Introduction: Navigating the Global Market for pier tech hydraulic hoses

In an increasingly interconnected world, sourcing high-quality pier tech hydraulic hoses presents a unique challenge for international B2B buyers. With diverse applications across construction, engineering, and industrial sectors, selecting the right hydraulic hoses is crucial for ensuring operational efficiency and safety. This comprehensive guide delves into the myriad aspects of pier tech hydraulic hoses, including their types, applications, supplier vetting processes, and cost considerations, tailored specifically for markets in Africa, South America, the Middle East, and Europe.

As the demand for reliable hydraulic solutions grows, understanding the nuances of hydraulic hose technology is essential for making informed purchasing decisions. This guide empowers B2B buyers by providing actionable insights into identifying reputable suppliers and evaluating product specifications that align with their unique project requirements. By exploring the latest innovations in hydraulic hose technology and installation methods, buyers can enhance their operational capabilities and remain competitive in their respective markets.

From the challenges of navigating local regulations to optimizing supply chain logistics, this guide serves as a vital resource for international buyers seeking to streamline their procurement processes. With expert advice and industry best practices, you will be equipped to make confident decisions that not only meet your immediate needs but also foster long-term partnerships with suppliers.

Índice

- Top 3 Pier Tech Hydraulic Hoses Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pier tech hydraulic hoses

- Understanding pier tech hydraulic hoses Types and Variations

- Key Industrial Applications of pier tech hydraulic hoses

- 3 Common User Pain Points for ‘pier tech hydraulic hoses’ & Their Solutions

- Strategic Material Selection Guide for pier tech hydraulic hoses

- In-depth Look: Manufacturing Processes and Quality Assurance for pier tech hydraulic hoses

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pier tech hydraulic hoses’

- Comprehensive Cost and Pricing Analysis for pier tech hydraulic hoses Sourcing

- Alternatives Analysis: Comparing pier tech hydraulic hoses With Other Solutions

- Essential Technical Properties and Trade Terminology for pier tech hydraulic hoses

- Navigating Market Dynamics and Sourcing Trends in the pier tech hydraulic hoses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pier tech hydraulic hoses

- Strategic Sourcing Conclusion and Outlook for pier tech hydraulic hoses

- Descargo de responsabilidad y condiciones de uso

Understanding pier tech hydraulic hoses Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Standard Hydraulic Hoses | Flexible, durable, and designed for high-pressure applications. | General construction and foundation work. | Pros: High versatility and compatibility. Contras: May require frequent replacements in harsh environments. |

| High-Temperature Hoses | Engineered to withstand elevated temperatures and pressures. | Oil and gas, industrial machinery. | Pros: Enhanced durability in extreme conditions. Contras: Mayor coste en comparación con las mangueras estándar. |

| Spiral-Wound Hydraulic Hoses | Reinforced design for maximum strength and pressure resistance. | Heavy-duty construction and mining. | Pros: Excelente para aplicaciones de alta presión. Contras: Less flexible, may be cumbersome in tight spaces. |

| Thermoplastic Hoses | Lightweight and resistant to abrasion and chemicals. | Agricultural and mobile machinery. | Pros: Easy handling and installation. Contras: Limited temperature range compared to rubber hoses. |

| Specialty Hydraulic Hoses | Custom-built for specific applications and environments. | Niche markets like aerospace and marine. | Pros: Tailored solutions for unique needs. Contras: Longer lead times and potentially higher costs. |

What are the Characteristics of Standard Hydraulic Hoses?

Standard hydraulic hoses are typically made from rubber or thermoplastic materials and are designed to handle high-pressure applications. They feature a flexible construction that allows for easy routing in various machinery setups, making them ideal for general construction and foundation work. When purchasing, buyers should consider factors such as compatibility with existing systems, pressure ratings, and environmental conditions, as these hoses may require more frequent replacements in harsh environments.

How Do High-Temperature Hoses Perform in Extreme Conditions?

High-temperature hoses are specifically engineered to withstand elevated temperatures and pressures, making them suitable for industries like oil and gas or industrial machinery. These hoses often incorporate specialized materials that provide enhanced durability under extreme conditions. When considering these hoses, B2B buyers should evaluate the specific temperature ranges they will encounter and balance the higher costs against the long-term benefits of reduced failure rates.

What Advantages Do Spiral-Wound Hydraulic Hoses Offer?

Spiral-wound hydraulic hoses are reinforced to provide maximum strength and pressure resistance, making them an excellent choice for heavy-duty applications in construction and mining. Their design allows them to maintain structural integrity under high-stress conditions. Buyers should assess the pressure requirements of their projects and consider the trade-off between strength and flexibility, as these hoses can be less maneuverable in tight spaces.

Why Choose Thermoplastic Hoses for Mobile Machinery?

Thermoplastic hoses are lightweight and resistant to abrasion and chemicals, making them particularly useful in agricultural and mobile machinery applications. Their ease of handling and installation can lead to increased efficiency on the job site. However, buyers should be aware of the limitations regarding temperature ranges compared to traditional rubber hoses, which may impact long-term performance in certain environments.

What are the Benefits of Specialty Hydraulic Hoses?

Specialty hydraulic hoses are custom-built to meet the specific needs of niche markets, such as aerospace and marine applications. These hoses are designed to perform optimally under unique environmental conditions, providing tailored solutions for complex projects. While they offer significant advantages in terms of performance, buyers should consider the longer lead times and potentially higher costs associated with these specialized products.

Key Industrial Applications of pier tech hydraulic hoses

| Industria/Sector | Specific Application of pier tech hydraulic hoses | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Construcción | Foundation installation using helical piers | Enhances structural integrity and reduces settlement risks | Ensure compatibility with various machinery types and soil conditions |

| Petróleo y gas | Hydraulic systems for drilling and extraction | Increases operational efficiency and safety | Look for high-pressure ratings and resistance to harsh chemicals |

| Agricultura | Hydraulic equipment for tillage and planting | Improves productivity and reduces downtime | Assess durability against soil abrasiveness and weather conditions |

| Minería | Hydraulic systems for mineral extraction | Maximizes extraction efficiency and minimizes equipment failure | Source hoses with high abrasion resistance and flexibility |

| Manufacturing | Hydraulic machinery for assembly lines | Streamlines production processes and reduces costs | Evaluate for heat resistance and compatibility with hydraulic fluids |

How Are Pier Tech Hydraulic Hoses Used in Construction?

In the construction industry, pier tech hydraulic hoses are essential for the installation of helical piers, which provide foundational support for buildings and structures. These hoses connect hydraulic systems to the machinery used for driving piers into the ground, ensuring that the installation process is efficient and reliable. The primary problem solved is the risk of structural failure due to inadequate foundations, especially in regions with unstable soil. International buyers must consider the compatibility of hoses with various machinery types and the specific soil conditions in their regions to ensure optimal performance.

What Role Do Hydraulic Hoses Play in Oil & Gas Operations?

In the oil and gas sector, pier tech hydraulic hoses are utilized in drilling and extraction operations, where they facilitate the transfer of hydraulic fluids necessary for powering drilling equipment. These hoses must withstand high pressures and corrosive environments, making their durability crucial for maintaining operational efficiency. By ensuring safe and efficient extraction processes, businesses can significantly reduce operational downtime. Buyers in this sector should prioritize sourcing hoses with high-pressure ratings and chemical resistance to adapt to the harsh conditions of oil and gas operations.

How Are Hydraulic Hoses Beneficial in Agriculture?

Agricultural operations leverage pier tech hydraulic hoses in various equipment, such as tractors and planters, to enhance tillage and planting processes. The hoses play a pivotal role in powering hydraulic systems that operate attachments and implements, boosting productivity and minimizing downtime during critical planting seasons. For international buyers, especially in regions with diverse climates, it is essential to assess the hoses’ durability against soil abrasiveness and varying weather conditions to ensure longevity and reliability in field operations.

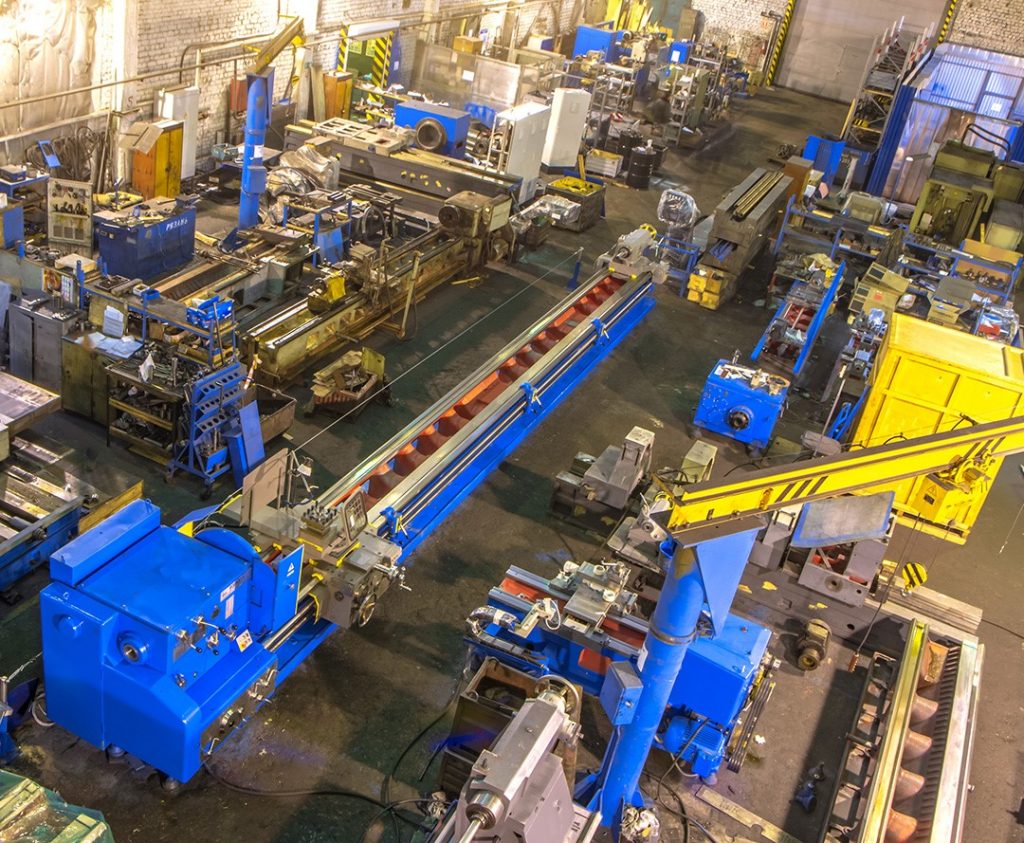

Illustrative image related to pier tech hydraulic hoses

Why Are Hydraulic Hoses Critical in Mining?

In the mining industry, pier tech hydraulic hoses are integral to the hydraulic systems used for mineral extraction. They are responsible for transferring hydraulic fluids that power heavy machinery, which is crucial for maximizing extraction efficiency while minimizing equipment failure. The rugged environments of mining sites demand hoses that can withstand high abrasion and extreme conditions. Buyers should focus on sourcing hoses that offer exceptional durability and flexibility to ensure they can handle the demanding requirements of mining operations.

How Do Hydraulic Hoses Enhance Manufacturing Processes?

In manufacturing, pier tech hydraulic hoses are employed in hydraulic machinery that drives assembly lines, enhancing production efficiency. These hoses facilitate the transfer of hydraulic fluids, ensuring that machinery operates smoothly and consistently. By streamlining production processes, businesses can achieve significant cost savings and improved output. Buyers in this sector should evaluate hoses for heat resistance and compatibility with various hydraulic fluids to maintain performance and safety in fast-paced manufacturing environments.

3 Common User Pain Points for ‘pier tech hydraulic hoses’ & Their Solutions

Scenario 1: Hydraulic Hose Durability in Harsh Environments

El problema:

B2B buyers often encounter the challenge of hydraulic hoses failing prematurely due to harsh environmental conditions. For example, construction projects in regions with extreme temperatures, abrasive dust, or exposure to chemicals can significantly shorten the lifespan of hydraulic hoses. When hoses fail, it leads to costly downtime, project delays, and increased maintenance expenses, causing frustration for both the contractor and the client.

La solución:

To address this issue, buyers should prioritize sourcing hydraulic hoses that are specifically designed for durability in challenging environments. Look for hoses made from high-grade materials that offer resistance to temperature fluctuations, abrasion, and chemical exposure. Additionally, implementing regular maintenance checks can help identify wear and tear before it leads to failure. Buyers should also consider investing in specialized protective covers that shield hoses from environmental hazards. By ensuring that the right hoses are chosen and maintained, businesses can enhance reliability and minimize costly interruptions.

Illustrative image related to pier tech hydraulic hoses

Scenario 2: Incorrect Hose Specifications Leading to System Failures

El problema:

Another common pain point for B2B buyers is the challenge of selecting the correct specifications for hydraulic hoses. Using hoses that do not meet the required pressure ratings or compatibility with hydraulic fluids can lead to system failures. This miscalculation often occurs when buyers are overwhelmed with technical specifications or lack sufficient guidance, resulting in wasted resources and potential safety hazards.

La solución:

To prevent these issues, buyers should engage in thorough discussions with manufacturers or suppliers to fully understand the technical requirements of their hydraulic systems. It is essential to consider factors such as the maximum operating pressure, hose diameter, and compatibility with hydraulic fluids. Utilizing a hose selection guide or consulting with a hydraulic engineer can also provide clarity in choosing the right product. Additionally, developing a standardized checklist for hose specifications can streamline the purchasing process and ensure that all necessary criteria are met before making a decision.

Scenario 3: Delays Due to Slow Hose Replacement Services

El problema:

Timeliness is critical in the construction and engineering sectors, and delays in hydraulic hose replacement can significantly impact project schedules. Buyers often find themselves waiting for replacement hoses, especially in remote locations or during peak project seasons, leading to increased labor costs and potential penalties for missed deadlines.

La solución:

To combat delays, B2B buyers should establish a proactive maintenance and replacement plan for hydraulic hoses. This includes maintaining an inventory of critical spare hoses and components that can be accessed quickly in the event of a failure. Partnering with a reliable hydraulic service provider that offers rapid on-site hose replacement can also minimize downtime. Additionally, setting up a scheduled inspection and maintenance routine can help identify potential issues before they lead to breakdowns. By being proactive and having contingency plans in place, businesses can keep projects on track and avoid costly delays.

Strategic Material Selection Guide for pier tech hydraulic hoses

What Are the Key Materials Used in Pier Tech Hydraulic Hoses?

When selecting hydraulic hoses for pier tech applications, understanding the materials used is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials utilized in hydraulic hoses, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Rubber

Rubber is a traditional material for hydraulic hoses due to its flexibility and resilience. It typically has a temperature rating of -40°F to 212°F (-40°C to 100°C) and can withstand pressures up to 3,000 psi, depending on the specific formulation.

Pros:

– Excellent flexibility and bend radius, making it suitable for applications requiring movement.

– Good resistance to abrasion and wear.

– Generally lower cost compared to synthetic alternatives.

Contras:

– Limited resistance to certain chemicals and oils, which can degrade the material.

– UV exposure can lead to cracking over time.

– May require additional protective coverings for outdoor applications.

Illustrative image related to pier tech hydraulic hoses

Impacto en la aplicación:

Rubber hoses are ideal for general-purpose hydraulic applications but may not be suitable for environments with aggressive chemicals. Buyers should consider the specific media used in their operations.

Consideraciones para compradores internacionales:

Rubber hoses must comply with various international standards (e.g., ASTM, ISO). Buyers in regions with high UV exposure, such as Africa and the Middle East, should prioritize UV-resistant formulations.

2. Thermoplastic

Thermoplastic hoses are gaining popularity due to their lightweight and high-pressure capabilities. They can handle pressures exceeding 5,000 psi and temperatures ranging from -40°F to 200°F (-40°C to 93°C).

Pros:

– Lightweight, which reduces overall equipment weight and improves handling.

– Excellent chemical resistance, making them suitable for diverse applications.

– Can be manufactured in longer lengths without joints, reducing leak points.

Illustrative image related to pier tech hydraulic hoses

Contras:

– Generally more expensive than rubber hoses.

– Less flexible than rubber, which may limit installation options in tight spaces.

– Can be less durable in extreme temperatures.

Impacto en la aplicación:

Thermoplastic hoses are ideal for applications involving aggressive fluids or where weight savings are critical. Buyers should ensure compatibility with the specific media in their operations.

Consideraciones para compradores internacionales:

Thermoplastic hoses should meet relevant international standards (e.g., DIN, JIS). Buyers should also consider local sourcing options to reduce shipping costs and lead times.

3. Stainless Steel

Stainless steel hoses are often used in high-pressure and high-temperature applications, with the ability to withstand temperatures up to 1,200°F (649°C) and pressures exceeding 10,000 psi.

Pros:

– Exceptional corrosion and abrasion resistance, making them suitable for harsh environments.

– Long lifespan and minimal maintenance requirements.

– Can handle extreme pressures and temperatures.

Contras:

– High cost compared to rubber and thermoplastic options.

– Heavier, which may not be suitable for all applications.

– Requires specialized fittings and installation techniques.

Impacto en la aplicación:

Stainless steel hoses are ideal for applications in corrosive environments, such as offshore drilling or chemical processing. Buyers must assess the total cost of ownership, including installation and maintenance.

Illustrative image related to pier tech hydraulic hoses

Consideraciones para compradores internacionales:

Compliance with international standards (e.g., ASTM, ISO) is critical. Buyers should also consider the availability of compatible fittings and connectors in their regions.

4. Composite Materials

Composite hoses are engineered to combine the benefits of various materials, typically featuring layers of thermoplastic and reinforcement fibers. They can handle pressures up to 3,000 psi and temperatures ranging from -40°F to 180°F (-40°C to 82°C).

Pros:

– Lightweight and flexible, making them easy to handle and install.

– Excellent chemical resistance and low permeability.

– Customizable for specific applications.

Contras:

– Generally more expensive than traditional rubber hoses.

– Limited availability in some regions.

– May require specific handling and installation techniques.

Illustrative image related to pier tech hydraulic hoses

Impacto en la aplicación:

Composite hoses are suitable for applications requiring flexibility and chemical resistance, such as in the oil and gas industry. Buyers should evaluate the specific needs of their projects.

Consideraciones para compradores internacionales:

Buyers should ensure compliance with local and international standards. Availability may vary by region, so sourcing from reliable suppliers is essential.

Summary Table

| Material | Typical Use Case for pier tech hydraulic hoses | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | General-purpose hydraulic applications | Excellent flexibility | Resistencia química limitada | Bajo |

| Thermoplastic | Lightweight and high-pressure applications | Excelente resistencia química | Less flexible | Medio |

| Acero inoxidable | High-pressure and high-temperature applications | Exceptional corrosion resistance | High cost | Alta |

| Composite Materials | Flexible and chemical-resistant applications | Customizable for specific needs | Limited availability | Media a alta |

This material selection guide equips international B2B buyers with critical insights to make informed decisions when sourcing hydraulic hoses for pier tech applications.

In-depth Look: Manufacturing Processes and Quality Assurance for pier tech hydraulic hoses

What Are the Key Stages in the Manufacturing Process of Pier Tech Hydraulic Hoses?

The manufacturing of Pier Tech hydraulic hoses is a meticulous process involving several critical stages. Understanding these stages can help B2B buyers assess the quality and reliability of the hoses they plan to procure.

Material Preparation: What Raw Materials Are Used?

The first step in the manufacturing process is the preparation of raw materials. Pier Tech hydraulic hoses typically utilize high-grade synthetic rubber and steel reinforcements. The choice of materials is crucial, as they determine the hose’s flexibility, durability, and resistance to environmental factors such as temperature and pressure.

Illustrative image related to pier tech hydraulic hoses

During this stage, suppliers often inspect the raw materials for consistency and compliance with industry standards. Only materials that meet the specified criteria are approved for use. This initial scrutiny is vital to ensuring that the final product can withstand demanding applications.

How Are Hydraulic Hoses Formed?

Once the materials are prepared, the next phase is forming the hoses. This involves shaping the rubber and embedding steel wire or textile reinforcements to enhance strength. The hoses are extruded through a process that shapes them into the desired diameter and length.

Advanced manufacturing techniques such as braiding or spiral wrapping are employed to integrate the reinforcement layers effectively. This process not only improves the hose’s pressure rating but also enhances its flexibility and performance under different operational conditions.

What Happens During Assembly?

The assembly stage is where the components of the hydraulic hose are brought together. This typically involves attaching end fittings, which are crucial for the hose’s functionality. The fittings must be securely attached to prevent leaks and ensure a strong connection to the hydraulic system.

Illustrative image related to pier tech hydraulic hoses

Specialized equipment is used to crimp the fittings onto the hoses, ensuring a tight seal. This stage may also include the application of protective coatings to enhance resistance to abrasion, chemicals, and UV exposure, which is especially important for hoses used in outdoor or industrial settings.

How Is the Finishing Process Conducted?

The finishing stage involves several quality control measures. After assembly, each hose undergoes a thorough cleaning process to remove any contaminants. This is followed by a visual inspection for any defects in the materials or assembly.

Once cleaned, the hoses may be subjected to additional treatments, such as curing or aging, to enhance their performance characteristics. This ensures that the hoses meet the necessary standards before they are packaged and shipped to customers.

What Quality Assurance Standards Are Relevant for Pier Tech Hydraulic Hoses?

Quality assurance is a pivotal aspect of the manufacturing process for Pier Tech hydraulic hoses. Buyers need to be familiar with international standards and industry-specific certifications to ensure they are procuring high-quality products.

Illustrative image related to pier tech hydraulic hoses

Which International Standards Should B2B Buyers Consider?

One of the most recognized international standards is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that the manufacturer has established a systematic approach to quality assurance, ensuring consistency in production and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking and API (American Petroleum Institute) certification are crucial for hydraulic hoses used in specialized applications. CE marking indicates compliance with EU safety standards, while API certification is essential for hoses used in oil and gas applications.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining the integrity of the manufacturing process. Common checkpoints include:

- Control de calidad entrante (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications.

- Control de calidad durante el proceso (IPQC): This stage includes monitoring the manufacturing process itself. Techniques such as statistical process control (SPC) can be employed to identify variations and address them promptly.

- Control de calidad final (CCF): Before shipment, a comprehensive inspection is conducted to ensure that the finished product meets all specifications and quality standards.

What Common Testing Methods Are Used for Hydraulic Hoses?

Testing methods are crucial for validating the performance and safety of hydraulic hoses. Some common testing techniques include:

- Burst Pressure Testing: This assesses the maximum pressure the hose can withstand before failure, ensuring it meets operational requirements.

- Impulse Testing: This simulates the cyclical pressure conditions the hose will face in actual use, helping to evaluate its durability over time.

- Leak Testing: This ensures that all connections and fittings are secure and that the hose will not leak under operational conditions.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

Verifying a supplier’s quality control processes is essential for B2B buyers, particularly those operating in international markets. Here are several strategies to ensure the reliability of your suppliers:

Illustrative image related to pier tech hydraulic hoses

-

Conduct Audits: Regular audits of the manufacturing facilities can help assess compliance with quality standards. Consider employing third-party inspection services for an unbiased evaluation.

-

Request Quality Reports: Ask suppliers for detailed quality reports, including results from testing and inspections. This documentation can provide insights into their quality management practices.

-

Compruebe las certificaciones: Ensure that the manufacturer holds relevant certifications such as ISO 9001, CE, or API. These certifications validate the supplier’s commitment to quality and adherence to industry standards.

-

Evaluate Performance History: Investigate the supplier’s track record in delivering quality products. Customer testimonials and case studies can provide valuable insights into their reliability.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances when it comes to quality control in international trade. Regulatory requirements may vary significantly across regions, necessitating a thorough understanding of local standards.

In Europe, for instance, compliance with CE marking is mandatory, while in North America, adherence to SAE (Society of Automotive Engineers) standards is critical. Buyers should also consider logistical factors, such as the potential for delays in shipping and customs clearance, which can affect the timely delivery of quality products.

Furthermore, cultural differences in business practices may influence the way quality assurance is approached. Establishing strong communication channels and building relationships with suppliers can help bridge these gaps and ensure a mutual understanding of quality expectations.

By understanding the manufacturing processes and quality assurance practices behind Pier Tech hydraulic hoses, B2B buyers can make informed decisions that align with their operational needs and ensure they source reliable, high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pier tech hydraulic hoses’

Introducción

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring Pier Tech hydraulic hoses. By following these steps, you can ensure that your procurement process is efficient, effective, and aligned with your operational needs. Proper sourcing is critical for maintaining the performance and reliability of hydraulic systems, especially in demanding environments.

Primer paso: Defina sus especificaciones técnicas

Clearly outline the technical specifications required for your hydraulic hoses. This includes factors such as pressure ratings, temperature tolerances, and compatibility with hydraulic fluids. Understanding these parameters is crucial, as they directly influence the performance and longevity of the hoses in your applications.

Illustrative image related to pier tech hydraulic hoses

- Presión nominal: Ensure the hoses can handle the maximum pressure of your systems.

- Material Compatibility: Confirm that the hose materials are suitable for the specific hydraulic fluids you plan to use.

Segundo paso: Assess Application Requirements

Evaluate the specific applications where the hydraulic hoses will be used. Different environments, such as construction sites or industrial settings, may impose unique demands on the hoses, including flexibility, durability, and resistance to wear.

- Condiciones ambientales: Consider factors such as exposure to chemicals, UV light, or extreme temperatures.

- Installation Space: Ensure the hoses can be installed in the available space without kinking or stressing.

Tercer paso: Identify Potential Suppliers

Research and compile a list of potential suppliers specializing in Pier Tech hydraulic hoses. This step is essential for ensuring that you have access to high-quality products and reliable service.

- Supplier Reputation: Look for suppliers with a proven track record in the hydraulic industry.

- Geographical Reach: Ensure that the supplier can service your region effectively, especially if you are in Africa, South America, the Middle East, or Europe.

Paso 4: Verificar las certificaciones de los proveedores

Before making a final decision, verify the certifications and standards that suppliers adhere to. Certifications ensure that the hoses meet industry standards for safety and performance.

- ISO Certifications: Check for ISO 9001 or other relevant certifications that demonstrate quality management.

- Compliance with Local Regulations: Ensure that the products comply with local regulations in your region.

Paso 5: Request Samples and Test Performance

Once you’ve narrowed down potential suppliers, request samples of the hydraulic hoses for testing. This step is vital for assessing the quality and performance of the hoses in real-world conditions.

- Performance Testing: Evaluate the hoses under the expected working conditions to identify any potential issues.

- Durability Assessment: Consider conducting stress tests to determine the hoses’ resistance to wear and tear.

Paso 6: Negociar condiciones y precios

Engage in discussions with your selected suppliers to negotiate terms, including pricing, delivery schedules, and warranties. Effective negotiation can lead to better terms and ensure that you receive the best value for your investment.

- Descuentos por volumen: Inquire about discounts for bulk purchases or long-term contracts.

- Warranty Provisions: Ensure that warranties cover defects and performance issues over a reasonable period.

Paso 7: Establish a Maintenance Plan

After procurement, create a maintenance plan for the hydraulic hoses to extend their lifespan and optimize performance. Regular inspections and maintenance can prevent costly downtime and ensure safety.

- Scheduled Inspections: Set up regular checks to assess wear and tear on the hoses.

- Replacement Protocols: Establish guidelines for timely replacement of hoses to avoid operational failures.

By following this checklist, B2B buyers can navigate the procurement process for Pier Tech hydraulic hoses with confidence, ensuring they select the right products for their specific applications.

Comprehensive Cost and Pricing Analysis for pier tech hydraulic hoses Sourcing

What Are the Key Cost Components in Sourcing Pier Tech Hydraulic Hoses?

When sourcing Pier Tech hydraulic hoses, understanding the cost structure is critical for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiales: The choice of materials significantly impacts the cost. High-quality rubber, synthetic materials, and reinforcement fibers are common in hydraulic hoses, with prices fluctuating based on market demand and material grades. Investing in durable materials can lead to longer-lasting hoses, reducing replacement frequency.

-

Trabajo: Labor costs vary by region and can affect the final price. Skilled labor is required for the precise assembly and testing of hydraulic hoses, which is crucial for ensuring safety and performance standards. Regions with higher labor costs may see increased pricing.

-

Gastos generales de fabricación: This includes costs related to facility operation, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, allowing suppliers to offer competitive pricing.

-

Herramientas: Initial tooling costs can be significant, especially for custom or specialized hose designs. These costs are often amortized over production runs, meaning higher volume orders can reduce the per-unit cost.

-

Control de calidad: Implementing stringent QC measures is essential for hydraulic hoses, particularly for those used in high-stakes applications. The costs associated with testing and certification can be considerable but are necessary to ensure reliability and compliance with industry standards.

-

Logística: Transportation and warehousing costs also contribute to the overall price. International shipping, customs duties, and handling fees can add complexity, particularly for buyers in Africa, South America, the Middle East, and Europe.

-

Margen: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary based on market conditions, competition, and the supplier’s business model.

How Do Price Influencers Impact the Cost of Hydraulic Hoses?

Several factors influence the pricing of Pier Tech hydraulic hoses beyond the base cost components:

-

Volumen/MOQ: Bulk orders can lead to significant discounts, making it essential for buyers to assess their needs and negotiate minimum order quantities (MOQs) that provide cost benefits.

-

Especificaciones y personalización: Custom hoses tailored to specific applications often come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs while ensuring the product meets their operational needs.

-

Calidad y certificaciones: Hoses that meet international safety and quality standards may carry higher prices. However, these certifications can reduce liability and maintenance costs in the long run.

-

Factores del proveedor: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Hydraulic Hoses?

For B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to more favorable pricing:

-

Investigación y evaluación comparativa: Conduct thorough market research to understand price ranges and common practices. This knowledge empowers buyers during negotiations and helps them identify fair pricing.

-

Coste total de propiedad (TCO): Consider the TCO rather than just the upfront price. Evaluate factors such as durability, maintenance, and operational efficiency to make informed purchasing decisions.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and favorable terms in future transactions.

-

Leverage Multiple Quotes: Obtaining quotes from several suppliers can provide leverage during negotiations, helping to secure the best deal.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, trade policies, and regional pricing trends, which can affect overall costs.

Disclaimer

Prices for Pier Tech hydraulic hoses can vary widely based on the factors discussed above. The information provided is indicative and should be verified through direct supplier engagement for the most accurate pricing.

Alternatives Analysis: Comparing pier tech hydraulic hoses With Other Solutions

Exploring Alternatives to Pier Tech Hydraulic Hoses: A Comparative Analysis

When evaluating hydraulic solutions for construction and foundation work, it is crucial for B2B buyers to consider various options that can meet their operational needs. Pier Tech hydraulic hoses are a popular choice due to their reliability and performance, but alternatives may offer distinct advantages depending on specific project requirements. Below, we provide a comparative analysis of Pier Tech hydraulic hoses against other viable solutions: traditional rubber hydraulic hoses and thermoplastic hydraulic hoses.

| Aspecto comparativo | Pier Tech Hydraulic Hoses | Traditional Rubber Hydraulic Hoses | Thermoplastic Hydraulic Hoses |

|---|---|---|---|

| Rendimiento | High durability and flexibility, designed for heavy-duty applications | Good performance but can degrade under harsh conditions | Excellent performance in high-temperature and high-pressure environments |

| Coste | Higher initial investment but longer lifespan reduces total cost of ownership | Coste inicial generalmente inferior | Mid-range cost, competitive with rubber hoses |

| Facilidad de aplicación | Requires specific fittings and installation expertise | Simple installation, widely used and understood | Moderate installation complexity, requires specific fittings |

| Mantenimiento | Low maintenance due to durable materials | Moderate; susceptible to wear and tear | Low maintenance, resistant to abrasion and chemicals |

| El mejor caso de uso | Heavy-duty applications requiring reliability and longevity | General applications with moderate pressure | Applications needing flexibility and resistance to extreme conditions |

In-Depth Analysis of Alternatives

Traditional Rubber Hydraulic Hoses

Traditional rubber hydraulic hoses have been a staple in the industry for decades. They are generally less expensive upfront and easy to source, making them a popular choice for many contractors. However, their performance can diminish in extreme temperatures or when exposed to harsh chemicals, leading to potential failures. While they are suitable for general applications, those requiring consistent high performance may find that rubber hoses do not meet longevity expectations, resulting in higher replacement costs over time.

Thermoplastic Hydraulic Hoses

Thermoplastic hydraulic hoses represent a modern alternative that offers several advantages. They are lightweight, flexible, and resistant to abrasion and chemicals, making them ideal for a variety of applications, including those with space constraints. Thermoplastic hoses can handle high pressures and temperatures, which makes them suitable for demanding environments. However, their installation may require specific fittings and knowledge of the system, which could pose a barrier for some contractors. Cost-wise, they fall between rubber hoses and Pier Tech options, providing a balanced choice for those seeking performance without breaking the bank.

Conclusion: How to Choose the Right Hydraulic Hose Solution

Selecting the appropriate hydraulic hose solution is critical for optimizing project efficiency and ensuring long-term reliability. B2B buyers should consider factors such as performance requirements, budget constraints, ease of installation, and maintenance needs. For projects demanding high durability and performance, Pier Tech hydraulic hoses may be the best choice despite their higher initial costs. Alternatively, for more general applications, traditional rubber hoses might suffice, while thermoplastic hoses can be a strong option for environments requiring flexibility and chemical resistance. Ultimately, the right choice will depend on the specific operational demands and conditions of the projects at hand.

Essential Technical Properties and Trade Terminology for pier tech hydraulic hoses

What Are the Key Technical Properties of Pier Tech Hydraulic Hoses?

When evaluating pier tech hydraulic hoses, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should consider:

-

Calidad del material

Hydraulic hoses are typically made from synthetic rubber, thermoplastic, or steel-reinforced materials. The material grade affects durability, flexibility, and resistance to environmental factors like temperature and chemicals. For instance, hoses made from higher-grade synthetic rubber can withstand extreme conditions, making them suitable for demanding applications in various climates. -

Presión nominal

This specification indicates the maximum pressure a hydraulic hose can safely handle, often measured in PSI (pounds per square inch). It is vital for ensuring that the hose can withstand the operational pressures of the hydraulic system without risk of failure. Selecting a hose with an appropriate pressure rating is essential to maintain safety and efficiency in heavy-duty applications. -

Temperatura

The operational temperature range specifies the highest and lowest temperatures the hose can endure. This is particularly important in regions with extreme weather conditions. Hoses designed for high-temperature environments will typically have enhanced thermal stability, which helps in preventing hose degradation and ensures longevity. -

Radio de curvatura

Bend radius refers to the minimum radius at which a hose can be bent without compromising its structural integrity. A smaller bend radius allows for easier installation in tight spaces, but it may also increase the risk of kinking. Understanding the required bend radius is critical for ensuring smooth operation and avoiding costly downtime due to hose failure. -

Resistencia a la abrasión

This property indicates how well a hose can withstand wear and tear from external factors. Hoses with high abrasion resistance are crucial in environments where they may encounter rough surfaces or sharp objects. Investing in hoses with superior abrasion resistance can significantly reduce maintenance costs and increase the lifespan of the equipment. -

Coupling Compatibility

Couplings are essential for connecting hoses to equipment. Ensuring compatibility between the hose and the couplings used in your hydraulic system is vital for maintaining a leak-free operation. Different industries may require specific coupling styles, so understanding these requirements can facilitate smoother installations and maintenance.

What Are the Common Trade Terms Associated with Pier Tech Hydraulic Hoses?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B hydraulic hose market. Here are some common terms you should know:

-

OEM (fabricante de equipos originales)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM specifications ensures that the hydraulic hoses will fit and function correctly with existing equipment. -

MOQ (Cantidad mínima de pedido)

MOQ defines the smallest number of units a supplier is willing to sell. Being aware of MOQs helps buyers plan their inventory and budget, ensuring they can meet demand without overcommitting financially. -

RFQ (solicitud de presupuesto)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. For buyers, submitting an RFQ is a strategic step in obtaining competitive pricing and ensuring that all potential suppliers understand the exact specifications needed. -

Incoterms (Términos comerciales internacionales)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce, which are widely used in international trade. Understanding Incoterms helps buyers comprehend their responsibilities regarding shipping, insurance, and tariffs, which can impact overall project costs. -

Plazos de entrega

Lead time refers to the amount of time it takes from placing an order until it is delivered. Knowing the lead times for hydraulic hoses can assist buyers in planning their projects more effectively and avoiding delays. -

Hydraulic Fluid Compatibility

This term refers to the ability of a hose to function effectively with different types of hydraulic fluids. Ensuring compatibility is critical to prevent chemical degradation of the hose, which can lead to system failures.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions regarding pier tech hydraulic hoses, ultimately enhancing project efficiency and performance.

Navigating Market Dynamics and Sourcing Trends in the pier tech hydraulic hoses Sector

What Are the Current Market Dynamics and Key Trends for Pier Tech Hydraulic Hoses?

The global market for pier tech hydraulic hoses is increasingly driven by the expansion of construction and infrastructure projects in emerging economies, particularly in regions like Africa, South America, and the Middle East. As urbanization accelerates, the demand for reliable hydraulic systems in foundation engineering and construction is paramount. B2B buyers are now focusing on sourcing high-quality hydraulic hoses that can withstand extreme conditions, ensuring durability and efficiency in their operations.

Key trends shaping the market include the integration of advanced technology in hydraulic systems, such as real-time monitoring and automation, which enhances operational efficiency. Additionally, there is a growing preference for equipment that provides versatility, enabling contractors to handle various project sizes with ease. International buyers are also prioritizing suppliers who can offer comprehensive packages, including installation equipment and accessories, to streamline their procurement processes.

Emerging markets are witnessing a shift towards more localized sourcing strategies. This trend is driven by the need to reduce lead times and costs while ensuring that suppliers can respond quickly to market demands. The availability of on-site services, such as those offered by companies like PIRTEK, is becoming a significant factor in supplier selection, as it minimizes downtime and enhances project timelines.

Illustrative image related to pier tech hydraulic hoses

How Is Sustainability and Ethical Sourcing Shaping the B2B Landscape for Hydraulic Hoses?

As sustainability becomes a central tenet of global business practices, the pier tech hydraulic hoses sector is not exempt from this movement. The environmental impact of hydraulic systems, particularly in terms of resource consumption and waste generation, is prompting B2B buyers to seek suppliers that adhere to sustainable practices. This shift includes the use of eco-friendly materials and manufacturing processes that minimize carbon footprints.

Ethical sourcing is increasingly important for international buyers, particularly in regions with stringent environmental regulations. Companies are looking for suppliers who can provide transparency in their supply chains, demonstrating responsible sourcing of materials and adherence to labor standards. Certifications such as ISO 14001 for environmental management and other ‘green’ credentials are becoming essential for suppliers to differentiate themselves in a competitive market.

Moreover, the demand for hydraulic hoses made from recyclable materials is on the rise. Buyers are now more inclined to partner with manufacturers who can offer products that not only meet performance standards but also contribute to a circular economy. This focus on sustainability is not only beneficial for the environment but can also enhance a company’s brand reputation and appeal to a more eco-conscious clientele.

What Is the Historical Context of Pier Tech Hydraulic Hoses in the B2B Sector?

The evolution of pier tech hydraulic hoses can be traced back to the advancements in hydraulic technology during the mid-20th century. Initially, hydraulic systems were limited in application, primarily serving industrial machinery. However, as construction techniques evolved and the need for more robust foundation solutions emerged, hydraulic hoses began to play a critical role in supporting helical pier installation and other foundation applications.

Over the decades, innovations in materials and design have significantly improved the performance and reliability of hydraulic hoses. The introduction of synthetic materials and enhanced manufacturing processes has resulted in hoses that are more resistant to wear, abrasion, and environmental factors. This evolution has expanded their use in various applications, including commercial construction and residential projects, leading to a more competitive B2B landscape.

Today, the focus on high-performance hydraulic systems reflects the ongoing demand for efficiency and safety in construction practices. As international markets continue to grow and evolve, the pier tech hydraulic hoses sector remains a vital component of the broader construction and engineering industries, adapting to meet the changing needs of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of pier tech hydraulic hoses

-

How do I ensure the quality of pier tech hydraulic hoses before purchasing?

To ensure the quality of pier tech hydraulic hoses, request certifications and test reports from suppliers that demonstrate compliance with international standards such as ISO 9001. It’s also advisable to inquire about the materials used, such as whether they meet industry specifications for durability and resistance to environmental factors. Conducting a sample test, if feasible, can provide firsthand insight into performance under expected operating conditions. Lastly, review testimonials or case studies from other clients to gauge the reliability and effectiveness of the hoses in real-world applications. -

What is the best hydraulic hose for high-pressure applications?

For high-pressure applications, select hydraulic hoses that are rated for pressures significantly above your operational requirements. Look for hoses constructed with high tensile strength materials, such as reinforced synthetic rubber or thermoplastic, designed to handle dynamic pressures. Consider hoses with a smaller bend radius for flexibility in tight spaces. Brands with proven track records in heavy-duty sectors, such as PierTech, often offer hoses specifically engineered for high-pressure environments, ensuring safety and longevity. -

What are the typical lead times for ordering pier tech hydraulic hoses internationally?

Lead times for international orders of pier tech hydraulic hoses can vary based on factors like manufacturing location, order volume, and shipping methods. Generally, expect a lead time ranging from 4 to 8 weeks. It is essential to communicate with your supplier regarding production schedules and logistics to get a more precise timeframe. If time is critical, inquire about expedited shipping options or stock availability for quicker turnaround. -

What customization options are available for hydraulic hoses?

Many manufacturers, including PierTech, offer customization options for hydraulic hoses, such as specific lengths, diameters, and fittings to meet unique project requirements. You can also request specific material compositions or protective coatings to enhance durability against environmental factors. Discuss your project needs with the supplier to explore available customization options, which can optimize performance and compatibility with your existing equipment. -

What is the minimum order quantity (MOQ) for pier tech hydraulic hoses?

The minimum order quantity (MOQ) for pier tech hydraulic hoses typically varies by supplier and product type. Some suppliers may have an MOQ of 100 meters, while others might offer flexibility for smaller orders. It’s crucial to clarify the MOQ during initial discussions with potential suppliers, especially if you are a smaller business or testing a new market. This can help in managing inventory effectively and aligning your purchase with project demands. -

How can I vet potential suppliers for hydraulic hoses?

Vetting potential suppliers involves several steps: first, check their certifications and industry experience to ensure they meet quality standards. Look for reviews or testimonials from previous clients to assess reliability and service quality. Request samples to evaluate the product firsthand. Additionally, consider visiting their manufacturing facilities or engaging in virtual tours to better understand their production capabilities and quality control processes. -

What payment terms should I expect when ordering hydraulic hoses internationally?

Payment terms for international orders of hydraulic hoses can vary widely based on the supplier and your business relationship. Common terms include a deposit upfront (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment through secure platforms like PayPal or escrow services for added security. Always clarify payment terms in advance and consider negotiating terms that align with your cash flow requirements. -

What logistics considerations should I keep in mind when importing hydraulic hoses?

When importing hydraulic hoses, consider factors such as shipping methods (air or sea), customs regulations, and potential tariffs or duties applicable in your country. Ensure that your supplier provides all necessary documentation, including invoices and packing lists, to facilitate smooth customs clearance. Additionally, work with a logistics partner experienced in international shipping to navigate potential delays and ensure timely delivery. Keeping an open line of communication with your supplier can also help address any logistical challenges as they arise.

Top 3 Pier Tech Hydraulic Hoses Manufacturers & Suppliers List

1. PIRTEK – Hydraulic & Industrial Hoses

Dominio: pirtekusa.com

Inscrita: 1997 (28 años)

Introducción: PIRTEK offers a range of hydraulic and industrial hoses including: Push-Lock Hose, Superior Multi-Purpose Hose, Compressed Air Hose, Hot Air Blower Hose, Fuel Tank Hose, Oil/Fuel Suction Hose, Hot Tar Hose, Blue or Green Chemical Suction & Discharge Hose, Sand Blast Hose, Dry Material Discharge Powder Hose, and PIRTEK Endurance Series® Hose. They also provide a wide assortment of fittings, adapter…

2. PierTech – Skid Steer Equipment Package

Dominio: piertech.com

Matriculado: 2000 (25 años)

Introducción: PierTech™ offers various helical pier installation equipment packages designed for different machinery and job requirements. Key packages include:

1. **Skid Steer Equipment Package**:

– High-Torque Drive Head

– Drive Tool & Hex Adapter

– 45mm pin & Link Arm

– Telescopic Skid Steer Attachment

– In-Line Relief with Gauges

– Digital Torque Monitor & Torque Pin (optional)

…

3. PIRTEK – Mobile Hose Service Franchise

Dominio: pirtekusafranchise.com

Registered: 2019 (6 years)

Introducción: PIRTEK is a hydraulic and industrial hose service franchise offering mobile hose maintenance and replacement. The franchise operates over 475 locations globally and provides 24/7/365 on-site service with a 1-Hour ETA. The investment structure includes Tier 1 (full-service franchise with a store location and mobile service vehicles) and Tier 2 (fully mobile business option). Estimated initial inves…

Strategic Sourcing Conclusion and Outlook for pier tech hydraulic hoses

As the demand for reliable and efficient hydraulic solutions continues to grow globally, strategic sourcing of Pier Tech hydraulic hoses becomes imperative for businesses looking to enhance their operational efficiency and project outcomes. Leveraging high-quality hydraulic hoses ensures that contractors can handle the demands of various environments, whether they are in Africa, South America, the Middle East, or Europe. The integration of hydraulic hoses with PierTech’s robust helical pier installation equipment can significantly reduce downtime and improve productivity on construction sites.

Investing in the right hydraulic solutions not only streamlines installation processes but also minimizes long-term maintenance costs. By prioritizing quality and reliability in sourcing, businesses can ensure that their hydraulic systems are equipped to tackle challenging soil conditions and demanding project requirements.

Looking ahead, it is essential for international B2B buyers to stay informed about advancements in hydraulic technology and sourcing strategies. By engaging with trusted suppliers and exploring innovative solutions, businesses can position themselves for success in an increasingly competitive landscape. Take the next step towards optimizing your operations—connect with industry experts and explore the extensive range of Pier Tech hydraulic hoses available to meet your project needs.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to pier tech hydraulic hoses

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.