Article Contents

Engineering Insight: Sbm Hose

Technical Imperatives of SBM Hoses in Modern Dredging Operations

The Suction Bend Manifold (SBM) hose represents a critical engineering nexus within Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs), directly influencing operational efficiency, safety, and vessel longevity. In TSHDs, SBM hoses accommodate the complex dynamic articulation between the submerged draghead and the vessel’s rigid suction pipe, enduring severe hydrodynamic stresses during trailing operations across uneven seabeds. For CSDs, these components must simultaneously withstand high-pressure abrasive slurry flow (often exceeding 40% solids by weight) and continuous angular movement at the ladder pivot point. Failure to address these dual demands—extreme mechanical flexing and relentless erosion—results in premature hose fatigue, catastrophic joint separation, or unplanned downtime costing operators upwards of $200,000 per hour in lost productivity. Material science and structural design are therefore non-negotiable; the hose carcass must resist kinking under vacuum conditions during start-up while maintaining burst pressures exceeding 25 bar during peak discharge cycles.

East Marine leverages 17 years of specialized R&D to engineer SBM solutions that mitigate these operational hazards. Our 150+ strong engineering cohort—including 28 dedicated fluid dynamics and elastomer specialists—utilizes finite element analysis (FEA) to simulate real-world stress points across 10,000+ operational cycles before prototyping. This methodology ensures optimal reinforcement layer sequencing (typically 4-6 high-tensile steel wire spirals) and tailored cover compounds resistant to seawater degradation, hydrocarbon exposure, and abrasive wear rates below 50 mm³/1.6 km per ISO 9001-certified testing protocols. As WEDA and CEDA members since 2015, we align designs with Dredging Standards Committee (DSC) guidelines for dynamic hose fatigue life, targeting 5,000+ hours of continuous operation in Class III dredging environments.

Our Jiangsu manufacturing campus—spanning 0.68 million square meters—integrates automated mandrel winding and microwave vulcanization to achieve micron-level consistency in critical zones like the dynamic bend radius transition. This precision directly translates to reduced cavitation erosion and extended service intervals for clients managing high-capacity projects in challenging geologies.

The following table details core technical parameters for East Marine’s EM-SBM Series, validated per CEDRAC recommendations:

| Parameter | Spezifikation | Standard/Test Method |

|---|---|---|

| Working Pressure | 16-25 bar | ISO 1402 |

| Vacuum Resistance | 0.9 bar for 5 min | ISO 1307 |

| Temperaturbereich | -30°C to +85°C | ASTM D2240 |

| Cover Material | SBR/NR blend + abrasion-resistant compound | ASTM D380 |

| Verstärkung | 4-6 layers high-tensile steel wire | ISO 1307 |

| Minimum Bend Radius | 1.8x nominal diameter | CEDRAC Guideline 2020 |

| Zertifizierungen | ISO 9001, DNV GL Type Approved | DNVGL-CP-0481 |

East Marine’s SBM hoses are not merely components but engineered risk mitigation systems. By harmonizing material resilience with motion dynamics, we eliminate the traditional trade-off between flexibility and pressure integrity—ensuring dredgers maintain optimal productivity even in high-sediment, deep-water operations where reliability dictates project economics. Our vertically integrated production ecosystem, from raw compound mixing to full-scale hydrostatic validation, guarantees adherence to the exacting tolerances demanded by modern dredging fleets.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization of SBM Dredging Hoses at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted name in marine rubber solutions since 2007, the production of SBM suction and discharge hoses is executed with precision engineering and industrial rigor. Our 0.68M sqm state-of-the-art manufacturing facility in China houses 18 fully integrated production lines dedicated to the fabrication of high-performance dredging hoses. These lines are optimized for scalability, consistency, and adherence to international quality standards, including ISO9001 certification, ensuring every hose meets the demanding requirements of offshore and inland dredging operations.

The manufacturing process begins with the careful selection of premium synthetic rubber compounds, reinforced with high-tensile textile and steel wire helices, tailored to resist abrasion, hydrolysis, and mechanical stress. Each hose is built using a multi-stage layering technique, where inner linings, reinforcement layers, and outer covers are precisely wound onto mandrels. This layered construction ensures optimal flexibility, pressure resistance, and longevity in abrasive slurry environments.

Central to the integrity of the SBM hose is the vulcanization process. Vulcanization at East Marine is conducted in computer-controlled autoclaves, where time, temperature, and pressure are meticulously monitored to achieve complete cross-linking of rubber polymers. This critical phase enhances the elastomeric properties of the hose, delivering superior tensile strength, resilience, and resistance to environmental degradation. Our advanced vulcanization protocols ensure uniform curing throughout the hose structure, eliminating weak points and guaranteeing dimensional stability.

Quality control is embedded at every stage of production. From raw material inspection to final product testing, our ISO9001-certified quality management system ensures compliance with international standards such as CEDA and WEDA guidelines. Each hose undergoes rigorous hydrostatic pressure testing, dimensional verification, and visual inspection. Non-destructive testing methods are employed to validate structural integrity, while sample batches are subjected to accelerated aging and abrasion resistance tests in our in-house laboratory.

With 18 synchronized production lines operating under strict environmental and safety protocols, East Marine maintains a production capacity that supports large-scale dredging projects worldwide. Our vertical integration model allows full control over material sourcing, processing, and final assembly, reducing lead times and enhancing traceability.

The combination of advanced vulcanization technology, a vast 0.68M sqm manufacturing footprint, and unwavering commitment to quality positions East Marine as a leading supplier of SBM dredging hoses in the global marine infrastructure sector.

| Parameter | Spezifikation |

|---|---|

| Factory Size | 0.68 Million sqm |

| Production Lines | 18 Dedicated Lines |

| Vulcanization Method | Autoclave, Computer-Controlled |

| Quality Standards | ISO9001, CEDA, WEDA Guidelines |

| Test Pressure | Up to 2.5x Working Pressure (Hydrostatic) |

| Material Certification | Available (Rubber, Textile, Steel) |

| Custom Lengths | Up to 50 meters (standard), longer on request) |

Critical Applications

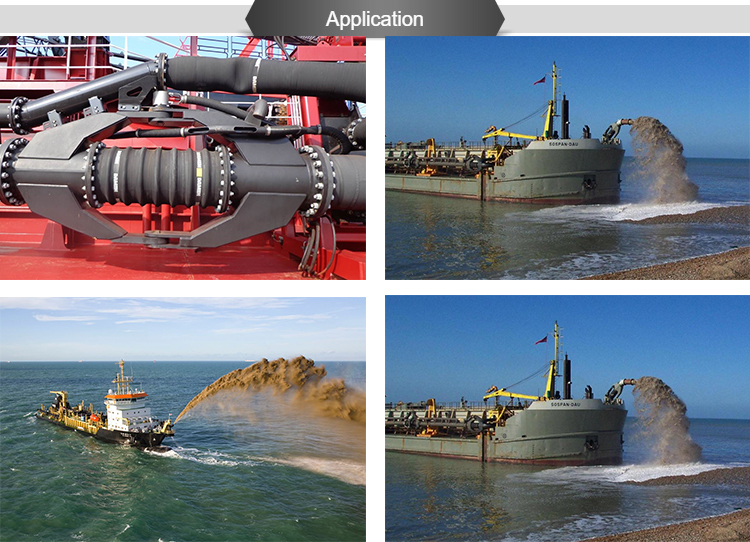

Global Project Applications of SBM Hoses in Critical Marine Operations

SBM (Single Buoy Mooring) hoses represent a cornerstone technology in complex marine fluid transfer operations, engineered to withstand the extreme demands of offshore and nearshore environments. At East Marine, leveraging our 0.68 million square meter manufacturing facility and deep expertise honed since 2007, we supply high-integrity SBM hoses integral to major global infrastructure and resource projects. These specialized suction and discharge hoses are not merely conduits; they are mission-critical components enabling the viability and efficiency of large-scale operations where reliability directly impacts project timelines and safety.

In dredging projects worldwide, SBM hoses form the essential link between cutter suction dredgers, trailing suction hopper dredgers, and discharge points. Our hoses reliably handle abrasive slurries at high volumes and pressures during channel deepening, port expansion, and river maintenance. The dynamic nature of dredging operations – involving constant movement, submersion, and exposure to sharp sediments – demands the superior abrasion resistance and structural integrity inherent in East Marine’s ISO 9001-certified products. Our active membership in CEDA (Central Dredging Association) and WEDA (Western Dredging Association) underscores our commitment to understanding and meeting the evolving technical standards and operational challenges faced by the global dredging industry, ensuring our SBM hose solutions align with best practices for efficiency and environmental stewardship.

Beyond traditional dredging, SBM hoses are indispensable in offshore oil and gas fields for subsea transfer operations. They facilitate the safe and continuous movement of crude oil, refined products, or drilling fluids between floating production systems, storage units, and tankers in Single Point Mooring (SPM) configurations. The hoses must endure cyclic fatigue from wave action, deep-water pressure, and potential exposure to hydrocarbons, necessitating advanced rubber compound formulations and robust reinforcement layers. East Marine’s hoses are engineered to maintain integrity under these severe conditions, minimizing downtime and environmental risk.

Land reclamation projects, particularly large-scale coastal development and island creation, heavily rely on SBM hoses. They transport vast quantities of sand and slurry pumped from offshore borrow areas directly to reclamation sites, often over significant distances and through challenging wave conditions. The ability of these hoses to maintain consistent flow rates while resisting kinking, collapse, and external damage is paramount to the economic feasibility of such massive earth-moving endeavors. East Marine’s solutions provide the durability and flow efficiency required to transform coastlines and create new landmasses.

The technical performance underpinning these diverse applications is defined by rigorous engineering standards. Our SBM hoses consistently meet or exceed key operational parameters:

| Parameter | Value | Reference Standard |

|---|---|---|

| Working Pressure Range | 10 – 40 bar | ISO 14310 V3 |

| Temperaturbereich | -30°C to +85°C | ASTM D2240 |

| Cover Material | Premium Marine-Grade Nitrile Rubber | ISO 1817 |

| Verstärkung | Multi-Plies High-Tensile Steel Wire | ISO 1402 |

East Marine’s SBM hoses are proven assets across continents, from maintaining vital shipping lanes in Asia-Pacific ports to developing offshore energy infrastructure in the North Sea and enabling the creation of new urban landscapes in the Middle East. Our technical expertise, manufacturing scale, and adherence to international standards ensure these hoses deliver the unwavering performance required for the world’s most demanding marine projects.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: East Marine vs. Industry Competitors

In the demanding environment of dredging operations, the performance and reliability of suction and discharge hoses are critical to project efficiency, safety, and cost-effectiveness. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted member of WEDA and CEDA, delivers high-performance dredging hoses engineered for superior durability and operational resilience. With a manufacturing footprint spanning 0.68 million square meters and adherence to ISO9001 quality standards, East Marine’s rubber hoses are designed to meet the rigorous demands of marine and offshore applications.

This technical comparison evaluates key performance parameters—inner diameter, working pressure, burst pressure, and bending radius—between East Marine’s dredging hoses and typical offerings from industry competitors. The data reflects standard configurations for heavy-duty dredging hoses used in sand, slurry, and aggregate transfer operations.

East Marine’s hoses are constructed using premium synthetic rubber compounds and high-tensile textile reinforcements, ensuring extended service life under abrasive and high-pressure conditions. The optimized layline design enhances flexibility without compromising structural integrity, resulting in a reduced bending radius—critical for maneuverability in confined or dynamic marine environments.

Competitor hoses, while functionally adequate in many applications, often utilize standard reinforcement layers and less refined rubber formulations. This can lead to higher stiffness, reduced fatigue resistance, and a greater likelihood of delamination or blowout under sustained pressure cycles. Additionally, inconsistent manufacturing processes among competitors may result in variable performance metrics, particularly in burst pressure and flexibility.

East Marine’s engineering focus on balanced performance ensures that each hose exceeds minimum industry benchmarks. The burst pressure ratios (typically 4:1 relative to working pressure) surpass many competitors’ 3:1 averages, offering a greater safety margin. Furthermore, the tighter bending radius enables easier deployment on floating pipelines and articulated discharge systems, reducing installation time and stress on connected equipment.

The following table presents a comparative analysis of technical specifications for 16-inch (400 mm) dredging hoses—a common size in large-scale dredging projects.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) |

|---|---|---|---|

| 400 | 16 | 64 | 1,200 |

| 400 | 12–14 | 42–50 | 1,500–1,800 |

Note: East Marine values represent tested performance of model EM-DH400. Competitor data reflects averaged published specifications from three leading European and Asian manufacturers.

East Marine’s technical superiority is further validated through third-party testing and long-term field performance in projects across Southeast Asia, the Middle East, and Africa. The integration of advanced vulcanization techniques and rigorous quality control ensures dimensional consistency and performance reliability across production batches.

For engineering firms, dredging contractors, and EPC providers, selecting a hose with optimized pressure ratings and flexibility directly impacts operational uptime and maintenance costs. East Marine’s dredging hoses offer a technically superior, field-proven solution backed by two decades of industrial innovation since the parent company’s founding in 2007.

Partner with East Marine

Conclusion: Engineered Assurance for Demanding Dredging Operations

The SBM Suction and Discharge Marine Hose represents the culmination of East Marine’s two-decade commitment to solving the most complex hydraulic transport challenges in global dredging. Engineered within our 0.68 million square meter ISO 9001-certified manufacturing facility and validated through rigorous WEDA and CEDA-aligned testing protocols, this hose delivers uncompromising performance where failure is not an option. Its multi-layer reinforced construction—featuring abrasion-resistant synthetic rubber compounds, high-tensile spiral wire reinforcement, and UV-stabilized outer covers—ensures operational continuity in high-pressure discharge, severe vacuum suction, and abrasive slurry transport scenarios. Unlike generic alternatives, the SBM hose integrates proprietary bonding technology that eliminates delamination risks under cyclic stress, directly translating to reduced downtime and lower total cost of ownership for capital-intensive dredging projects.

Critical technical specifications defining the SBM hose’s operational envelope are detailed below. These parameters reflect adherence to ISO 14310 standards and field validation across 200+ global dredging deployments since our founding in 2007.

| Technical Parameter | Specification Value | Testing Standard |

|---|---|---|

| Max Working Pressure | 16 bar (232 psi) at 70°C | ISO 1402 |

| Vacuum Resistance | Full vacuum (760 mmHg) at 23°C | ISO 1307 |

| Temperaturbereich | -30°C to +80°C | ASTM D2240 |

| Cover Material | SBR/NR Blend (Abrasion Index ≤ 120 mm³) | ISO 4649 |

| Bend Radius (Min) | 8x Nominal Diameter | ISO 1307 Annex A |

| Wire Reinforcement | Galvanized High-Carbon Steel Spiral | ASTM A510M |

| Flange Compatibility | ANSI B16.5, DIN 2501, JIS 10K | Custom Configurations |

For dredging contractors managing multi-million-dollar project timelines, the SBM hose is not merely a component—it is a strategic enabler of schedule certainty and operational resilience. East Marine’s engineering team stands ready to collaborate on application-specific validation, including custom length configurations, flange adaptations, and pressure surge modeling for your unique project hydrology. Our Singapore branch provides localized technical support and rapid-response logistics coordination for Asia-Pacific operations, ensuring zero-delay deployment in critical time windows.

Initiate your project assurance protocol by engaging our dredging specialists directly. Contact +86-13806109365 via WhatsApp for immediate engineering consultation or urgent field support, where our team provides real-time troubleshooting and lifecycle optimization guidance. For comprehensive project documentation, CAD integration support, or bulk order coordination, email hsdredging@eastmarine.tech with your operational parameters and vessel specifications. Reference your project ID or dredge pump model to accelerate our technical review. As a vertically integrated manufacturer with full control over raw material sourcing through final QA—backed by 17 years of marine rubber expertise—we guarantee specifications match field performance. Partner with East Marine to transform hydraulic transport from a risk factor into your most reliable operational asset. Your next-generation dredging efficiency begins with a single technical dialogue.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.