Introducción: Navegar por el mercado mundial de PE flotante

En el competitivo panorama actual, el abastecimiento de flotadores de polietileno (PE) de alta calidad supone un reto importante para los compradores B2B internacionales, sobre todo para los que operan en entornos diversos y exigentes de África, Sudamérica, Oriente Medio y Europa. Los flotadores de PE son componentes esenciales en diversas aplicaciones, como el dragado marino, la acuicultura y la gestión de tuberías, donde la flotabilidad y la durabilidad son primordiales. Esta completa guía ofrece un análisis en profundidad del mercado mundial de flotadores de PE, detallando los distintos tipos disponibles, sus aplicaciones específicas y las consideraciones críticas para la selección de proveedores.

Navegar por las complejidades del abastecimiento de flotadores de PE puede resultar desalentador, especialmente si se tienen en cuenta las variaciones regionales en cuanto a calidad, precios y normas de cumplimiento. Esta guía está diseñada para ayudar a los compradores B2B proporcionándoles información práctica sobre estructuras de costes, especificaciones de rendimiento y las últimas innovaciones en tecnología de flotadores de PE. Tanto si se encuentra en Vietnam buscando proveedores fiables como si está en Alemania intentando optimizar su cadena de suministro, este recurso le proporcionará los conocimientos necesarios para tomar decisiones de compra con conocimiento de causa. Centrados en la eficiencia y la eficacia, nuestro objetivo es agilizar su proceso de aprovisionamiento, garantizando que sus operaciones se beneficien de lo mejor que ofrece el mercado mundial.

Índice

- Lista de los 6 mejores fabricantes y proveedores de Flotador de Pe

- Introducción: Navegar por el mercado mundial de PE flotante

- Tipos y variaciones del flotador PE

- Principales aplicaciones industriales del flotador de PE

- 3 puntos débiles habituales de los usuarios de "PE Float" y sus soluciones

- Guía estratégica de selección de materiales para flotadores de PE

- En profundidad: Procesos de fabricación y garantía de calidad para PE Float

- Guía práctica de contratación: Lista de comprobación paso a paso para "PE Float

- Análisis exhaustivo de costes y precios para el abastecimiento de flotadores de PE

- Análisis de alternativas: Comparación de PE Float con otras soluciones

- Propiedades técnicas esenciales y terminología comercial del PE flotante

- Dinámica del mercado y tendencias de abastecimiento en el sector de los flotadores de polietileno

- Preguntas más frecuentes (FAQ) para compradores B2B de PE Float

- Conclusiones y perspectivas de la contratación estratégica de PE Float

- Descargo de responsabilidad y condiciones de uso

Tipos y variaciones del flotador PE

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Flotadores de PE estándar | Carcasa de polietileno de densidad media, rellena de espuma de poliuretano | Dragado, apoyo a oleoductos, acuicultura | Pros: Gran flotabilidad, resistencia a los golpes. Contras: Las opciones de tamaño limitadas pueden no adaptarse a todas las aplicaciones. |

| Flotadores de alta resistencia | Mayor durabilidad, carcasas más gruesas para condiciones extremas | Construcción naval, operaciones en alta mar | Pros: Excelente resistencia a los impactos, adecuado para mares agitados. Contras: Un coste más elevado puede disuadir a los compradores con poco presupuesto. |

| Flotadores ligeros | Diseño ligero, fácil de instalar | Instalaciones temporales, uso recreativo | Pros: Bajo mantenimiento, rentable. Contras: Puede carecer de la flotabilidad necesaria para aplicaciones pesadas. |

| Flotadores personalizables | Tamaños y especificaciones a medida | Proyectos especializados, requisitos únicos | Pros: Se adapta perfectamente a las necesidades específicas. Contras: Plazos de producción más largos. |

| Flotadores ecológicos | Fabricado con materiales reciclados, respetuoso con el medio ambiente | Proyectos sostenibles, industrias ecológicas | Pros: Reduce el impacto medioambiental. Contras: Disponibilidad limitada en algunos mercados. |

¿Cuáles son las principales características de los flotadores de PE estándar?

Los flotadores de PE estándar están fabricados con polietileno de densidad media (MDPE) y rellenos de espuma de poliuretano, lo que proporciona una flotabilidad y durabilidad excepcionales. Estos flotadores se utilizan habitualmente en dragados, soporte de tuberías y acuicultura debido a su resistencia a los golpes y su estructura compacta. Al considerar su compra, los compradores B2B deben evaluar la capacidad de carga del flotador y su compatibilidad con tamaños específicos de tuberías para garantizar un rendimiento óptimo en sus aplicaciones.

¿Cómo destacan los flotadores de alta resistencia en aplicaciones marinas?

Los flotadores de alta resistencia se caracterizan por sus carcasas más gruesas y su construcción robusta, diseñada para soportar condiciones marinas extremas. Son ideales para la construcción naval y las operaciones en alta mar, donde la fiabilidad es primordial. Los compradores B2B deben sopesar las ventajas de una mayor durabilidad frente a los costes más elevados, asegurándose de que la inversión se ajusta a las exigencias del proyecto y a las limitaciones presupuestarias.

¿Por qué elegir flotadores ligeros para instalaciones temporales?

Los flotadores ligeros están diseñados para facilitar su manejo e instalación, por lo que son adecuados para instalaciones temporales y usos recreativos. Su bajo mantenimiento y su rentabilidad resultan atractivos para las empresas que buscan soluciones asequibles. Sin embargo, los compradores deben tener en cuenta las limitaciones de flotabilidad de estos flotadores, ya que pueden no ser adecuados para aplicaciones pesadas.

¿Qué ventajas ofrecen los flotadores personalizables para proyectos especializados?

Los flotadores personalizables ofrecen la flexibilidad necesaria para adaptar los tamaños y las especificaciones a los requisitos específicos de cada proyecto. Esta adaptabilidad los hace ideales para aplicaciones especializadas en las que los tamaños estándar pueden no ser suficientes. Sin embargo, los compradores deben prever plazos de producción más largos, lo que puede afectar a los plazos del proyecto.

¿Cómo contribuyen los flotadores ecológicos a las prácticas sostenibles?

Los flotadores ecológicos se fabrican a partir de materiales reciclados y están destinados a sectores centrados en la sostenibilidad. Estos flotadores ayudan a reducir el impacto ambiental, manteniendo al mismo tiempo los estándares de rendimiento. Los compradores B2B deben evaluar la disponibilidad de estos productos en sus regiones, ya que el abastecimiento puede ser un reto en determinados mercados.

Principales aplicaciones industriales del flotador de PE

| Industria/Sector | Aplicación específica del flotador de PE | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Construcción naval | Sistemas de tuberías flotantes | Mejora la flotabilidad y la estabilidad en el transporte de agua | Garantizar el cumplimiento de la normativa marítima y las normas de durabilidad |

| Acuicultura | Soluciones de flotabilidad para piscifactorías | Soporta sistemas de alimentación y redes, reduciendo la mano de obra | Verificar la compatibilidad con las condiciones ambientales locales |

| Operaciones de dragado | Manguera de apoyo en actividades de dragado | Facilita la eliminación eficaz de sedimentos | Considerar la capacidad de carga y la resistencia a entornos difíciles |

| Limpieza medioambiental | Barreras flotantes contra vertidos de petróleo | Proporciona apoyo inmediato a los esfuerzos de contención | Evaluar la resistencia química y la facilidad de despliegue |

| Gestión del suministro de agua | Flotación de tuberías de suministro de agua | Mantiene un caudal de agua eficaz en terrenos difíciles | Evaluar la capacidad de flotación y la eficacia de la instalación |

¿Cómo se utiliza el flotador de PE en la construcción naval y qué problemas resuelve?

En la construcción naval, los flotadores de PE son fundamentales para los sistemas de tuberías flotantes, ya que proporcionan la flotabilidad esencial que permite suspender las tuberías por encima del agua. Esta aplicación es crucial en proyectos que implican instalaciones submarinas, donde los soportes tradicionales son poco prácticos. Utilizando flotadores de PE, las empresas pueden mejorar la estabilidad y minimizar el riesgo de daños en las tuberías durante la instalación o el transporte. Los compradores de este sector deben dar prioridad al suministro de flotadores que cumplan las estrictas normativas marinas y posean una gran durabilidad para resistir los duros entornos marinos.

¿Qué papel desempeña el flotador de PE en la acuicultura?

En el sector de la acuicultura, los flotadores de PE se emplean para sostener los sistemas de alimentación y las redes, garantizando su flotabilidad y funcionalidad. Esta aplicación no sólo optimiza la eficacia de la alimentación, sino que también reduce el trabajo manual, haciendo que las operaciones sean más rentables. Para los compradores internacionales, especialmente en regiones como África y Sudamérica, es esencial verificar que los flotadores son compatibles con las condiciones ambientales locales, como la salinidad y la temperatura, para garantizar su longevidad y rendimiento.

¿Por qué es esencial el flotador de PE para las operaciones de dragado?

Los flotadores de PE son cruciales en las operaciones de dragado, ya que proporcionan soporte a las mangueras utilizadas en la retirada de sedimentos. Al mantener las mangueras a flote, facilitan un dragado eficaz y reducen las posibilidades de que se enreden o dañen. Las empresas deben tener en cuenta la capacidad de carga de los flotadores, sobre todo cuando trabajan en aguas profundas o turbulentas, para garantizar la seguridad y eficacia de las operaciones. Los compradores también deben evaluar la resistencia de los flotadores al desgaste por materiales abrasivos.

Imagen ilustrativa relacionada con PE Float

¿De qué manera ayuda el flotador PE a los esfuerzos de limpieza medioambiental?

Durante la limpieza medioambiental, especialmente en respuesta a vertidos de petróleo, los flotadores de PE se utilizan para crear barreras flotantes que contengan los vertidos y eviten una mayor contaminación. Esta aplicación es vital para que los esfuerzos de remediación sean rápidos y eficaces. Las empresas dedicadas a los servicios medioambientales deben centrarse en el suministro de flotadores que ofrezcan resistencia química y sean fáciles de desplegar, ya que estos factores influyen significativamente en el tiempo de respuesta y la eficacia en situaciones críticas.

¿Cuál es la importancia del flotador PE en la gestión del suministro de agua?

Los flotadores de PE se utilizan en la gestión del suministro de agua para sostener líneas flotantes que transportan agua a través de terrenos difíciles. Esta aplicación es vital para mantener un flujo de agua eficaz y garantizar el acceso a agua limpia en zonas remotas. Los compradores deben evaluar la capacidad de flotación de los flotadores y su eficacia de instalación, especialmente en regiones con infraestructuras limitadas. Comprender la normativa local y abastecerse de materiales de alta calidad puede aumentar la fiabilidad de los sistemas de abastecimiento de agua.

3 puntos débiles habituales de los usuarios de "PE Float" y sus soluciones

Situación 1: Flotabilidad inadecuada para cargas pesadas

El problema: Una empresa de construcción que opera en una región costera se enfrenta a menudo a retos relacionados con el transporte de materiales pesados por el agua. Han experimentado casos en los que los flotadores de PE que utilizaban no tenían el tamaño adecuado para el peso de las mangueras y los materiales, lo que provocaba una flotabilidad inferior a la óptima y posibles riesgos para la seguridad. Esta situación no sólo retrasa los proyectos, sino que también plantea problemas de cumplimiento de las normas de seguridad.

La solución: Para garantizar que los flotadores de PE cumplen los requisitos de flotabilidad, los compradores deben realizar un análisis exhaustivo de la carga antes de seleccionar el tamaño del flotador. Es crucial calcular el peso total de las mangueras de descarga y los materiales que se soportarán y, a continuación, elegir un flotador que ofrezca un índice de flotabilidad significativamente superior a este peso. Trabajar con fabricantes que proporcionen especificaciones detalladas sobre la capacidad de carga y los índices de flotabilidad, como las que se encuentran en las fichas técnicas, puede reducir significativamente el riesgo de una flotación inadecuada. Además, considerar flotadores con un diámetro mayor o los diseñados para aplicaciones pesadas puede mejorar la seguridad y la eficacia.

Escenario 2: Dificultad de instalación y mantenimiento

El problema: Las empresas de servicios náuticos suelen tener problemas con la instalación y el mantenimiento de los flotadores de PE, sobre todo en condiciones meteorológicas adversas. La complejidad de alinear y fijar los flotadores a las mangueras puede provocar retrasos en la instalación, mientras que los factores ambientales adversos pueden causar desgaste, haciendo necesarias sustituciones frecuentes. Esto no sólo afecta a los plazos operativos, sino que también aumenta los costes del proyecto.

La solución: Para agilizar los procesos de instalación y mantenimiento, los compradores deben considerar los flotadores de PE que presentan diseños fáciles de usar, como sistemas de apriete integrados o mecanismos de liberación rápida. Elegir flotadores ligeros y fáciles de manejar también puede reducir el tiempo de instalación. Además, deben establecerse programas de mantenimiento periódicos, incluidas inspecciones después de fenómenos meteorológicos severos. Al optar por flotadores fabricados con materiales duraderos resistentes a los rayos UV y diseñados para soportar condiciones adversas, las empresas pueden prolongar considerablemente la vida útil de sus equipos y minimizar las interrupciones.

Escenario 3: Problemas medioambientales y de cumplimiento de la normativa

El problema: Las empresas dedicadas a la gestión medioambiental se enfrentan cada vez más al escrutinio de los materiales utilizados en sus equipos flotantes. Muchos flotadores tradicionales plantean riesgos medioambientales, lo que plantea problemas de cumplimiento de la normativa local en materia de contaminación y preservación del ecosistema. Esta situación puede poner en peligro sus contratos y su reputación en el sector.

La solución: Para hacer frente a estas preocupaciones medioambientales, los compradores B2B deben dar prioridad al abastecimiento de flotadores de PE fabricados con materiales respetuosos con el medio ambiente, como el polietileno de alta densidad (HDPE) con un menor impacto medioambiental. La contratación de proveedores que proporcionen certificaciones y demuestren su adhesión a la normativa medioambiental puede mejorar el cumplimiento y garantizar a los clientes su compromiso con la sostenibilidad. Además, la implantación de un programa de reciclaje de flotadores viejos y el fomento del uso de materiales biodegradables o reciclables en sus operaciones pueden reforzar aún más su reputación y su integridad operativa en los mercados ecológicamente sensibles.

Guía estratégica de selección de materiales para flotadores de PE

¿Cuáles son los principales materiales utilizados en la producción de flotadores de PE?

A la hora de seleccionar los materiales para los flotadores de PE, es esencial tener en cuenta varias opciones que cumplan criterios de rendimiento específicos. Los materiales más comunes son el polietileno de media densidad (MDPE), el polietileno de alta densidad (HDPE), la espuma de poliuretano (PURF) y el polipropileno (PP). Cada material tiene propiedades, ventajas y limitaciones distintas que pueden influir significativamente en la aplicación y la idoneidad para los mercados internacionales.

¿Cómo funciona el polietileno de densidad media (MDPE) para flotadores de PE?

El polietileno de densidad media (MDPE) se utiliza ampliamente para el revestimiento exterior de los flotadores de PE debido a su excelente equilibrio entre resistencia y flexibilidad. Puede soportar temperaturas de entre -60 °C y 80 °C, por lo que es adecuado para diversas condiciones ambientales. Además, el MDPE presenta una buena resistencia a los productos químicos, la radiación UV y los impactos, lo que garantiza su longevidad en aplicaciones marinas.

Pros: El MDPE es ligero, rentable y fácil de fabricar, lo que permite procesos de fabricación rápidos. Su dureza y resistencia a los golpes lo hacen ideal para aplicaciones sometidas a grandes esfuerzos.

Contras: Aunque el polietileno de densidad media ofrece una durabilidad adecuada, es posible que no resista temperaturas extremas o fuertes tensiones mecánicas tan bien como otros materiales como el polietileno de alta densidad.

Impacto en la aplicación: El polietileno de densidad media es compatible con diversos medios, incluidos el agua y los lodos, lo que lo hace adecuado para aplicaciones de dragado y vertido.

Consideraciones para compradores internacionales: El cumplimiento de normas internacionales como ASTM y DIN es crucial. Los compradores de regiones como África y Sudamérica deben asegurarse de que el MDPE utilizado cumple la normativa medioambiental local.

¿Qué ventajas ofrece el polietileno de alta densidad (HDPE) para los flotadores de PE?

El HDPE es otra opción popular para los flotadores de PE, sobre todo para aplicaciones que requieren una mayor durabilidad y resistencia a los factores medioambientales. Ofrece una resistencia al impacto superior y puede soportar un rango de temperaturas más amplio que el MDPE.

Pros: El HDPE es muy resistente a la corrosión, por lo que resulta ideal para entornos marinos difíciles. También tiene una vida útil más larga y un mejor rendimiento general en condiciones extremas.

Contras: El proceso de fabricación del HDPE puede ser más complejo y costoso que el del MDPE, lo que puede afectar a los precios para los compradores internacionales.

Impacto en la aplicación: Los flotadores de polietileno de alta densidad son especialmente eficaces en aplicaciones que implican operaciones marinas pesadas, como oleoductos y gasoductos, donde la durabilidad es primordial.

Consideraciones para compradores internacionales: Los compradores deben comprobar que los productos de HDPE cumplen las normas locales e internacionales, especialmente en Europa, donde se aplican reglamentos muy estrictos.

¿Cómo mejora la espuma de poliuretano (PURF) los flotadores de PE?

El PURF se utiliza habitualmente como material de relleno del núcleo de los flotadores de PE, proporcionando flotabilidad y aislamiento térmico. Es conocido por su gran resistencia y sus excelentes propiedades de flotabilidad.

Pros: La naturaleza ligera del PURF aumenta la flotabilidad general del flotador, lo que lo hace ideal para aplicaciones que requieren una elevación significativa. También proporciona una excelente absorción de impactos.

Contras: El PURF puede ser sensible a la exposición a los rayos UV y puede requerir revestimientos protectores adicionales para garantizar su longevidad.

Impacto en la aplicación: El PURF es especialmente eficaz en entornos con temperaturas fluctuantes, ya que mantiene la flotabilidad incluso cuando está sometido a presiones variables.

Consideraciones para compradores internacionales: Los compradores deben asegurarse de que el PURF utilizado en los flotadores cumple la normativa medioambiental, sobre todo en las regiones donde la eliminación de la espuma puede ser un problema.

¿Qué papel desempeña el polipropileno (PP) en las aplicaciones de flotadores de PE?

El polipropileno es menos común que los materiales antes mencionados, pero ofrece ventajas únicas, sobre todo en aplicaciones específicas. Es ligero y resistente a la humedad, lo que lo hace adecuado para determinadas aplicaciones marinas.

Pros: El PP es rentable y ofrece una buena resistencia química, por lo que resulta adecuado para diversas aplicaciones.

Contras: Su menor resistencia a la tracción en comparación con el MDPE y el HDPE puede limitar su uso en entornos sometidos a grandes esfuerzos.

Impacto en la aplicación: Los flotadores de PP suelen utilizarse en aplicaciones en las que el peso es un factor crítico, como en la acuicultura o en estructuras flotantes temporales.

Consideraciones para compradores internacionales: Garantizar que los productos de PP cumplen las normas de conformidad necesarias, especialmente en regiones con normativas medioambientales específicas.

Tabla resumen de selección de materiales para flotadores de PE

| Material | Caso típico de uso del flotador PE | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Polietileno de media densidad (MDPE) | Aplicaciones de dragado y vertido | Ligero y rentable | Resistencia limitada a la temperatura | Bajo |

| Polietileno de alta densidad (HDPE) | Operaciones marítimas pesadas | Durabilidad y resistencia a la corrosión superiores | Mayor coste de fabricación | Medio |

| Espuma de poliuretano (PURF) | Relleno de núcleo para flotabilidad | Excelente flotabilidad y absorción de impactos | Sensible a la exposición UV | Medio |

| Polipropileno (PP) | Acuicultura y estructuras temporales | Rentable y resistente a la humedad | Menor resistencia a la tracción | Bajo |

Esta guía ofrece una visión completa de las opciones de materiales para flotadores de PE, lo que permite a los compradores internacionales B2B tomar decisiones informadas basadas en sus necesidades específicas y requisitos de cumplimiento.

En profundidad: Procesos de fabricación y garantía de calidad para PE Float

¿Cuáles son las etapas clave del proceso de fabricación de flotadores de PE?

El proceso de fabricación de flotadores de polietileno (PE) implica varias etapas críticas que garantizan que el producto final cumpla altos estándares de calidad y rendimiento. Estas etapas incluyen la preparación del material, el conformado, el montaje y el acabado.

-

Preparación del material: El proceso comienza con la selección de materiales de alta calidad. En el caso de los flotadores de PE, se suele utilizar polietileno de densidad media (MDPE) para la cubierta exterior, debido a su excelente resistencia a la compresión y durabilidad. El núcleo interior suele rellenarse con espuma de poliuretano de alta resistencia (PURF) para proporcionar flotabilidad. Los proveedores suelen realizar pruebas de preproducción con las materias primas para asegurarse de que cumplen unas propiedades mecánicas y químicas específicas.

-

Formando: En esta etapa, el MDPE se somete a un proceso de moldeo, que puede incluir el moldeo rotacional o el moldeo por soplado. El moldeo rotacional es el preferido para producir estructuras huecas como flotadores, lo que permite un grosor uniforme y diseños sin costuras. El polímero se calienta hasta que se vuelve flexible y luego se enfría para darle la forma deseada. La precisión en esta fase es fundamental, ya que cualquier defecto puede comprometer la flotabilidad y la integridad estructural del flotador.

-

Montaje: Una vez formados los flotadores, se procede a su ensamblaje, que puede implicar la integración de componentes adicionales, como accesorios de fijación o mecanismos de sujeción. Esta etapa suele incluir la aplicación de accesorios galvanizados de calidad marina para aumentar la durabilidad y la resistencia a la corrosión.

-

Acabado: La etapa final consiste en el tratamiento y la inspección de la superficie. Esto puede incluir la aplicación de revestimientos resistentes a los rayos UV para proteger los flotadores de los daños causados por el sol. Es crucial que los productos acabados se limpien a fondo y se preparen para el envasado para evitar la contaminación durante el transporte.

¿Cómo se garantiza la calidad durante la producción de flotadores de PE?

La garantía de calidad es un aspecto vital del proceso de fabricación de flotadores de PE. Los fabricantes suelen cumplir normas internacionales como la ISO 9001, que establece un marco para los sistemas de gestión de la calidad. Además, se pueden solicitar certificaciones específicas del sector, como CE y API, para demostrar el cumplimiento de los requisitos de seguridad y rendimiento.

-

Puntos de control de calidad: A lo largo del proceso de fabricación se establecen diversos puntos de control para garantizar la calidad. Entre ellos se incluyen:

– Control de calidad entrante (IQC): Este control inicial evalúa la calidad de las materias primas en el momento de su recepción. Se comprueba que las muestras cumplen las normas especificadas.

– Control de calidad durante el proceso (IPQC): Durante la producción, se prueban muestras aleatorias para controlar la calidad del proceso de fabricación. Esto incluye comprobar la consistencia del grosor del material y las propiedades de flotabilidad.

– Control de calidad final (CCF): Antes del envasado, los productos acabados se someten a pruebas exhaustivas. Esto incluye pruebas de flotabilidad, pruebas de resistencia e inspecciones para detectar defectos superficiales. -

Métodos de ensayo habituales: Se emplean varios métodos de ensayo para validar el rendimiento de los flotadores de PE. Entre ellos se incluyen:

– Pruebas de resistencia a la tracción: Mide la capacidad del flotador para soportar fuerzas de estiramiento y tracción.

– Pruebas de resistencia al impacto: Evalúa la durabilidad del flotador frente a golpes e impactos.

– Pruebas de flotabilidad: Garantiza que el flotador pueda soportar el peso especificado sin sumergirse.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

Para los compradores B2B, especialmente los de regiones como África, Sudamérica, Oriente Medio y Europa, verificar las prácticas de control de calidad de los proveedores es esencial para garantizar la fiabilidad del producto.

-

Auditorías de proveedores: La realización de auditorías a posibles proveedores puede proporcionar información sobre sus procesos de fabricación y sistemas de control de calidad. Esto puede implicar visitar las instalaciones de producción para observar las prácticas y revisar la documentación.

-

Solicitud de informes de calidad: Los compradores deben solicitar a los proveedores informes de calidad detallados que incluyan los resultados de los procesos IQC, IPQC y FQC. Estos informes deben describir las metodologías de ensayo, los resultados y las medidas correctivas adoptadas en caso de no conformidad.

-

Inspecciones de terceros: Contratar servicios de inspección de terceros puede proporcionar una evaluación imparcial de las medidas de control de calidad del proveedor. Estas inspecciones pueden incluir inspecciones previas al envío, en las que se comprueba si muestras aleatorias del producto cumplen las especificaciones.

-

Verificación de la certificación: Los compradores deben verificar cualquier afirmación sobre certificaciones consultando a los organismos certificadores. Así se garantiza que el proveedor mantiene sus certificaciones y cumple las normas exigidas.

¿Qué matices deben tener en cuenta los compradores internacionales en el control de calidad de los flotadores de PE?

Al tratar con proveedores internacionales, es fundamental conocer los matices específicos que pueden afectar a los procesos de control de calidad.

-

Cumplimiento de la normativa: Las normativas de fabricación de productos marinos pueden variar de una región a otra. Los compradores deben asegurarse de que los proveedores cumplen la normativa local de sus respectivos mercados, que puede incluir normas medioambientales y de seguridad.

-

Diferencias culturales en las normas de calidad: Las expectativas de calidad pueden diferir considerablemente de una cultura a otra. Los compradores deben comunicar claramente sus requisitos de calidad y asegurarse de que los proveedores comprenden la importancia de cumplirlos.

-

Consideraciones logísticas: El transporte de flotadores de PE puede exponerlos a condiciones que podrían afectar a la calidad. Los compradores deben discutir los métodos de embalaje y envío con los proveedores para asegurarse de que los productos están protegidos durante el tránsito.

-

Asociaciones a largo plazo: Establecer relaciones a largo plazo con los proveedores puede mejorar la garantía de calidad. La comunicación y la colaboración regulares pueden ayudar a abordar los problemas de forma proactiva y mejorar la calidad general del producto con el paso del tiempo.

Conclusiones: Garantizar la calidad y la fiabilidad en la fabricación de flotadores de PE

En conclusión, los procesos de fabricación y las medidas de garantía de calidad de los flotadores de PE son fundamentales para suministrar productos fiables a los compradores B2B internacionales. Al conocer las etapas de producción, los puntos de control de calidad y los métodos de verificación, los compradores pueden tomar decisiones informadas a la hora de seleccionar proveedores. Además, reconocer los matices de las normas de calidad internacionales ayudará a fomentar asociaciones fructíferas y a garantizar que los flotadores satisfagan las necesidades específicas de los diversos mercados.

Guía práctica de contratación: Lista de comprobación paso a paso para "PE Float

Para ayudar a los compradores B2B en la adquisición de Flotadores de PE, esta guía proporciona una lista de comprobación estructurada para garantizar un proceso de abastecimiento exhaustivo y eficaz. Los pasos que se describen a continuación le ayudarán a navegar por las complejidades de la selección del flotador de PE adecuado para sus necesidades específicas, centrándose en la calidad, el rendimiento y la fiabilidad del proveedor.

Primer paso: Defina sus especificaciones técnicas

Establezca especificaciones técnicas claras para el flotador PE que se adapten a sus requisitos operativos. Tenga en cuenta factores como la capacidad de carga del flotador, sus dimensiones y las condiciones ambientales (por ejemplo, rango de temperaturas y exposición a productos químicos). Esta claridad le ayudará a comunicar eficazmente sus necesidades a los posibles proveedores.

Imagen ilustrativa relacionada con PE Float

- Especificaciones clave a tener en cuenta:

- Material de la carcasa exterior (por ejemplo, MDPE) para mayor durabilidad.

- Requisitos de flotabilidad en función de la aplicación (por ejemplo, mangueras de descarga).

- Resistencia a la temperatura para climas variables.

Segundo paso: Investigación Proveedores y fabricantes

Lleve a cabo una investigación exhaustiva para identificar proveedores y fabricantes de flotadores de PE de buena reputación. Busque empresas con una trayectoria demostrada en el sector y opiniones positivas de los clientes. Una buena reputación suele estar relacionada con la fiabilidad del producto y la calidad del servicio.

- Cosas que investigar:

- Años de experiencia en la fabricación de flotadores de PE.

- Certificaciones industriales (por ejemplo, ISO) que validan sus normas de calidad.

- Ubicación geográfica y capacidades logísticas para una entrega puntual.

Tercer paso: Evaluar posibles proveedores

Antes de comprometerse con un proveedor, es esencial investigarlo a fondo. Solicite perfiles de empresa, estudios de casos y referencias de compradores de sectores o regiones similares. Este paso le garantiza que se asociará con un proveedor que entiende su mercado y puede satisfacer sus necesidades específicas.

- Criterios de evaluación importantes:

- Capacidad de producción y plazos de entrega.

- Procesos de aseguramiento de la calidad y metodologías de prueba.

- Capacidad de respuesta y asistencia del servicio de atención al cliente.

Paso 4: Solicitar muestras de productos

Solicite siempre muestras del flotador de PE antes de realizar una compra al por mayor. Probar las muestras le permite evaluar la calidad, la flotabilidad y el rendimiento general en condiciones reales. Este paso mitiga los riesgos asociados a grandes pedidos de productos potencialmente inadecuados.

- Qué buscar en las muestras:

- Atributos físicos como el peso y la talla.

- Rendimiento bajo las tensiones operativas previstas.

- Durabilidad frente a factores ambientales (por ejemplo, exposición a los rayos UV).

Paso 5: Verificar el cumplimiento de la normativa

Asegúrese de que los flotadores de PE cumplen la normativa local e internacional aplicable a su sector. El cumplimiento no solo afecta a la seguridad, sino también a la longevidad y eficiencia de los flotadores en sus operaciones.

Imagen ilustrativa relacionada con PE Float

- Aspectos reglamentarios que deben comprobarse:

- Normativa medioambiental sobre el uso de materiales.

- Normas de seguridad específicas de los equipos marinos.

- Normativa sobre importación y exportación que pueda afectar a la contratación.

Paso 6: Negociar las condiciones

Una vez que haya seleccionado un proveedor, negocie términos y condiciones favorables. Esto debe incluir precios, condiciones de pago, garantías y políticas de devolución. Un acuerdo bien definido puede ahorrarle posibles disputas y garantizar un proceso de transacción fluido.

- Puntos clave de la negociación:

- Descuentos por pedidos al por mayor y flexibilidad de pago.

- Duración de la garantía y cobertura de los defectos.

- Políticas claras de devolución y sustitución en caso de incumplimiento.

Paso 7: Establecer una asociación a largo plazo

Considere la posibilidad de establecer una relación a largo plazo con el proveedor elegido. Un socio fiable puede ofrecerle asistencia continua, actualizaciones puntuales sobre nuevos productos y posibles ahorros de costes a lo largo del tiempo. La comunicación y los comentarios periódicos pueden mejorar la colaboración y la innovación de los productos.

- Ventajas de una asociación a largo plazo:

- Garantía de calidad constante basada en la confianza establecida.

- Acceso prioritario a nuevas tecnologías y productos.

- Mejor comprensión de la evolución de sus necesidades empresariales.

Esta lista de comprobación le guiará a lo largo del proceso de adquisición y le permitirá tomar decisiones con conocimiento de causa a la hora de adquirir flotadores de PE adaptados a sus necesidades operativas.

Análisis exhaustivo de costes y precios para el abastecimiento de flotadores de PE

¿Cuáles son los principales componentes del coste de la compra de flotadores de PE?

A la hora de adquirir flotadores de PE, es fundamental conocer la estructura de costes para tomar decisiones de compra con conocimiento de causa. Los principales componentes del coste son:

-

Materiales: La carcasa exterior suele ser de polietileno de densidad media (MDPE), que ofrece una excelente durabilidad y flotabilidad. El núcleo interior suele estar relleno de espuma de poliuretano de alta resistencia (PURF) para aumentar la flotabilidad y la resistencia a los golpes. La elección de los materiales influye significativamente en el coste total, ya que los materiales de mayor calidad suelen conllevar precios más elevados.

-

Trabajo: Los costes laborales pueden variar según la región y la complejidad de los procesos de fabricación. La mano de obra cualificada es necesaria para el control de calidad y el montaje, lo que puede contribuir a elevar los costes.

-

Gastos generales de fabricación: Incluye los gastos relacionados con el funcionamiento de la fábrica, el mantenimiento de los equipos y los servicios públicos. Unos procesos de fabricación eficientes pueden ayudar a reducir estos gastos generales, influyendo así en el precio final.

-

Herramientas: Los diseños personalizados o las dimensiones específicas pueden requerir herramientas especializadas, lo que aumenta la inversión inicial. Los compradores deben tener en cuenta estos costes al evaluar a los proveedores que ofrecen personalización.

-

Control de calidad: Garantizar que los flotadores cumplen las normas y especificaciones del sector exige rigurosas pruebas y procesos de control de calidad. Estas medidas de control de calidad, aunque esenciales para la seguridad y el rendimiento, también pueden aumentar el coste global.

-

Logística: Los gastos de envío pueden variar mucho en función de la ubicación del proveedor, el destino y el método de envío elegido. Los compradores internacionales, sobre todo de regiones como África y Sudamérica, deben tener en cuenta los posibles aranceles y derechos de aduana que pueden aumentar los gastos totales.

-

Margen: Los proveedores suelen aplicar un margen para cubrir sus costes y generar beneficios. Este margen puede variar en función de la reputación del proveedor, la demanda del mercado y la competencia.

¿Cómo afectan los factores que influyen en el precio a la cotización del PE?

Varios factores pueden influir en el precio de los flotantes de PE, que los compradores internacionales deben tener en cuenta:

-

Volumen/MOQ: Los pedidos más grandes suelen dar lugar a precios unitarios más bajos debido a las economías de escala. Los compradores deben evaluar sus necesidades y negociar cantidades mínimas de pedido (MOQ) para lograr eficiencias de costes.

-

Especificaciones y personalización: Los flotadores personalizados adaptados a aplicaciones específicas pueden conllevar precios más elevados. Los compradores deben sopesar su necesidad de personalización con los costes asociados.

-

Calidad del material y certificaciones: Los flotadores fabricados con materiales de mayor calidad o con certificaciones específicas (por ejemplo, resistencia a los rayos UV o respeto del medio ambiente) pueden tener precios más elevados. Los compradores deben evaluar los beneficios a largo plazo de invertir en una mayor calidad.

-

Factores del proveedor: La reputación, fiabilidad y nivel de servicio de un proveedor pueden influir en el precio. Los proveedores establecidos pueden cobrar más por su experiencia y atención al cliente.

-

Incoterms: Comprender los términos comerciales (Incoterms) es vital para los compradores internacionales. En ellos se establecen las responsabilidades de compradores y vendedores en materia de transporte, seguros y despacho de aduanas, lo que puede repercutir significativamente en los costes totales.

¿Cuáles son los consejos más eficaces para comprar flotadores de PE?

Para optimizar las estrategias de aprovisionamiento y minimizar los costes, los compradores deben tener en cuenta los siguientes consejos:

-

Negociar precios: No dude en negociar con los proveedores. Hablar de pedidos al por mayor, contratos a largo plazo o compras de varios productos puede suponer mejores precios.

-

Centrarse en el coste total de propiedad (TCO): Evalúe no sólo el precio de compra inicial, sino también el mantenimiento, los costes operativos y la vida útil potencial. Un flotador barato puede resultar más caro con el tiempo si hay que sustituirlo con frecuencia.

-

Investigar las tarifas del mercado: Manténgase informado sobre los precios y tendencias actuales del mercado. Conocer las fluctuaciones de los precios puede ser una ventaja en las negociaciones.

-

Tenga en cuenta a los proveedores locales: Para los compradores de regiones como África o Sudamérica, abastecerse de proveedores locales puede reducir los costes de envío y los plazos de entrega. Además, los proveedores locales pueden ofrecer un mejor conocimiento de las normativas y requisitos regionales.

-

Evaluar la calidad frente al coste: Aunque puede resultar tentador optar por la opción más barata, invertir en flotadores de mayor calidad puede evitar problemas futuros y costes adicionales. Dé prioridad a los proveedores que demuestren su compromiso con la garantía de calidad.

Descargo de responsabilidad sobre precios indicativos

Los precios de los flotadores de PE pueden variar significativamente en función de las especificaciones, el volumen del pedido y factores relacionados con el proveedor. Es aconsejable que los compradores soliciten presupuestos a varios proveedores para asegurarse precios competitivos adaptados a sus necesidades específicas.

Análisis de alternativas: Comparación de PE Float con otras soluciones

Alternativas a la flotación de PE: ¿Qué solución le conviene?

A la hora de evaluar soluciones flotantes para aplicaciones marinas, es crucial considerar varias alternativas al PE Float. Este análisis ayudará a los compradores B2B a comprender los puntos fuertes y débiles del PE Float en comparación con otras opciones viables del mercado, lo que permitirá tomar decisiones de compra informadas.

| Aspecto comparativo | Flotador PE | Flotadores de polietileno para muelles | Flotadores de muelle rellenos de espuma |

|---|---|---|---|

| Rendimiento | Gran flotabilidad, resistente a los golpes | Buena flotabilidad, menos duradero | Flotabilidad moderada, gran durabilidad |

| Coste | Coste moderado | Varía mucho, generalmente asequible | Mayor inversión inicial |

| Facilidad de aplicación | Fácil de instalar, ligero | Suele requerir hardware adicional | Complejidad moderada, requiere configuración |

| Mantenimiento | Bajo mantenimiento | Moderado debido a los posibles daños causados por los rayos UV | Bajo mantenimiento, resistente al desgaste |

| El mejor caso de uso | Ideal para mangueras de descarga en entornos marinos | Adecuado para muelles y puertos deportivos | Lo mejor para estructuras flotantes a largo plazo |

Análisis en profundidad de las alternativas al PE Float

Flotadores de polietileno para muelles

Los flotadores de polietileno para muelles son una alternativa popular, utilizada a menudo en la construcción de diques flotantes y puertos deportivos. Proporcionan una buena flotabilidad y son relativamente asequibles. Sin embargo, su durabilidad puede ser un problema, sobre todo en entornos marinos hostiles, donde la exposición a los rayos UV y a las inclemencias del tiempo puede degradar el material con el tiempo. Su instalación puede requerir herrajes adicionales, lo que puede complicar el proceso de montaje.

Flotadores de muelle rellenos de espuma

Los flotadores de muelle rellenos de espuma ofrecen una alternativa robusta para aplicaciones que requieren una mayor durabilidad. Estos flotadores están diseñados para soportar un desgaste significativo, por lo que son adecuados para instalaciones a largo plazo. Aunque suelen conllevar una mayor inversión inicial, su resistencia a los daños y sus reducidos requisitos de mantenimiento pueden suponer un ahorro de costes a largo plazo. La instalación puede ser más compleja que la de los flotadores de PE, ya que suele requerir una planificación y una configuración cuidadosas para garantizar la estabilidad y la seguridad.

La elección correcta para las necesidades de su empresa

A la hora de elegir la solución flotante adecuada, tenga en cuenta los requisitos específicos de su aplicación, incluidas las condiciones ambientales, las limitaciones presupuestarias y el uso previsto de los flotadores. Los flotadores de PE son una opción excelente para proyectos que priorizan la flotabilidad y la facilidad de instalación, sobre todo en entornos marinos donde la resistencia a los golpes es crucial. Por otro lado, si su prioridad es la durabilidad y el rendimiento a largo plazo, los flotadores de espuma para muelles pueden ser la mejor opción a pesar de su mayor coste. En última instancia, la evaluación de las compensaciones entre rendimiento, coste e implantación guiará a los compradores B2B hacia la solución más adecuada para sus necesidades operativas.

Propiedades técnicas esenciales y terminología comercial del PE flotante

¿Cuáles son las propiedades técnicas esenciales del flotador de PE?

Al considerar el flotador de PE para aplicaciones como la marina, el dragado o la acuicultura, es crucial comprender sus propiedades técnicas para tomar decisiones de compra informadas. He aquí algunas especificaciones clave a tener en cuenta:

-

Calidad del material: Polietileno de media densidad (MDPE)

- Los flotadores de PE se fabrican principalmente con MDPE, conocido por su resistencia a la compresión y dureza superiores. Este material garantiza la durabilidad en entornos marinos hostiles, por lo que es adecuado para el uso a largo plazo en diversas aplicaciones. Los compradores deben dar prioridad a los productos que especifican MDPE para garantizar la fiabilidad. -

Capacidad de flotación

- La flotabilidad es una métrica de rendimiento crítica para los flotadores de PE, determinada por su tamaño y diseño. Una capacidad de flotación adecuada garantiza que el flotador pueda soportar eficazmente el peso de las mangueras u otros equipos. Esto es especialmente importante en aplicaciones con mangueras de descarga pesadas, en las que una flotabilidad inadecuada podría provocar fallos operativos. -

Resistencia a la temperatura

- Los flotadores de PE deben funcionar eficazmente en una gama de temperaturas de -60°C a +80°C. Esta especificación es vital para los compradores internacionales que pueden encontrarse con condiciones ambientales variables. Comprender la resistencia a la temperatura ayuda a seleccionar flotadores que no se degraden ni pierdan rendimiento con el tiempo. -

Resistencia a los golpes y flexibilidad

- La capacidad de resistir golpes y flexiones bajo presión es esencial para los flotadores de PE, sobre todo en mares agitados. Los flotadores con alta resistencia a los golpes minimizan el riesgo de daños durante el transporte y la instalación, reduciendo así los costes de mantenimiento. Esta propiedad es una consideración importante para las industrias que operan en entornos difíciles. -

Facilidad de instalación y mantenimiento

- Un flotador de PE bien diseñado debe facilitar la instalación y requerir un mantenimiento mínimo. Esta característica es vital para los compradores B2B que buscan optimizar la eficiencia operativa y reducir el tiempo de inactividad. Los productos que vienen con directrices de instalación sencillas y requieren poco cuidado continuo son más atractivos para las empresas que buscan reducir costes. -

Resistencia medioambiental

- Los flotadores de PE deben demostrar una excelente resistencia a la radiación UV, a la intemperie y a la exposición química. Esto garantiza la longevidad y la consistencia del rendimiento, especialmente en aplicaciones exteriores. Los compradores deben buscar flotadores que especifiquen estas propiedades de resistencia para asegurarse de que están haciendo una inversión sostenible.

¿Cuáles son los términos comerciales más comunes relacionados con la flotación de PE?

Navegar por el proceso de adquisición implica comprender la terminología comercial clave. He aquí algunos términos esenciales para las transacciones de PE Float:

-

OEM (fabricante de equipos originales)

- Este término se refiere a las empresas que fabrican productos que luego se venden bajo la marca de otra empresa. En el contexto de los flotadores de PE, los proveedores OEM pueden suministrar flotadores personalizados adaptados a necesidades operativas específicas, lo que resulta especialmente ventajoso para los compradores B2B que buscan soluciones especializadas. -

MOQ (Cantidad mínima de pedido)

- MOQ se refiere a la cantidad más pequeña de un producto que un proveedor está dispuesto a vender. Comprender las MOQ es crucial para que los compradores se aseguren de que pueden cumplir los requisitos de compra al tiempo que gestionan el inventario de forma eficaz. Este término ayuda a las empresas a planificar sus pedidos en función del presupuesto y la demanda. -

RFQ (solicitud de presupuesto)

- Una petición de oferta es un documento que se envía a los proveedores solicitando precios y condiciones para productos específicos. Para los compradores de flotadores de PE, la emisión de una petición de oferta puede agilizar el proceso de compra, permitiendo comparaciones entre proveedores y garantizando precios competitivos. -

Incoterms (Términos comerciales internacionales)

- Se trata de términos comerciales estandarizados que definen las responsabilidades de compradores y vendedores en materia de transporte, seguros y aranceles. Familiarizarse con los Incoterms es fundamental para que los compradores internacionales comprendan sus obligaciones y riesgos al comprar flotadores de PE a proveedores internacionales. -

Plazos de entrega

- El plazo de entrega es el periodo que transcurre entre la realización de un pedido y la recepción del producto. Este término es especialmente importante para las empresas que trabajan con calendarios ajustados, ya que afecta a los plazos de los proyectos. Conocer los plazos de entrega de los pedidos de PE Float ayuda a planificar y gestionar eficazmente la logística de la cadena de suministro. -

Garantía

- Una garantía es una garantía proporcionada por el fabricante con respecto a la calidad y longevidad de un producto. Comprender las condiciones de la garantía de los flotadores de PE es esencial para que los compradores se aseguren de estar protegidos frente a defectos y puedan esperar un rendimiento fiable durante la vida útil del producto.

Al comprender estas propiedades técnicas y términos comerciales, los compradores B2B pueden tomar decisiones informadas que se ajusten a sus necesidades operativas y objetivos estratégicos.

Dinámica del mercado y tendencias de abastecimiento en el sector de los flotadores de polietileno

¿Cuáles son las principales tendencias del mercado que influyen en el sector de los PE flotantes?

El mercado mundial de flotadores de PE está experimentando un fuerte crecimiento impulsado por la creciente demanda en diversos sectores, como la construcción marina, la acuicultura y las operaciones de dragado. Las principales tendencias que influyen en este mercado son la adopción de tecnologías de fabricación avanzadas, como el moldeo por inyección y el moldeo por soplado, que mejoran la durabilidad y la flotabilidad del producto. Además, el creciente énfasis en la sostenibilidad está impulsando a los fabricantes a utilizar materiales ecológicos, lo que empuja la demanda de flotadores de polietileno de alta densidad (HDPE) y polietileno de densidad media (MDPE).

Los compradores B2B internacionales, sobre todo en África, Sudamérica, Oriente Medio y Europa, se centran cada vez más en adquirir productos que ofrezcan un equilibrio entre calidad y rentabilidad. La aparición de plataformas en línea ha revolucionado los procesos de adquisición, permitiendo a los compradores acceder a una gama más amplia de proveedores y productos, lo que fomenta la competitividad de precios. Los compradores también están aprovechando el análisis de datos para evaluar el rendimiento de los proveedores y gestionar los riesgos de la cadena de suministro con mayor eficacia.

Además, la creciente importancia del cumplimiento de las normas internacionales, como las certificaciones ISO, está influyendo en las decisiones de aprovisionamiento. Los compradores son más proclives a asociarse con proveedores que demuestren el cumplimiento de las normas de calidad y seguridad, lo que garantiza la fiabilidad de los productos de PE float que adquieren.

¿Cómo influyen la sostenibilidad y el abastecimiento ético en el mercado de flotadores de polietileno?

La sostenibilidad se está convirtiendo en un factor crítico en la adquisición de flotadores de PE, ya que las empresas reconocen cada vez más el impacto medioambiental de sus decisiones de abastecimiento. La producción de polietileno, aunque eficiente, puede contribuir a la contaminación por plásticos si no se gestiona de forma responsable. Por ello, los compradores internacionales dan prioridad a los proveedores que aplican prácticas sostenibles, como el uso de materiales reciclados o la adopción de procesos de fabricación de circuito cerrado.

El abastecimiento ético es igualmente importante en el mercado actual. Los compradores exigen transparencia en la cadena de suministro, garantizando que los materiales se obtienen de forma responsable sin dañar los ecosistemas ni las comunidades locales. Certificaciones como Green Seal o ISO 14001 pueden servir de indicadores del compromiso de un proveedor con la gestión medioambiental.

Además, muchos compradores están explorando alternativas a los flotadores de PE tradicionales, como los fabricados con materiales biodegradables o los que incorporan contenido reciclado. Estas iniciativas no sólo reducen la huella ambiental, sino que también atraen a una creciente base de consumidores que valora la sostenibilidad. Al elegir flotadores de PE de origen ético y respetuosos con el medio ambiente, las empresas pueden mejorar su imagen de marca y cumplir los requisitos normativos al tiempo que contribuyen positivamente al planeta.

¿Cuál es la evolución del sector de las PE flotantes y su importancia para los compradores B2B?

El sector de los flotadores de PE ha evolucionado mucho en las últimas décadas. Al principio, los flotadores se fabricaban principalmente con madera o metal, lo que planteaba problemas de peso, corrosión y mantenimiento. La introducción del polietileno revolucionó el sector, ofreciendo alternativas ligeras, duraderas y resistentes a la corrosión, más fáciles de instalar y mantener.

Imagen ilustrativa relacionada con PE Float

A medida que crecía la demanda de aplicaciones marinas y de construcción, los avances en la tecnología de materiales condujeron al desarrollo de flotadores de alto rendimiento con mayor flotabilidad y resistencia a los golpes. El cambio hacia materiales sintéticos no solo ha mejorado el rendimiento del producto, sino que también ha ampliado la gama de aplicaciones de los flotadores de PE, haciéndolos esenciales en sectores como la acuicultura, el dragado y el petróleo y el gas.

Para los compradores B2B, comprender la evolución del mercado de flotadores de PE es crucial para tomar decisiones de compra con conocimiento de causa. Reconocer los avances en la ciencia y la tecnología de los materiales puede ayudar a los compradores a elegir productos que satisfagan sus requisitos operativos específicos, garantizando al mismo tiempo la fiabilidad y el rendimiento a largo plazo. Este contexto histórico también subraya la importancia de la innovación para mantener la competitividad dentro del sector.

Preguntas más frecuentes (FAQ) para compradores B2B de PE Float

-

¿Cómo elijo el flotador de PE adecuado para mi proyecto?

La selección del flotador de PE adecuado implica tener en cuenta los requisitos específicos de la aplicación, como el tipo de fluido transportado, la flotabilidad requerida y las condiciones ambientales. Evalúe las especificaciones de diámetro interior y exterior para garantizar la compatibilidad con sus mangueras o tuberías. Además, evalúe la resistencia del flotador a los golpes, la estabilidad a los rayos UV y la resistencia a la temperatura, ya que estos factores influyen en el rendimiento en distintos climas. Consultar a los proveedores para obtener recomendaciones basadas en las necesidades específicas de su proyecto puede aportar información valiosa. -

¿Cuáles son las principales ventajas de utilizar flotadores de PE en aplicaciones marinas?

Los flotadores de PE ofrecen numerosas ventajas en aplicaciones marinas, como construcción ligera, alta flotabilidad y resistencia a golpes, ácidos y rayos UV. Su duradera carcasa exterior de polietileno de densidad media (MDPE) y su relleno de espuma de poliuretano mejoran su rendimiento, haciéndolos adecuados para condiciones marinas adversas. Su fácil instalación y bajos costes de mantenimiento contribuyen aún más a su atractivo, garantizando una fiabilidad a largo plazo en entornos exigentes como el dragado o las aplicaciones de mangueras de descarga. -

¿Qué opciones de personalización existen para los flotadores de PE?

La mayoría de los fabricantes ofrecen opciones de personalización para los flotadores de PE, incluidos el tamaño, el color y las especificaciones de flotabilidad para satisfacer los requisitos específicos del proyecto. Los flotadores personalizados pueden adaptarse a sistemas de tuberías o condiciones ambientales particulares. Cuando hable de personalización con los proveedores, facilíteles especificaciones detalladas y cualquier norma industrial pertinente para asegurarse de que el producto final cumple sus expectativas. Es aconsejable solicitar muestras o prototipos para probarlos antes de finalizar pedidos grandes. -

¿Cuál es la cantidad mínima de pedido (MOQ) para los flotadores de PE?

Las cantidades mínimas de pedido de flotadores de PE pueden variar considerablemente de un proveedor a otro, a menudo en función de las capacidades de fabricación y los costes de los materiales. Normalmente, las cantidades mínimas de pedido oscilan entre unas pocas unidades y varias docenas o más para tamaños personalizados. Cuando se abastezca, aclare la cantidad mínima de pedido con los posibles proveedores y explore las opciones de descuentos por compras al por mayor. Si sus necesidades son inferiores a la MOQ, considere la posibilidad de colaborar con otras empresas para consolidar pedidos o pregunte por artículos en stock que puedan estar disponibles. -

¿Cómo investigo a los proveedores de flotadores de PE?

Cuando busque proveedores de flotadores de PE, tenga en cuenta factores como su reputación en el sector, su capacidad de producción y el cumplimiento de las normas de calidad internacionales. Pida referencias a clientes anteriores y compruebe si tienen certificaciones, como la ISO, para garantizar una calidad constante. Evalúe su capacidad de respuesta a las consultas y su disposición a proporcionar información detallada sobre el producto y muestras. Además, considere la posibilidad de visitar sus instalaciones de producción, si es posible, u opte por proveedores con una trayectoria consolidada en su región. -

¿Qué condiciones de pago debo esperar al comprar flotadores de PE?

Las condiciones de pago para la compra de flotadores de PE pueden variar, pero suelen incluir opciones como el pago por adelantado, el pago parcial por adelantado o el pago a la entrega. Muchos proveedores pueden ofrecer condiciones de crédito para empresas establecidas, permitiendo el pago en un plazo específico posterior a la entrega. Aclare siempre las condiciones de pago por adelantado y considere la posibilidad de negociar condiciones favorables que se ajusten a su flujo de caja y a los plazos del proyecto. Utilizar métodos de pago seguros también puede mitigar los riesgos asociados a las transacciones internacionales. -

¿Cómo se gestiona el proceso de garantía de calidad de las carrozas de PE?

La garantía de calidad de los flotadores de PE implica múltiples etapas, como la selección de materiales, la supervisión de la producción y las inspecciones finales. Los fabricantes reputados realizarán pruebas rigurosas para garantizar el cumplimiento de las normas y especificaciones del sector. Busque proveedores que ofrezcan certificaciones o garantías sobre la durabilidad y el rendimiento de sus productos. Además, infórmese sobre las condiciones de la garantía y el servicio posventa para resolver posibles problemas después de la compra. -

¿Qué consideraciones logísticas debo tener en cuenta a la hora de comprar flotadores de PE en el extranjero?

Cuando se abastezca de flotadores de PE a nivel internacional, tenga en cuenta factores logísticos como los métodos de envío, los plazos de entrega y la normativa aduanera. Colabore con proveedores que tengan experiencia en envíos internacionales para asegurarse de que los productos se embalan adecuadamente para soportar las condiciones de transporte. Conocer los aranceles e impuestos de importación de su país también puede ayudarle a evitar costes inesperados. Establezca una comunicación clara con su proveedor logístico para hacer un seguimiento de los envíos y garantizar la entrega puntual en el lugar del proyecto.

Lista de los 6 mejores fabricantes y proveedores de Flotador de Pe

1. McMaster - Flotadores de polietileno

Dominio: mcmaster.com

Matriculado: 1994 (31 años)

Introducción: Esta empresa, McMaster - Flotadores de polietileno, es una entidad notable en el mercado. Para obtener detalles específicos del producto, se recomienda visitar directamente su sitio web.

2. DockBuilders – Permafloat™ Dock Floats

Dominio: dockbuilders.com

Inscrito: 1998 (27 años)

Introducción: Permafloat™ Dock Floats are a one-piece rotationally molded part with a nominal wall thickness of 0.150″. They are made of strong virgin polyethylene with UV inhibitors, designed to resist damage from sun, saltwater, freshwater, debris, oil, gas, and marine organisms. Each float is foam filled with expanded polystyrene, free of CFCs and HCFCs. They feature molded-in mounting slots for easy attachm…

3. A.Y. McDonald - Flotador de polietileno negro

Dominio: watermainsupply.com

Matriculado: 2020 (5 años)

Introducción: {"nombre_producto": "Flotador de polietileno negro", "dimensiones": "3×12 pulgadas", "price": "$65.60", "sku": "6813-199", "weight": "2.0 lb", "vendor": "A.Y. McDonald", "shipping": "Envío gratuito en pedidos superiores a $499", "availability": "Disponible para pedido", "descripción": "Flotadores para válvula de flotador"}

4. Pentair - Flotadores de polietileno

Dominio: pentairaes.com

Inscrito: 2012 (13 años)

Introducción: {"nombre_producto": "Flotadores de polietileno Pentair Aquatic Eco-Systems", "SKU": ["FT3X5B/W", "FT5X9B/W"], "features": ["Flotadores de polietileno rígido", "Resistentes a los rayos UV", "Extremadamente duraderos"], "ideal_for": ["Redes de cerco", "Redes", "Trampas"], "models": [{"model": "FT3X5B/W", "color": "Azul/Blanco", "tamaño_agujero": "1/2\"", "tamaño": "3\" x 5\"", "price": "$3.66"}, {"model": "FT5X9B/W", "color": "Azul/Blanco", "tamaño_agujero": "...

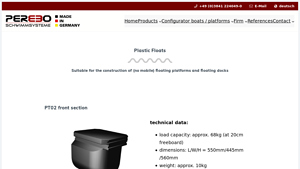

5. Perebo - PT02 Sección de dique flotante

Dominio: perebo.com

Inscrito: 2012 (13 años)

Introducción: {'PT02_front_section': {'capacidad_de_carga': 'aprox. 68kg (a 20cm de francobordo)', 'dimensiones': 'L/W/H = 550mm/445mm/560mm', 'peso': 'aprox. 10kg', 'material': 'plástico (PE= polietileno)', 'grosor_pared': '7mm', 'aplicación': 'diques flotantes pequeños o dedos de dique flotantes'}, 'PT02_middle_section': {'capacidad_de_carga': 'aprox. 68kg (a 20cm de francobordo)', 'dimensiones': 'L/W/H = 550mm/445mm/560mm', 'w...

6. Boshart - Flotadores de polietileno

Dominio: boshart.com

Inscrita: 1997 (28 años)

Introducción: Flotadores de polietileno: El diámetro mínimo recomendado es de 8″ para su uso con válvulas de 1-1/4″ a 2″; los flotadores de 6″ y menores sólo pueden utilizarse con una presión de entrada muy baja. Tamaños disponibles: 10,00 (28-BFVF-PL10), 4,50 (28-BFVF-PL4,5), 5,00 (28-BFVF-PL5), 6,00 (28-BFVF-PL6), 8,00 (28-BFVF-PL8).

Conclusiones y perspectivas de la contratación estratégica de PE Float

En el dinámico panorama del comercio mundial, el aprovisionamiento estratégico de flotadores de PE presenta importantes oportunidades para los compradores internacionales. Los flotadores de PE, fabricados con polietileno de densidad media (MDPE) y rellenos de espuma de poliuretano de alta resistencia, ofrecen una flotabilidad, durabilidad y resistencia excepcionales a las condiciones ambientales adversas. Esto los hace indispensables en diversas aplicaciones, como operaciones marinas, acuicultura y proyectos de construcción.

Entre las principales conclusiones para los compradores B2B se incluye la importancia de seleccionar materiales de alta calidad para garantizar la longevidad y el rendimiento. Al dar prioridad a los proveedores que ofrecen soluciones personalizables y una asistencia sólida, los compradores pueden mejorar la eficiencia operativa y minimizar los costes de mantenimiento. Además, teniendo en cuenta la creciente demanda en regiones como África, Sudamérica, Oriente Medio y Europa, existe una clara oportunidad de aprovechar el aprovisionamiento estratégico para optimizar los procesos de adquisición y garantizar precios favorables.

De cara al futuro, será crucial adoptar la innovación en las prácticas de abastecimiento. Se anima a los compradores a que se pongan en contacto con proveedores que no sólo cumplan las especificaciones técnicas, sino que también demuestren su compromiso con la sostenibilidad y las prácticas respetuosas con el medio ambiente. De este modo, las empresas pueden posicionarse de forma competitiva en el mercado, garantizando una cadena de suministro de flotadores de PE resistente que satisfaga las demandas futuras.

Imagen ilustrativa relacionada con PE Float

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.