Introduction: Navigating the Global Market for sbm hose

In today’s competitive global market, sourcing high-quality SBM hose can be a daunting challenge for B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe. With varying industrial standards, fluctuating prices, and a multitude of suppliers, navigating this landscape requires an informed approach. This guide aims to demystify the complexities of procuring SBM hose by providing a thorough examination of its types, applications, and essential considerations for effective supplier vetting.

Understanding the specific applications of SBM hose—ranging from hydraulic systems to brake lines in various machinery—can significantly influence purchasing decisions. Additionally, recognizing the nuances of pricing and quality assurance can help buyers avoid costly mistakes. This comprehensive resource will empower international B2B buyers with the insights needed to make confident and strategic sourcing decisions.

By delving into the intricacies of SBM hose specifications, compatibility with equipment, and potential suppliers, this guide serves as a crucial tool for businesses looking to enhance their procurement process. Whether you are seeking reliable partners in Brazil or Saudi Arabia, the knowledge contained herein will facilitate informed choices that align with your operational needs and budgetary constraints. Prepare to navigate the global market for SBM hose with confidence, ensuring that your purchasing strategy is both effective and efficient.

Índice

- Top 7 Sbm Hose Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sbm hose

- Understanding sbm hose Types and Variations

- Key Industrial Applications of sbm hose

- 3 Common User Pain Points for ‘sbm hose’ & Their Solutions

- Strategic Material Selection Guide for sbm hose

- In-depth Look: Manufacturing Processes and Quality Assurance for sbm hose

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sbm hose’

- Comprehensive Cost and Pricing Analysis for sbm hose Sourcing

- Alternatives Analysis: Comparing sbm hose With Other Solutions

- Essential Technical Properties and Trade Terminology for sbm hose

- Navigating Market Dynamics and Sourcing Trends in the sbm hose Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sbm hose

- Strategic Sourcing Conclusion and Outlook for sbm hose

- Descargo de responsabilidad y condiciones de uso

Understanding sbm hose Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Hydraulic SBM Hose | Typically made from reinforced rubber, designed for high pressure | Heavy machinery, construction, and mining | Pros: High durability, pressure resistance. Contras: Can be heavy and less flexible. |

| Brake SBM Hose | Specialized for brake systems, often with banjo fittings | Automotive, cycling, and industrial vehicles | Pros: Ensures safety and performance. Contras: Compatibility issues with different systems. |

| Fuel SBM Hose | Resistant to various fuels and chemicals, often with a smooth interior | Oil and gas, automotive fuel systems | Pros: Excellent chemical resistance. Contras: Rango de temperatura limitado. |

| Air SBM Hose | Lightweight and flexible, designed for compressed air systems | Pneumatic tools, factories, and workshops | Pros: Easy to handle and install. Contras: May not withstand high temperatures. |

| Specialty SBM Hose | Custom designs for unique applications, varying materials | Aerospace, medical, and food processing | Pros: Tailored to specific needs. Contras: Higher cost and longer lead times. |

What Are the Characteristics of Hydraulic SBM Hoses?

Hydraulic SBM hoses are engineered to handle high-pressure applications, often found in heavy machinery and construction equipment. Their reinforced rubber construction provides exceptional durability and pressure resistance. When purchasing, buyers should consider the hose’s pressure rating, compatibility with hydraulic fluids, and temperature resistance to ensure optimal performance in demanding environments.

How Do Brake SBM Hoses Differ from Other Types?

Brake SBM hoses are specifically designed for brake systems in vehicles and bicycles, featuring fittings like banjos for secure connections. These hoses are critical for ensuring safety and performance in braking applications. Buyers must verify compatibility with existing systems, as different manufacturers may have unique specifications that affect installation and functionality.

What Should Buyers Know About Fuel SBM Hoses?

Fuel SBM hoses are crafted to resist various chemicals and fuels, making them ideal for oil and gas industries and automotive fuel systems. Their smooth interior design minimizes flow resistance. Buyers should prioritize chemical compatibility and consider the hose’s temperature range when selecting fuel hoses to avoid degradation and ensure longevity.

Why Are Air SBM Hoses Ideal for Pneumatic Applications?

Air SBM hoses are lightweight and flexible, making them suitable for compressed air systems used in pneumatic tools and workshops. Their ease of handling and installation is a significant advantage. However, buyers should be cautious about temperature limitations and select hoses that can withstand the operational conditions of their specific applications.

What Are the Benefits of Specialty SBM Hoses?

Specialty SBM hoses are tailored for unique applications, such as aerospace, medical, or food processing industries. These hoses can be constructed from various materials to meet specific regulatory and performance standards. While they offer the advantage of customization, buyers should be prepared for potentially higher costs and longer lead times due to the specialized nature of these products.

Key Industrial Applications of sbm hose

| Industria/Sector | Specific Application of sbm hose | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Automotive Manufacturing | Hydraulic systems in vehicles | Ensures reliable braking and fluid transfer | Compatibility with various vehicle models and standards |

| Construcción | Concrete pumping systems | Facilitates efficient transport of concrete mixtures | Durability and resistance to abrasion and pressure |

| Petróleo y gas | Fluid transfer in drilling and extraction operations | Enhances safety and efficiency in hazardous environments | Compliance with international safety standards |

| Agricultura | Irrigation and fluid delivery systems | Increases crop yield and resource efficiency | Resistance to environmental factors and chemical exposure |

| Marine | Fuel and fluid transfer in ships and offshore platforms | Reduces risk of leaks and environmental contamination | Material compatibility with marine conditions |

How is ‘sbm hose’ Used in Automotive Manufacturing and What Problems Does It Solve?

In the automotive manufacturing sector, sbm hose is integral to hydraulic systems, specifically in brake and steering applications. These hoses facilitate the transfer of hydraulic fluid, ensuring effective braking and steering control. The reliability of these hoses is critical, as any failure can lead to safety hazards. For international buyers, sourcing hoses that meet specific vehicle model requirements and adhere to regional safety standards is essential to mitigate risks and ensure compliance.

What Role Does ‘sbm hose’ Play in Construction Applications?

In construction, sbm hose is predominantly used in concrete pumping systems. This application enables the efficient transport of concrete mixtures from mixers to construction sites, especially in high-rise projects. The hoses must withstand high pressures and be resistant to abrasion from the concrete. Buyers should prioritize sourcing hoses that offer durability and are compatible with various pumping equipment to ensure seamless operations and reduce downtime.

How is ‘sbm hose’ Essential in the Oil & Gas Industry?

In the oil and gas industry, sbm hose is critical for fluid transfer during drilling and extraction processes. These hoses must handle high pressures and aggressive chemicals while ensuring safety in hazardous environments. The reliability of sbm hoses minimizes the risk of leaks, which can lead to environmental disasters and financial losses. Buyers should focus on sourcing hoses that comply with international safety standards and are tested for extreme conditions.

Illustrative image related to sbm hose

What Benefits Does ‘sbm hose’ Provide in Agriculture?

In agriculture, sbm hose is used in irrigation and fluid delivery systems, which are vital for effective water management and crop yield enhancement. These hoses must be resistant to environmental factors like UV exposure and chemical fertilizers. For international buyers, sourcing hoses that meet local regulations and are suitable for various irrigation methods is crucial to optimize resource efficiency and maximize agricultural output.

How Does ‘sbm hose’ Contribute to Marine Applications?

In the marine sector, sbm hose is used for fuel and fluid transfer in ships and offshore platforms. The importance of these hoses lies in their ability to prevent leaks and spills, which can have severe environmental consequences. Buyers in this sector should ensure that the hoses are made from materials compatible with marine conditions and that they meet international maritime safety standards to protect both the environment and their operations.

3 Common User Pain Points for ‘sbm hose’ & Their Solutions

Scenario 1: Sourcing Quality SBM Hose for Diverse Applications

El problema: B2B buyers often encounter difficulties in sourcing high-quality SBM hoses that meet specific application requirements. Given the diversity of industries and applications—such as automotive, industrial machinery, and hydraulics—buying the wrong hose can lead to compatibility issues, performance failures, or safety hazards. This can be particularly challenging for buyers in regions like Africa and South America, where product availability and quality assurance may vary widely. The fear of investing in subpar products that could jeopardize operational efficiency or safety is a significant concern.

La solución: To mitigate these risks, B2B buyers should establish relationships with reputable suppliers who specialize in SBM hoses. Begin by conducting thorough market research to identify suppliers with a strong track record and positive reviews. When sourcing, prioritize suppliers who provide detailed product specifications, including material composition, pressure ratings, and compatibility information for various applications. Utilize tools like product datasheets and compatibility charts to ensure the selected hose is suitable for the intended use. Additionally, consider suppliers that offer a guarantee or warranty on their products, which can provide peace of mind regarding quality and performance.

Scenario 2: Understanding Technical Specifications for Optimal Performance

El problema: Another common pain point for buyers is the complexity of technical specifications related to SBM hoses. Terms like pressure ratings, temperature tolerance, and fitting types can be overwhelming, especially for teams that may not have specialized technical knowledge. Misunderstanding these specifications can result in selecting a hose that fails under operational conditions, leading to costly downtime and repairs.

La solución: To address this issue, buyers should invest in training for their procurement and technical teams, focusing on the critical specifications of SBM hoses. Attending industry seminars or workshops can enhance understanding and help teams make informed decisions. Additionally, buyers should request technical support from suppliers during the selection process. Many reputable suppliers provide expert advice to help buyers understand how different specifications affect performance. A detailed consultation can assist in matching the right hose with the intended application, ensuring longevity and optimal performance.

Illustrative image related to sbm hose

Scenario 3: Efficient Logistics and Supply Chain Management for SBM Hose Procurement

El problema: For international B2B buyers, managing logistics and supply chain issues can pose significant challenges when procuring SBM hoses. Delays in shipping, customs clearance, and unexpected tariffs can disrupt operations and lead to increased costs. This is especially pertinent for buyers in regions with less stable infrastructure or logistics networks, where timely delivery is critical to maintaining production schedules.

La solución: To streamline logistics, buyers should develop a comprehensive procurement strategy that includes contingency planning. This involves working closely with suppliers to understand lead times and potential delays. Establishing a solid relationship with a logistics provider experienced in international shipping can also facilitate smoother transactions. Buyers should consider utilizing just-in-time inventory practices to minimize stockpiling and reduce costs. Additionally, exploring multiple sourcing options can help mitigate risks associated with supply chain disruptions. By diversifying suppliers and logistics partners, buyers can enhance their ability to respond to unforeseen challenges swiftly.

Strategic Material Selection Guide for sbm hose

What Are the Key Properties of Common Materials Used in SBM Hose Production?

When selecting materials for SBM hoses, it is essential to consider properties such as temperature and pressure ratings, flexibility, and corrosion resistance. Here are four common materials used in the manufacturing of SBM hoses:

1. Polyethylene (PE)

Polyethylene is widely used in the production of SBM hoses due to its excellent chemical resistance and flexibility. It typically has a temperature rating of up to 80°C and can withstand moderate pressures. Polyethylene is resistant to many chemicals, making it suitable for transporting various media.

Pros: The material is lightweight, cost-effective, and easy to manufacture. Its flexibility allows for easy installation and routing in tight spaces.

Contras: Polyethylene can become brittle over time when exposed to UV light and extreme temperatures, limiting its long-term durability. It is not suitable for high-pressure applications.

Impacto en la aplicación: Polyethylene is ideal for transporting water and some chemicals, but it may not be suitable for high-temperature or high-pressure applications.

Consideraciones para compradores internacionales: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM for safety and performance.

2. Polyvinyl Chloride (PVC)

PVC is another popular choice for SBM hoses, known for its durability and resistance to environmental factors. It can handle temperatures up to 60°C and moderate pressures, making it suitable for various applications.

Pros: PVC is resistant to corrosion and has a long service life. It is also relatively inexpensive and widely available.

Contras: The rigidity of PVC can make it challenging to work with in some applications. Additionally, it may not perform well in high-temperature environments.

Impacto en la aplicación: PVC hoses are commonly used in agricultural and industrial applications for fluid transfer, but care must be taken regarding temperature limitations.

Illustrative image related to sbm hose

Consideraciones para compradores internacionales: Compliance with DIN standards is crucial for buyers in Europe, ensuring that the hoses meet safety and performance requirements.

3. Rubber (Nitrile or EPDM)

Rubber hoses, particularly those made from nitrile or EPDM, are favored for their excellent flexibility and resistance to abrasion and wear. They can withstand temperatures ranging from -40°C to 120°C, making them versatile for various applications.

Pros: Rubber hoses offer high durability and excellent resistance to oils and chemicals. Their flexibility makes them easy to install and maneuver.

Contras: Rubber can be more expensive than plastic alternatives and may require more complex manufacturing processes. Its performance can degrade under prolonged exposure to UV light.

Impacto en la aplicación: Rubber hoses are ideal for high-pressure applications and can transport a wide range of media, including oils and fuels.

Consideraciones para compradores internacionales: Buyers should consider the availability of rubber hoses that comply with JIS standards, particularly in the Middle East and Asia, where such certifications are often required.

4. Stainless Steel

Stainless steel hoses are known for their exceptional strength and resistance to corrosion, making them suitable for extreme environments. They can handle high temperatures and pressures, often exceeding 200°C.

Pros: Stainless steel offers unparalleled durability and is compatible with a wide range of media, including corrosive substances.

Contras: The primary drawback is the higher cost associated with stainless steel hoses. Additionally, they are heavier and less flexible than rubber or plastic alternatives.

Impacto en la aplicación: Ideal for industrial applications where high pressure and temperature are factors, stainless steel hoses are commonly used in chemical processing and oil and gas industries.

Consideraciones para compradores internacionales: Compliance with international standards such as ASTM and ISO is critical for buyers in Europe and North America, ensuring product reliability and safety.

Summary Table of Material Selection for SBM Hose

| Material | Typical Use Case for sbm hose | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Polyethylene (PE) | Water and chemical transport | Ligero y rentable | Brittle under UV exposure | Bajo |

| Cloruro de polivinilo (PVC) | Agricultural and industrial fluid transfer | Durable and corrosion-resistant | Rigid, limited high-temperature performance | Bajo |

| Rubber (Nitrile/EPDM) | High-pressure applications | Excelente flexibilidad y durabilidad | Higher cost and UV degradation | Med |

| Acero inoxidable | Chemical processing and oil & gas industries | Exceptional strength and corrosion resistance | High cost and less flexibility | Alta |

This guide should serve as a valuable resource for international B2B buyers looking to make informed decisions regarding the material selection for SBM hoses, ensuring compliance with regional standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for sbm hose

What Are the Main Stages of the Manufacturing Process for SBM Hose?

The manufacturing process for SBM (Shimano Brake) hoses involves several critical stages, each designed to ensure the final product meets the stringent requirements of performance and safety expected by B2B buyers. These stages include material preparation, forming, assembly, and finishing.

-

Preparación del material: The process begins with the selection of high-quality materials, typically specialized polymers and metal components. The materials are subjected to rigorous testing to verify their durability, flexibility, and resistance to environmental factors such as temperature and moisture. This initial step is crucial as the quality of raw materials directly impacts the performance of the hose.

-

Formando: In this stage, the prepared materials are shaped into the required dimensions. Advanced techniques such as extrusion and molding are commonly employed. Extrusion allows for the continuous formation of hose lengths, while molding is used for creating specific fittings and connectors. Precision is paramount, as even minor deviations can lead to performance issues.

-

Montaje: Once the individual components are formed, they are assembled into the final hose product. This may involve integrating various fittings, such as banjo or straight connectors, and ensuring that they are securely attached to prevent leaks. Automated assembly lines are often used to enhance efficiency and consistency.

-

Acabado: The final stage involves applying any necessary surface treatments, such as coatings for additional protection against wear and corrosion. Quality checks are also performed at this stage to ensure that the hoses meet aesthetic and functional specifications.

How Is Quality Control Implemented in SBM Hose Manufacturing?

Quality assurance in the manufacturing of SBM hoses is a multi-layered approach that adheres to international and industry-specific standards. B2B buyers should be aware of these practices to ensure they partner with reputable suppliers.

-

Cumplimiento de las normas internacionales: Many manufacturers adhere to ISO 9001, which establishes criteria for a quality management system. This standard emphasizes continuous improvement and customer satisfaction, which are vital for maintaining high product quality. Additionally, industry-specific certifications such as CE and API may also apply, depending on the hose’s intended use.

-

Puntos de control de calidad: The quality assurance process typically includes several checkpoints:

– Control de calidad entrante (IQC): This involves inspecting the raw materials upon arrival to ensure they meet predefined standards.

– Control de calidad durante el proceso (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process and catch any deviations early.

– Control de calidad final (CCF): After the product is assembled, a comprehensive inspection is performed to ensure that the finished hoses meet all specifications and performance standards. -

Métodos de ensayo: Common testing methods for SBM hoses include pressure testing, flexibility testing, and environmental testing. These tests ensure that the hoses can withstand operational demands and environmental conditions without failure. For instance, pressure testing checks for leaks under various pressure levels, while flexibility testing assesses the hose’s ability to bend without kinking.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of potential suppliers is crucial. Here are effective strategies to ensure suppliers meet your quality expectations:

-

Auditorías de proveedores: Conducting audits of the manufacturing facilities can provide valuable insights into their quality management practices. This includes evaluating their adherence to international standards, the competence of their workforce, and the effectiveness of their quality control processes.

-

Solicitud de informes de calidad: Suppliers should be able to provide documentation of their quality control processes, including reports from IQC, IPQC, and FQC. These documents can help verify that the supplier maintains consistent quality across their production runs.

-

Inspecciones de terceros: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspections can be arranged at various stages of production, providing assurance that the hoses meet the required specifications before shipping.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

International buyers must navigate specific nuances when it comes to quality control in the manufacturing of SBM hoses. Understanding these factors can aid in making informed purchasing decisions:

-

Diferencias culturales en las normas de calidad: Different regions may have varying interpretations of quality standards. For instance, while a supplier may comply with ISO 9001, the implementation of these standards might differ based on local practices. Buyers should ensure that their quality expectations align with the supplier’s operational realities.

-

Consideraciones logísticas: The distance between the buyer and supplier can complicate quality control. Delays in communication or shipping can result in challenges related to quality verification. B2B buyers should establish clear channels of communication and consider working with suppliers who have a proven track record of reliability and responsiveness.

-

Certification Recognition: Not all certifications are recognized equally across regions. B2B buyers should verify that the certifications held by suppliers are acknowledged in their target market, as this can impact the acceptance of the products within local regulatory frameworks.

Conclusión

Understanding the manufacturing processes and quality assurance protocols for SBM hoses is essential for B2B buyers looking to make informed purchasing decisions. By focusing on material preparation, forming, assembly, and finishing, along with a robust quality control framework, buyers can ensure they are selecting reliable suppliers. Through diligent verification processes, including audits and inspections, buyers can mitigate risks and secure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sbm hose’

To assist international B2B buyers in procuring SBM hoses efficiently, this guide provides a structured checklist. By following these steps, you can ensure that you select the right products and suppliers, ultimately enhancing your operational efficiency and product quality.

Primer paso: Defina sus especificaciones técnicas

Before initiating the sourcing process, clearly outline the technical specifications required for your SBM hoses. Consider factors such as hose length, compatibility with existing systems, and any specific materials needed. This clarity will help you communicate effectively with suppliers and avoid costly miscommunications later on.

Segundo paso: Buscar posibles proveedores

Conduct thorough research to identify potential suppliers who specialize in SBM hoses. Utilize industry directories, trade shows, and online platforms to find reputable vendors. Pay attention to their experience in your specific market region—whether in Africa, South America, the Middle East, or Europe—as local regulations and requirements can vary significantly.

Tercer paso: Evaluate Supplier Certifications and Compliance

Verify that your chosen suppliers meet relevant industry standards and certifications. This step is critical for ensuring product quality and safety, particularly if your SBM hoses are used in high-stakes environments. Look for certifications such as ISO or other local compliance marks that guarantee the products meet international standards.

Paso 4: Solicitud de muestras para pruebas

Before placing a bulk order, request samples of the SBM hoses you are considering. Testing samples allows you to assess the quality, durability, and compatibility of the hoses with your equipment. This hands-on evaluation can prevent future issues related to performance and safety.

Paso 5: Review Pricing and Payment Terms

Once you have narrowed down your options, review the pricing structures and payment terms offered by each supplier. Ensure that the prices are competitive and that the payment terms align with your financial capabilities. Look for suppliers who provide flexible payment options, especially if you are ordering large quantities.

Paso 6: Assess Shipping and Delivery Options

Evaluate the shipping methods and delivery timelines offered by your suppliers. Efficient logistics are essential to minimize downtime in your operations. Confirm that the supplier can meet your delivery deadlines and that their shipping costs are transparent and reasonable.

Paso 7: Establecer un plan de comunicación

Once you finalize your supplier, establish a clear communication plan to facilitate ongoing dialogue. Regular check-ins can help address any potential issues quickly and maintain a strong supplier relationship. This proactive approach is essential for ensuring that your supply chain remains smooth and responsive to changes in demand.

By following this checklist, B2B buyers can streamline their sourcing process for SBM hoses, ensuring that they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for sbm hose Sourcing

What Are the Key Cost Components in SBM Hose Manufacturing?

When sourcing SBM hoses, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materiales: The raw materials used, such as high-quality rubber or specialized plastics, significantly impact the overall cost. Prices can fluctuate based on global commodity markets, which may affect your sourcing budget.

-

Trabajo: Labor costs can vary widely depending on the region. In countries with higher labor costs, such as those in Europe, manufacturers may charge more for their products. Conversely, sourcing from regions with lower labor costs may provide savings.

-

Gastos generales de fabricación: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Buyers should consider manufacturers’ efficiency and operational practices when evaluating quotes.

-

Herramientas: The initial setup costs for production, including molds and specialized equipment, can be substantial, particularly for custom hose specifications. These costs are often amortized over larger production runs, making bulk orders more cost-effective.

-

Control de calidad: Ensuring product quality is crucial, especially for critical applications. The cost of implementing QC processes can vary, but it is essential for maintaining reliability and compliance with industry standards.

-

Logística: Transportation and shipping costs play a significant role in the total cost of ownership. Factors such as distance, shipping method, and freight terms can influence these expenses.

-

Margen: Finally, the manufacturer’s profit margin will be included in the final pricing. Understanding the typical margins in the industry can help buyers gauge whether they are receiving a fair quote.

How Do Price Influencers Affect SBM Hose Sourcing?

Several factors can influence pricing for SBM hoses:

-

Volumen/MOQ (Cantidad mínima de pedido): Bulk purchases often lead to lower per-unit costs. Manufacturers may offer tiered pricing based on order volume, incentivizing larger orders.

-

Especificaciones y personalización: Custom hoses tailored to specific applications or certifications may incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Calidad del material y certificaciones: Premium materials and industry certifications can increase costs but may provide better performance and longevity. Buyers should weigh the long-term benefits against upfront costs.

-

Factores del proveedor: The supplier’s reputation, reliability, and service level can also impact pricing. Established suppliers with proven track records may command higher prices but offer better support and quality assurance.

-

Incoterms: Understanding the shipping terms and responsibilities (Incoterms) is crucial for calculating total costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly alter the final price.

What Are Effective Buyer Tips for Cost-Efficient SBM Hose Sourcing?

To maximize value when sourcing SBM hoses, consider the following tips:

-

Negotiate Wisely: Leverage volume discounts and be prepared to negotiate on price, especially if you are a repeat customer. Building a long-term relationship with suppliers can also lead to better pricing over time.

-

Evaluar el coste total de propiedad (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, durability, and potential downtime costs. A higher upfront investment in quality may yield savings in the long run.

-

Understand Pricing Nuances for International Buyers: Factors such as import duties, taxes, and currency fluctuations can affect overall costs. Buyers from regions like Africa, South America, and the Middle East should factor these elements into their budgeting.

-

Research and Compare Suppliers: Always seek multiple quotes and assess the offerings from various suppliers. This not only helps in finding the best price but also provides insight into industry standards and practices.

-

Stay Informed on Market Trends: Awareness of market conditions and material prices can help you anticipate changes in pricing. This knowledge can be crucial for timing purchases effectively.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and specific buyer requirements. Always conduct thorough research and request updated quotes before finalizing any sourcing decisions.

Alternatives Analysis: Comparing sbm hose With Other Solutions

Introduction to Alternative Solutions for sbm Hose

In the realm of hydraulic and brake systems, the choice of hose can significantly influence performance and reliability. The sbm hose, known for its compatibility with various Shimano brake systems, is one of several options available to businesses. However, understanding alternatives can help B2B buyers make informed decisions based on their specific operational requirements, budget constraints, and performance expectations.

Comparison of sbm Hose with Alternative Solutions

| Aspecto comparativo | Sbm Hose | Alternative 1: PTFE Hose | Alternative 2: Rubber Hose |

|---|---|---|---|

| Rendimiento | Excellent hydraulic performance; low expansion under pressure | Superior chemical resistance; maintains integrity under extreme conditions | Good flexibility; moderate performance for general use |

| Coste | Moderate ($41.16 – $49.00) | Higher ($70.00 – $100.00) | Lower ($20.00 – $35.00) |

| Facilidad de aplicación | Fácil de instalar con accesorios estándar | Requires specialized fittings; installation may be complex | Simple installation; compatible with various systems |

| Mantenimiento | Low maintenance; durable materials | Requires occasional inspection; can be affected by high temperatures | Moderate maintenance; prone to wear and tear over time |

| El mejor caso de uso | Ideal for high-performance bike systems | Best for chemical applications and extreme environments | Suitable for general applications and cost-sensitive projects |

Desglose detallado de alternativas

PTFE Hose

PTFE (Polytetrafluoroethylene) hoses are known for their exceptional chemical resistance and ability to maintain integrity under high temperatures and pressures. This makes them an ideal choice for industries that require a high level of durability and reliability, such as chemical processing or high-performance automotive applications. However, the cost of PTFE hoses is generally higher than that of sbm hoses, which may deter budget-conscious buyers. Additionally, installation may require specialized fittings and skills, making it less accessible for those without technical expertise.

Rubber Hose

Rubber hoses are one of the most common and cost-effective solutions in various industries. They offer good flexibility and are easy to install, making them a popular choice for general applications. However, they do not perform as well as sbm hoses or PTFE hoses in high-pressure situations and can degrade over time, requiring more frequent replacements. While their lower cost is attractive, the potential for increased maintenance and replacement expenses should be considered when evaluating long-term value.

Conclusion: Choosing the Right Hose for Your Needs

Selecting the right hose solution involves evaluating the specific requirements of your application, including performance expectations, budget limitations, and maintenance capabilities. The sbm hose stands out for its excellent performance in high-end bicycle systems, while PTFE hoses are better suited for demanding chemical environments. On the other hand, rubber hoses provide a cost-effective option for general uses, albeit with limitations in durability. By carefully considering these factors, B2B buyers can make informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for sbm hose

What Are the Key Technical Properties of SBM Hose?

When sourcing SBM hoses, understanding the essential technical properties can significantly influence purchasing decisions. Below are critical specifications that define the quality and suitability of SBM hoses for various applications.

-

Calidad del material

SBM hoses are typically made from high-grade materials such as rubber, thermoplastics, or composite materials. The choice of material affects durability, flexibility, and resistance to environmental factors like heat and chemicals. For B2B buyers, selecting the right material grade is crucial to ensure long-term performance in specific applications, particularly in harsh environments. -

Hose Length

Standard hose lengths often range from 1000mm to 2000mm, depending on the application needs. Length impacts installation flexibility and can determine how effectively the hose fits within a system. Buyers should consider the specific requirements of their equipment or machinery to avoid operational inefficiencies caused by incorrect hose lengths. -

Presión nominal

The pressure rating, usually expressed in PSI (pounds per square inch), indicates the maximum pressure the hose can withstand without failure. A higher pressure rating is essential for applications involving hydraulic systems or high-pressure fluid transport. B2B buyers must match the hose’s pressure rating to the operational demands of their systems to prevent costly failures or safety hazards. -

Tolerancia térmica

Different hoses have varying temperature tolerances, which can affect performance in extreme conditions. Knowing the operational temperature range is essential for ensuring the hose will not degrade or fail. For businesses operating in environments with fluctuating temperatures, selecting hoses with appropriate tolerance levels is vital for maintaining operational integrity. -

Connection Type

Hoses come with different connection types, such as straight or banjo fittings. The choice of connection type can influence installation ease and compatibility with existing systems. For B2B buyers, understanding the connection requirements is crucial to ensure seamless integration into their operations.

What Are Common Trade Terms Related to SBM Hose?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you may encounter:

-

OEM (fabricante de equipos originales)

OEM refers to companies that manufacture products or components that are sold under another company’s brand name. For B2B buyers, sourcing SBM hoses from OEMs can ensure high-quality components that meet specific standards and compatibility requirements. -

MOQ (Cantidad mínima de pedido)

MOQ is the smallest number of units that a supplier is willing to sell. This term is vital for buyers as it affects inventory management and cash flow. Understanding MOQs helps businesses plan purchases effectively, especially when dealing with large-scale operations. -

RFQ (solicitud de presupuesto)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products or services. In the context of SBM hoses, submitting an RFQ can help buyers obtain competitive pricing and evaluate different suppliers based on their offerings. -

Incoterms (Términos comerciales internacionales)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Knowing these terms can help buyers understand shipping costs, risk management, and delivery obligations when importing SBM hoses from different regions. -

Plazos de entrega

Lead time refers to the time taken from placing an order to the delivery of the product. For B2B buyers, understanding lead times is crucial for project planning and ensuring that operations are not delayed due to supply chain issues. -

Garantía

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of a product over a specified period. Knowing the warranty terms for SBM hoses can provide peace of mind and protect against potential defects or failures.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right SBM hoses for their specific needs while optimizing their purchasing processes.

Navigating Market Dynamics and Sourcing Trends in the sbm hose Sector

What Are the Current Market Dynamics and Key Trends in the SBM Hose Sector?

The SBM hose market is witnessing transformative dynamics driven by technological advancements and evolving buyer expectations. As industries increasingly focus on efficiency and performance, the demand for high-quality, durable hoses is surging. Global drivers such as urbanization, infrastructure development, and a growing emphasis on automation are particularly prominent in emerging markets across Africa, South America, the Middle East, and Europe. In Brazil and Saudi Arabia, for instance, investments in infrastructure are fueling the need for reliable and efficient fluid transfer solutions, which includes SBM hoses.

Additionally, international B2B buyers are increasingly leveraging digital platforms for sourcing. The integration of e-commerce solutions and online marketplaces facilitates easier access to a wider range of products and suppliers. This trend allows buyers to compare pricing, quality, and specifications efficiently, streamlining the procurement process. Furthermore, the rise of Industry 4.0 technologies, including IoT and smart supply chains, is influencing sourcing strategies. These innovations enable better tracking of inventory and enhance the quality control processes within the supply chain, ensuring that buyers receive products that meet their specifications.

How Are Sustainability and Ethical Sourcing Impacting the SBM Hose Sector?

Sustainability has become a critical focal point for B2B buyers in the SBM hose sector, with an increasing number of companies prioritizing ethical sourcing practices. The environmental impact of manufacturing processes is under scrutiny, leading buyers to seek suppliers that demonstrate a commitment to reducing their carbon footprint. This includes adopting eco-friendly materials and production methods that minimize waste and energy consumption.

Illustrative image related to sbm hose

Certifications such as ISO 14001 and compliance with REACH regulations are becoming essential for suppliers aiming to establish credibility in the market. Buyers are increasingly looking for ‘green’ materials, such as recycled plastics or bio-based alternatives, that can be used in the production of hoses. This shift not only addresses environmental concerns but also aligns with the corporate social responsibility goals of many organizations. Moreover, ethical supply chains that ensure fair labor practices and transparency are gaining traction, as buyers recognize the importance of supporting suppliers that prioritize social responsibility.

What Is the Brief Evolution and History of SBM Hoses in the B2B Context?

The SBM hose sector has evolved significantly over the past few decades, transitioning from traditional rubber hoses to advanced composite materials that enhance performance and durability. Initially, hoses were primarily designed for basic fluid transfer applications, but as industries advanced, the need for specialized hoses capable of withstanding higher pressures and varying temperatures became evident.

The introduction of synthetic materials and improved manufacturing techniques has allowed for the development of hoses that not only meet rigorous industry standards but also offer greater flexibility and longevity. Today, SBM hoses are utilized across diverse sectors, including automotive, construction, and manufacturing, reflecting a broader trend towards specialized, high-performance components in the B2B landscape. This evolution highlights the importance of innovation in meeting the changing demands of international buyers and underscores the need for suppliers to remain agile in a competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of sbm hose

-

How do I choose the right SBM hose for my application?

Selecting the appropriate SBM hose involves understanding your specific application requirements, such as pressure ratings, fluid compatibility, and temperature ranges. Consider the type of fluid that will flow through the hose, as certain materials may react adversely to specific chemicals. Additionally, assess the environmental conditions the hose will be exposed to, including UV exposure or extreme temperatures. Collaborating with suppliers who offer comprehensive product specifications and technical support can also help ensure you make the right choice. -

What is the best supplier for SBM hoses in international markets?

The best supplier for SBM hoses will depend on various factors, including product quality, compliance with international standards, and customer support. Look for suppliers with a proven track record in your region, particularly those who understand local regulations and market demands. It’s beneficial to request samples to evaluate quality firsthand and review customer testimonials. Suppliers with robust logistics capabilities and responsive communication can also enhance your purchasing experience and ensure timely delivery. -

What are the minimum order quantities (MOQ) for SBM hoses?

Minimum order quantities for SBM hoses can vary significantly between suppliers. Generally, MOQs are set based on production costs, inventory levels, and the supplier’s operational capacity. Many suppliers may offer flexible MOQs for established clients or larger orders. When negotiating, inquire about potential reductions in MOQ if you are willing to commit to future orders or consider a wider range of products from the supplier. -

What payment terms should I expect when sourcing SBM hoses?

Payment terms can vary based on supplier policies and the nature of the transaction. Common terms include upfront payments, partial payments upon order confirmation, or net 30/60 days after delivery. International transactions may involve additional considerations such as currency exchange and banking fees. It’s crucial to clarify these terms upfront to avoid misunderstandings. Establishing a good relationship with your supplier can also lead to more favorable payment terms over time. -

How do I ensure quality assurance (QA) for SBM hoses?

Quality assurance is vital when sourcing SBM hoses, as substandard products can lead to operational failures. Request documentation of quality certifications such as ISO 9001 or relevant industry-specific standards. Additionally, inquire about the supplier’s QA processes, including testing methods and inspection protocols. Conducting periodic audits or requesting third-party inspections can also help ensure that the products meet your quality expectations before shipment. -

What logistics considerations should I keep in mind when importing SBM hoses?

Logistics play a critical role in the successful importation of SBM hoses. Evaluate the shipping methods available, including air freight for urgent needs versus sea freight for cost savings. Consider the supplier’s ability to handle customs clearance and the associated documentation. Additionally, understanding the lead times for production and shipping can help you plan better. Collaborating with a logistics partner experienced in international trade can further streamline the process. -

Can SBM hoses be customized to meet specific requirements?

Yes, many suppliers offer customization options for SBM hoses to meet specific application needs. Customizations can include variations in length, diameter, material, and fittings. When discussing customization, provide detailed specifications to ensure the final product aligns with your requirements. Be mindful that custom orders may have longer lead times and higher costs, so plan accordingly in your procurement process. -

What are the common uses for SBM hoses in various industries?

SBM hoses are utilized across multiple industries, including automotive, aerospace, and manufacturing. They are commonly used for fluid transfer in hydraulic systems, brake systems, and other applications where reliable performance is critical. Understanding the industry-specific applications can help you identify the right type of hose for your needs. Additionally, collaborating with industry experts or suppliers can provide insights into the latest innovations and applications of SBM hoses.

Top 7 Sbm Hose Manufacturers & Suppliers List

1. Shimano – XTR Hydraulic Disc Brake Hose SM-BH90-SBM

Dominio: bike.shimano.com

Matriculado: 1995 (30 años)

Introducción: Product Name: XTR Hydraulic Disc Brake Hose SM-BH90-SBM

Compatibility: For use with XTR hydraulic brake systems

Features: One banjo fitting and one straight connection

Color: Black

Type: Straight-banjo type hose joint

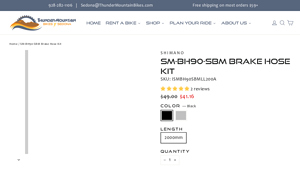

2. Shimano – SM-BH90-SBM Brake Hose Kit

Dominio: thundermountainbikes.com

Matriculado: 2020 (5 años)

Introducción: {‘name’: ‘Shimano SM-BH90-SBM Brake Hose Kit’, ‘sku’: ‘ISMBH90SBMLL200A’, ‘price’: ‘$41.16’, ‘compare_at_price’: ‘$49.00’, ‘color_options’: [‘Black’, ‘Silver’], ‘length’: ‘2000mm’, ‘connection_type’: ‘Straight / Banjo’, ‘includes’: ‘One brake hose and fittings’, ‘compatibility’: [‘Shimano XTR: BL-M9120 / BR-M9120, BL-M9000 / BR-M9000, BL-M9020 / BR-M9020’, ‘Shimano XT: BL-M8100 / BR-M8100, BL-M810…

3. Shimano – SM-BH90 Hose Kits

Dominio: universalcycles.com

Inscrita: 1997 (28 años)

Introducción: Product Name: Shimano SM-BH90 Hose Kits

Available Models:

– BH90-SB (1700mm, Black) – Fits: BR-M985 calipers & BL-M985, BL-M988 levers, XT BR-M785 caliper & BL-M785 levers (0/90 deg)

– BH90-SS (1700mm, Black) – Fits: BR-M596 Brakes (0/0 deg)

– BH90-JK-SSR (1700mm, Black) – Fits: BR-R9170 Brakes (ST Side; 2 type, BR Side; 1 Type), includes olive & connect insert, W/TL-BH61

– BH90-SBLS (2000mm, Bla…

4. PT COUPLING – SBM-2P Dust Plug

Dominio: alliancehose.com

Inscrita: 1997 (28 años)

Introducción: {‘part_number’: ‘SBM-2P’, ‘coupling_material’: ‘Anti-Static Polypropylene’, ‘coupling_size’: ‘2″‘, ‘end_type_a’: ‘Male Adapter’, ‘id_in’: ‘2’, ‘type’: ‘Dust Plug’, ‘weight_lbs’: ‘0.57’, ‘min_temp_f’: ‘-15’, ‘max_temp_f’: ‘150’, ‘manufacturer’: ‘PT COUPLING’, ‘availability’: ‘Out of Stock’}

5. Facebook – Hose Connection

Dominio: facebook.com

Inscrita: 1997 (28 años)

Introducción: This company, Facebook – Hose Connection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

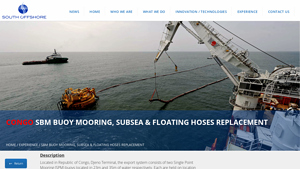

6. South Offshore – SPM Buoy Mooring Solutions

Dominio: south-offshore.com

Registered: 2010 (15 years)

Introducción: SBM Buoy Mooring, Subsea & Floating Hoses Replacement project located at Djeno Terminal, Republic of Congo. Involves two Single Point Mooring (SPM) buoys in 23m and 35m of water, held by six mooring chains and drag anchors. Scope includes uninstallation and re-alignment of mooring, replacement of hawsers, floating hoses, subsea hoses, umbilicals, and PLEM maintenance. Project management, engineeri…

7. Shimano – Brake Upgrade Guide

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Upgrading Shimano brakes from SM-BH90-SS to SM-BH90-SBM; SM-BH90-SS is straight + straight hose type, while SM-BH90-SBM is straight + banjo. Existing hose cannot be used with new connectors as banjo connectors are permanently crimped.

Strategic Sourcing Conclusion and Outlook for sbm hose

In today’s competitive landscape, strategic sourcing of SBM hoses is crucial for international B2B buyers, particularly those operating in emerging markets across Africa, South America, the Middle East, and Europe. By focusing on quality, compatibility, and supplier reliability, businesses can ensure they select the right products that meet their operational needs. Understanding the specifics, such as hose lengths and fittings compatible with various brake systems, can significantly enhance procurement efficiency.

Moreover, leveraging strong supplier relationships can lead to better pricing, improved delivery times, and access to innovative products. As buyers increasingly prioritize sustainability and cost-effectiveness, sourcing from manufacturers who adhere to these values can provide a competitive edge.

Illustrative image related to sbm hose

Looking ahead, the demand for high-quality SBM hoses will continue to rise as industries evolve and expand. International buyers are encouraged to stay informed about market trends and establish strategic partnerships that align with their long-term goals. By embracing a proactive sourcing strategy, businesses can not only meet current demands but also position themselves for future growth. Engage with reliable suppliers today to secure the best solutions for your operations and drive your business forward.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Illustrative image related to sbm hose