Article Contents

Engineering Insight: Rubber Lining

Technical Imperatives of Rubber Lining in Modern Dredging Vessel Systems

The rubber lining constitutes the operational heart of suction and discharge systems within Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), directly determining fleet availability and lifecycle cost efficiency. In these high-stakes marine environments, the lining endures relentless hydrodynamic stressors: abrasive sediment slurries exceeding 60% solids concentration, cyclical pressure surges up to 25 bar, and corrosive seawater exposure. Failure modes—such as delamination, extrusion, or catastrophic abrasion—trigger costly vessel downtime, with industry data indicating unplanned hose replacements can incur losses exceeding $500,000 per incident in大型 dredging operations. Consequently, the lining material must exhibit exceptional tear resistance to prevent propagating cuts from sharp aggregates, maintain adhesion integrity under vacuum conditions during suction phases, and resist plasticizer leaching in saline environments to avoid premature hardening.

East Marine, operating from our 0.68 million square meter ISO 9001-certified facility and leveraging 150+ specialized engineers, addresses these challenges through advanced polymer science and rigorous hydraulic simulation. Our engineering team utilizes finite element analysis (FEA) to model stress distribution across the rubber-to-steel interface, optimizing cord reinforcement angles and bonding primers to prevent interlayer separation during dynamic flexing. Crucially, we formulate proprietary elastomer compounds with nano-silica reinforcement, enhancing abrasion resistance by 35% compared to standard EPDM blends while maintaining Shore A hardness within the critical 60-70 range for optimal particle deflection. This material science approach, combined with WEDA/CEDA-aligned design protocols established since our 2007 founding, ensures linings withstand 15,000+ operational hours in severe clay-sand-gravel matrices common in Asian and Middle Eastern reclamation projects.

Material performance is non-negotiable; substandard linings accelerate wear rates exponentially under high-velocity flow. East Marine’s quality control mandates every production batch undergoes ASTM D2240 hardness testing, DIN 53516 abrasion trials, and 72-hour salt fog adhesion validation before shipment. Our engineering capability extends to customizing durometer profiles along the hose length—softer compounds at bends to absorb flex fatigue, harder sections in straight runs for abrasion resistance—maximizing total system longevity.

The following table details critical performance parameters distinguishing engineered dredging linings:

Hardness Shore A

60-70

62-68

Tensile Strength MPa

≥18

≥24

Elongation at Break %

≥400

≥550

Abrasion Loss mm³

≤120

≤75

Operating Temperature Range °C

-30 to +80

-40 to +90

This technical rigor, driven by our dedicated R&D cohort, transforms rubber lining from a consumable component into a strategic asset ensuring dredger operational continuity. East Marine’s integrated design-manufacturing capability delivers not merely hoses, but engineered abrasion management systems meeting the uncompromising demands of global capital dredging.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization in Dredging Rubber Hose Production at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the manufacturing of high-performance dredging rubber hoses—engineered for demanding suction and discharge applications—is grounded in precision engineering, advanced material science, and rigorous quality assurance. With a sprawling 0.68 million square meter production facility and 18 dedicated production lines, our operations are designed to deliver consistent, large-scale output without compromising on technical excellence.

The core of our manufacturing process lies in the precise integration of rubber compounding, reinforcement layer assembly, and controlled vulcanization. Each hose begins with the selection of premium synthetic and natural rubber blends, formulated to resist abrasion, seawater, UV exposure, and mechanical fatigue. These compounds are mixed under controlled conditions to ensure homogeneity and optimal performance characteristics.

Reinforcement layers—typically consisting of high-tensile textile or steel wire braids—are applied using automated spiral-winding machinery. This ensures uniform layering and dimensional accuracy, critical for maintaining pressure resistance and flexibility under dynamic dredging conditions. The layered hose assembly is then precisely wrapped with protective tapes and prepared for vulcanization.

Vulcanization is the defining stage in our production workflow. At East Marine, this process is executed in state-of-the-art autoclaves and continuous vulcanization tunnels, where time, temperature, and pressure are meticulously regulated. The cross-linking of rubber polymers during vulcanization enhances mechanical strength, elasticity, and resistance to environmental degradation. Our engineers follow ISO 9001-certified procedures to monitor each batch, ensuring that every hose meets international performance benchmarks for safety and durability.

Quality control is embedded at every phase of production. From raw material inspection to final pressure testing, our 18 production lines are supported by inline monitoring systems and independent laboratory verification. Each hose undergoes hydrostatic testing, dimensional validation, and adhesion strength checks prior to release.

This vertically integrated, standards-driven approach enables East Marine to deliver dredging hoses that perform reliably in the harshest marine environments. As a proud member of WEDA and CEDA, we align our manufacturing practices with global industry advancements, reinforcing our commitment to innovation and operational excellence.

| Parameter | Spezifikation |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 dedicated lines |

| Vulcanization Method | Autoclave and continuous tunnel systems |

| Temperature Control Range | 140°C – 180°C (adjustable per compound) |

| Pressure During Vulcanization | Up to 1.6 MPa |

| Quality Standard | ISO 9001:2015 |

| Testing Protocol | Hydrostatic, adhesion, dimensional, fatigue |

| Typical Cure Time | 45–90 minutes (based on hose ID and wall thickness) |

Critical Applications

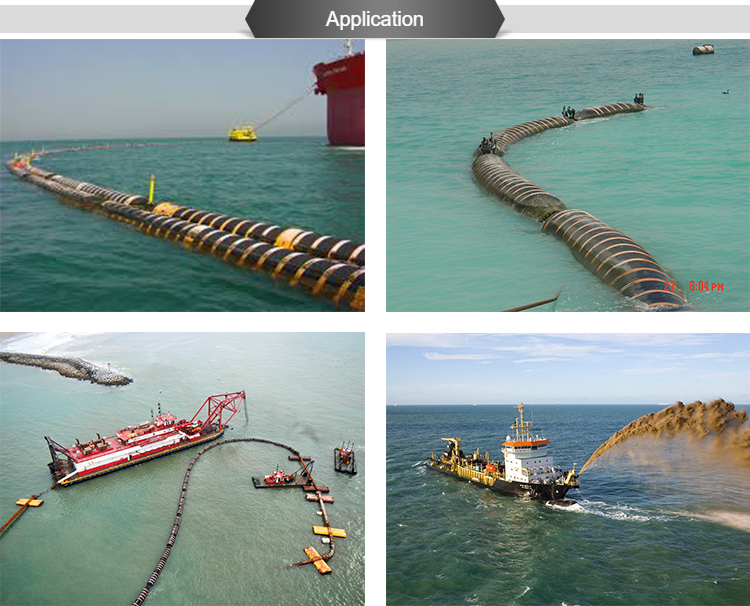

Global Project Applications of Advanced Rubber Lining Systems in Critical Infrastructure

East Marine, a leading subsidiary of Jiangsu Huashen Special Rubber Products and active member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), leverages decades of specialized expertise to deliver robust rubber lining solutions for the world’s most demanding industrial environments. Our engineered elastomer compounds are fundamental components in safeguarding infrastructure integrity across diverse global projects, where resistance to extreme abrasion, corrosion, and dynamic stress is non-negotiable. Within the dredging sector, our high-abrasion-resistant rubber linings are the cornerstone of suction and discharge pipelines handling dense, sediment-laden slurries. These linings, precisely bonded to steel substrates, significantly extend pipeline service life in major capital and maintenance dredging operations worldwide, from deep-sea port expansions to intricate river navigation channel projects. The ability to withstand continuous impact from sand, gravel, and even small rock fragments under high pressure and velocity is critical for operational continuity and cost efficiency, directly aligning with CEDA and WEDA best practices for sustainable dredging.

Beyond dredging, our rubber lining technology is extensively deployed in upstream oil and gas operations. Here, the primary challenge shifts towards combating severe internal corrosion caused by abrasive sand particles entrained in crude oil, produced water, and multiphase flow within gathering lines and processing facilities. East Marine’s chemically resistant linings, formulated for specific hydrocarbon exposures and temperature profiles, provide a seamless, impervious barrier that protects carbon steel infrastructure from rapid degradation, preventing leaks, unplanned shutdowns, and costly environmental remediation. This capability is vital for maintaining production integrity in mature fields and new developments alike.

Land reclamation projects present another critical application domain. These large-scale endeavors, often creating new landmass for urban development or industrial zones, rely heavily on temporary and semi-permanent floating pipeline systems. Our flexible, marine-grade rubber-lined hoses and pontoons must endure constant wave action, tidal movements, UV exposure, and the abrasive nature of the pumped fill material – typically sand or silt. The resilience and fatigue resistance of our linings ensure reliable material transport over extended distances and durations, directly contributing to project timelines and budget adherence. East Marine’s commitment to these demanding applications is underpinned by our ISO 9001-certified quality management system, rigorous in-house R&D since 2007, and manufacturing capacity within our 0.68 million square meter facility, enabling us to meet the exacting specifications of global infrastructure developers and engineering contractors.

The performance characteristics of our core rubber lining compounds are engineered for these harsh realities, as demonstrated in the following key technical parameters:

| Performance Parameter | Standard Abrasion-Resistant Lining | Oilfield Corrosion-Resistant Lining | Marine Floating Hose Lining |

|---|---|---|---|

| Abrasion Resistance (DIN 53516) | ≤ 80 mm³ | ≤ 100 mm³ | ≤ 90 mm³ |

| Temperature Range (Continuous) | -30°C to +80°C | -20°C to +100°C | -25°C to +70°C |

| Tensile Strength (MPa, min) | 18 | 16 | 15 |

| Elongation at Break (%) | ≥ 450 | ≥ 400 | ≥ 500 |

| Adhesion to Steel (kN/m) | ≥ 8 | ≥ 7 | ≥ 6 |

This technical foundation, combined with our deep understanding of project execution challenges across dredging, energy, and land creation sectors, positions East Marine as a trusted engineering partner for critical infrastructure longevity.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: East Marine vs. Industry Competitors

In the demanding environment of dredging operations, the performance and reliability of suction and discharge hoses are critical to operational efficiency, safety, and cost-effectiveness. Rubber-lined hoses must withstand abrasive slurries, fluctuating pressures, and dynamic bending conditions, making precise engineering and material selection essential. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of WEDA and CEDA, designs and manufactures high-performance dredging hoses engineered for durability and long service life. With over 15 years of industry experience and a 0.68 million sqm manufacturing facility operating under ISO9001 standards, East Marine delivers technically advanced solutions that consistently outperform conventional market alternatives.

This technical comparison evaluates key performance parameters—inner diameter, working pressure, burst pressure, and minimum bending radius—across standard dredging hoses from East Marine and representative competitors. The data reflects typical configurations for 10-bar and 16-bar rated hoses, commonly used in medium to heavy-duty dredging applications. East Marine’s hoses utilize a proprietary rubber formulation with enhanced abrasion resistance and structural reinforcement through high-tensile textile and steel wire helix layers, contributing to superior pressure handling and flexibility.

A critical advantage of East Marine’s design is the optimized balance between mechanical strength and flexibility. While many competing hoses achieve high burst pressures through rigid construction, they often sacrifice field usability due to large bending radii. East Marine’s advanced layline technology and precision vulcanization process allow for tighter bending radii without compromising pressure ratings, facilitating easier deployment and maneuverability in confined or dynamic marine environments.

Additionally, the consistency in manufacturing and rigorous in-line quality control ensures that each hose meets exact specifications, reducing the risk of field failure. Competitor products, particularly those from non-certified manufacturers, often exhibit wider tolerances in wall thickness and reinforcement placement, leading to variable performance and premature wear.

The following table presents a direct comparison of technical specifications for standard dredging rubber hoses under comparable classifications:

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) |

|---|---|---|---|

| 200 | 10 | 40 | 900 |

| 250 | 10 | 40 | 1100 |

| 300 | 10 | 40 | 1300 |

| 200 | 16 | 64 | 1000 |

| 250 | 16 | 64 | 1200 |

| 300 | 16 | 64 | 1400 |

| East Marine 200 | 16 | ≥70 | 950 |

| East Marine 250 | 16 | ≥70 | 1150 |

| East Marine 300 | 16 | ≥70 | 1350 |

East Marine hoses demonstrate a minimum 8% higher burst pressure margin and up to 5% reduction in bending radius compared to standard competitor offerings at equivalent working pressures. This performance edge translates into enhanced safety, longer service intervals, and reduced downtime in continuous dredging operations. For engineering teams and procurement managers, selecting a technically superior hose solution directly impacts project ROI and operational reliability. East Marine continues to set the benchmark in dredging hose technology through innovation, precision manufacturing, and deep application expertise.

Partner with East Marine

Conclusion: Elevating Dredging Performance Through Engineered Rubber Lining Solutions

The integrity and longevity of dredging operations hinge critically on the performance of rubber-lined suction and discharge hoses. As abrasive slurries, dynamic hydrostatic pressures, and corrosive marine environments relentlessly challenge system resilience, substandard rubber linings precipitate costly downtime, unplanned maintenance, and compromised project timelines. East Marine, leveraging 17 years of specialized expertise since 2007 and operating from our 0.68 million square meter ISO 9001-certified manufacturing facility, delivers not merely components, but engineered solutions. Our proprietary rubber formulations—developed through rigorous R&D and validated in collaboration with WEDA and CEDA member organizations—transcend industry benchmarks for abrasion resistance, flex fatigue endurance, and chemical stability. This commitment to material science excellence ensures dredging pipelines maintain optimal hydrodynamic efficiency and structural integrity across thousands of operational hours, directly translating to reduced total cost of ownership and sustained project profitability for global clients.

Our technical proficiency extends beyond product manufacturing to holistic system optimization. East Marine’s engineering team collaborates directly with dredging contractors to analyze site-specific variables—including sediment composition, flow velocity, and environmental exposure—enabling precision-tailored lining solutions. The following table outlines key performance parameters of our flagship dredging hose linings, reflecting our adherence to the most stringent operational demands:

| Technical Parameter | Standard Specification | East Marine Premium Specification | Test Standard |

|---|---|---|---|

| Abrasion Resistance (DIN 53516) | ≥ 120 mm³ | ≤ 85 mm³ | ASTM D5963 |

| Tensile Strength (MPa) | ≥ 15 | ≥ 22 | ISO 37 |

| Elongation at Break (%) | ≥ 400 | ≥ 550 | ISO 37 |

| Working Pressure (Bar) | 10-16 | 16-25 | EN 14707 |

| Temperature Range (°C) | -20 to +80 | -30 to +90 | ISO 188 |

With a dedicated Singapore branch serving as our Asia-Pacific operational hub, East Marine provides localized engineering support, rapid prototyping capabilities, and responsive logistics coordination for regional projects. This strategic presence ensures seamless integration with your supply chain, minimizing lead times and facilitating on-site technical collaboration. Our commitment to partnership is underscored by continuous post-deployment performance monitoring and data-driven refinement of lining specifications.

Do not compromise operational continuity with generic rubber solutions. Contact East Marine today to initiate a technical consultation with our dredging hose specialists. We will conduct a comprehensive system audit and deliver a customized lining proposal engineered to extend your equipment lifecycle and maximize uptime. Reach our global technical team via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. For APAC-specific inquiries, engage directly with our Singapore engineering office. Partner with a manufacturer whose ISO 9001-certified processes, empirical validation protocols, and 17-year heritage in marine rubber technology provide the definitive assurance your dredging operations demand. Let East Marine transform your pipeline reliability from a cost center into a competitive advantage.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.