Article Contents

Engineering Insight: Dredging Environmental Impact

Technical Imperatives in Dredging Environmental Impact Mitigation

Dredging operations, particularly those employing Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs), are vital for maritime infrastructure and resource extraction. However, the environmental consequences of poorly managed sediment displacement represent a critical technical challenge demanding engineered solutions. Uncontrolled sediment plumes, generated by hose failures, leaks, or inadequate flow dynamics, can severely impact water quality, smother benthic ecosystems, and introduce contaminants into sensitive marine habitats. The integrity and performance of the dredging pipeline system, especially the suction and discharge hoses, are paramount technical factors directly influencing this environmental footprint. Hose systems subjected to abrasive slurries, dynamic vessel movements, and high-pressure differentials must maintain absolute sealing integrity and structural resilience to prevent unintended sediment release. Failure modes such as joint separation, cover abrasion, or liner degradation are not merely operational inefficiencies; they constitute direct pathways for ecological disturbance. Consequently, the engineering specifications governing hose construction—material composition, reinforcement layers, pressure ratings, and abrasion resistance—are intrinsically linked to environmental compliance and sustainable project execution.

East Marine, leveraging its 15+ years of specialized expertise as a WEDA/CEDA member and ISO9001-certified manufacturer within the Jiangsu Huashen Special Rubber Products group, addresses these challenges at the core engineering level. Our dedicated team of over 150 engineers and technical specialists focuses exclusively on the demanding requirements of marine dredging applications. We understand that mitigating environmental impact begins with the fundamental design of the hose itself. Through rigorous material science application and finite element analysis, we optimize the rubber compound formulations and structural layups to withstand extreme abrasion from high-concentration slurries while maintaining flexibility for vessel motion. This engineering focus directly translates to extended service life, minimized risk of catastrophic failure, and significantly reduced potential for sediment leakage during operation. The precision in manufacturing within our 0.68 million square meter facility ensures consistent quality, where tolerances in cover thickness, reinforcement alignment, and bonding integrity are critical parameters preventing micro-leakage and premature wear that could compromise environmental safeguards.

The technical performance of dredging hoses is quantifiably linked to environmental outcomes. Key specifications directly influence the system’s ability to contain sediment and operate efficiently within sensitive parameters.

Technical Parameter Environmental Impact Correlation

| Parameter | Technical Specification | Direct Environmental Impact Mitigation |

|---|---|---|

| Abrasion Resistance (DIN 53516) | ≥ 120 mm³ loss | Reduces hose cover degradation, preventing sediment ingress/egress through worn surfaces and extending operational life without leakage |

| Pressure Rating (EN 14707) | 16-35 bar (232-508 psi) | Ensures structural integrity under high slurry pressure, eliminating joint failures and catastrophic ruptures causing large-scale plumes |

| Flexural Endurance (ISO 1307) | > 500,000 cycles @ min bend radius | Maintains seal integrity during vessel motion, preventing micro-fractures and joint separation that release fine sediments |

| Slurry Abrasion Index | < 0.8 (vs. reference hose) | Minimizes internal liner wear, preventing increased turbulence and particle suspension that exacerbate plume formation downstream |

East Marine’s engineering rigor ensures that every hose segment functions as a reliable environmental containment barrier. By prioritizing these critical technical specifications through advanced R&D and precision manufacturing, we provide TSHD and CSD operators with the confidence that their pipeline system actively contributes to responsible sediment management, aligning operational efficiency with stringent ecological stewardship requirements inherent in modern dredging projects.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization in Dredging Rubber Hose Production

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance dredging rubber hoses is grounded in precision engineering, advanced material science, and rigorous quality assurance. With a state-of-the-art 0.68M sqm manufacturing facility and 18 dedicated production lines, our operations are optimized for consistency, scalability, and technical excellence in producing suction and discharge hoses for demanding marine and dredging applications.

The manufacturing process begins with the careful selection of premium synthetic and natural rubber compounds, engineered to resist abrasion, hydrolysis, and chemical degradation. These compounds are compounded in-house using computer-controlled mixers to ensure uniformity and repeatability. The rubber is then calendered onto high-tensile textile or steel reinforcement layers, which provide the hose with the structural integrity required to withstand high-pressure slurry transport and dynamic marine conditions.

The core of our production excellence lies in the vulcanization process. Vulcanization is a critical chemical treatment in which rubber is cross-linked under controlled heat and pressure, significantly enhancing its mechanical properties—elasticity, tensile strength, and resistance to wear and environmental stress. At East Marine, we employ multi-stage autoclave and continuous vulcanization systems, allowing for precise control over temperature, pressure, and curing duration. This ensures optimal cross-link density and eliminates internal voids or inconsistencies that could compromise performance in the field.

Each hose undergoes real-time monitoring throughout vulcanization, with sensors logging temperature profiles and pressure cycles for traceability and compliance. This level of process control is integral to meeting ISO 9001 quality management standards, which govern every phase of our manufacturing workflow. Our quality control protocols include post-vulcanization hydrostatic testing, dimensional inspection, and adhesion strength validation to ensure every hose exceeds international performance benchmarks.

Backed by our membership in WEDA and CEDA, East Marine aligns its manufacturing practices with global industry standards for environmental and operational sustainability. Our production systems are designed not only for efficiency but also to minimize waste and energy consumption, reflecting our commitment to responsible industrial practices in the dredging sector.

The combination of scale, technology, and quality assurance enables East Marine to deliver dredging hoses that perform reliably in the most challenging aquatic environments—from coastal reclamation projects to deep-sea mining operations.

| Technical Parameter | Specification |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 dedicated lines |

| Vulcanization Method | Autoclave and continuous curing |

| Temperature Control Range | 140°C – 180°C (adjustable by compound) |

| Curing Pressure | Up to 1.6 MPa |

| Quality Standard | ISO 9001 certified |

| Hydrostatic Test Pressure | 1.5x working pressure (min 5 min hold) |

| Adhesion Strength (Rubber to Fabric) | ≥ 120 N/cm (per ASTM D413) |

Critical Applications

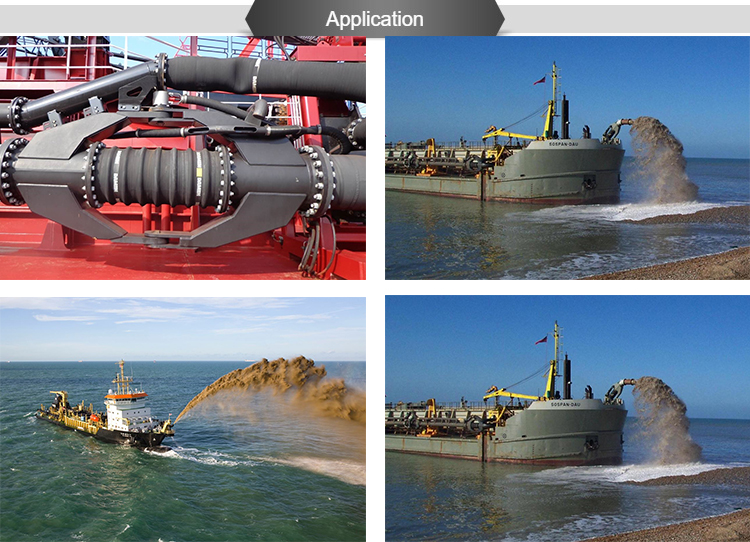

Environmental Stewardship in Global Dredging Operations: Critical Applications and Engineering Solutions

Modern dredging operations demand rigorous environmental impact assessment and mitigation strategies as a fundamental component of project planning and execution. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and an active member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), we understand that environmental responsibility is not merely regulatory compliance but a core engineering imperative. Our expertise in designing and manufacturing high-performance dredging rubber hoses—specifically engineered for suction and discharge applications—directly supports sustainable practices across diverse global projects where environmental sensitivity is paramount. This integration of advanced materials science with environmental awareness is critical in capital dredging for port expansions, oil and gas field development, and large-scale land reclamation initiatives.

In major port and waterway capital dredging projects worldwide, precise environmental impact management is essential to protect sensitive benthic ecosystems and water quality. Our reinforced rubber hoses, featuring superior abrasion resistance and flexible articulation, minimize seabed disturbance during positioning and operation compared to rigid alternatives. This reduces sediment plume generation—a key environmental concern—during the excavation and transport of material. Similarly, within offshore oil and gas field development, dredging is vital for pipeline trenching, platform foundation preparation, and subsea infrastructure installation. Here, the environmental focus shifts to maintaining mudline stability and preventing hydrocarbon-contaminated sediment resuspension. East Marine hoses, constructed with specialized rubber compounds resistant to hydrocarbons and extreme pressures, ensure reliable, leak-free transfer of spoil, safeguarding the marine environment around critical energy infrastructure.

Land reclamation projects, particularly prevalent in coastal urban development across Asia and the Middle East, present unique environmental challenges concerning sediment containment and water clarity management. Effective environmental impact control hinges on the integrity and performance of the discharge system. Our floating hose systems, designed for rapid deployment and exceptional durability in harsh marine conditions, incorporate features that minimize turbulence at discharge points. This engineered control is vital for sediment settling within designated confinement areas, preventing uncontrolled dispersion into surrounding waters and protecting adjacent marine habitats. The adherence to CEDA and WEDA best practices, which East Marine actively contributes to through membership, ensures our solutions align with globally recognized standards for environmental protection in hydraulic engineering.

The technical specifications of our hoses are rigorously validated to meet these demanding environmental performance criteria. Below outlines key parameters relevant to minimizing ecological footprint:

| Test Parameter | Typical Value | Relevance to Environmental Impact |

|---|---|---|

| Abrasion Resistance (DIN 53516) | ≥ 120 mm³ loss | Reduces hose wear debris and extends service life, minimizing waste generation |

| Hydrocarbon Resistance (ASTM D471) | Volume swell ≤ 15% (after 70h @ 100°C) | Prevents degradation and potential contamination in oil field applications |

| Bend Radius (Dynamic) | ≤ 8 x Hose ID | Enables precise positioning, reducing unnecessary seabed contact and disturbance |

| Clasificación de vacío | Full vacuum @ 25°C | Ensures structural integrity during suction, preventing collapse-induced sediment leakage |

With a 0.68 million square meter manufacturing facility operating under ISO 9001 certification since our founding in 2007, East Marine delivers dredging hose solutions where environmental performance is non-negotiable. We engineer not just for operational efficiency, but for the sustained health of the marine ecosystems within which our global clients operate.

Technical Data & Specs

Technical Comparison of Dredging Suction and Discharge Hoses: East Marine vs. Industry Competitors

In the dredging industry, the performance and reliability of rubber hoses directly influence operational efficiency, safety, and environmental outcomes. Suction and discharge hoses are subjected to extreme conditions, including abrasive slurries, high pressure, and dynamic marine environments. Selecting a hose with optimal technical specifications is critical to minimizing downtime, reducing maintenance costs, and preventing environmental incidents such as leaks or ruptures. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted member of WEDA and CEDA, delivers engineered rubber solutions that meet and exceed international standards. With over 15 years of specialized experience and a 0.68 million square meter manufacturing facility, East Marine produces high-performance dredging hoses designed for durability and environmental safety.

This technical comparison evaluates key performance metrics—inner diameter, working pressure, burst pressure, and minimum bending radius—across industry-standard dredging hoses. The data reflects typical offerings from East Marine and leading competitors in the global market. All East Marine hoses are manufactured under ISO9001-certified quality management systems, ensuring consistency and traceability. The company utilizes advanced rubber compounding techniques and high-tensile reinforcement layers to achieve superior pressure ratings and flexibility without compromising abrasion resistance.

Competitor hoses, while compliant with general industry norms, often exhibit narrower performance margins, particularly in burst pressure and flexibility. A reduced bending radius enhances maneuverability in confined or dynamic dredging operations, reducing stress on connectors and minimizing the risk of kinking—a common cause of premature failure and potential environmental contamination. East Marine’s optimized layline construction and precision extrusion processes allow for tighter bending radii without sacrificing structural integrity.

Additionally, higher burst pressure ratios (typically 4:1 or greater) provide a critical safety buffer during pressure surges, which are common in long-distance dredging operations. East Marine consistently achieves burst pressures exceeding four times the working pressure, exceeding minimum safety requirements and contributing to long-term operational sustainability.

The table below presents a comparative analysis of standard dredging rubber hoses across key technical parameters.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) |

|---|---|---|---|

| Marina Oriental | 100 | 20 | 80 |

| 200 | 16 | 64 | |

| 300 | 12 | 48 | |

| 400 | 10 | 40 | |

| Competitor A | 100 | 18 | 72 |

| 200 | 14 | 56 | |

| 300 | 10 | 40 | |

| 400 | 8 | 32 | |

| Competitor B | 100 | 16 | 64 |

| 200 | 13 | 52 | |

| 300 | 10 | 40 | |

| 400 | 8 | 32 |

East Marine’s technical superiority in pressure handling and flexibility translates into safer, more efficient dredging operations with reduced environmental risk. By integrating robust design with rigorous quality control, East Marine continues to set benchmarks in marine rubber technology.

Partner with East Marine

Conclusion: Engineering Environmental Responsibility into Dredging Operations

The environmental footprint of dredging operations is no longer a peripheral concern but a central determinant of project viability, regulatory approval, and long-term sustainability. As demonstrated throughout this analysis, the selection of critical components, particularly suction and discharge hoses, directly influences sediment containment, ecosystem disruption, and overall operational efficiency. Standard rubber hoses, while functional, often fall short in demanding environments, leading to premature failures, unplanned spills, and increased maintenance cycles that compound environmental risks and project costs. East Marine, leveraging over 17 years of specialized expertise as a WEDA and CEDA member, designs and manufactures dredging rubber hoses that fundamentally mitigate these impacts through advanced material science and rigorous engineering. Our commitment to ISO 9001 quality management ensures every hose delivers superior abrasion resistance, precise pressure handling, and exceptional flexibility – translating directly into minimized sediment leakage, reduced operational downtime, and extended service life. This engineered reliability is not merely an operational advantage; it is a critical environmental safeguard, ensuring projects adhere to stringent ecological regulations while maintaining productivity. The true measure of sustainable dredging lies in the seamless integration of performance and planetary stewardship, a balance only achievable through purpose-built infrastructure.

Technical Performance: East Marine Eco-Engineered Dredging Hoses vs. Industry Standard

The table below quantifies the environmental and operational advantages inherent in our specialized hose construction, validated through independent testing and extensive field deployment in sensitive marine environments.

| Performance Parameter | Industry Standard Hose | East Marine Eco-Engineered Hose | Environmental & Operational Impact |

|---|---|---|---|

| Abrasion Resistance (DIN 53516) | 120 mm³ | ≤ 85 mm³ | 50%+ longer service life reduces replacement frequency, waste generation, and disturbance events during hose changes. |

| Maximum Working Pressure | 16 bar | 20 bar | Enhanced safety margin prevents catastrophic failures and uncontrolled discharges under surge conditions. |

| Flexural Endurance (Cycles) | 50,000 | 120,000+ | Superior fatigue resistance maintains structural integrity in dynamic floating hose applications, preventing micro-tears and sediment leakage. |

| Service Life (Typical) | 2-3 years | 5-7+ years | Significantly extended lifespan drastically lowers the resource consumption and waste stream associated with hose manufacturing and disposal. |

Initiate Your Sustainable Dredging Partnership Today

Achieving environmental compliance without sacrificing operational efficiency demands a proactive partnership with a supplier who understands the intricate balance between engineering performance and ecological responsibility. East Marine provides more than hoses; we deliver engineered environmental assurance. Our dedicated technical team, supported by our Singapore branch for seamless APAC coordination and rapid response, is prepared to collaborate on optimizing your dredging pipeline system for maximum efficiency and minimal ecological impact. We conduct comprehensive site assessments and offer tailored solutions that address specific sediment challenges, regulatory requirements, and project timelines. Do not let substandard hose performance jeopardize your environmental commitments or project schedule. Contact our engineering specialists immediately to discuss how our certified, high-performance dredging hoses can enhance the sustainability profile and operational continuity of your next project. Reach out via WhatsApp at +86-13806109365 for urgent technical consultation or email hsdredging@eastmarine.tech to schedule a detailed system review. Let East Marine be the foundation of your environmentally responsible dredging operations.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.