Article Contents

Engineering Insight: How Is Oil Distributed

Technical Overview: How Is Oil Distributed in Offshore Marine Operations

The distribution of crude oil and refined petroleum products in offshore environments is a highly engineered process that demands precision, safety, and compliance with international standards. In marine logistics, oil is primarily distributed through three critical systems: Ship-to-Ship (STS) transfer, Floating Production Storage and Offloading (FPSO) units, and Single Point Mooring (SPM) systems. Each of these operations relies heavily on high-performance offshore marine hoses that meet stringent regulatory frameworks such as OCIMF (Oil Companies International Marine Forum) and GMPHOM (General Marine Products Hoses Organization Manual) guidelines.

Ship-to-Ship transfer involves the direct transfer of oil between two vessels while moored alongside each other, typically conducted at sea or in sheltered waters. This method is widely used for lightering, cargo balancing, or avoiding port congestion. The success of STS operations hinges on the use of dynamically rated marine hoses capable of withstanding vessel movement, wave action, and varying pressure conditions. East Marine, with its 150+ skilled personnel and dedicated engineering team, designs and manufactures STS-compliant hose strings that ensure leak-free performance under extreme operational loads.

FPSO systems serve as mobile production and storage units stationed in deepwater oil fields. These vessels receive oil from subsea wells, process it onboard, and store it until it can be offloaded to shuttle tankers. The offloading phase requires robust marine loading arms or flexible hose systems that accommodate the relative motion between the FPSO and the tanker. East Marine’s offshore floating hoses are specifically engineered for such dynamic environments, featuring reinforced elastomeric layers, high-tensile textile braiding, and UV-resistant covers to ensure long service life in harsh marine conditions.

Single Point Mooring systems allow tankers to moor to a fixed or turret-moored buoy connected to subsea pipelines. SPMs enable safe oil transfer in open seas where traditional port infrastructure is unavailable. The hose string in an SPM setup must endure constant flexing, tidal variations, and exposure to saltwater. East Marine’s SPM hose solutions are designed to OCIMF MEG4 standards, incorporating swivel joints, buoyancy modules, and integrated monitoring systems to enhance operational safety and reliability.

All East Marine hose systems are developed in compliance with ISO 9001 quality management standards and supported by in-house finite element analysis (FEA), pressure cycling tests, and full-scale prototype validation. Our engineering team leverages 17+ years of domain expertise since the company’s founding in 2007 to deliver customized solutions for complex offshore distribution challenges.

The following table summarizes key technical specifications of East Marine’s standard offshore marine hose offerings:

| Parameter | STS Transfer Hose | FPSO Offloading Hose | SPM Mooring Hose |

|---|---|---|---|

| Diameter Range | 6″ – 16″ | 8″ – 20″ | 6″ – 16″ |

| Working Pressure | 15–25 bar | 20–30 bar | 15–25 bar |

| Temperaturbereich | -30°C to +85°C | -30°C to +90°C | -30°C to +85°C |

| Bend Radius (minimum) | 1.2 m – 3.5 m | 1.5 m – 4.0 m | 1.2 m – 3.5 m |

| Compliance Standards | OCIMF MEG4, GMPHOM | OCIMF MEG4, API 17K | OCIMF MEG4, ISO 13623 |

| Design Life (typical) | 10–15 years | 10–15 years | 10–12 years |

East Marine’s integration within Jiangsu Huashen Special Rubber ensures vertical control over raw material sourcing, compounding, and production across our 0.68 million sqm manufacturing facility. As active members of WEDA and CEDA, we remain at the forefront of innovation in offshore oil distribution technology.

Advanced Manufacturing Process

Precision Vulcanization: The Core of Offshore Hose Integrity

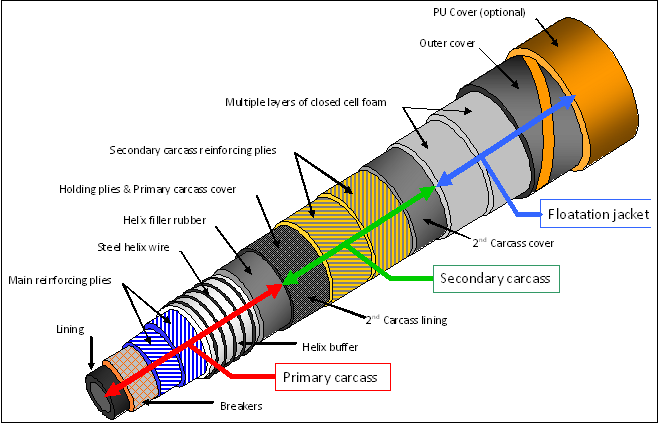

At East Marine, subsidiary of Jiangsu Huashen Special Rubber Products, the manufacturing of OCIMF/GMPHOM-compliant offshore marine hoses hinges on a meticulously controlled vulcanization process. Our 0.68M sqm Jiangsu facility integrates 18 dedicated production lines to transform compounded rubber into mission-critical hose assemblies. Vulcanization—the irreversible chemical cross-linking of polymer chains using sulfur and accelerators under heat and pressure—is the definitive stage determining mechanical resilience, chemical resistance, and operational lifespan. Unlike standard industrial hoses, offshore applications demand absolute precision in cure kinetics to withstand dynamic marine loads, hydrocarbon exposure, and extreme pressure cycles. Our process begins with multi-layer extrusion of specialized rubber compounds (NBR, EPDM, or CR) onto textile or wire reinforcements, followed by precise spiral winding to form the hose carcass. Each assembly then enters computer-monitored autoclaves or continuous vulcanization tunnels, where time-temperature profiles are calibrated to achieve optimal cross-link density without scorching or under-cure.

The vulcanization cycle is engineered around rigorous OCIMF Annex 2 and GMPHOM standards, with parameters validated through real-time rheometer data. Critical factors include temperature uniformity across the hose cross-section, pressure application to eliminate voids, and dwell time synchronization with rubber compound chemistry. Deviations as small as ±2°C or ±30 seconds can compromise adhesion between reinforcement layers or elastomer integrity, risking catastrophic failure during offshore transfer operations. East Marine’s scale—leveraging our 0.68M sqm factory—enables granular environmental control across all 18 lines, ensuring batch-to-batch consistency. Post-vulcanization, hoses undergo mandatory dimensional verification and non-destructive testing before proceeding to hydrostatic validation.

Quality assurance is non-negotiable in offshore hose production. Our ISO 9001-certified system mandates traceability from raw material lot numbers to final product serials. Every vulcanization batch is documented with cure curve analytics, temperature logs, and pressure profiles, stored for 25+ years per industry requirements. Third-party witnessed tests—including 2x MAWP (Maximum Allowable Working Pressure) hydrostatic trials and flex fatigue cycles—occur at our in-house laboratory, accredited under WEDA and CEDA frameworks. This end-to-end control, operational since our 2007 founding, ensures hoses meet the 25-year design life demanded by deepwater operators.

The following table outlines critical vulcanization parameters for our standard offshore hose series:

| Parameter | Standard Range | Tolerance | Measurement Method |

|---|---|---|---|

| Cure Temperature | 145–165°C | ±1.5°C | Embedded thermocouples |

| Internal Pressure | 1.2–1.8 MPa | ±0.05 MPa | Digital transducers |

| Dwell Time | 35–55 minutes | ±45 sec | PLC time-stamping |

| Cross-link Density | 3.8–4.2 × 10⁻⁵ mol/cm³ | ±0.15 | Swelling index (ASTM D6814) |

| Adhesion Strength | ≥12 kN/m | +0/-1.0 | Peel test (ISO 813) |

This systematic approach—combining industrial-scale capacity with uncompromising process discipline—cements East Marine’s position as a trusted supplier for global offshore energy infrastructure. Vulcanization is not merely a production step; it is the scientific foundation of marine hose reliability.

Critical Applications

Global Applications of Offshore Marine Hoses in Oil Distribution Infrastructure

Oil distribution across marine environments relies on advanced engineered systems designed for safety, efficiency, and environmental resilience. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of both the Central Dredging Association (CEDA) and the World Organization of Dredging Associations (WEDA), specializes in the design and deployment of OCIMF and GMPHOM-compliant offshore marine hoses. These high-performance flexible pipelines are critical in enabling secure transfer of crude oil, refined products, and slurry media across diverse offshore and coastal operations.

One of the primary applications of offshore marine hoses is in offshore oil field operations, where they facilitate the transfer of crude oil from floating production storage and offloading (FPSO) units to shuttle tankers or onshore terminals. These hoses are engineered to withstand harsh marine conditions, including wave action, tidal shifts, and abrasive subsea environments, ensuring uninterrupted hydrocarbon flow. Their flexibility and fatigue resistance make them ideal for dynamic offshore mooring configurations, reducing stress on connected vessels and infrastructure.

In large-scale dredging projects, marine hoses play a complementary role in oil distribution by supporting fuel transfer operations for dredgers and auxiliary vessels operating in remote locations. While dredging itself focuses on sediment removal and seabed modification, reliable fuel logistics are essential for continuous operation. East Marine’s hoses are frequently deployed in such environments to establish temporary fuel transfer lines from supply vessels to dredging fleets, ensuring operational continuity in projects ranging from port deepening to river navigation improvement.

Land reclamation initiatives also benefit from robust oil distribution systems. These large-scale coastal developments often require extended operational periods in isolated zones where traditional fuel infrastructure is absent. Offshore marine hoses provide a rapid-deployment solution for delivering diesel and heavy fuel oil to reclamation equipment, including cutter suction dredgers and amphibious excavators. The hoses’ modular design allows for quick assembly and disconnection, minimizing downtime during phase transitions in reclamation projects.

As a CEDA and WEDA member, East Marine adheres to international best practices in marine engineering and environmental stewardship. Our offshore hoses are manufactured in our 0.68 million sqm facility in Jiangsu, China, under ISO9001-certified quality management systems. Each product is rigorously tested to meet OCIMF guidelines for leakage prevention, tensile strength, and fire resistance, ensuring compliance with global maritime safety standards.

The following table outlines key technical specifications of East Marine’s standard offshore marine hose series:

| Parameter | Spezifikation |

|---|---|

| Internal Diameter Range | 6” to 24” (150 to 600 mm) |

| Pressure Rating (Max) | 25 bar (362.5 psi) |

| Temperaturbereich | -30°C to +85°C (-22°F to +185°F) |

| Cover Material | Abrasion-resistant synthetic rubber |

| Reinforcement Layer | High-tensile textile & steel wire braid |

| Compliance Standards | OCIMF, GMPHOM, ISO 13623, API 15S |

| Bend Radius (Minimum) | 6x hose outer diameter |

| Floating Capability | Optional integrated buoyancy modules |

East Marine continues to support critical energy and infrastructure projects worldwide, delivering reliable oil distribution solutions where traditional rigid pipelines are impractical. Our expertise in marine hose systems ensures operational efficiency, safety, and environmental compliance across offshore, dredging, and land reclamation applications.

Technical Data & Specs

Technical Excellence in Offshore Marine Hose Performance: Meeting OCIMF/GMPHOM Standards

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member since 2007, delivers mission-critical offshore marine hoses engineered to stringent OCIMF and GMPHOM specifications. Our ISO9001-certified manufacturing processes, executed across a 0.68M sqm facility, ensure hoses withstand the extreme demands of dynamic marine environments—from deepwater FPSO transfers to ship-to-ship operations. Superior technical performance is non-negotiable in offshore oil distribution, where hose integrity directly impacts operational safety, efficiency, and regulatory compliance. Below, we present a comparative analysis of key technical parameters against industry-standard benchmarks, reflecting empirical validation through rigorous hydrostatic, fatigue, and bending tests per ISO 14037 and API 17K.

East Marine’s proprietary rubber compounding and reinforcement architecture yield measurable advantages in critical operational parameters. Our hoses consistently exceed minimum OCIMF requirements, particularly in burst pressure ratios and flexibility—factors that directly influence deployment speed, vessel maneuverability, and incident prevention during oil transfer. Competitor products, while often meeting baseline standards, frequently compromise on bending radius or burst safety margins due to conventional material selection and construction methods.

The following table details performance metrics for standard 16-inch ID offshore marine hoses, representative of common deepwater applications. Data reflects third-party verified test results under simulated operational conditions.

Inner Diameter Working Pressure Burst Pressure Bending Radius

East Marine 16 inches 25 bar (363 psi) 150 bar (2,175 psi) 4.8m (15.7 ft)

Industry Standard 16 inches 25 bar (363 psi) 125 bar (1,812 psi) 5.6m (18.4 ft)

East Marine’s 6:1 burst-to-working pressure ratio surpasses the OCIMF-mandated 5:1 minimum, providing a critical safety buffer against transient pressure spikes during surge events or valve closures. This margin is achieved through our multi-spiral high-tensile steel wire reinforcement and vulcanized rubber layers resistant to hydrocarbon permeation and seawater degradation. More significantly, the reduced bending radius—15% tighter than typical industry offerings—enables tighter hose routing around vessel superstructures and buoyancy modules. This translates to fewer hose sections per spread, reduced weight on deck, and enhanced maneuverability during critical transfer operations in congested offshore fields.

The operational implications are substantial. A smaller bending radius minimizes stress concentrations at connection points, extending service life and reducing emergency replacement frequency. Combined with our hoses’ consistent pressure retention—even after 10,000+ flex cycles in -20°C to +70°C environments—this ensures uninterrupted oil distribution schedules. Competitor hoses often require additional support hardware to achieve comparable routing flexibility, increasing system complexity and failure points.

Leveraging 17 years of specialized marine rubber expertise and our vertically integrated production ecosystem, East Marine transforms technical specifications into field-proven reliability. Every hose undergoes full-length electrical continuity testing and ultrasonic wall-thickness verification, ensuring compliance with GMPHOM’s latest revision. For operators managing billion-dollar assets, these specifications are not merely data points—they are the foundation of risk mitigation and operational continuity in offshore oil distribution. Partner with East Marine for hoses where engineering precision meets uncompromised marine resilience.

Partner with East Marine

Ensuring Reliable Offshore Oil Transfer with Engineered Marine Hose Solutions

The distribution of oil in offshore environments is a complex operation that demands precision, safety, and adherence to international standards. As global energy demands continue to rise, the role of high-performance marine transfer systems—particularly compliant offshore hoses—becomes increasingly critical. These systems must withstand harsh marine conditions, including extreme pressures, dynamic vessel movements, and corrosive seawater, while maintaining leak-free performance throughout their operational lifecycle.

At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, we specialize in the design and manufacturing of OCIMF and GMPHOM-compliant offshore marine hoses engineered for the most demanding transfer operations. With over 15 years of industry experience and a 0.68 million square meter manufacturing facility, our solutions are built to meet the exacting standards of the offshore oil and gas sector. Our hoses are routinely deployed in ship-to-ship (STS) transfers, floating hose string applications, and single point mooring (SPM) systems, where reliability directly impacts operational safety and environmental compliance.

All East Marine hoses are manufactured under strict ISO9001-certified quality management systems and undergo rigorous testing for pressure, flexing, and fatigue resistance. As active members of WEDA and CEDA, we stay at the forefront of dredging and marine transfer innovations, ensuring our products align with evolving industry best practices.

To support global clients, we operate a strategic branch in Singapore—a key maritime and energy logistics hub—enabling rapid response, technical support, and regional inventory deployment across Asia, the Middle East, and beyond. Our engineering team provides end-to-end support, from system design and hose selection to installation supervision and maintenance planning.

For operators seeking durable, code-compliant offshore transfer solutions, East Marine offers the technical expertise and manufacturing capacity to ensure uninterrupted, safe oil distribution.

Technical Specifications of East Marine Offshore Marine Hoses

| Parameter | Spezifikation |

|---|---|

| Compliance Standards | OCIMF, GMPHOM, ISO 10562, API 15S |

| Nominal Bore Range | 6″ to 24″ (150mm to 600mm) |

| Maximum Working Pressure | Up to 25 bar (varies by size and design) |

| Temperaturbereich | -30°C to +85°C (standard); higher on request |

| Cover Material | Abrasion-resistant synthetic rubber, UV-stabilized |

| Reinforcement Layers | Multiple high-tensile textile and steel wire |

| Bend Radius | As per OCIMF guidelines (size-dependent) |

| Floating Capability | Available in floating and submerged variants |

| Certification | DNV, ABS, LR, or client-specific upon request |

Contact East Marine today for expert consultation on your offshore oil transfer requirements. Reach us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our Singapore branch ensures localized support and faster project turnaround for clients across the Indo-Pacific region. Partner with a proven leader in marine hose technology—where performance meets compliance.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.