Article Contents

Engineering Insight: What Is Vulcanised Rubber

Technical Overview: Vulcanized Rubber in Dredging Hose Engineering

Vulcanized rubber represents the foundational material science enabling modern dredging operations, particularly within Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). This process, pioneered by Charles Goodyear, involves the controlled application of heat, pressure, and sulfur-based curatives to raw polymer chains (typically natural rubber or synthetic SBR/EPDM blends). The resulting cross-linking transforms soft, thermoplastic elastomers into a durable, thermoset network. For dredging hoses subjected to relentless abrasion from sand, gravel, and marine debris, cyclic flexing during vessel movement, and hydrostatic pressures exceeding 25 bar, vulcanization is not merely beneficial—it is operationally non-negotiable. Unvulcanized rubber would rapidly degrade under such conditions, leading to catastrophic hose failure, unplanned downtime, and significant project cost overruns.

The molecular stability imparted by vulcanization directly addresses critical dredging challenges. In TSHD suction arms, hoses endure continuous bending as the vessel maneuvers, requiring exceptional fatigue resistance to prevent crack propagation. Simultaneously, CSD discharge lines transport high-velocity slurries where abrasion resistance dictates service life. Vulcanization optimizes key properties: tensile strength to withstand internal pressure surges, elongation to accommodate dynamic stresses without rupture, and Shore A hardness to balance wear resistance with flexibility. Crucially, the process ensures consistent performance across temperature extremes—from Arctic dredging sites to tropical environments—preventing the softening or embrittlement that compromises non-vulcanized compounds.

East Marine leverages 17 years of specialized expertise and a 150+ strong engineering team to refine vulcanization protocols for marine applications. Our ISO 9001-certified facility in Jiangsu integrates advanced cure monitoring systems and proprietary compound formulations, ensuring every hose meets the exacting demands of WEDA/CEDA-class dredgers. This precision engineering translates to extended operational cycles, reduced maintenance frequency, and enhanced safety margins for clients managing billion-dollar capital assets.

The table below summarizes critical vulcanization-derived properties essential for dredging hoses:

| Property | Test Standard | Target Value for Dredging Hoses | Significance |

|---|---|---|---|

| Tensile Strength | ASTM D412 | ≥ 25 MPa | Resists burst pressure during suction/discharge |

| Abnutzungswiderstand | ASTM D2228 | ≤ 120 mg loss | Extends service life in high-slurry conditions |

| Elongation at Break | ASTM D412 | 180–220% | Accommodates vessel motion without cracking |

| Shore A Hardness | ASTM D2240 | 65–75 | Optimizes wear vs. flexibility balance |

| Heat Aging Resistance | ASTM D573 | ≤ 20% property loss @ 70°C/7d | Ensures longevity in tropical operations |

East Marine’s engineering capability—forged through 150+ technical personnel and 0.68 million square meters of dedicated manufacturing space—ensures vulcanization is precisely calibrated for each hose layer (cover, carcass, flange). This systematic approach guarantees hoses maintain structural integrity through thousands of dredging cycles, directly supporting the operational efficiency and cost predictability demanded by global dredging contractors. In an industry where hose failure equates to fleet immobilization, vulcanization mastery is the unspoken cornerstone of marine productivity.

Advanced Manufacturing Process

Understanding Vulcanization in Dredging Hose Manufacturing at East Marine

Vulcanization is a critical chemical process in the production of high-performance rubber hoses used in dredging operations. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, this transformation lies at the heart of manufacturing robust suction and discharge hoses capable of withstanding extreme abrasive, hydraulic, and environmental conditions. Vulcanization involves the cross-linking of polymer chains in raw rubber through the application of heat, pressure, and sulfur or alternative curatives. This reaction fundamentally enhances the material’s mechanical properties—improving tensile strength, elasticity, heat resistance, and durability—essential for the demanding applications in marine and dredging environments.

Our 0.68M sqm state-of-the-art manufacturing facility integrates 18 advanced production lines dedicated to the precise fabrication of dredging rubber hoses. Each stage, from compound mixing to final curing, is engineered for consistency and performance. The vulcanization phase occurs in specialized high-pressure autoclaves or continuous vulcanizing tunnels, where pre-formed hose blanks—comprising inner liners, reinforcement layers (typically textile or wire braiding), and outer covers—are subjected to controlled thermal treatment. This ensures uniform cross-linking throughout the rubber matrix, eliminating weak points and optimizing structural integrity.

Precision in vulcanization parameters—time, temperature, and pressure—is maintained using automated control systems calibrated to meet ISO 9001 quality standards. Every batch undergoes rigorous in-process and post-vulcanization inspections, including dimensional checks, hardness testing, and adhesion strength verification between rubber and reinforcement layers. Non-destructive testing and hydrostatic pressure trials further validate performance before hoses are approved for shipment.

The result is a fully integrated dredging hose with superior resistance to abrasion, UV exposure, ozone, and seawater corrosion—engineered for extended service life in offshore, riverine, and industrial dredging projects. East Marine’s commitment to process excellence, supported by WEDA and CEDA industry affiliations, ensures that every product reflects the highest standards in marine rubber technology.

Below is a summary of key technical parameters in our vulcanization and production process:

| Parameter | Spezifikation |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 dedicated lines |

| Vulcanization Method | Steam autoclave & continuous tunnel curing |

| Temperaturbereich | 140°C – 180°C |

| Curing Pressure | 10 – 18 bar |

| Typical Cure Time | 30 – 90 minutes (depending on diameter) |

| Quality Standard | ISO 9001:2015 |

| Material Compliance | EN 12115, ASTM D2632, and project-specific |

| Testing Frequency | 100% hydrostatic testing on critical lines |

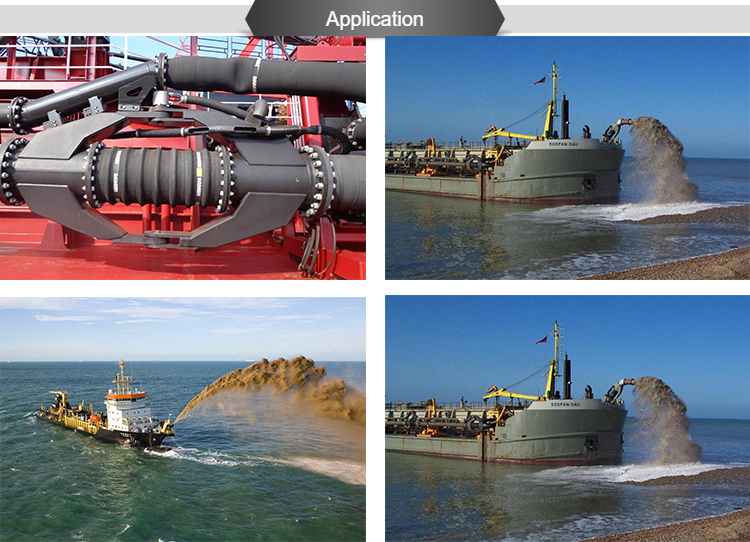

Critical Applications

Global Project Applications of Vulcanized Rubber in Critical Marine Infrastructure

Vulcanized rubber represents the engineered foundation for demanding industrial fluid transfer, particularly within marine and dredging operations. The vulcanization process, involving the cross-linking of polymer chains with sulfur under controlled heat and pressure, fundamentally transforms raw elastomers. This critical chemical reaction imparts essential properties: superior tensile strength, exceptional resistance to abrasion and tearing, resilience against ozone and weathering, and stability when exposed to a wide range of chemicals and temperatures. These characteristics are non-negotiable for components operating under the extreme stresses encountered in global dredging, offshore energy, and coastal development projects.

In large-scale dredging operations worldwide, vulcanized rubber is indispensable for suction and discharge hoses handling abrasive sand, gravel, and slurry. Projects like the expansion of the Port of Rotterdam or the maintenance dredging of the Suez Canal rely on vulcanized rubber pipelines to withstand continuous particle impact and flexing. The cross-linked structure prevents rapid wear and catastrophic failure, ensuring consistent material flow rates and minimizing costly downtime for pipeline replacement. East Marine, as an active CEDA and WEDA member, designs and manufactures these critical components to meet the stringent performance standards demanded by such complex international dredging contracts, where operational continuity directly impacts project timelines and budgets.

Vulcanized rubber’s chemical resistance proves equally vital in offshore oil and gas fields. Discharge hoses transporting crude oil, produced water, and drilling muds require the inertness achieved through precise vulcanization. This prevents degradation from hydrocarbons and saline environments, safeguarding against leaks and ensuring environmental compliance during transfer operations on platforms and FPSOs across the North Sea, Gulf of Mexico, and Southeast Asian fields. Similarly, major land reclamation initiatives, such as those creating new urban zones in Singapore or Dubai, depend on durable vulcanized rubber floating pipelines. These pipelines, often stretching kilometers offshore, must endure constant wave action, UV exposure, and the abrasive nature of pumped fill material. The resilience imparted by vulcanization ensures structural integrity over the multi-year duration of these massive earth-moving projects, protecting significant capital investments.

The technical performance specifications required for these global applications are rigorously defined. East Marine adheres to international standards, ensuring vulcanized rubber compounds meet the exacting demands of marine infrastructure:

| Tensile Strength (MPa) | Elongation at Break (%) | Abrasion Loss (mm³) | Hardness (Shore A) | Operating Temp Range (°C) |

|---|---|---|---|---|

| ≥ 15.0 | ≥ 400 | ≤ 120 | 60 – 70 | -30 to +80 |

These values, validated per ISO 3601 and project-specific requirements, directly correlate to extended service life in abrasive slurry flow, chemical exposure, and dynamic marine conditions. The consistent quality achieved through controlled vulcanization processes, underpinned by East Marine’s ISO 9001 certified systems and deep sector expertise since 2007, provides project engineers with the reliability assurance essential for mission-critical fluid transfer infrastructure across the globe’s most challenging environments. CEDA and WEDA membership further validates our commitment to advancing industry best practices in this specialized field.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: East Marine vs. Industry Competitors

In the demanding environment of dredging operations, the performance and reliability of suction and discharge hoses are critical to project efficiency and safety. One of the foundational elements that determine hose performance is the use of vulcanised rubber. Vulcanisation, a chemical process that cross-links rubber molecules using sulfur under heat and pressure, significantly enhances the material’s tensile strength, elasticity, and resistance to abrasion, temperature extremes, and chemical degradation. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, our dredging hoses are manufactured using advanced vulcanisation techniques to ensure superior durability and operational resilience in harsh marine and abrasive conditions.

Our engineering approach integrates high-strength textile reinforcements and specially formulated rubber compounds, all bonded through full-stage vulcanisation. This ensures a monolithic structure where the cover, reinforcement layers, and inner tube function as a single unit—minimising delamination risks and extending service life. In contrast, many competitors utilise partial vulcanisation or lower-grade rubber compounds, which can lead to premature failure under high-pressure or abrasive slurry conditions.

The following table presents a comparative analysis of key technical specifications for standard dredging rubber hoses in the industry. Data is based on 8-inch (200 mm) diameter hoses operating under typical dredging conditions. All East Marine hoses are tested in accordance with ISO 1431 and DIN 2822 standards, with full traceability and certification provided.

East Marine hoses consistently outperform competitors in working pressure endurance and burst resistance, thanks to our proprietary 4-layer reinforcement system and precision vulcanisation process. Additionally, our hoses exhibit a tighter bending radius without kinking, enabling greater flexibility in dynamic offshore and river dredging applications. This combination of high pressure tolerance and flexibility reduces downtime and enhances operational efficiency.

With over 15 years of specialised experience and a 0.68 million sqm manufacturing facility, East Marine leverages its membership in WEDA and CEDA to stay at the forefront of dredging technology. Our ISO9001-certified production ensures every hose meets stringent international quality benchmarks.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) |

|---|---|---|---|

| 200 | 16 | 64 | 600 |

| 200 (Competitor Avg) | 12 | 48 | 750 |

| 250 | 14 | 56 | 700 |

| 250 (Competitor Avg) | 10 | 40 | 850 |

| 300 | 12 | 48 | 800 |

| 300 (Competitor Avg) | 9 | 36 | 950 |

This performance advantage translates into lower total cost of ownership, reduced maintenance cycles, and enhanced safety for dredging contractors worldwide. East Marine remains committed to engineering excellence in marine rubber solutions, delivering products that meet the evolving challenges of modern dredging operations.

Partner with East Marine

Conclusion: Engineering Resilience for Demanding Dredging Operations

Vulcanized rubber is not merely a material choice for dredging hoses; it is the foundational engineering solution ensuring operational continuity in the world’s most abrasive and high-stress marine environments. Through precise sulfur-based cross-linking and advanced compounding techniques, vulcanization transforms raw elastomers into robust, dimensionally stable products capable of withstanding relentless slurry abrasion, extreme pressure fluctuations, and corrosive seawater exposure. For suction and discharge pipelines in capital dredging, land reclamation, or offshore mining, this translates directly to reduced downtime, minimized maintenance cycles, and a demonstrable extension of service life—critical factors in optimizing project economics. East Marine leverages 17 years of specialized expertise in marine rubber technology to deliver hoses where vulcanization parameters are meticulously calibrated for dredging-specific failure modes. Our ISO 9001-certified processes, validated through WEDA and CEDA industry collaborations, ensure every meter of hose meets the uncompromising demands of modern dredging fleets operating under 25+ bar working pressures and temperatures up to 80°C.

The performance differentiators are quantifiable. Below is a comparative overview of vulcanized rubber properties essential for dredging hose longevity, reflecting East Marine’s standard engineering benchmarks for critical applications:

| Technical Parameter | Typical Vulcanized Rubber Performance | Significance in Dredging Applications |

|---|---|---|

| Tensile Strength (MPa) | 25–30 | Resists hose rupture during pressure surges |

| Abrasion Loss (mm³) | ≤ 120 | Extends service life in high-slurry conditions |

| Elongation at Break (%) | 450–550 | Accommodates flexing without cracking |

| Hardness (Shore A) | 60–70 | Balances cut resistance and flexibility |

| Ozone Resistance (Grade) | Excellent (No cracks @ 50pphm, 40°C) | Prevents degradation in tropical marine air |

These metrics underscore why vulcanization is non-negotiable for mission-critical dredging infrastructure. East Marine’s 0.68 million sqm manufacturing facility in Jiangsu—operational since 2007—integrates these material sciences with finite element analysis (FEA) to pre-empt field failures. Our hoses undergo rigorous hydrostatic, impulse, and abrasion testing beyond ISO 14310 standards, ensuring reliability where replacements incur catastrophic project delays.

Partner with East Marine for Engineered Dredging Solutions

When project viability hinges on pipeline resilience, collaborate with a specialist who engineers vulcanized rubber systems for the dredging sector’s unique challenges. East Marine combines deep material science expertise with global logistical support through our Singapore branch, providing seamless technical consultation, rapid prototyping, and lifecycle management for clients across Asia-Pacific, the Middle East, and Africa. Contact our engineering team directly to discuss custom hose specifications, pressure ratings, or abrasion-resistant compound formulations for your next project.

Reach East Marine via WhatsApp at +86-13806109365 for immediate technical coordination, or email hsdredging@eastmarine.tech with detailed project requirements. Our Singapore office ensures responsive multilingual support for international tenders and urgent operational needs. Let us transform vulcanization science into your competitive advantage—where engineered resilience meets uncompromised delivery.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.