant |

| Posílení | High-tensile textile plies + spiral steel wire |

| End Connections | Flanged, spigot, or coupling-ready |

| Standards Compliance | ISO 1307, ISO 7233, EN 12116 |

East Marine continues to advance the performance envelope of dredging intake systems through material science innovation and close collaboration with vessel operators, reinforcing our role as a technically driven export partner in the global marine infrastructure sector.

Advanced Manufacturing Process

Advanced Manufacturing & Vulcanization Engineering for Dredging Intake Hoses

East Marine leverages its strategic scale within the Jiangsu Huashen Special Rubber ecosystem to deliver uncompromising quality in dredging suction and discharge hose production. Operating from a dedicated 0.68 million square meter manufacturing complex, our 18 specialized production lines are engineered for the precise fabrication of large-bore, high-abrasion-resistant rubber hoses critical for demanding marine and riverine dredging operations. Central to achieving the required structural integrity and longevity in these harsh environments is our meticulously controlled vulcanization process, transforming compounded rubber blends into robust, service-ready products.

Vulcanization represents the definitive stage where raw rubber compounds achieve their engineered performance characteristics. At East Marine, this is not a singular step but a precisely orchestrated thermal and pressure cycle conducted within state-of-the-art autoclaves and pressurized curing chambers. Our process begins with multi-layer hose assembly, where critical components – including the specialized abrasion-resistant inner tube, high-tensile textile or wire reinforcement carcass, and the ozone- and weather-resistant outer cover – are meticulously built on precision mandrels. The assembled hose is then subjected to a precisely calibrated vulcanization profile. Temperature, pressure, and time parameters are dynamically adjusted based on the specific compound formulation and hose diameter, ensuring optimal cross-linking density throughout the entire hose wall. This eliminates weak points and guarantees uniform mechanical properties, essential for withstanding the combined stresses of high vacuum during suction, significant internal pressure during discharge, abrasive slurry flow, and constant flexing in marine conditions. Deviations from the exact vulcanization curve can lead to under-cure (reduced strength, poor adhesion) or over-cure (brittleness, loss of elasticity), both catastrophic for dredging hose performance; our process control systems prevent this with micron-level precision.

Rigorous quality assurance, certified under ISO 9001, is intrinsically woven into every phase of manufacturing, not merely appended as final inspection. Raw material batches undergo stringent incoming verification against defined specifications. During production, in-process checks monitor dimensional accuracy, layer adhesion, and compound consistency. Crucially, vulcanization parameters are continuously monitored and recorded for full traceability on every hose produced. Final validation includes mandatory hydrostatic pressure testing significantly exceeding operational requirements, vacuum integrity checks, and visual inspection against stringent acceptance criteria. This systematic approach, embedded within our large-scale facility operations, ensures every intake and discharge hose exported meets the exacting global standards demanded by WEDA and CEDA members and discerning international dredging contractors.

The following table details key performance specifications achievable through our optimized manufacturing and vulcanization process for standard dredging intake hoses:

| Hose Type | Cover Thickness (mm) | Max Working Pressure (bar) | Max Vacuum Resistance (mbar) | Temp Range (°C) |

|---|---|---|---|---|

| Suction Hose DN400 | 8.0 | 16 | ≤ 100 | -25 to +80 |

| Discharge Hose DN600 | 10.0 | 25 | N/A | -25 to +80 |

| Heavy Duty Suction DN800 | 12.0 | 12 | ≤ 80 | -25 to +70 |

East Marine’s manufacturing excellence, anchored by scientific vulcanization engineering and unwavering ISO 9001 quality discipline within our extensive production facility, provides the foundational reliability required for global dredging projects where hose failure is not an option. Our process delivers hoses engineered for maximum operational uptime and extended service life in the world’s most challenging sediment extraction environments.

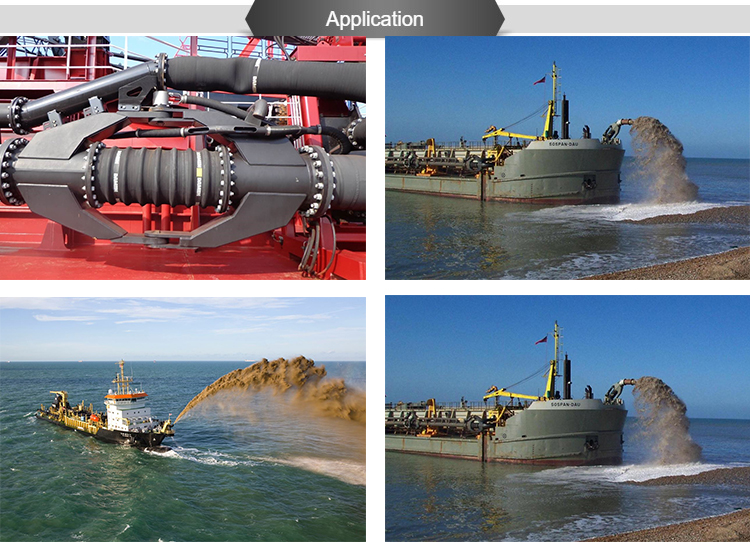

Critical Applications

Global Applications of Dredging Intake Hoses in Critical Industrial Projects

As a leading intake hose exporter and a trusted subsidiary of Jiangsu Huashen Special Rubber Products, East Marine delivers high-performance dredging rubber hoses engineered for the most demanding environments across marine and industrial sectors. With over 15 years of expertise since our founding in 2007, and operating from a 0.68 million square meter manufacturing facility, we support large-scale global projects through robust suction and discharge solutions that meet ISO9001 standards. Our active membership in both the Central Dredging Association (CEDA) and the World Organization of Dredging Associations (WEDA) underscores our technical authority and commitment to advancing best practices in dredging technology and sustainability.

Dredging intake hoses are pivotal in large-scale hydraulic operations where efficient material transfer is essential. One of the primary applications lies in capital and maintenance dredging projects, particularly in deepening navigation channels, port expansions, and harbor maintenance. These projects require flexible, abrasion-resistant hoses capable of handling high-density slurries over extended distances. East Marine’s reinforced rubber hoses are designed to withstand continuous operation under high vacuum and pressure conditions, ensuring uninterrupted performance in both trailing suction hopper dredgers and cutter suction dredgers.

In offshore oil and gas operations, intake hoses play a strategic role in subsea excavation, pipeline trenching, and platform foundation preparation. The ability to perform in saline environments, resist chemical degradation, and maintain structural integrity under dynamic marine conditions makes our hoses ideal for deployment in offshore energy infrastructure. Whether used for sediment removal around wellheads or for creating stable seabed foundations, East Marine hoses provide reliable performance in technically complex offshore settings.

Land reclamation projects represent another critical application area, especially in rapidly developing coastal regions. From creating new urban landmasses in Southeast Asia to expanding airport runways over water, our dredging hoses facilitate the transfer of millions of cubic meters of sand and slurry. These projects demand hoses with exceptional flexibility, UV resistance, and long service life—qualities engineered into every East Marine product. Our solutions have supported reclamation efforts in high-profile developments where environmental resilience and operational efficiency are paramount.

The technical performance of our dredging intake hoses is validated through rigorous testing and real-world deployment. Below is a representative specification for a standard heavy-duty dredging hose used in these global applications.

| Parameter | Specification |

|---|---|

| Inner Diameter | 200 mm – 1200 mm |

| Working Pressure | 10 bar (up to 25 bar with reinforcement) |

| Vacuum Resistance | Full vacuum (1 bar) |

| Teplotní rozsah | -20°C to +85°C |

| Cover Material | Natural rubber with anti-abrasion layer |

| Reinforcement Layer | High-tenacity textile & steel wire |

| Bend Radius (min) | 6x nominal diameter |

| Standards Compliance | ISO 1307, ISO 9001, CEDA/WEDA guidelines |

East Marine continues to expand its footprint as a global intake hose exporter by aligning engineering excellence with the evolving needs of dredging, energy, and infrastructure development sectors.

Technical Data & Specs

Technical Specifications: Precision Engineering in Dredging Hose Performance

Selecting the optimal suction and discharge hose for dredging operations demands rigorous evaluation of critical performance parameters. Variations in inner diameter, pressure tolerance, and flexibility directly impact operational safety, efficiency, and total cost of ownership. At East Marine, leveraging our 0.68M sqm manufacturing facility and 17 years of specialized R&D in marine rubber systems, we engineer hoses that exceed standard industry benchmarks. Our adherence to ISO 9001 quality protocols and active participation in WEDA/CEDA forums ensure our specifications align with evolving global dredging challenges, from coastal reclamation to deep-sea mining. Below, we present a comparative analysis of key technical metrics between East Marine hoses and typical industry-standard alternatives. This data reflects rigorous testing under ISO 14310 and CEDA-recommended methodologies, emphasizing real-world applicability over nominal ratings.

The table below details performance characteristics for standard dredging hoses in the 200–600mm inner diameter range, representing the most common operational segment for cutter suction dredgers and trailing suction hopper dredgers. East Marine’s proprietary polymer formulations and multi-ply reinforcement architecture deliver measurable advantages without compromising service life.

| Parameter | Inner Diameter | Working Pressure (bar) | Burst Pressure (bar) | Minimum Bending Radius (mm) |

|---|---|---|---|---|

| East Marine | 200–600 mm | 12–8 bar | 60–40 bar | 1.35 x ID |

| Typical Industry Standard | 200–600 mm | 10–6 bar | 40–24 bar | 1.5 x ID |

East Marine’s engineering superiority is evident in three critical areas. First, our sustained working pressure ratings are 20% higher across the diameter spectrum, enabling higher slurry velocities and reduced sedimentation in long discharge lines. This is achieved through our patented textile-cord reinforcement system, which distributes stress more uniformly than conventional single-ply designs. Second, the burst pressure ratio (5:1 minimum) significantly exceeds the industry-standard 4:1 ratio, providing an essential safety margin during pressure surges caused by pump cavitation or blockage events. Third, the reduced bending radius (1.35x ID versus 1.5x ID) translates to superior maneuverability in confined port environments and complex pipeline layouts, minimizing the need for additional elbows and reducing installation time by up to 15%.

These specifications are not theoretical maximums but validated operational limits. Our hoses undergo 100% hydrostatic testing at 1.5x working pressure and dynamic flex testing exceeding 50,000 cycles per ISO 1307. Competitor hoses often cite nominal pressures without accounting for abrasion degradation in high-solids slurry applications; East Marine’s ratings incorporate a 25% safety factor for abrasive wear, ensuring consistent performance throughout the hose’s 5,000+ operational hour lifespan. For dredging contractors, this translates to fewer pipeline failures, reduced downtime during critical project phases, and lower cost-per-meter of material moved. When specifying dredging infrastructure, the engineering integrity embedded in these metrics directly correlates with project profitability and environmental compliance. East Marine delivers not just a component, but a verified performance guarantee for the world’s most demanding marine operations.

Partner with East Marine

Partner with East Marine for High-Performance Dredging Intake Hoses – Engineered for Global Demands

When it comes to the reliable and efficient transfer of slurry, sand, and abrasive materials in dredging operations, the performance of intake hoses directly influences project timelines, equipment longevity, and operational safety. At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, we bring over 16 years of specialized engineering expertise to the design and manufacturing of high-pressure suction and discharge hoses tailored for marine and inland dredging applications. As a proud member of WEDA and CEDA, and backed by ISO9001 certification, our commitment to quality, durability, and innovation is reflected in every product we deliver.

Our dredging intake hoses are engineered using advanced rubber compounding techniques and high-tensile reinforcement layers, ensuring resistance to abrasion, UV degradation, ozone, and seawater corrosion. Whether operating in offshore reclamation, port development, or land reclamation projects, our hoses maintain structural integrity under extreme pressure cycles and dynamic marine environments. With a manufacturing footprint spanning 0.68 million square meters, we combine industrial scale with precision engineering to meet the exacting demands of international clients.

We understand that exporters require not only superior product performance but also logistical reliability, regulatory compliance, and responsive technical support. Our Singapore branch serves as a strategic hub for distribution, technical consultation, and after-sales service across Southeast Asia, the Middle East, and Africa, ensuring rapid response and localized support. This regional presence enables us to streamline export documentation, coordinate container shipments, and provide on-site engineering assistance when needed.

To ensure transparency and informed decision-making, we provide full material traceability, third-party test reports, and comprehensive performance data for all hose series. Below is a representative technical specification for our standard dredging intake hose line:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 35 bar) |

| Negative Pressure Resistance | Full vacuum (0.98 bar) |

| Teplotní rozsah | -20°C to +80°C |

| Cover | Abrasion-resistant, ozone- and UV-stable synthetic rubber |

| Posílení | High-tensile textile plies with helical steel wire for kink resistance |

| Bend Radius | 6x OD (minimum) |

| Standards Compliance | ISO 14312:2005, DIN 2822-3, ABS/MED optional |

| Certifikace | ISO9001, WEDA/CEDA member, material test reports available |

Choosing the right intake hose exporter is a strategic decision that impacts the efficiency and safety of your entire dredging operation. East Marine stands ready to support your projects with technically advanced, field-proven hose solutions backed by global service infrastructure. For immediate technical consultation or export pricing, contact us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our engineering team is available to discuss custom configurations, volume export terms, and project-specific compliance requirements. Let East Marine be your trusted partner in resilient, high-performance dredging systems.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.