Einführung: Navigieren auf dem globalen Markt für Einzelpunktverankerungssysteme spm

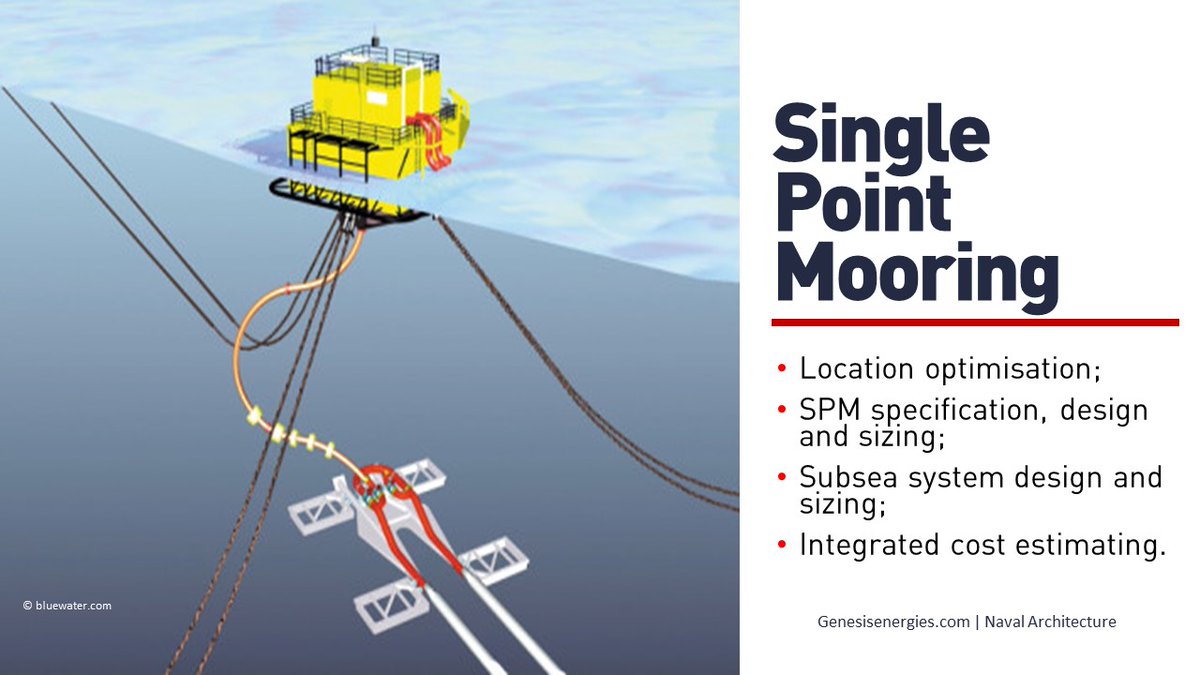

In einem zunehmend wettbewerbsintensiven Umfeld stellt die Beschaffung von Single-Point-Mooring-Systemen (SPM) eine große Herausforderung für internationale B2B-Einkäufer dar. Diese spezialisierten schwimmenden Strukturen sind entscheidend für den effizienten Umschlag von Flüssigladungen, insbesondere in Regionen, in denen es keine traditionellen Hafenanlagen gibt. Da die Nachfrage nach Erdöl und anderen flüssigen Produkten in Afrika, Südamerika, dem Nahen Osten und Europa steigt, ist das Verständnis der Feinheiten von SPM-Systemen für Unternehmen, die ihre Lieferketten und ihre betriebliche Effizienz optimieren wollen, von größter Bedeutung.

Dieser umfassende Leitfaden befasst sich mit den verschiedenen Arten von SPM-Systemen, einschließlich Catenary Anchor Leg Mooring (CALM) und Single Anchor Leg Mooring (SALM), sowie mit ihren spezifischen Anwendungen in verschiedenen Meeresumgebungen. Käufer erhalten Einblicke in die kritischen Aspekte der Lieferantenprüfung, um sicherzustellen, dass sie mit seriösen Herstellern und Dienstleistern zusammenarbeiten, die sich an die Industriestandards halten, wie sie vom Oil Companies International Marine Forum (OCIMF) festgelegt wurden.

Darüber hinaus befasst sich der Leitfaden mit Kostenerwägungen und der potenziellen Kapitalrendite und gibt Entscheidungsträgern das nötige Wissen an die Hand, um fundierte Kaufentscheidungen zu treffen. Durch die Präsentation von umsetzbaren Erkenntnissen und einem gründlichen Verständnis des SPM-Marktes befähigt diese Ressource internationale B2B-Einkäufer, insbesondere aus Regionen wie Nigeria und Deutschland, die Komplexität der Beschaffung und Implementierung dieser wichtigen Systeme effektiv zu bewältigen.

Inhaltsverzeichnis

- Top 5 Single Point Mooring Systems Spm Hersteller & Lieferanten Liste

- Einführung: Navigieren auf dem globalen Markt für Einzelpunktverankerungssysteme spm

- Verständnis von Einpunktverankerungen spm Typen und Variationen

- Wichtige industrielle Anwendungen von Einpunktverankerungssystemen spm

- 3 häufige Schmerzpunkte der Nutzer von 'single point mooring systems spm' und ihre Lösungen

- Leitfaden für die strategische Materialauswahl für Einzelpunktverankerungssysteme spm

- Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für Einzelpunktverankerungssysteme spm

- Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für 'single point mooring systems spm'.

- Umfassende Kosten- und Preisanalyse für Einzelpunktverankerungssysteme spm Sourcing

- Analyse der Alternativen: Vergleich von Einpunktverankerungssystemen spm mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für Einpunktverankerungssysteme spm

- Marktdynamik und Beschaffungstrends im Sektor der Einpunktverankerungssysteme spm navigieren

- Häufig gestellte Fragen (FAQs) für B2B-Einkäufer von Einpunktverankerungssystemen spm

- Strategische Beschaffung - Fazit und Ausblick für Einzelpunktverankerungssysteme spm

- Wichtiger Haftungsausschluss & Nutzungsbedingungen

Verständnis von Einpunktverankerungen spm Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

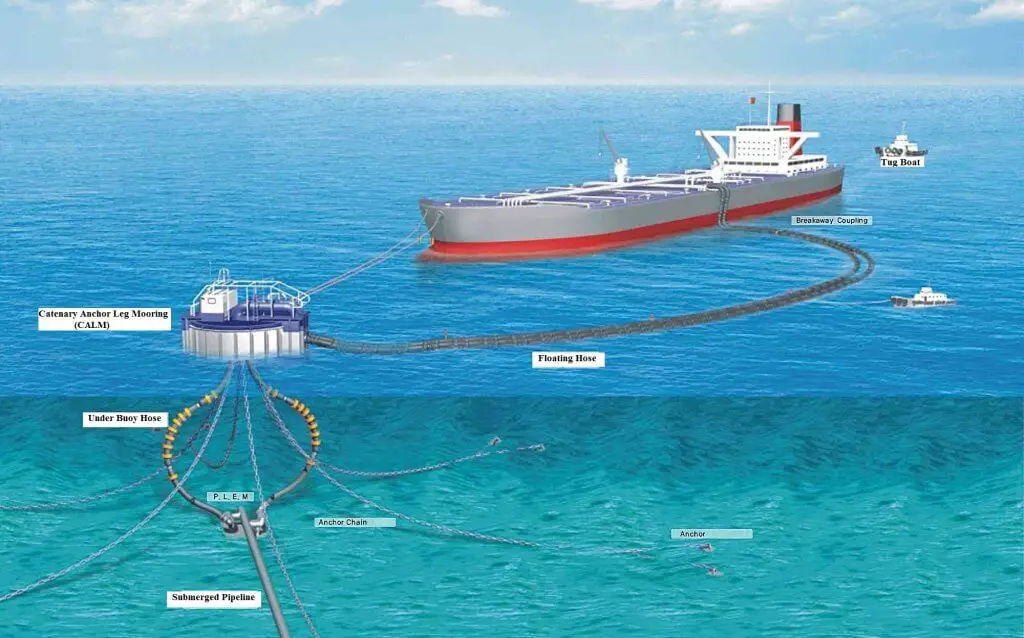

| CALM | Verankerung mit Kettenankern; flexibel, erlaubt Schiffsbewegungen | Offshore-Öl- und Gasverladung | Vorteile: Beherrscht große Schiffe, anpassungsfähig an das Wetter; Nachteile: Höhere Installationskosten. |

| SALM | Verankerung mit einem Ankerbein; starrer, eingeschränkte Schiffsbewegung | Tiefwassereinsätze | Vorteile: Stabil bei rauer See, effizient in der Tiefsee; Nachteile: Weniger flexibel als CALM. |

| SBM | Einzelne Bojenverankerung; vielseitige Konstruktion für verschiedene Ladungen | Transport von flüssigen Massengütern | Vorteile: Geeignet für verschiedene Flüssigkeitsarten; Nachteile: Erfordert regelmäßige Wartung. |

| SPAR | Mit vertikalen Festmacherleinen am Meeresboden verankert | Schwimmendes Produktionslager | Vorteile: Ausgezeichnete Stabilität in tiefen Gewässern; Nachteile: Komplizierter Installationsprozess. |

| Tension Leg Platform (TLP) | Gespannte vertikale Festmacherleinen; minimiert die Bewegung | Förderung und Lagerung in tiefen Gewässern | Vorteile: Hohe Stabilität, geeignet für raue Umgebungen; Nachteile: Hohe technische Anforderungen. |

Was sind die Merkmale und Anwendungen von CALM-Systemen?

Catenary Anchor Leg Mooring (CALM) Systeme zeichnen sich durch eine flexible Verankerung aus, die es den Tankschiffen ermöglicht, sich mit den Gezeiten und Wetterbedingungen zu bewegen. Dieser Typ eignet sich besonders für die Offshore-Öl- und Gasverladung, wo große Schiffe untergebracht werden müssen. Käufer sollten die Installationskosten berücksichtigen, da CALM-Systeme aufgrund ihrer komplexen Konstruktion teurer sein können. Ihre Anpassungsfähigkeit an wechselnde Wetterbedingungen macht sie jedoch zu einer günstigen Wahl für viele Betriebe.

Wie unterscheiden sich SALM-Systeme von anderen Verankerungsarten?

Single Anchor Leg Mooring (SALM) Systeme zeichnen sich durch ihre Steifigkeit aus und bieten eine stabile Plattform für Tiefseeeinsätze. Im Gegensatz zu CALM-Systemen schränkt SALM die Bewegung des Schiffes ein und ist daher ideal für Umgebungen mit starken Strömungen und Wellen. Diese Stabilität ist ein bedeutender Vorteil für Unternehmen, die Sicherheit und Effizienz beim Be- und Entladen optimieren wollen. Allerdings müssen die Käufer diesen Vorteil gegen die geringere Flexibilität bei den Verankerungsmöglichkeiten abwägen.

Was macht SBM-Systeme für den Flüssigkeitstransport so vielseitig?

Single-Buoy-Mooring-Systeme (SBM) sind für eine Vielzahl von Flüssigladungen ausgelegt und daher äußerst vielseitig. Sie werden in der Regel für den Transport von flüssigen Massengütern eingesetzt und können für verschiedene Schiffstypen angepasst werden. SBMs bieten zwar den Vorteil der Flexibilität, müssen aber regelmäßig gewartet werden, um die Betriebseffizienz zu gewährleisten. Für Unternehmen, die sich auf die Beförderung verschiedener Flüssigkeitsarten konzentrieren, kann die Anpassungsfähigkeit von SBM-Systemen ein großer Vorteil sein.

Warum Spar Systems für Tiefseeeinsätze wählen?

Spar-Systeme werden mit vertikalen Verankerungsleinen am Meeresboden verankert und bieten so eine außergewöhnliche Stabilität in tiefen Gewässern. Diese Art der Verankerung ist besonders vorteilhaft für schwimmende Produktionslager, bei denen konstante Betriebsbedingungen entscheidend sind. Spar-Systeme bieten zwar eine hohe Stabilität, aber die Komplexität ihrer Installation kann für Käufer eine Herausforderung darstellen. Unternehmen müssen ihre technischen Möglichkeiten und Projektanforderungen bewerten, wenn sie diese Option in Betracht ziehen.

Was sind die wichtigsten Überlegungen für Tension Leg Platforms (TLP)?

Tension-Leg-Plattformen (TLP) nutzen gespannte vertikale Verankerungsleinen, um die Schiffsbewegungen zu minimieren, und eignen sich daher für die Tiefseeproduktion und -lagerung. Dank ihrer Konstruktion können sie rauen Umgebungsbedingungen standhalten, was sie zu einer bevorzugten Wahl für Einsätze mit hohem Risiko macht. Die technischen Anforderungen für TLP-Systeme können jedoch beträchtlich sein, was zu höheren Kosten und längeren Projektlaufzeiten führen kann. Käufer sollten bei der Prüfung von TLP-Optionen ihre betrieblichen Anforderungen und Budgetbeschränkungen sorgfältig prüfen.

Wichtige industrielle Anwendungen von Einpunktverankerungssystemen spm

| Industrie/Sektor | Spezifische Anwendung von Einpunktverankerungssystemen spm | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Öl und Gas | Offshore-Erdöltransfer | Effizientes Be- und Entladen von großen Schiffen, wodurch die Überlastung der Häfen und die Betriebskosten verringert werden | Einhaltung der OCIMF-Normen, leistungsstarke Systeme und zuverlässige Wartungsdienste |

| Chemische Industrie | Transport von flüssigen Chemikalien | Sicherer Transport von Gefahrstoffen, Minimierung von Umweltrisiken und Einhaltung von Vorschriften | Qualität der Materialien, Sicherheitsmerkmale und Zertifizierungen der Lieferanten |

| Erneuerbare Energie | Verankerung für schwimmende LNG-Terminals | Erleichtert den Umschlag von LNG auf Tanker und erhöht die Flexibilität der Energieverteilung | Kompatibilität mit bestehender Infrastruktur und Umweltverträglichkeitsprüfungen |

| Versand und Logistik | Lager- und Vertriebszentrum für Flüssiggüter | Straffung der Lieferkette und Verkürzung der Transitzeiten für Flüssiggutsendungen | Robustes Design für raue Meeresbedingungen und Skalierbarkeit für zukünftige Anforderungen |

| Fischerei und Aquakultur | Unterstützung für Offshore-Fischfarmen | Bietet eine stabile Plattform für den Betrieb und erhöht die Produktivität und Sicherheit in der Aquakultur | Beständigkeit gegen Meeresbewuchs und Witterungseinflüsse sowie Installationsdienste |

Wie werden Einpunktverankerungssysteme in der Öl- und Gasindustrie eingesetzt?

In der Öl- und Gasindustrie sind Einpunktverankerungssysteme (SPM) für den Offshore-Transfer von Rohöl von Tankschiffen zu Anlagen an Land von entscheidender Bedeutung. Diese Systeme ermöglichen das Anlegen von sehr großen Rohöltankern (VLCC) in beträchtlicher Entfernung von der Küste, was ein effizientes Be- und Entladen ohne Hafenaufenthalte ermöglicht. Dies spart nicht nur Zeit und Treibstoff, sondern minimiert auch das Risiko von Hafenüberlastungen. Einkäufer in diesem Sektor müssen Lieferanten bevorzugen, die die OCIMF-Normen erfüllen und Systeme mit hoher Kapazität anbieten, die große Mengen flüssiger Ladung umschlagen können.

Welche Rolle spielen Einpunktverankerungssysteme in der chemischen Industrie?

In der chemischen Industrie werden SPM-Systeme für den sicheren Transfer verschiedener flüssiger Chemikalien, einschließlich gefährlicher Stoffe, eingesetzt. Die Konstruktion dieser Systeme stellt sicher, dass der Transferprozess strenge Sicherheits- und Umweltvorschriften einhält, wodurch das Risiko von Verschüttungen und Unfällen verringert wird. Für internationale Einkäufer, vor allem in Regionen mit strengen Vorschriften, ist die Beschaffung von SPM-Systemen, die sich durch hochwertige Materialien und fortschrittliche Sicherheitsmechanismen auszeichnen, von entscheidender Bedeutung für den Schutz sowohl ihrer Betriebe als auch der Umwelt.

Wie verbessern Einpunktverankerungssysteme den Betrieb erneuerbarer Energien?

Im Bereich der erneuerbaren Energien werden zunehmend Einpunktverankerungssysteme eingesetzt, insbesondere für schwimmende LNG-Terminals. Diese Systeme ermöglichen den effizienten Umschlag von Flüssigerdgas (LNG) von und zu Tankschiffen und erhöhen die Flexibilität der Energieverteilung. Durch die Möglichkeit, weit vor der Küste zu verankern, tragen SPM-Systeme dazu bei, die mit ungünstigen Wetterbedingungen verbundenen Risiken zu mindern. Käufer sollten bei der Beschaffung dieser Systeme die Kompatibilität mit der bestehenden Infrastruktur und die Umweltverträglichkeitsprüfungen berücksichtigen.

Welche Vorteile bieten Single Point Mooring Systeme für Schifffahrt und Logistik?

In Schifffahrt und Logistik dienen SPM-Systeme als strategische Knotenpunkte für die Lagerung und Verteilung von Flüssigladungen und stellen eine nahtlose Verbindung zwischen dem Seeverkehr und landgestützten Einrichtungen her. Diese Einrichtung rationalisiert die Lieferkettenabläufe und verkürzt die Transitzeiten für Massengüter erheblich. Für Unternehmen in diesem Sektor ist es von entscheidender Bedeutung, in robuste SPM-Konstruktionen zu investieren, die den rauen Bedingungen auf See standhalten und gleichzeitig die Skalierbarkeit für künftiges Wachstum gewährleisten.

Wie sind Einpunktverankerungssysteme für die Fischerei und Aquakultur von Vorteil?

Im Fischerei- und Aquakultursektor unterstützen Einpunktverankerungssysteme Offshore-Fischfarmen, indem sie eine stabile Plattform für den Betrieb bieten. Diese Stabilität erhöht die Produktivität und Sicherheit und ermöglicht ein effizientes Management von Aquakulturaktivitäten. Käufer, die SPM-Lösungen in dieser Branche einführen möchten, sollten sich auf die Beständigkeit gegen Meereswachstum und extreme Wetterbedingungen sowie auf die Verfügbarkeit von Installations- und Wartungsdienstleistungen konzentrieren, um einen langfristigen Betriebserfolg sicherzustellen.

3 häufige Schmerzpunkte der Nutzer von 'single point mooring systems spm' und ihre Lösungen

Szenario 1: Komplexe regulatorische Anforderungen für SPM-Systeme bewältigen

Das Problem:

B2B-Einkäufer stehen bei der Einführung von Single-Point-Mooring-Systemen (SPM) oft vor der Herausforderung, sich in einer komplexen Landschaft von gesetzlichen Anforderungen zurechtzufinden. Besonders ausgeprägt ist dieses Problem in Regionen wie Europa und dem Nahen Osten, wo die Vorschriften streng und von Land zu Land sehr unterschiedlich sein können. Käufer können Schwierigkeiten haben, die Einhaltung der von Organisationen wie dem Oil Companies International Marine Forum (OCIMF) oder den örtlichen Schifffahrtsbehörden festgelegten Standards zu gewährleisten, was zu möglichen Verzögerungen bei der Projektgenehmigung, höheren Kosten und sogar rechtlichen Konsequenzen führen kann.

Die Lösung:

Um diese Herausforderung zu meistern, ist es entscheidend, bereits in der Projektplanungsphase einen Experten für die Einhaltung von Vorschriften hinzuzuziehen. Erstellen Sie eine Checkliste der relevanten Vorschriften auf der Grundlage der Betriebsregion und des spezifischen SPM-Systems, das eingeführt werden soll. Arbeiten Sie mit lokalen Behörden und Branchenverbänden zusammen, um Einblicke in die neuesten Standards und bewährten Verfahren zu erhalten. Ziehen Sie außerdem die Zusammenarbeit mit erfahrenen Anbietern in Betracht, die nachweislich Erfahrung im Umgang mit Vorschriften haben. Diese Zulieferer können Anleitungen und Dokumentationen bereitstellen, die die Einhaltung der Vorschriften belegen und dazu beitragen, die Genehmigungsverfahren zu straffen und das Risiko kostspieliger Verzögerungen zu verringern.

Szenario 2: Verwaltung der betrieblichen Ausfallzeiten während der SPM-Wartung

Das Problem:

Betriebsunterbrechungen sind ein großes Problem für Unternehmen, die sich auf Einpunktverankerungssysteme verlassen, insbesondere in Sektoren wie der Öl- und Gasindustrie, in denen ein kontinuierlicher Betrieb entscheidend ist. Wartungsarbeiten können zu unerwarteten Unterbrechungen führen, die Umsatzeinbußen und höhere Betriebskosten zur Folge haben. Für den Käufer kann es schwierig sein, Wartungspläne zu erstellen, die die Ausfallzeiten minimieren und gleichzeitig die Sicherheit und Effizienz der SPM-Systeme gewährleisten.

Die Lösung:

Die Umsetzung einer proaktiven Wartungsstrategie ist für ein effektives Management von Ausfallzeiten unerlässlich. Dies kann durch die Anwendung eines zustandsorientierten Wartungskonzepts (CBM) erreicht werden, bei dem die Daten von Überwachungssystemen genutzt werden, um den Zustand der SPM-Ausrüstung kontinuierlich zu bewerten. Planen Sie Routineinspektionen und -wartungen außerhalb der Hauptverkehrszeiten oder bei geringem Tankeraufkommen, um Unterbrechungen zu minimieren. Darüber hinaus kann eine Partnerschaft mit einem Dienstleister, der schnelle Reaktions- und Reparaturmöglichkeiten bietet, die Ausfallzeiten weiter reduzieren. Auf diese Weise können Käufer sicherstellen, dass ihre SPM-Systeme betriebsbereit bleiben, während sie die Wartungspläne einhalten.

Szenario 3: Gewährleistung sicherer und effizienter Be- und Entladevorgänge

Das Problem:

B2B-Einkäufer haben oft mit der Herausforderung zu kämpfen, sichere und effiziente Lade- und Löschvorgänge in SPM-Anlagen zu gewährleisten. Faktoren wie ungünstige Witterungsbedingungen, Ausrüstungsstörungen und unsachgemäßes Festmachen können zu Betriebsgefahren führen, einschließlich Auslaufen oder Unfällen. Dies gefährdet nicht nur die Sicherheit, sondern kann auch zu erheblichen finanziellen Verlusten und Rufschädigung führen.

Die Lösung:

Um die Sicherheit und Effizienz zu erhöhen, ist es unerlässlich, umfassende Schulungsprogramme für das an den Be- und Entladevorgängen beteiligte Personal durchzuführen. Diese Schulungen sollten Notfallprotokolle, korrekte Verankerungstechniken und die Handhabung der Ausrüstung umfassen. Darüber hinaus kann die Investition in fortschrittliche Technologien wie automatische Überwachungssysteme Echtzeitdaten zu Wetterbedingungen und Ausrüstungsstatus liefern und so eine schnelle Entscheidungsfindung ermöglichen. Regelmäßige Übungen und Sicherheitsprüfungen können die Sicherheitskultur stärken und sicherstellen, dass das gesamte Personal auf mögliche Herausforderungen vorbereitet ist. Durch die Priorisierung von Schulung und Technologie können Einkäufer die mit Be- und Entladevorgängen in SPM-Anlagen verbundenen Risiken erheblich verringern.

Leitfaden für die strategische Materialauswahl für Einzelpunktverankerungssysteme spm

Was sind die wichtigsten Materialien für Einpunktverankerungssysteme (SPM)?

Die Auswahl der richtigen Materialien für Einpunktverankerungssysteme (SPM) ist entscheidend für die Gewährleistung der Betriebseffizienz, der Sicherheit und der Einhaltung internationaler Normen. Im Folgenden analysieren wir vier gängige Materialien, die in SPM-Anwendungen verwendet werden, und konzentrieren uns dabei auf ihre Eigenschaften, Vorteile, Nachteile und Überlegungen für internationale Käufer.

Wie verhält sich Stahl in Einpunktverankerungssystemen?

Wichtige Eigenschaften: Stahl ist bekannt für seine hohe Zugfestigkeit und Haltbarkeit. Er kann extremen Temperaturen und Drücken standhalten und ist daher für verschiedene Offshore-Anwendungen geeignet. Darüber hinaus kann Stahl für Korrosionsbeständigkeit behandelt werden, was seine Lebensdauer in rauen Meeresumgebungen erhöht.

Pro und Kontra: Der Hauptvorteil von Stahl ist seine Festigkeit, die den Bau von robusten Verankerungssystemen ermöglicht. Allerdings kann er bei unzureichendem Schutz korrosionsanfällig sein, was zu erhöhten Wartungskosten führt. Auch die Komplexität der Herstellung kann ein Problem darstellen, da Stahlkomponenten oft geschweißt und speziell bearbeitet werden müssen.

Auswirkungen auf die Anwendung: Stahl ist mit verschiedenen Medien, einschließlich Erdöl und Chemikalien, kompatibel, was ihn zu einer vielseitigen Wahl für SPM-Systeme macht. Es muss jedoch unbedingt sichergestellt werden, dass die verwendete Stahlsorte für das vorgesehene Medium geeignet ist, um chemische Reaktionen zu vermeiden.

Überlegungen für internationale Einkäufer: Bei der Beschaffung von Stahlkomponenten ist die Einhaltung von Normen wie ASTM oder ISO entscheidend. Käufer aus Regionen wie Afrika und Südamerika sollten auch die lokale Verfügbarkeit und mögliche Einfuhrzölle berücksichtigen.

Welche Rolle spielt Polyethylen in SPM-Systemen?

Wichtige Eigenschaften: Polyethylen (PE) ist ein leichtes, flexibles Material mit ausgezeichneter chemischer Beständigkeit. Es kann in einem breiten Temperaturbereich effektiv arbeiten und wird häufig für flexible Schläuche in SPM-Systemen verwendet.

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

Pro und Kontra: Der Hauptvorteil von Polyethylen ist seine Korrosions- und Chemikalienbeständigkeit, die seine Lebensdauer in Meeresumgebungen verlängert. Seine im Vergleich zu Metallen geringere Zugfestigkeit kann jedoch bei hochbelasteten Anwendungen eine Einschränkung darstellen. Außerdem können die Herstellungsverfahren für Polyethylen hoher Dichte komplexer und kostspieliger sein.

Auswirkungen auf die Anwendung: Polyethylen eignet sich aufgrund seiner Flexibilität und Beständigkeit gegen verschiedene Chemikalien besonders gut für den Transport von Flüssiggut. Es ist jedoch nicht unbedingt für Hochdruckanwendungen geeignet, es sei denn, es wurde speziell für diesen Einsatz konzipiert.

Überlegungen für internationale Einkäufer: Die Käufer sollten sicherstellen, dass das verwendete Polyethylen internationalen Normen wie DIN oder JIS entspricht. Auch die Kenntnis der örtlichen Vorschriften für Kunststoffe ist wichtig, insbesondere in Regionen mit strengen Umweltgesetzen.

Warum ist rostfreier Stahl die bevorzugte Wahl für SPM-Komponenten?

Wichtige Eigenschaften: Edelstahl bietet eine ausgezeichnete Korrosionsbeständigkeit und hohe Festigkeit und eignet sich daher ideal für Anwendungen im Schiffsbau. Er kann rauen Umweltbedingungen standhalten und hat eine lange Lebensdauer.

Pro und Kontra: Der Hauptvorteil von rostfreiem Stahl ist seine Langlebigkeit und Rostbeständigkeit, wodurch sich die Wartungskosten mit der Zeit verringern. Allerdings ist er im Allgemeinen teurer als Kohlenstoffstahl und kann aufgrund seiner Härte schwierig zu bearbeiten sein.

Auswirkungen auf die Anwendung: Edelstahl verträgt sich mit verschiedenen Flüssigkeiten, auch mit korrosiven Stoffen, und ist daher eine bevorzugte Wahl für Komponenten wie Ventile und Fittings in SPM-Systemen.

Überlegungen für internationale Einkäufer: Die Käufer sollten sich vergewissern, dass die verwendeten Edelstahlsorten internationalen Normen wie ASTM A312 oder ISO 9001 entsprechen. Dies ist vor allem in Regionen wie Europa wichtig, wo die Einhaltung streng überwacht wird.

Wie verbessern Verbundwerkstoffe die SPM-Systeme?

Wichtige Eigenschaften: Verbundwerkstoffe, die oft aus einer Kombination von Harz und Fasern bestehen, bieten ein hohes Verhältnis von Festigkeit zu Gewicht und eine hervorragende Korrosionsbeständigkeit. Sie können für spezifische Anwendungen entwickelt werden und sind daher vielseitig einsetzbar.

Pro und Kontra: Der Hauptvorteil von Verbundwerkstoffen ist ihr geringes Gewicht, das die Installation vereinfacht und die Transportkosten senkt. Sie können jedoch teurer sein und erfordern möglicherweise spezielle Fertigungstechniken.

Auswirkungen auf die Anwendung: Verbundwerkstoffe eignen sich aufgrund ihrer Widerstandsfähigkeit gegenüber der Meeresumwelt für verschiedene Anwendungen, darunter Auftriebskörper und flexible Schläuche. Ihre Kompatibilität mit verschiedenen Medien hängt von dem verwendeten Harz ab.

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

Überlegungen für internationale Einkäufer: Käufer sollten sicherstellen, dass Verbundwerkstoffe den einschlägigen Normen und Zertifizierungen entsprechen. Die Kenntnis des lokalen Marktes für Verbundwerkstoffe, insbesondere in aufstrebenden Regionen, kann Wettbewerbsvorteile bringen.

Übersichtstabelle zur strategischen Materialauswahl für SPM-Systeme

| Material | Typischer Anwendungsfall für Einzelpunktverankerungssysteme spm | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Strukturelle Komponenten, Verankerungsketten | Hohe Festigkeit und Haltbarkeit | Anfällig für Korrosion | Hoch |

| Polyethylen | Flexible Schläuche für den Flüssigkeitstransfer | Ausgezeichnete chemische Beständigkeit | Geringere Zugfestigkeit | Mittel |

| Rostfreier Stahl | Ventile, Armaturen und Bauelemente | Korrosionsbeständigkeit und Haltbarkeit | Höhere Kosten und schwierige Bearbeitung | Hoch |

| Komposit | Auftriebskörper, flexible Schläuche | Leicht und korrosionsbeständig | Höhere Kosten und spezialisierte Fertigung | Mittel |

Dieser Leitfaden bietet B2B-Einkäufern verwertbare Einblicke in die Materialauswahl für Einzelpunktverankerungssysteme und gewährleistet fundierte Entscheidungen, die mit den betrieblichen Anforderungen und Konformitätsstandards übereinstimmen.

Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für Einzelpunktverankerungssysteme spm

Was sind die wichtigsten Schritte im Herstellungsprozess von Einpunktverankerungssystemen?

Der Herstellungsprozess von Einpunktverankerungssystemen (SPM) ist kompliziert und umfasst mehrere kritische Phasen, um sicherzustellen, dass das Endprodukt die hohen Anforderungen für den Offshore-Betrieb erfüllt. Zu den wichtigsten Phasen gehören Materialvorbereitung, Formgebung, Montage und Endbearbeitung.

-

Vorbereitung des Materials

Der Herstellungsprozess beginnt mit der Auswahl hochwertiger Materialien, die den rauen Meeresbedingungen standhalten können. Zu den gängigen Materialien gehören hochfester Stahl, korrosionsbeständige Legierungen und spezielle Polymere für Schläuche und Dichtungen. Die Zulieferer müssen sicherstellen, dass die Materialien internationalen Normen wie ASTM- und ISO-Spezifikationen entsprechen. Die Materialeigenschaften, einschließlich der Zugfestigkeit und Korrosionsbeständigkeit, werden streng geprüft, bevor die nächste Stufe erreicht wird. -

Bildung von

Sobald die Materialien vorbereitet sind, werden sie verschiedenen Formgebungsverfahren unterzogen. Dazu gehören Schneiden, Schweißen und Biegen, um Komponenten wie den Bojenkörper, Verankerungsketten und Produkttransfersysteme herzustellen. Moderne Techniken wie CNC-Bearbeitung und Roboterschweißen werden häufig eingesetzt, um Präzision und Effizienz zu steigern. Die Formgebungsphase ist von entscheidender Bedeutung, da sie die Grundlage für die strukturelle Integrität und Leistung des SPM-Systems bildet. -

Montage

In der Montagephase werden die einzelnen Komponenten zu einer zusammenhängenden Einheit zusammengefügt. Dazu gehören das Anbringen des Verankerungssystems an der Boje, die Installation der Produkttransfersysteme und die Integration von Sicherheitsmerkmalen wie Abreißkupplungen und Alarmsystemen. An verschiedenen Stellen des Montageprozesses werden Qualitätskontrollen durchgeführt, um sicherzustellen, dass alle Komponenten richtig passen und wie vorgesehen funktionieren. Eine ordnungsgemäße Dokumentation des Montageprozesses ist für die Rückverfolgbarkeit und die Einhaltung der Industrienormen unerlässlich. -

Fertigstellung

Die letzte Phase ist die Endbearbeitung, die Oberflächenbehandlungsverfahren wie Lackierung, Beschichtung oder Verzinkung zum Schutz vor Korrosion und Verschleiß umfasst. Diese Phase umfasst auch eine gründliche Prüfung der gesamten Baugruppe, um sicherzustellen, dass alle Qualitätsstandards eingehalten werden. Zerstörungsfreie Prüfverfahren (NDT) wie Ultraschallprüfung und Magnetpulverprüfung werden üblicherweise eingesetzt, um verborgene Mängel zu entdecken, bevor das Produkt ausgeliefert wird.

Welche Maßnahmen zur Qualitätskontrolle sind für Einpunktverankerungssysteme unerlässlich?

Die Qualitätskontrolle (QC) ist bei der Herstellung von Einpunktverankerungssystemen von größter Bedeutung, um Sicherheit, Zuverlässigkeit und die Einhaltung der internationalen Vorschriften zu gewährleisten. Dieser Prozess umfasst die Einhaltung verschiedener Normen und sorgfältiger Prüfprotokolle.

-

Internationale und branchenspezifische Normen

Die Einhaltung internationaler Qualitätsmanagementnormen wie ISO 9001 ist für Hersteller von SPM-Systemen entscheidend. Darüber hinaus bieten branchenspezifische Normen von Organisationen wie dem American Petroleum Institute (API) und dem Oil Companies International Marine Forum (OCIMF) spezielle Richtlinien für den Einsatz auf See und im Offshore-Bereich. Diese Normen decken alle Bereiche ab, von der Konstruktion und Herstellung bis hin zur Prüfung und Installation. -

Kontrollpunkte der Qualitätskontrolle

Eine wirksame Qualitätskontrolle umfasst mehrere Kontrollpunkte während des gesamten Herstellungsprozesses:

– Eingehende Qualitätskontrolle (IQC): Die Materialien werden bei ihrer Ankunft geprüft, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen.

– Prozessbegleitende Qualitätskontrolle (IPQC): Die kontinuierliche Überwachung während der Herstellung gewährleistet, dass die Prozesse innerhalb der festgelegten Parameter bleiben.

– Endgültige Qualitätskontrolle (FQC): Vor der Auslieferung wird eine umfassende Bewertung des fertigen Systems durchgeführt, um zu überprüfen, ob alle Spezifikationen und Normen erfüllt sind. -

Gängige Prüfmethoden

Zur Bewertung der Qualität und Leistung von SPM-Systemen werden verschiedene Prüfverfahren eingesetzt:

– Hydrostatische Prüfung: Zur Überprüfung der Unversehrtheit von Druckbehältern und Schläuchen.

– Belastungstests: Um sicherzustellen, dass die Verankerungssysteme den betrieblichen Belastungen standhalten.

– Umweltprüfungen: Zur Simulation von Meeresbedingungen und zur Bewertung der Korrosionsbeständigkeit.

Wie können B2B-Einkäufer die Qualitätskontrolle von Lieferanten überprüfen?

Für B2B-Einkäufer, insbesondere aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, ist die Sicherstellung der Qualität von SPM-Systemen entscheidend. Hier sind einige wirksame Strategien zur Überprüfung der Qualitätskontrolle von Lieferanten:

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

-

Durchführung von Audits

Regelmäßige Audits bei potenziellen Lieferanten können Aufschluss über deren Herstellungsverfahren, Qualitätskontrollmaßnahmen und die Einhaltung internationaler Normen geben. Einkäufer sollten Auditberichte von früheren Bewertungen anfordern, um die Zuverlässigkeit des Lieferanten zu beurteilen. -

Anfordern von Qualitätssicherungsunterlagen

Die Einkäufer sollten ausführliche Unterlagen über die Qualitätssicherungsprozesse verlangen, einschließlich Bescheinigungen über die Einhaltung der einschlägigen Normen (ISO, API, CE). In diesen Unterlagen sollten die bei der Prüfung und Inspektion angewandten Methoden dargelegt werden. -

Beauftragung von Inspektionsdiensten durch Dritte

Die Inanspruchnahme von Inspektionsdiensten Dritter kann eine unparteiische Bewertung der Herstellungsverfahren und Endprodukte liefern. Diese Dienste können Inspektionen in verschiedenen Phasen der Produktion durchführen und detaillierte Berichte über die Einhaltung der Spezifikationen erstellen.

Was sind die Feinheiten der Qualitätskontrolle und der Zertifizierung für internationale Einkäufer?

Internationale Einkäufer müssen sich bei der Beschaffung von Einpunktverankerungssystemen mit verschiedenen Nuancen der Qualitätskontrolle und Zertifizierung auseinandersetzen. Das Verständnis dieser Nuancen kann helfen, Risiken zu mindern und die Produktqualität zu gewährleisten.

-

Regionale Normen und Einhaltung der Vorschriften

In verschiedenen Regionen gibt es möglicherweise spezifische Vorschriften und Normen, die für den Schiffsbetrieb gelten. So könnten europäische Einkäufer beispielsweise die Einhaltung der CE-Kennzeichnung bevorzugen, während Einkäufer im Nahen Osten sich auf die lokalen Schifffahrtsvorschriften konzentrieren könnten. Für Einkäufer ist es wichtig, die spezifischen Anforderungen ihrer Region zu kennen und sicherzustellen, dass die Lieferanten sie erfüllen können. -

Kulturelle Erwägungen im Qualitätsmanagement

Kulturelle Einstellungen zu Qualität und Sicherheit können von Region zu Region sehr unterschiedlich sein. Einkäufer sollten diese kulturellen Nuancen berücksichtigen, wenn sie mit Lieferanten zusammenarbeiten, da sie sich auf die gesamten Qualitätssicherungsprozesse auswirken können. Eine klare Kommunikation und klare Erwartungen können helfen, eventuelle Lücken zu schließen. -

Transparenz der Lieferkette

Bei internationalen Geschäften ist die Aufrechterhaltung der Transparenz in der gesamten Lieferkette entscheidend. Käufer sollten Lieferanten suchen, die Einblick in ihre Herstellungsprozesse, die Beschaffung von Materialien und Qualitätskontrollmaßnahmen gewähren. Diese Transparenz kann das Vertrauen stärken und reibungslosere Transaktionen ermöglichen.

Zusammenfassend lässt sich sagen, dass es für B2B-Einkäufer von entscheidender Bedeutung ist, die Herstellungsverfahren und Qualitätssicherungsmaßnahmen für Einpunktverankerungssysteme zu verstehen. Indem sie sich auf die Materialvorbereitung, die Montage und die strenge Qualitätskontrolle konzentrieren, können Käufer sicherstellen, dass sie zuverlässige und konforme Produkte beschaffen, die ihre betrieblichen Anforderungen erfüllen.

Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für 'single point mooring systems spm'.

In der komplexen Welt der Offshore-Logistik erfordert die Beschaffung eines Single Point Mooring (SPM)-Systems eine sorgfältige Planung und Ausführung. Dieser Leitfaden dient als praktische Checkliste für B2B-Einkäufer, insbesondere für diejenigen, die in verschiedenen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa tätig sind. Die Befolgung dieser Schritte wird dazu beitragen, einen erfolgreichen Beschaffungsprozess zu gewährleisten, der die betrieblichen Anforderungen erfüllt und gleichzeitig die Industriestandards einhält.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Die Festlegung klarer technischer Spezifikationen ist entscheidend für die Abstimmung des SPM-Systems auf Ihre betrieblichen Anforderungen. Berücksichtigen Sie Faktoren wie die Art der umzuschlagenden Flüssigkeit, die maximale Schiffsgröße und die Umweltbedingungen am Installationsort. Vergewissern Sie sich, dass Ihre Spezifikationen auch die notwendigen Sicherheitsmerkmale und die Einhaltung internationaler Normen, wie die des Oil Companies International Marine Forum (OCIMF), umfassen.

Schritt 2: Führen Sie Marktforschung durch

Eine gründliche Marktforschung ist unerlässlich, um potenzielle Lieferanten zu ermitteln, die sich auf SPM-Systeme spezialisiert haben. Untersuchen Sie verschiedene Hersteller, ihr Produktangebot und ihre bisherige Leistung bei ähnlichen Projekten. Achten Sie auf geografische Faktoren, da Lieferanten mit Erfahrung in Ihrer Region möglicherweise Einblicke in lokale Vorschriften und logistische Herausforderungen haben.

Schritt 3: Potenzielle Lieferanten evaluieren

Bevor Sie eine Zusage machen, sollten Sie die in die engere Wahl gekommenen Lieferanten gründlich prüfen. Fordern Sie Unternehmensprofile, Fallstudien und Referenzen von Einkäufern in ähnlichen Branchen oder Regionen an, um deren Glaubwürdigkeit und Fachwissen zu beurteilen. Suchen Sie nach Anbietern, die eine starke Erfolgsbilanz bei der Installation und Wartung von SPM-Systemen vorweisen können.

Schritt 4: Überprüfen von Zertifizierungen und Konformität

Vergewissern Sie sich, dass die von Ihnen ausgewählten Lieferanten über die entsprechenden Zertifizierungen verfügen und die Branchenvorschriften einhalten. Dazu gehören Zertifizierungen von anerkannten Organisationen wie DNV GL, ABS oder BV, die die Sicherheit und Qualität ihrer Produkte bestätigen. Die Einhaltung internationaler Normen gewährleistet nicht nur die Zuverlässigkeit der Produkte, sondern mindert auch die mit dem Offshore-Betrieb verbundenen Risiken.

Schritt 5: Bewertung des Kundendienstes und der Wartungsdienste

Ein starkes Kundendienstsystem ist für den langfristigen Erfolg Ihres SPM-Systems von entscheidender Bedeutung. Erkundigen Sie sich nach den Wartungsdiensten des Lieferanten, den Reaktionszeiten bei Reparaturen und der Verfügbarkeit von Ersatzteilen. Eine klare Vorstellung von der Unterstützung, die Sie erhalten werden, kann Ihnen in Zukunft viel Zeit und Kosten sparen.

Schritt 6: Überprüfung der Finanzstabilität

Die finanzielle Solidität Ihres Lieferanten ist ein entscheidender Faktor, um sicherzustellen, dass er Ihr Projekt während seines gesamten Lebenszyklus unterstützen kann. Fordern Sie Finanzberichte oder Kreditauskünfte an, um die Stabilität des Anbieters zu beurteilen. Ein finanziell gesunder Anbieter ist eher in der Lage, über einen längeren Zeitraum hinweg gleichbleibende Qualität und zuverlässige Dienstleistungen zu erbringen.

Schritt 7: Bedingungen und Konditionen verhandeln

Nehmen Sie schließlich Verhandlungen auf, um die Bedingungen Ihres Beschaffungsvertrags endgültig festzulegen. Legen Sie Lieferfristen, Zahlungsbedingungen, Garantien und Haftungen klar fest, um spätere Streitigkeiten zu vermeiden. Stellen Sie sicher, dass der Vertrag Bestimmungen für mögliche Änderungen des Projektumfangs oder unvorhergesehene Umstände enthält.

Anhand dieser umfassenden Checkliste können B2B-Einkäufer die Komplexität der Beschaffung von Single Point Mooring-Systemen sicher beherrschen und sicherstellen, dass ihre Investition den betrieblichen Anforderungen und Industriestandards entspricht.

Umfassende Kosten- und Preisanalyse für Einzelpunktverankerungssysteme spm Sourcing

Was sind die wichtigsten Kostenkomponenten von Einpunktverankerungssystemen?

Bei der Beschaffung von Einpunktverankerungssystemen (SPM) ist es für B2B-Einkäufer entscheidend, die Kostenstruktur zu verstehen. Zu den wichtigsten Kostenkomponenten gehören:

-

Materialien: Die Materialkosten machen einen erheblichen Teil des Gesamtpreises aus. Dazu gehören hochfester Stahl für die Boje und die Verankerungsketten, spezielle Schläuche für den Produkttransport und korrosionsbeständige Beschichtungen. Je nach den spezifischen Anforderungen und Umweltbedingungen kann die Auswahl der Materialien sowohl die Anschaffungskosten als auch die langfristige Haltbarkeit beeinflussen.

-

Arbeit: Die Arbeitskosten umfassen die Ausgaben für qualifizierte Techniker und Ingenieure, die für die Installation, die Wartung und den Betrieb der SPM-Systeme erforderlich sind. Die Komplexität des Installationsprozesses, insbesondere in Offshore-Umgebungen, erfordert spezialisierte Arbeitskräfte, was die Kosten weiter in die Höhe treiben kann.

-

Fertigungsgemeinkosten: Dazu gehören indirekte Kosten, die mit der Produktion von SPM-Systemen verbunden sind, wie z. B. die Instandhaltung von Anlagen, Versorgungsleistungen und Verwaltungskosten. Effiziente Herstellungsverfahren können bei der Verwaltung der Gemeinkosten helfen, was sich letztlich auf die Preisgestaltung auswirkt.

-

Werkzeugbau: Ein weiterer Kostenfaktor sind die Investitionen in spezielle Werkzeuge und Anlagen für die Herstellung von SPM-Systemen. Dazu gehören Formen, Vorrichtungen und Maschinen, die für die Produktion benötigt werden und die je nach verwendeter Technologie variieren können.

-

Qualitätskontrolle (QC): Die Sicherstellung, dass SPM-Systeme den Industrienormen und Zertifizierungen entsprechen, verursacht zusätzliche Kosten. Strenge Prüf- und Qualitätssicherungsprozesse sind unerlässlich, um künftige Betriebsausfälle zu verhindern, insbesondere in der maritimen Industrie, in der viel auf dem Spiel steht.

-

Logistik: Die Transport- und Logistikkosten können beträchtlich sein, insbesondere bei großen, schweren Bauteilen, die zu Offshore-Standorten transportiert werden müssen. Diese Kosten können je nach Entfernung und verwendetem Transportmittel erheblich variieren.

-

Marge: Die Lieferanten schlagen in der Regel eine Gewinnspanne auf, um ihre Kosten zu decken und Nachhaltigkeit zu gewährleisten. Diese Marge kann je nach Ruf des Lieferanten, seiner Erfahrung und der Marktnachfrage variieren.

Was beeinflusst die Preisgestaltung von SPM-Systemen?

Mehrere Faktoren können die Preisgestaltung von Einpunktverankerungen beeinflussen:

-

Volumen und Mindestbestellmenge (MOQ): Größere Bestellungen führen aufgrund von Skaleneffekten häufig zu Preisnachlässen. Die Käufer sollten in Erwägung ziehen, MOQs auszuhandeln, um die Kosten zu optimieren.

-

Spezifikationen und Anpassungen: Maßgeschneiderte SPM-Systeme, die auf spezifische betriebliche Anforderungen zugeschnitten sind, können die Kosten erheblich beeinflussen. Die Käufer müssen den Bedarf an individueller Anpassung mit den damit verbundenen Preissteigerungen abwägen.

-

Materialqualität und Zertifizierungen: Das Qualitätsniveau und die erforderlichen Zertifizierungen (z. B. OCIMF-Normen) können die Kosten beeinflussen. Hochwertige Materialien und zertifizierte Systeme können teurer sein, bieten aber auch eine höhere Zuverlässigkeit und Langlebigkeit.

-

Lieferanten-Faktoren: Der Ruf, die Zuverlässigkeit und die Erfahrung des Lieferanten können sich auf die Preisgestaltung auswirken. Etablierte Lieferanten verlangen aufgrund ihrer nachgewiesenen Erfolgsbilanz möglicherweise einen Aufschlag für ihre Produkte.

-

Incoterms: Die in den Incoterms (International Commercial Terms) festgelegten Versandbedingungen können die Gesamtkostenstruktur beeinflussen. Käufer sollten die Auswirkungen von Begriffen wie FOB (Free on Board) oder CIF (Cost, Insurance, and Freight) auf ihre Gesamtkosten kennen.

Was sind die besten Praktiken für die Verhandlung von SPM-Preisen?

Für internationale B2B-Einkäufer, vor allem aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, können wirksame Verhandlungsstrategien helfen, Kosteneinsparungen zu erzielen:

-

Verstehen der Gesamtbetriebskosten (TCO): Bewerten Sie nicht nur den Anschaffungspreis, sondern auch die mit den SPM-Systemen verbundenen Kosten für Wartung, Betrieb und mögliche Ausfallzeiten. Diese ganzheitliche Sichtweise kann bei Verhandlungen von Vorteil sein.

-

Mehrere Zitate nutzen: Holen Sie Angebote von mehreren Anbietern ein, um das Marktangebot zu verstehen. Dies kann eine bessere Verhandlung ermöglichen und Einblicke in eine faire Preisgestaltung geben.

-

Langfristige Beziehungen aufbauen: Der Aufbau einer engen Beziehung zu den Lieferanten kann zu besseren Preisen führen, insbesondere bei Nachbestellungen. Lieferanten können Rabatte oder günstige Konditionen für treue Kunden anbieten.

-

Lokale Zulieferer berücksichtigen: Die Zusammenarbeit mit lokalen Lieferanten kann die Logistikkosten senken und zu schnelleren Reaktionszeiten bei Wartung und Support führen.

Schlussfolgerung

Für internationale B2B-Einkäufer ist es wichtig, die Kostenstruktur und die Preisdynamik von Einpunktverankerungssystemen zu verstehen. Durch das Erkennen der verschiedenen Kostenkomponenten, Preisbeeinflusser und Verhandlungsstrategien können Einkäufer fundierte Entscheidungen treffen, die ihre Beschaffungsprozesse optimieren und gleichzeitig betriebliche Effizienz und Zuverlässigkeit gewährleisten. Denken Sie immer daran, mehrere Quellen zu konsultieren und die langfristigen Auswirkungen Ihrer Investition zu berücksichtigen.

Analyse der Alternativen: Vergleich von Einpunktverankerungssystemen spm mit anderen Lösungen

Erforschung von Alternativen zu Einpunktverankerungssystemen (SPM)

In der Schifffahrts- sowie der Öl- und Gasindustrie ist die Wahl der Anlegesysteme entscheidend für einen effizienten Betrieb. Single-Point-Mooring-Systeme (SPM) sind eine zuverlässige Lösung für den Umschlag von Flüssigladungen von Tankschiffen zu Landanlagen. Es gibt jedoch mehrere Alternativen, die je nach den spezifischen betrieblichen Erfordernissen, dem Budget und den geografischen Gegebenheiten besser geeignet sein können. Diese Analyse vergleicht SPM-Systeme mit zwei praktikablen Alternativen: Multi-Point Mooring (MPM) und Dynamische Positionierungssysteme (DP).

| Vergleich Aspekt | Einpunktverankerungssysteme (SPM) | Multi-Point Mooring (MPM) | Dynamische Positionierungssysteme (DP) |

|---|---|---|---|

| Leistung | Hohe Effizienz für große Schiffe | Mäßig bis hoch, aber wetterbedingt eingeschränkt | Sehr hoch; kann mit unterschiedlichen Bedingungen umgehen |

| Kosten | Moderate Anschaffungs- und Betriebskosten | Geringere Anschaffungskosten, höhere Betriebskosten | Hohe Anfangsinvestition, aber effizient |

| Leichte Implementierung | Erfordert eine umfangreiche Infrastruktur | Leichtere Implementierung in bestehende Einrichtungen | Komplexe Einrichtung; erfordert qualifiziertes Personal |

| Wartung | Regelmäßige Wartung erforderlich, mäßig | Höhere Wartungsfrequenz; witterungsabhängig | Geringer, erfordert aber eine spezielle Ausbildung |

| Bester Anwendungsfall | Abgelegene Standorte mit tiefen Gewässern | Flache Gewässer oder in Küstennähe | Umgebungen mit hohem Seegang und dynamischen Bedingungen |

Detaillierte Aufschlüsselung der Alternativen

Multi-Point Mooring (MPM)

Bei MPM-Systemen werden mehrere Anker und Festmacherleinen verwendet, um ein Schiff zu sichern. Diese Methode bietet Flexibilität und Stabilität, insbesondere in geschützten Gewässern. Die Anfangsinvestitionen für MPM sind in der Regel niedriger als für SPM; die Betriebskosten können jedoch aufgrund der Notwendigkeit regelmäßiger Wartung und der Komplexität der Verwaltung mehrerer Leinen in die Höhe schnellen. MPM ist ideal für flache Gewässer und Regionen, in denen ein schneller Zugang zum Ufer erforderlich ist, und eignet sich daher für kleinere Schiffe und vorübergehende Einsätze.

Dynamische Positionierungssysteme (DP)

DP-Systeme nutzen computergesteuerte Propeller und Strahlruder, um die Position eines Schiffes ohne Ankern zu halten. Diese Technologie eignet sich hervorragend für schwierige Wetterbedingungen und ermöglicht Schiffen den Einsatz auf hoher See und bei starken Strömungen. DP-Systeme sind zwar mit hohen Einrichtungskosten verbunden und erfordern eine spezielle Ausbildung der Besatzung, bieten aber eine unvergleichliche Manövrierfähigkeit und Betriebseffizienz. DP ist besonders vorteilhaft bei Offshore-Bohr- und Bauarbeiten, bei denen es auf Präzision ankommt.

Schlussfolgerung: Die Wahl der richtigen Lösung für Ihre Bedürfnisse

Bei der Erwägung von Verankerungslösungen müssen B2B-Einkäufer spezifische betriebliche Anforderungen, einschließlich Schiffsgröße, Umweltbedingungen und Budgetbeschränkungen, berücksichtigen. Single-Point-Mooring-Systeme sind optimal für abgelegene Offshore-Einsätze mit großen Tankschiffen, während Multi-Point-Mooring-Systeme für flache Gewässer und kleinere Schiffe besser geeignet sein können. Dynamische Positionierungssysteme bieten trotz ihrer höheren Kosten eine unübertroffene Anpassungsfähigkeit in dynamischen maritimen Umgebungen. Letztendlich sollte sich die Entscheidung an den operativen Zielen, finanziellen Erwägungen und den spezifischen Herausforderungen des geplanten Standorts orientieren.

Wesentliche technische Eigenschaften und Fachterminologie für Einpunktverankerungssysteme spm

Was sind die wesentlichen technischen Eigenschaften von Einpunktverankerungssystemen (SPM)?

Für internationale B2B-Einkäufer, insbesondere im Öl- und Gassektor, ist es wichtig, die technischen Eigenschaften von Single Point Mooring (SPM) Systemen zu verstehen. Hier sind einige der wichtigsten Spezifikationen, die zu beachten sind:

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

1. Material Klasse

SPM-Komponenten, einschließlich Bojen und Festmacherleinen, werden in der Regel aus hochwertigen Materialien wie Kohlenstoffstahl oder korrosionsbeständigen Legierungen hergestellt. Die Wahl des Materials wirkt sich auf die Haltbarkeit und die Widerstandsfähigkeit gegenüber rauen Meeresumgebungen aus. Ein hochwertigerer Stahl kann beispielsweise den korrosiven Auswirkungen von Salzwasser widerstehen, was zu geringeren Wartungskosten und einer längeren Lebensdauer führt.

2. Stärke der Festmacherleine

Die Festmacher, die oft aus synthetischen Fasern wie Nylon oder Polyester bestehen, müssen besonders widerstandsfähig sein. Diese Leinen müssen dem Gewicht und den dynamischen Kräften standhalten, die durch das Tankschiff und die Umweltbedingungen ausgeübt werden. Zu den Spezifikationen gehören die Bruchfestigkeit und die prozentuale Dehnung, die bestimmen, wie viel Last die Verankerung sicher tragen kann, ohne zu versagen. Dies ist besonders wichtig für die Aufrechterhaltung der Sicherheitsstandards und der betrieblichen Effizienz.

3. Abmessungen und Gewicht der Boje

Die Größe und das Gewicht der Boje sind für die Stabilität und die betriebliche Effizienz entscheidend. Größere Bojen können größere Tanker aufnehmen und höheren Wellengang bewältigen. Spezifikationen wie Bojendurchmesser, Tiefgang und Gesamtgewicht beeinflussen die Verankerungsfähigkeit und die Effizienz des Gesamtsystems. Käufer sollten sicherstellen, dass die Abmessungen der Boje mit ihren betrieblichen Anforderungen und den Eigenschaften der zu verankernden Schiffe übereinstimmen.

4. Fähigkeit zur dynamischen Positionierung

SPM-Systeme sind so konzipiert, dass sie eine dynamische Positionierung ermöglichen, was beim Be- und Entladen von entscheidender Bedeutung ist. Diese Fähigkeit wird durch den Drehbereich der Boje und die Flexibilität der angeschlossenen Schläuche bestimmt. Eine gut konzipierte Drehverbindung kann die Bewegung von Tankschiffen aufnehmen und gleichzeitig eine sichere Verbindung für den Produkttransfer aufrechterhalten, wodurch das Risiko von Leckagen oder Ausrüstungsausfällen verringert wird.

5. Übertragungsrate Kapazität

Die Umschlagskapazität, die in der Regel in Kubikmetern pro Stunde (m³/h) gemessen wird, gibt an, wie schnell flüssige Ladung geladen oder gelöscht werden kann. Diese Angabe ist für die betriebliche Effizienz von entscheidender Bedeutung, da höhere Umschlaggeschwindigkeiten zu kürzeren Umschlagszeiten für Schiffe führen. Käufer sollten diese Kapazität in Verbindung mit der Art der umgeschlagenen Ladung und der Anzahl der verwendeten Schläuche bewerten.

6. Umwelttoleranz

SPM-Systeme müssen so konstruiert sein, dass sie Umweltfaktoren wie Wind, Wellen und Strömungen standhalten. Zu den Spezifikationen für die Umweltverträglichkeit gehören die maximale Windgeschwindigkeit und Wellenhöhe. Die Kenntnis dieser Grenzwerte ist für einen sicheren Betrieb unerlässlich, insbesondere in Regionen, die für Unwetter anfällig sind.

Was sind gängige Handelsbegriffe bei Transaktionen mit einem einzigen Liegeplatz?

Um sich in der B2B-Landschaft zurechtzufinden, muss man mit der branchenspezifischen Terminologie vertraut sein. Hier sind einige Schlüsselbegriffe, die bei SPM-Transaktionen häufig vorkommen:

1. OEM (Original Equipment Manufacturer)

OEM bezieht sich auf Unternehmen, die Komponenten oder Systeme herstellen, die für die Herstellung anderer Produkte verwendet werden. Im Zusammenhang mit SPM können OEMs kritische Komponenten wie Bojen oder Verankerungssysteme liefern, und das Verständnis dieses Begriffs hilft Käufern, seriöse Hersteller für ihre Bedürfnisse zu identifizieren.

2. MOQ (Mindestbestellmenge)

MOQ ist die kleinste Menge eines Produkts, die ein Lieferant zu verkaufen bereit ist. Bei SPM-Transaktionen ist das Verständnis der MOQ wesentlich für die Budgetierung und die Bestandsverwaltung, insbesondere bei Komponenten, die lange Vorlaufzeiten haben oder erhebliche Investitionen erfordern.

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

3. RFQ (Request for Quotation)

Eine Anfrage ist ein Dokument, das von einem Einkäufer ausgestellt wird, um Preise und Bedingungen von Lieferanten anzufordern. Bei SPM-Systemen hilft eine Anfrage den Einkäufern, wettbewerbsfähige Angebote einzuholen und den Markt zu bewerten, damit sie fundierte Kaufentscheidungen treffen können.

4. Incoterms (Internationale Handelsklauseln)

Incoterms sind eine Reihe von vordefinierten internationalen Handelsbedingungen, die die Verantwortlichkeiten von Käufern und Verkäufern klären. Die Kenntnis dieser Bedingungen ist für SPM-Transaktionen von entscheidender Bedeutung, da sie Aspekte wie Versand, Versicherung und Risikotransfer vorschreiben und die Gesamtbetriebskosten beeinflussen.

5. P&L (Rohrleitung und Verteiler)

Das Pipeline- und Verteilersystem ist eine entscheidende Komponente von SPM-Systemen, die den Transfer von Flüssigladungen vom Meeresboden zum Tanker erleichtert. Die Vertrautheit mit diesem Begriff ermöglicht es den Käufern, die logistischen Aspekte des SPM-Betriebs besser zu verstehen.

6. Scheuer-Ketten

Scheuerketten sind Schutzvorrichtungen, die an den Verbindungspunkten von Festmacherleinen eingesetzt werden, um Verschleiß zu verhindern. Die Kenntnis dieses Begriffs unterstreicht die Bedeutung von Wartung und Sicherheit im SPM-Betrieb und gewährleistet, dass die Ausrüstung in optimalem Zustand bleibt.

Durch das Verständnis dieser wesentlichen technischen Eigenschaften und der Fachterminologie können internationale B2B-Einkäufer fundiertere Entscheidungen bei der Auswahl und dem Betrieb von Einpunktverankerungssystemen treffen.

Marktdynamik und Beschaffungstrends im Sektor der Einpunktverankerungssysteme spm navigieren

Was sind die wichtigsten Marktdynamiken, die Single Point Mooring Systems (SPM) beeinflussen?

Der Weltmarkt für Einpunktverankerungssysteme (SPM) erfährt durch die steigende Nachfrage nach effizientem Offshore-Öl- und Gastransport ein erhebliches Wachstum. Faktoren wie die Zunahme der Tiefsee-Exploration, der Bedarf an kosteneffizienten Lösungen für den Umschlag von Flüssigladungen und der Ausbau der Offshore-Infrastruktur in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa sind von entscheidender Bedeutung. Länder wie Nigeria und Deutschland positionieren sich als wichtige Akteure, indem sie in fortschrittliche SPM-Technologien investieren, die die betriebliche Effizienz und Sicherheit erhöhen.

Zu den sich abzeichnenden Trends bei der B2B-Beschaffung im SPM-Sektor gehört die Einführung digitaler Technologien wie IoT und KI für Echtzeitüberwachung und vorausschauende Wartung. Dieser Wandel verbessert nicht nur die Betriebszuverlässigkeit, sondern verringert auch die Ausfallzeiten - ein wichtiger Faktor für internationale Einkäufer. Darüber hinaus gewinnen modulare und flexible Konstruktionen an Zugkraft, die eine schnellere Installation und Skalierbarkeit ermöglichen, um unterschiedliche Nachfragen zu erfüllen.

Angesichts der zunehmenden Bedeutung von Sicherheits- und Umweltvorschriften bevorzugen internationale Einkäufer auch Lieferanten, die die Einhaltung der von Organisationen wie dem Oil Companies International Marine Forum (OCIMF) und dem American Petroleum Institute (API) festgelegten Standards nachweisen können. Diese Dynamik signalisiert eine sich schnell entwickelnde Landschaft, die strategische Beschaffungsentscheidungen erforderlich macht, um Wettbewerbsvorteile zu erhalten.

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

Wie beeinflusst die Nachhaltigkeit die Beschaffungsentscheidungen im SPM-Sektor?

Nachhaltigkeit wird zu einem Eckpfeiler der Beschaffungsstrategien im SPM-Sektor und spiegelt ein wachsendes Bewusstsein für Umweltauswirkungen und ethische Praktiken in der Lieferkette wider. Die Offshore-Öl- und -Gasindustrie sieht sich einer verstärkten Überprüfung ihrer Kohlenstoffbilanz gegenüber, was die Beteiligten dazu veranlasst, nach SPM-Systemen zu suchen, die nachhaltige Materialien und Prozesse beinhalten.

Einkäufer suchen zunehmend nach Lieferanten, die "grüne" Zertifizierungen vorweisen können, wie z. B. ISO 14001 für das Umweltmanagement, was ihr Markenimage verbessern und umweltbewusste Verbraucher ansprechen kann. Darüber hinaus werden die Verwendung von wiederverwertbaren Materialien beim Bau von SPM-Systemen und der Einsatz energieeffizienter Technologien zu Voraussetzungen für viele Beschaffungsverträge.

Darüber hinaus gewinnt die ethische Beschaffung immer mehr an Bedeutung, da die Unternehmen versuchen, die mit Menschenrechtsverletzungen in den Lieferketten verbundenen Risiken zu verringern. Einkäufer werden ermutigt, mit Lieferanten zusammenzuarbeiten, die Transparenz und Verantwortlichkeit demonstrieren, um einen verantwortungsvolleren Beschaffungsprozess zu fördern. Da Nachhaltigkeit zu einem geschäftlichen Imperativ wird, müssen B2B-Einkäufer im SPM-Sektor ihre Beschaffungsstrategien an diesen sich entwickelnden Erwartungen ausrichten, um ihre Marktrelevanz zu erhalten.

Was ist der historische Kontext von Einpunktverankerungssystemen?

Das Konzept der Einpunktverankerungssysteme entstand Mitte des 20. Jahrhunderts, als die Offshore-Öl- und Gasindustrie zu expandieren begann. Ursprünglich wurden SPM-Systeme entwickelt, um das Be- und Entladen von Tankern an Orten zu erleichtern, an denen herkömmliche Hafenanlagen unpraktisch waren. Die ersten Systeme waren relativ einfach, basierten auf grundlegenden Verankerungstechnologien und wurden hauptsächlich in flachen Gewässern eingesetzt.

Im Laufe der Jahrzehnte haben Fortschritte in der Materialwissenschaft und -technik zur Entwicklung anspruchsvollerer SPM-Systeme geführt, die in der Lage sind, größere Schiffe und komplexere Frachtarten zu befördern. Die Einführung technologiegestützter Lösungen wie dynamische Positionierung und fortschrittliche Überwachungssysteme hat den Betrieb revolutioniert und sowohl die Sicherheit als auch die Effizienz erhöht.

Heutzutage sind SPM-Systeme ein wesentlicher Bestandteil der globalen Energieversorgungsketten und ermöglichen den Transport großer Mengen flüssiger Ladung in anspruchsvollen maritimen Umgebungen. Das Verständnis dieser Entwicklung hilft B2B-Einkäufern, die technologischen Fortschritte zu verstehen, die das aktuelle Angebot und die potenziellen zukünftigen Entwicklungen im SPM-Sektor geprägt haben.

Häufig gestellte Fragen (FAQs) für B2B-Einkäufer von Einpunktverankerungssystemen spm

-

Wie wähle ich das richtige Einpunktverankerungssystem (SPM) für meine betrieblichen Anforderungen aus?

Die Wahl des richtigen SPM-Systems erfordert eine Bewertung Ihrer spezifischen betrieblichen Anforderungen, einschließlich der Art der Flüssigladung, der Schiffsgrößen und der Umweltbedingungen. Berücksichtigen Sie den Typ des Verankerungssystems (CALM oder SALM), denn jedes hat seine Vorteile. Beurteilen Sie die Be- und Entladeraten, die Wassertiefe am Standort und die Entfernung zu den Einrichtungen an Land. Die Zusammenarbeit mit erfahrenen Lieferanten, die maßgeschneiderte Lösungen und Unterstützung während des Auswahlprozesses bieten können, ist für eine optimale Leistung entscheidend. -

Was sind die wichtigsten Faktoren, die bei der Auswahl von Lieferanten für SPM-Systeme zu berücksichtigen sind?

Achten Sie bei der Prüfung von Anbietern vor allem auf deren Erfahrung in der Branche, insbesondere in Ihrer Region. Prüfen Sie die Erfolgsbilanz des Unternehmens anhand ähnlicher Projekte, Kundenaussagen und Zertifizierungen von anerkannten maritimen Organisationen wie OCIMF. Prüfen Sie, ob das Unternehmen in der Lage ist, Kundendienst, Wartungsdienste und Ersatzteile anzubieten. Erkundigen Sie sich außerdem nach der Einhaltung internationaler Sicherheits- und Umweltstandards, da dies die Zuverlässigkeit und Nachhaltigkeit der Systeme gewährleistet. -

Welche Anpassungsmöglichkeiten gibt es für Einzelpunktverankerungssysteme?

Die Anpassungsoptionen für SPM-Systeme können Modifikationen für bestimmte Schiffstypen, Ladungsmerkmale und Umweltbedingungen umfassen. Käufer können maßgeschneiderte Bojendesigns, verbesserte Verankerungssysteme und spezielle Produkttransfermechanismen anfordern. Es ist auch möglich, fortschrittliche Sicherheitsfunktionen zu integrieren, wie z. B. Systeme zur Verhinderung von Auslaufen und automatische Überwachungstechnologien. Durch eine frühzeitige Zusammenarbeit mit den Herstellern in der Entwurfsphase kann sichergestellt werden, dass das Endprodukt mit den betrieblichen Anforderungen übereinstimmt. -

Was sind die typischen Mindestbestellmengen (MOQ) für SPM-Systeme?

Die Mindestbestellmengen für SPM-Systeme können je nach Hersteller und Komplexität des Systems erheblich variieren. Im Allgemeinen verlangen die Lieferanten eine Mindestbestellmenge von einem kompletten System, insbesondere bei kundenspezifischen Lösungen. Bei Standardmodellen können einige Lieferanten niedrigere Mindestbestellmengen anbieten, was eine flexible Beschaffung ermöglicht. Es ist ratsam, Ihre Projektanforderungen direkt mit den Lieferanten zu besprechen, um deren MOQ-Politik und mögliche Verhandlungsbedingungen zu verstehen. -

Mit welchen Zahlungsbedingungen muss ich rechnen, wenn ich SPM-Systeme international kaufe?

Die Zahlungsbedingungen für internationale Käufe von SPM-Systemen umfassen in der Regel eine Kombination aus Vorauszahlungen und Meilensteinzahlungen, die an den Projektfortschritt gebunden sind. Üblich ist eine 30%-Anzahlung bei Auftragsbestätigung, wobei der Restbetrag vor Versand oder nach Abschluss der Installation fällig wird. Einige Lieferanten bieten Finanzierungsoptionen oder verlängerte Zahlungsfristen an, die von der Kreditwürdigkeit des Käufers abhängen. Achten Sie stets darauf, dass die Zahlungsbedingungen im Vertrag eindeutig festgelegt sind, um Missverständnisse zu vermeiden. -

Wie kann ich die Qualitätssicherung (QA) bei der Beschaffung meines SPM-Systems sicherstellen?

Fordern Sie von den Lieferanten detaillierte Spezifikationen und Zertifizierungen für die SPM-Systeme an, um die Qualität sicherzustellen. Implementieren Sie ein gründliches Inspektionsverfahren während der Herstellung, das auch Werksabnahmeprüfungen (FAT) und Audits durch Dritte umfassen kann. Legen Sie klare Leistungskriterien fest und führen Sie regelmäßige Überprüfungen während der Projektlaufzeit durch. Darüber hinaus kann eine offene Kommunikation mit den Lieferanten während des gesamten Beschaffungsprozesses dazu beitragen, mögliche Qualitätsprobleme proaktiv anzugehen. -

Welche logistischen Überlegungen sollte ich bei der Lieferung von SPM-Systemen anstellen?

Die Logistik für die Lieferung von SPM-Systemen erfordert eine sorgfältige Planung der Transportmethoden und -wege, insbesondere bei übergroßen Komponenten. Beurteilen Sie die Fähigkeiten Ihrer Zulieferer bei der Verwaltung der Logistik und ihre Erfahrung mit internationalen Versandvorschriften. Berücksichtigen Sie mögliche Herausforderungen wie Zollabfertigung, Transportgenehmigungen und Lieferfristen, insbesondere an abgelegenen Standorten. Die Zusammenarbeit mit Logistikexperten kann dazu beitragen, den Lieferprozess zu rationalisieren und Verzögerungen zu vermeiden. -

Was sind die Wartungsanforderungen für Einpunktverankerungssysteme?

Die Wartung von SPM-Systemen ist entscheidend für die Gewährleistung der Betriebssicherheit und Effizienz. Regelmäßige Inspektionen sollten durchgeführt werden, um die Integrität der Verankerungskomponenten, Bojensysteme und Transfermechanismen zu bewerten. Die Wartungspläne können je nach Nutzung variieren, umfassen aber in der Regel monatliche Kontrollen, jährliche Überholungen und sofortige Aufmerksamkeit bei Anzeichen von Verschleiß oder Schäden. Die Beauftragung von erfahrenen Dienstleistern mit der routinemäßigen Wartung kann die Lebensdauer des Systems verlängern und kostspielige Ausfallzeiten verhindern.

Top 5 Single Point Mooring Systems Spm Hersteller & Lieferanten Liste

1. Marine Insight - Einpunktverankerung (SPM)

Bereich: marineinsight.de

Registriert: 2010 (15 Jahre)

Einleitung: Single Point Mooring (SPM) ist eine schwimmende Boje/ein schwimmender Steg, die/der vor der Küste verankert ist und dem Umschlag von Flüssigladungen wie Erdölprodukten für Tankschiffe dient. Sie wird dort eingesetzt, wo keine speziellen Be- und Entladeeinrichtungen zur Verfügung stehen, die mehrere Kilometer von der Küste entfernt liegen und über Unterwasserpipelines miteinander verbunden sind. SPM kann große Schiffe wie VLCCs abfertigen und spart Treibstoff und Zeit, da die Schiffe nicht an Häfen andocken müssen. Schlüsselkomp...

2. Handelsmarine entschlüsselt - Einpunktverankerung

Bereich: merchantnavydecoded.com

Registriert: 2020 (5 Jahre)

Einleitung: Die Einpunktverankerung (Single Point Mooring, SPM) ist ein Offshore-Verankerungssystem, mit dem ein schwimmendes Schiff, z. B. ein Tanker, an einem einzigen Punkt verankert werden kann, wobei es sich frei um diesen Punkt drehen kann. Es wurde in den 1960er Jahren entwickelt, um die Probleme großer Tankschiffe zu lösen, insbesondere beim Be- und Entladen von Ladung in Häfen, die nicht für ihre Größe ausgelegt sind, oder bei ungünstigen Wetterverhältnissen. Das SPM-System ist pr...

3. Lankhorst Offshore - Einpunktverankerungssysteme

Bereich: lankhorstoffshore.com

Registriert: 2008 (17 Jahre)

Einleitung: Lankhorst Offshore ist ein führender Anbieter von SPM-Systemen (Single Point Mooring), die für Qualität, Zuverlässigkeit und Leistung in Entladeumgebungen ausgelegt sind, wie sie für Ölterminals und FPSO-Schiffe (Floating Production Storage and Offloading) typisch sind. Bei den SPM-Systemen handelt es sich um maßgeschneiderte Pakete, die Festmachertrossen, Pick-up- und Kurierseile, Reibungsketten, Stützbojen, Schäkel und Zusatzausrüstung umfassen...

4. ScienceDirect - Einpunktverankerungssysteme

Bereich: sciencedirect.com

Registriert: 1997 (28 Jahre)

Einleitung: Die Einpunktverankerung (Single Point Mooring, SPM) ist ein Verankerungssystem, das den Drehpunkt eines Schwimmers mit einer oder mehreren Leinen mit dem Meeresboden verbindet und es dem Schwimmer ermöglicht, sich den Umweltbedingungen anzupassen. Es gibt drei typische Ausführungen: Single Anchor Leg Mooring (SALM), Catenary Anchor Leg Mooring (CALM) und gelenkige Säulensysteme. SPM-Systeme sind für Tiefgang-Tankschiffe zum Umladen von Rohöl konzipiert...

5. Offspring International - SPM Systeme und Komponenten

Bereich: nachwuchsinternational.de

Registriert: 2000 (25 Jahre)

Einleitung: Single-Point-Mooring-Systeme (SPM), die auf die Anforderungen des jeweiligen Standorts und die Wassertemperaturen zugeschnitten sind. Zu den Komponenten gehören die Konfiguration mit zwei Trossen, die Trosse mit einem Bein und die Trosse mit Tülle. Einhaltung der OCIMF-Richtlinien, einschließlich OCIMF 2000 und OCIMF 2018. Die Produktpalette umfasst Festmachertrossen, Pick-up- und Kurierseile, Festmacherketten, Anker, OCIMF-Reibungsketten, ...

Strategische Beschaffung - Fazit und Ausblick für Einzelpunktverankerungssysteme spm

Zusammenfassend lässt sich sagen, dass die strategische Beschaffung von Single Point Mooring (SPM)-Systemen eine einzigartige Gelegenheit für internationale B2B-Einkäufer darstellt, insbesondere für solche, die in Afrika, Südamerika, dem Nahen Osten und Europa tätig sind. Durch die Nutzung der SPM-Technologie können Unternehmen ihre betriebliche Effizienz steigern, Kosten minimieren und die Abfertigung größerer Schiffe ohne die Einschränkungen herkömmlicher Hafenanlagen erleichtern. Die Flexibilität und die fortschrittliche Funktionalität von SPM-Systemen ermöglichen nahtlose Verbindungen zwischen Offshore- und Onshore-Betrieben und rationalisieren die Logistik des Flüssigladungsumschlags.

Investitionen in SPM-Systeme tragen nicht nur zu nachhaltigen Praktiken bei, indem sie den Treibstoffverbrauch bei der Hafenanfahrt reduzieren, sondern mindern auch die mit der Einhaltung von Umweltvorschriften verbundenen Risiken. Da die Nachfrage nach zuverlässigem und effizientem Frachtumschlag weiter steigt, wird die Beschaffung hochwertiger SPM-Lösungen für die Aufrechterhaltung des Wettbewerbsvorteils auf dem globalen Markt unerlässlich.

Mit Blick auf die Zukunft werden B2B-Einkäufer ermutigt, Partnerschaften mit renommierten Lieferanten und Herstellern zu suchen, die maßgeschneiderte Lösungen für spezifische betriebliche Anforderungen anbieten können. Indem sie der strategischen Beschaffung in ihren Beschaffungsprozessen Vorrang einräumen, können sich Unternehmen so positionieren, dass sie von der sich entwickelnden maritimen Landschaft profitieren und eine erfolgreiche Projektdurchführung sicherstellen. Die Zukunft der Offshore-Logistik ist vielversprechend, und jetzt ist es an der Zeit, in die Technologie zu investieren, die Ihr Unternehmen voranbringen wird.

Anschauliches Bild zum Thema Einpunktverankerungssysteme spm

Wichtiger Haftungsausschluss & Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, die Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.