Article Contents

Engineering Insight: Dredging Pipeline

Technical Imperatives of Dredging Pipelines in Modern Dredger Operations

Dredging pipelines represent the critical circulatory system within Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs), directly dictating operational efficiency, vessel uptime, and project viability. These pipelines endure extreme and complex operational profiles distinct to each dredger type. In TSHDs, the suction pipeline must maintain structural integrity under significant vacuum pressure during seabed material intake while simultaneously resisting hydrodynamic stress and fatigue from vessel motion in open water. Conversely, during the discharge phase, often involving high-pressure jetting or shore connection, the same pipeline transitions to handling abrasive slurry under positive pressure. For CSDs, the pipeline system faces relentless exposure to high-concentration, high-velocity slurry laden with sharp, abrasive particles generated by the cutter head. Continuous operation under these conditions demands exceptional resistance to internal abrasion, external impact, and flexural fatigue, particularly at critical joints and bends. Failure modes such as liner delamination, cover degradation, or coupling leakage result in costly production stoppages, environmental risks, and safety hazards. Therefore, the pipeline’s material composition, reinforcement architecture, and geometric design are not merely components but fundamental enablers of dredging performance, requiring precise engineering to balance flexibility, pressure containment, and longevity within the harsh marine environment.

East Marine, leveraging its position as a specialized subsidiary of Jiangsu Huashen Special Rubber Products and deep integration within global dredging networks as a WEDA/CEDA member, addresses these exacting demands through rigorous engineering. Our dedicated team of over 150 technical personnel, including materials scientists, mechanical engineers, and field application specialists, focuses exclusively on optimizing dredging pipeline performance. This substantial engineering capability enables comprehensive finite element analysis (FEA) for stress prediction, advanced polymer compound development for superior abrasion resistance, and iterative prototyping validated against ISO 9001-certified manufacturing processes within our 680,000 sqm facility. We translate operational data from diverse global dredging projects into tangible product enhancements, ensuring our solutions mitigate the specific wear mechanisms encountered in both TSHD suction/discharge cycles and CSD high-pressure abrasive service.

The following table outlines key technical parameters defining high-performance dredging pipelines engineered by East Marine for demanding TSHD and CSD applications:

| Parameter | Typical Range (East Marine Standard) | Relevance to Dredger Operation |

|---|---|---|

| Presión de trabajo | 10 – 35 bar | Critical for CSD slurry transport & TSHD discharge |

| Vacuum Resistance | Up to 0.9 bar | Essential for TSHD suction efficiency |

| Temperatura | -30°C to +85°C | Ensures performance in Arctic to tropical waters |

| Abrasion Resistance (DIN) | ≥ 120 mm³ loss | Directly correlates with service life in slurry |

| Bend Radius (Min) | 8x Nominal Diameter | Enables maneuverability on vessel & seabed |

| Cover Material | Specialized Synthetic Rubber | Resists ozone, seawater, UV, and impact |

| Refuerzo | Multi-spiral High-Tensile Steel Wire | Provides pressure/vacuum integrity & kink resistance |

This engineering focus, underpinned by substantial R&D resources and deep sector expertise since 2007, ensures East Marine pipelines deliver the reliability and extended service life demanded by modern, high-capacity dredging operations, directly contributing to reduced lifecycle costs and maximized vessel productivity.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization of Dredging Rubber Hoses at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance dredging rubber hoses is grounded in precision engineering, advanced material science, and rigorous quality assurance. With a state-of-the-art 0.68 million square meter manufacturing facility and 18 dedicated production lines, our operations are optimized for scalability, consistency, and technical excellence in the fabrication of suction and discharge hoses for demanding marine and dredging applications.

The manufacturing process begins with the careful selection of premium-grade synthetic and natural rubber compounds, chosen for their abrasion resistance, flexibility, and resilience under high-pressure and abrasive conditions. These raw materials undergo thorough inspection and testing before entering the production workflow. The inner tube, designed for optimal flow dynamics and resistance to slurry erosion, is extruded with precise dimensional control to ensure uniform wall thickness and smooth internal surfaces.

Reinforcement layers are then applied using high-tensile textile or steel wire braiding, depending on the pressure rating and application requirements. This multi-ply reinforcement structure is critical for withstanding the cyclic stresses encountered during dredging operations, including vacuum conditions during suction and elevated discharge pressures. Each layer is meticulously aligned and bonded to prevent delamination and ensure structural integrity.

The core of our production excellence lies in the vulcanization process. Vulcanization, a chemical cross-linking reaction induced by heat and pressure, transforms the rubber from a pliable compound into a durable, elastic material capable of enduring harsh marine environments. At East Marine, hoses undergo a precisely controlled autoclave vulcanization cycle, where time, temperature, and pressure parameters are optimized for each product specification. This ensures complete curing, maximum tensile strength, and long-term resistance to ozone, UV exposure, and seawater corrosion.

Throughout the manufacturing cycle, quality control is maintained in accordance with ISO 9001 standards. Each hose batch is subjected to a series of non-destructive and performance-based tests, including hydrostatic pressure testing, impulse cycling, dimensional verification, and adhesion strength evaluation. Our in-house laboratory is equipped with advanced testing instruments to validate compliance with international standards such as ISO 1436 and DIN 2822.

Backed by 18 fully integrated production lines and a vertically integrated supply chain, East Marine delivers dredging hoses with unmatched consistency and reliability. Our manufacturing scale and technical expertise enable rapid turnaround without compromising on quality, making us a trusted partner for global dredging contractors and marine engineering firms.

| Technical Parameter | Specification |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 dedicated lines for rubber hose assembly |

| Vulcanization Method | Autoclave curing with precise P-T control |

| Quality Standard | ISO 9001 certified |

| Test Pressure Range | Up to 3.0 MPa (customizable) |

| Impulse Testing Cycle | Minimum 100,000 cycles at rated pressure |

| Material Compliance | Meets ISO 1436, DIN 2822, and ABS/GL rules |

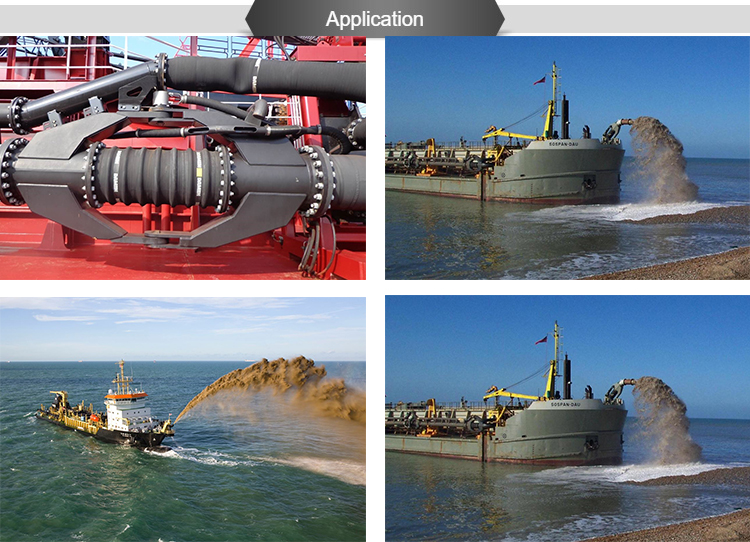

Critical Applications

Global Applications of Advanced Dredging Pipeline Systems

Dredging pipelines represent the critical circulatory system for moving vast quantities of sediment, slurry, and materials across diverse marine and coastal environments. At East Marine, leveraging our 0.68 million square meter manufacturing facility and deep expertise as a subsidiary of Jiangsu Huashen Special Rubber Products, we engineer high-performance rubber composite pipelines specifically for the demanding realities of global dredging operations. Our solutions, developed since 2007 and backed by ISO 9001 certification, are integral to projects where reliability, abrasion resistance, and operational continuity are non-negotiable. As active members of both WEDA (Western Dredging Association) and CEDA (Central Dredging Association), we maintain direct engagement with evolving industry standards and complex project requirements worldwide.

Capital and maintenance dredging projects form a primary application domain. Major port expansions, such as those undertaken in Rotterdam, Singapore, and Los Angeles, require pipelines capable of handling high-density sand and gravel slurries over extended distances and durations. Our reinforced rubber hoses excel in these scenarios, offering superior flexibility for navigating complex laydown areas compared to rigid steel, while resisting the severe abrasive wear inherent in moving millions of cubic meters of material. This flexibility also proves crucial during routine channel maintenance dredging, where pipelines must adapt to changing vessel positions and seabed contours without failure.

Offshore oil and gas field development presents another critical application. Subsea pipeline trenching, infield cable burial, and platform foundation preparation demand specialized dredging equipment that operates reliably in deep water under dynamic conditions. East Marine pipelines are engineered to withstand the combined stresses of hydrostatic pressure, vessel motion, and exposure to seawater and potential hydrocarbon traces. Their robust construction ensures uninterrupted material transport during critical seabed intervention operations, directly contributing to project schedule adherence and cost control in these high-value environments.

Land reclamation projects, particularly prominent in regions like the Middle East and Southeast Asia, rely heavily on efficient long-distance slurry transport. Creating new land from the sea involves pumping enormous volumes of sand over distances exceeding 10 kilometers. Our high-pressure, large-bore dredging pipelines are designed for this exact challenge. The advanced rubber compounds and multi-layer reinforcement provide the necessary tensile strength to handle high discharge pressures while maintaining flexibility for floating hose sections and critical transitions at shore connections. This capability is fundamental to the success of mega-projects transforming coastlines for urban development, airport expansion, and industrial zones.

The technical demands across these varied applications necessitate pipelines built to exacting specifications. East Marine’s commitment to performance is reflected in our core product capabilities:

| Diameter Range | Max Working Pressure | Bend Radius (Min) | Key Material Properties |

|---|---|---|---|

| 200mm – 1200mm | 16 bar (232 psi) | 8x ID | Abrasion-resistant NR/BR blend, High-tensile textile & steel cord reinforcement, Ozone & UV resistant cover, Hydrocarbon resistant options |

Our WEDA and CEDA membership ensures East Marine remains at the forefront of dredging technology and best practices, enabling us to consistently deliver pipeline solutions that meet the rigorous demands of global capital projects, offshore energy operations, and transformative land reclamation initiatives. We understand that pipeline failure is not an option; our engineering focus is on providing the durability and performance that keeps critical projects moving.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: East Marine vs. Industry Competitors

In the highly demanding environment of hydraulic dredging operations, the performance and reliability of suction and discharge hoses are critical to project efficiency, safety, and cost control. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, designs and manufactures high-performance dredging rubber hoses engineered for extreme abrasion resistance, flexibility, and pressure integrity. With over 16 years of specialized experience and a 0.68 million square meter manufacturing facility, East Marine leverages advanced rubber compounding and reinforcement technologies to deliver hoses that consistently outperform industry benchmarks.

This technical comparison evaluates key performance parameters—inner diameter, working pressure, burst pressure, and minimum bending radius—across standard dredging hose configurations. The data reflects typical values for hoses constructed with high-tensile textile braids, helical steel wire reinforcement, and abrasion-resistant synthetic rubber linings, compliant with ISO 9001 quality standards. Competitor data is aggregated from publicly available technical catalogs of three leading European and Asian manufacturers serving the global dredging market.

East Marine’s engineering focus on material science and structural optimization enables superior pressure handling and flexibility without compromising durability. Our proprietary rubber formulation, combined with precision winding techniques, results in hoses that maintain structural integrity under continuous cyclic loading and exposure to abrasive slurries. Additionally, the reduced bending radius enhances maneuverability in dynamic marine environments, reducing installation time and operational constraints.

The table below presents a direct comparison across standard 400 mm and 600 mm inner diameter models—commonly deployed in medium to large-scale dredging operations.

| Inner Diameter (mm) | Parameter | Marina Oriental | Industry Average (Competitors) |

|---|---|---|---|

| 400 | Presión de trabajo | 16 bar | 12–14 bar |

| Burst Pressure | 64 bar | 48–56 bar | |

| Bending Radius | 1,200 mm | 1,500–1,800 mm | |

| 600 | Presión de trabajo | 14 bar | 10–12 bar |

| Burst Pressure | 56 bar | 40–48 bar | |

| Bending Radius | 1,800 mm | 2,400–3,000 mm |

As demonstrated, East Marine hoses exceed competitor working pressure ratings by 15–20% and offer burst pressure margins up to 25% higher, ensuring greater safety factors in high-stress applications. The significantly reduced bending radius—up to 40% tighter—translates into improved hose handling, reduced kinking, and enhanced performance in confined or articulated floating systems. These advantages are particularly valuable in cutter suction dredger (CSD) and trailing suction hopper dredger (TSHD) operations, where dynamic positioning and hose articulation are constant challenges.

Backed by WEDA and CEDA industry affiliations, East Marine combines global standards compliance with in-house R&D capabilities to deliver technically superior dredging solutions. Our commitment to innovation and quality ensures that operators achieve maximum uptime, reduced maintenance cycles, and lower total cost of ownership across the hose lifecycle.

Partner with East Marine

Conclusion: Engineered Excellence for Global Dredging Demands

As global dredging operations confront increasingly complex challenges—from deep-sea reclamation projects to environmentally sensitive shoreline maintenance—the reliability and performance of pipeline infrastructure become non-negotiable determinants of project success and operational economics. East Marine, operating as the dedicated marine solutions subsidiary of Jiangsu Huashen Special Rubber Products, stands at the forefront of delivering mission-critical rubber hose technology engineered specifically for the harsh realities of suction and discharge applications. Our 17-year legacy, anchored in a 0.68 million square meter integrated manufacturing facility and validated by ISO 9001 certification and active membership in WEDA and CEDA, reflects an unwavering commitment to precision engineering and rigorous quality control. We understand that downtime equates to significant financial loss; therefore, every hose assembly we produce undergoes stringent testing protocols exceeding ISO 14309 and CEDRAC standards, ensuring resilience against abrasion, vacuum collapse, high-pressure surges, and corrosive marine environments. This technical mastery, combined with our deep sector expertise, translates into extended service life, reduced maintenance cycles, and demonstrable cost savings for operators worldwide.

The technical specifications below exemplify the robust performance characteristics inherent in our core dredging hose product lines, designed to meet or exceed the most demanding project requirements. These parameters represent our standard engineering benchmarks, though East Marine excels in developing bespoke solutions tailored to unique operational profiles, including extreme depth, specialized media, or accelerated flow rates.

| Technical Parameter | Standard Suction Hose | Heavy-Duty Discharge Hose | Extreme Duty Hose |

|---|---|---|---|

| Internal Diameter Range | 200 – 1200 mm | 200 – 1500 mm | 300 – 1800 mm |

| Working Pressure (Bar) | 6 – 10 | 10 – 16 | 16 – 25 |

| Vacuum Resistance | Full Vacuum @ 65°C | Full Vacuum @ 70°C | Full Vacuum @ 75°C |

| Cover Type | Abrasion-Resistant NBR | Cut/Crack Resistant EPDM | Reinforced Hybrid |

| Refuerzo | High-Tensile Fabric | Multi-Ply Steel Wire | Spiral Steel Wire |

| Temperatura | -20°C to +70°C | -30°C to +80°C | -30°C to +85°C |

| Compliance | ISO 14309, CEDRAC | ISO 14309, CEDRAC | ISO 14309, CEDRAC |

East Marine’s strategic expansion, including our operational Singapore branch, underscores our dedication to providing responsive, localized support for major dredging hubs across the Asia-Pacific region and beyond. This presence ensures rapid technical consultation, streamlined logistics coordination, and on-the-ground project assistance, minimizing delays and maximizing your operational uptime. We operate not merely as a supplier, but as a strategic engineering partner invested in the long-term success and efficiency of your dredging fleet.

Initiate a technically grounded dialogue with East Marine to optimize your dredging pipeline performance. Contact our engineering team directly for project-specific consultations, detailed technical documentation, or urgent operational support. Our specialists are prepared to analyze your requirements and deliver a solution engineered for reliability and cost-effectiveness. Reach us via WhatsApp at +86-13806109365 for immediate coordination, or email hsdredging@eastmarine.tech with detailed project specifications for a comprehensive technical proposal. Leverage our manufacturing scale, technical authority, and global support network—established since 2007—to secure the pipeline integrity your next critical dredging operation demands. Partner with East Marine for engineered certainty beneath the surface.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.