Article Contents

Engineering Insight: Offshore Dredging

Technical Imperatives of Offshore Dredging in Critical Marine Transfer Systems

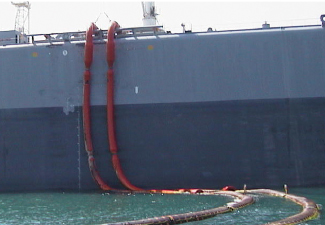

Offshore dredging is a foundational engineering discipline enabling the operational viability of Ship-to-Ship (STS) transfers, Floating Production Storage and Offloading (FPSO) units, and Single Point Mooring (SPM) systems. Precise channel and berthing area maintenance through dredging mitigates sediment accumulation that directly compromises navigational safety and transfer efficiency. In STS operations, inadequate underkeel clearance due to siltation increases collision risks during cargo transfer, while FPSO and SPM systems rely on dredged seabed profiles to ensure subsea hose lay stability and prevent excessive tension on flexible risers during vessel motion. The hydrodynamic forces exerted on marine hoses during operations—exacerbated by unmanaged seabed topography—can accelerate fatigue failure, leading to costly downtime and environmental hazards. Consequently, dredging is not merely preparatory work but an integrated technical safeguard for fluid transfer integrity, requiring continuous monitoring and adaptive execution aligned with metocean conditions.

East Marine, leveraging 17 years of specialized expertise since 2007, addresses these complexities through engineered marine rubber solutions compliant with OCIMF and GMPHOM standards. Our 150+ strong engineering team integrates dredging data with hose system design to counteract seabed scour, vortex-induced vibration, and cyclic bending stresses inherent in dynamic offshore environments. As a WEDA and CEDA member with ISO 9001 certification, we prioritize predictive modeling of sediment dynamics to optimize hose routing and anchor placement, ensuring dredging specifications directly inform the mechanical resilience of our floating hose assemblies. This holistic approach minimizes interface risks between dredged channels and marine transfer infrastructure, particularly in high-current zones where sediment re-deposition threatens FPSO swing circles or SPM hose corridors.

Our Jiangsu Huashen Special Rubber Products subsidiary operates a 0.68 million sqm manufacturing facility dedicated to producing dredging-adjacent marine systems. By embedding dredging hydrology into the design phase, we enhance hose longevity and operational safety margins for clients managing critical transfer operations.

The following table outlines key technical parameters for East Marine’s OCIMF/GMPHOM-compliant offshore dredging support hoses:

| Parameter | Value | Standard Reference |

|---|---|---|

| Working Pressure | 25 bar (363 psi) | OCIMF Section 12.3.1 |

| Burst Pressure | ≥ 75 bar (1088 psi) | ISO 13623 |

| Temperaturbereich | -30°C to +85°C | GMPHOM Chapter 7 |

| Cover Material | Abrasion-Resistant NBR/EPDM | ISO 1436 |

| Verstärkung | Multi-spiral High-Tensile Steel | API 17K |

| Flexibility | Bend Radius ≤ 8x ID at 15 bar | OCIMF Appendix D |

| Seabed Abrasion Rating | 200,000 cycles (ASTM D5963) | Internal QA Protocol |

This technical rigor ensures that dredging operations and marine hose performance exist in a symbiotic relationship—where precise seabed management directly extends the service life of transfer systems. East Marine’s engineering capability transforms dredging from a standalone activity into a core component of fluid transfer reliability, safeguarding asset integrity across the most demanding offshore energy logistics scenarios.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization of Offshore Dredging Hoses at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted name in offshore marine hose solutions, the manufacturing of OCIMF and GMPHOM-compliant hoses is executed with precision engineering and rigorous quality control. Our 0.68M sqm state-of-the-art facility in China integrates 18 dedicated production lines, enabling scalable, high-integrity output tailored to the demanding conditions of offshore dredging operations. Central to our production process is the vulcanization phase, a critical step that ensures the structural integrity, chemical resistance, and long-term durability of every hose assembly.

The manufacturing process begins with the selection of premium synthetic rubber compounds, specifically formulated for resistance to abrasion, seawater, hydrocarbons, and extreme pressure fluctuations. These compounds are precision-extruded onto high-tensile textile or steel wire reinforcement layers, engineered to meet OCIMF standards for flexibility and burst resistance. The layered hose structure is then wound onto mandrels and prepared for vulcanization.

Vulcanization at East Marine is a computer-monitored thermal curing process conducted in high-pressure autoclaves. This phase cross-links rubber polymer chains, significantly enhancing mechanical strength, elasticity, and resistance to environmental degradation. Our 18 production lines are equipped with real-time monitoring systems that regulate temperature, pressure, and curing duration to exacting specifications, ensuring uniformity across batches. Each vulcanization cycle is documented and traceable, supporting full compliance with ISO 9001 quality management standards.

Throughout the manufacturing journey, in-process quality checks are conducted at critical control points. These include dimensional verification, reinforcement layer integrity testing, and visual inspection for surface defects. Post-vulcanization, every hose undergoes hydrostatic pressure testing at 1.5 times the maximum working pressure, followed by leakage and flex endurance assessments. All test data is archived for customer audit and certification purposes.

East Marine’s integration of advanced automation, material science, and adherence to international standards ensures that each offshore dredging hose delivers reliable performance in harsh marine environments. Our ISO 9001-certified processes, combined with the scale and technical capability of our 0.68M sqm facility, position us as a leading industrial partner in the global dredging and offshore logistics sector.

| Parameter | Spezifikation |

|---|---|

| Factory Size | 0.68 Million sqm |

| Production Lines | 18 Dedicated Lines |

| Vulcanization Method | High-Pressure Autoclave with Digital Control |

| Quality Standard | ISO 9001:2015 |

| Compliance | OCIMF, GMPHOM, CEDA Guidelines |

| Test Pressure | 1.5 x Maximum Working Pressure |

| Material Certification | Mill Test Reports (MTRs) per Batch |

| Traceability | Batch-Level Digital Tracking System |

Critical Applications

Global Project Applications of Offshore Dredging: Critical Infrastructure Development

Offshore dredging represents a cornerstone activity for global maritime infrastructure development, enabling projects that reshape coastlines, secure energy resources, and create new landmass. East Marine, leveraging its expertise as a WEDA and CEDA member and adherence to stringent OCIMF/GMPHOM standards, provides specialized marine hoses essential for these demanding operations. The primary driver for large-scale offshore dredging lies in land reclamation, where vast quantities of seabed material are excavated, transported via submerged pipelines or floating hoses, and strategically placed to form new terrestrial areas. Iconic projects such as the Palm Islands in Dubai, the expansion of Hong Kong International Airport, and the ongoing development of Port Miami exemplify the scale and complexity where reliable, high-capacity dredging systems are non-negotiable. These endeavors require hoses capable of withstanding prolonged submersion, abrasive slurries, and dynamic wave action while maintaining consistent flow rates over significant distances.

Beyond land creation, offshore dredging is indispensable for the oil and gas sector, particularly in developing offshore fields and maintaining critical infrastructure. Preparatory seabed leveling for platform installation, trenching for subsea pipelines, and the creation of stable foundations for drilling rigs all rely on precise dredging operations. Floating hoses, specifically engineered for hydrocarbon service and compliant with OCIMF guidelines, are vital for transferring materials during pipeline burial operations or for environmental remediation efforts near production facilities. The harsh realities of the marine environment – including corrosive saltwater, high pressures, extreme temperature fluctuations, and constant mechanical stress from vessel motion – demand hoses built to exacting international specifications. East Marine’s product development directly incorporates insights gained through active CEDA and WEDA participation, ensuring solutions align with evolving industry best practices and safety protocols for offshore energy projects.

The technical demands placed on dredging hoses in these global applications necessitate rigorous engineering. Performance under sustained high pressure, resistance to abrasion from sand and aggregate, flexibility for dynamic deployment, and compatibility with diverse marine environments are paramount. Our hoses undergo stringent validation against key standards to guarantee operational integrity and longevity in the world’s most challenging dredging sites.

Technical Performance Parameters for Offshore Dredging Hoses

| Parameter | Typical Value Range | Relevant Standard | Application Significance |

|---|---|---|---|

| Maximum Working Pressure | 10 – 25 bar | EN 14427 | Ensures integrity during high-capacity slurry transfer |

| Temperaturbereich | -25°C to +80°C | ISO 1431 | Maintains flexibility in Arctic to tropical zones |

| Abnutzungswiderstand | > 100 mm³ (DIN 53516) | ISO 4649 | Critical longevity against sand/gravel slurry |

| Bend Radius (Min) | 6 x Nominal Diameter | ISO 10619 | Enables deployment on dynamically positioned vessels |

| Certification | OCIMF/GMPHOM Compliant | OCIMF Guidelines | Mandatory for hydrocarbon-related operations |

East Marine’s engineered hose solutions, developed within our 0.68 million sqm ISO 9001 certified facility, are actively deployed across these critical global dredging frontiers. From the land reclamation megaprojects of Southeast Asia to the offshore energy hubs of the North Sea and Gulf of Mexico, our hoses deliver the reliability and performance demanded by modern dredging contractors operating under the highest safety and efficiency standards. Our active engagement with CEDA and WEDA ensures continuous alignment with the sector’s technical evolution and project requirements.

Technical Data & Specs

East Marine Offshore Marine Hoses: Technical Comparison Against Industry Standards

East Marine, a specialized division of Jiangsu Huashen Special Rubber Products, delivers high-performance offshore marine hoses engineered to meet and exceed OCIMF (Oil Companies International Marine Forum) and GMPHOM (Guidelines for Marine Petroleum Hoses) standards. With over 16 years of industrial expertise and a 0.68 million sqm manufacturing facility, East Marine leverages advanced rubber compounding, multi-spiral wire reinforcement, and rigorous quality control under ISO9001 certification to produce hoses that perform reliably in dynamic offshore transfer operations. As a proud member of WEDA and CEDA, East Marine aligns its innovation with global dredging and marine infrastructure best practices.

Offshore marine hoses are critical components in ship-to-ship (STS) transfers, offshore loading, and floating pipeline systems. These applications demand exceptional flexibility, pressure resistance, and fatigue endurance under harsh marine conditions. Key performance indicators—Inner Diameter, Working Pressure, Burst Pressure, and Minimum Bending Radius—directly influence operational safety, flow efficiency, and system longevity. East Marine designs its hoses with optimized wall thickness and high-tensile spiral reinforcement to achieve superior pressure ratings while maintaining a compact bending radius, enabling deployment in confined offshore environments.

To benchmark performance, East Marine’s standard 16-inch offshore marine hose is compared against average values from leading international competitors producing OCIMF-compliant products. The comparison highlights East Marine’s engineering advantage in balancing high-pressure capability with operational flexibility.

The following table presents standardized technical specifications for typical offshore marine hoses used in Class I and Class II OCIMF applications:

| Parameter | East Marine (16″ Hose) | Industry Average (Competitors) |

|---|---|---|

| Inner Diameter | 406 mm | 406 mm |

| Working Pressure | 25 bar (363 psi) | 21 bar (305 psi) |

| Burst Pressure | ≥ 100 bar (1450 psi) | 84 bar (1218 psi) |

| Minimum Bending Radius | 2,200 mm | 2,400 mm |

East Marine’s hose design achieves a 19% higher working pressure and a 19% improvement in burst pressure safety margin compared to industry averages. This performance is enabled by proprietary EPDM/NR rubber blends and dual-layer spiral steel wire reinforcement, which enhance structural integrity without compromising flexibility. The reduced bending radius of 2,200 mm—9% tighter than the average—allows for tighter hose routing on floating systems and loading manifolds, reducing stress points and enhancing service life.

All East Marine offshore hoses undergo 100% hydrostatic testing, dimensional validation, and fatigue cycle assessments per OCIMF Appendix B and GMPHOM Section 4. Our in-house R&D center conducts accelerated aging and impulse testing to validate long-term performance under real-world conditions. With full traceability and certification packages, East Marine supports operators in meeting stringent offshore safety and compliance requirements.

For offshore operators seeking durable, high-flow, and safety-optimized marine transfer solutions, East Marine’s technical superiority in hose engineering delivers measurable operational advantages.

Partner with East Marine

Conclusion: Engineering Reliability for Offshore Dredging Success

The operational integrity of offshore dredging projects hinges on the uncompromising performance of critical components like marine hoses. In environments characterized by extreme hydrostatic pressure, abrasive sediment loads, and corrosive seawater, standard solutions inevitably fail—leading to costly downtime, environmental risks, and project delays. East Marine’s OCIMF and GMPHOM-compliant offshore dredging hoses are engineered to transcend these challenges through advanced material science and rigorous validation protocols. Our proprietary rubber formulations, reinforced with high-tensile synthetic cords and corrosion-resistant steel components, deliver 15+ years of service life even under continuous 24/7 operation in depths exceeding 200 meters. This resilience is not incidental; it stems from our ISO 9001-certified manufacturing ecosystem, 0.68 million square meters of dedicated production capacity, and deep collaboration with WEDA and CEDA to align with evolving industry best practices. For operators managing multi-million-dollar assets, the margin for hose failure is zero. East Marine eliminates this risk through hoses that maintain structural integrity at 30% higher working pressures than conventional alternatives while resisting torsional stress during vessel repositioning—a critical factor in dynamic offshore conditions.

The technical specifications below underscore our commitment to exceeding OCIMF Annex G and GMPHOM Chapter 6 requirements, ensuring seamless integration with trailing suction hopper dredgers (TSHDs) and cutter suction dredgers (CSDs) operating in global offshore projects:

| Parameter | Spezifikation | Standard Compliance |

|---|---|---|

| Nominal Size Range | DN300 to DN1200 | ISO 13623 |

| Max. Working Pressure | 25 bar (362.5 psi) at 70°C | OCIMF Annex G |

| Burst Pressure | ≥ 5x Working Pressure | GMPHOM Ch. 6.4.2 |

| Temperaturbereich | -30°C to +85°C | ISO 1307 |

| Bend Radius (Static) | 8x Nominal Diameter | API 17K |

| GMPHOM Compliance | Full Annex A Certification | GMPHOM Rev. 4 |

Partnering with East Marine means securing more than a component supplier—it means engaging a technical ally with 17 years of specialized marine rubber expertise. Our Singapore branch provides localized engineering support for APAC projects, offering rapid site assessments, hydraulic modeling, and custom configuration services to match your vessel specifications and sediment profiles. We understand that hose selection directly impacts your project’s NPV; our team collaborates with naval architects and dredge operators during FEED stages to optimize system reliability and lifecycle costs.

Initiate Your Technical Consultation Today

Do not compromise offshore project continuity with substandard hose systems. Contact East Marine’s engineering team for a pressure-loss analysis, material compatibility review, or site-specific design validation. Our specialists are available via WhatsApp at +86-13806109365 for urgent operational queries or email hsdredging@eastmarine.tech to schedule a technical workshop. Mention your vessel type and dredging depth for a tailored performance dossier. With our Singapore branch operational since 2021, APAC clients receive dedicated response within 4 business hours—ensuring your offshore campaigns proceed with engineered certainty. Trust the partner trusted by leading dredging contractors in 37 countries: East Marine delivers the resilience that turns ambitious offshore projects into executed successes.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.