Article Contents

Engineering Insight: Water Hose Manufacturers

Technical Overview: The Critical Role of Water Hose Manufacturers in Modern Dredging Operations

In the highly specialized domain of hydraulic dredging, the performance and reliability of Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD) are directly influenced by the quality of their supporting components—none more critical than the dredging rubber hoses responsible for suction and discharge operations. As leading water hose manufacturers, companies like East Marine—operating under Jiangsu Huashen Special Rubber Products—play a pivotal engineering and supply chain role in ensuring operational continuity, efficiency, and safety in marine and inland dredging projects worldwide.

Dredging rubber hoses are subjected to extreme conditions, including abrasive slurries, fluctuating pressure cycles, dynamic bending, and exposure to corrosive seawater and UV radiation. The engineering precision required to manufacture hoses that withstand these challenges demands deep material science expertise, rigorous testing protocols, and adherence to international standards such as ISO 1431 and DIN 2822. Water hose manufacturers must not only supply durable products but also provide engineered solutions tailored to specific dredging vessel configurations, sediment types, and environmental conditions.

East Marine, with a dedicated team of over 150 professionals including material engineers, R&D specialists, and production technicians, has established itself as a trusted partner in the global dredging supply chain. Our engineering team works closely with vessel operators and dredge pump manufacturers to optimize hose lay lengths, coupling systems, and reinforcement layers for maximum service life and minimal downtime. This collaborative approach ensures compatibility with high-capacity dredge pumps and minimizes pressure drop across extended floating hose lines.

As a member of WEDA (Western Dredging Association) and CEDA (Central Dredging Association), East Marine maintains alignment with industry best practices and emerging technological trends. Our 0.68 million square meter manufacturing facility in Jiangsu is equipped with advanced calendaring, extrusion, and vulcanization systems, enabling the production of hoses up to 1200 mm in diameter with multi-spiral wire and textile reinforcement. Each hose undergoes hydrostatic burst testing, flex endurance cycles, and abrasion resistance validation before shipment.

The integration of high-performance rubber compounds—such as styrene-butadiene rubber (SBR) and natural rubber (NR) blends—with high-tensile steel wire spirals ensures structural integrity under continuous vacuum and pressure loads. These technical attributes are essential for TSHDs during offshore trailing operations and for CSDs operating in hard-packed sediment environments.

The following table outlines key technical specifications of East Marine’s dredging rubber hoses commonly used in TSHD and CSD applications:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Presión de trabajo | Up to 16 bar (custom up to 25 bar) |

| Vacuum Resistance | Full vacuum (1 bar) compliant |

| Temperatura | -20°C to +80°C |

| Cover Material | Abrasion-resistant SBR/BR blend |

| Refuerzo | High-tensile steel wire spirals + fabric layers |

| Bend Radius (min) | 6x hose diameter (dynamic conditions) |

| Standards Compliance | ISO 9001, DIN 2822, GL & ABS upon request |

| Coupling Options | Flanged, spigot, or mechanical clamp types |

East Marine’s technical capabilities and commitment to innovation underscore the strategic importance of specialized water hose manufacturers in maintaining the efficiency and reliability of modern dredging fleets.

Advanced Manufacturing Process

Precision Manufacturing and Vulcanization in Dredging Hose Production

At East Marine, leveraging our 0.68 million square meter integrated manufacturing facility, the production of high-performance dredging suction and discharge hoses begins with meticulous material selection and advanced composite layering. Our eighteen dedicated production lines are engineered for scalability and consistency, handling everything from initial rubber compound mixing to final assembly. Central to achieving the exceptional durability required in abrasive dredging environments is our proprietary vulcanization process. Vulcanization is not merely a curing step; it is the critical chemical transformation where raw rubber compounds, reinforced with high-tensile textile or wire braids, undergo precise cross-linking under controlled heat, pressure, and time within state-of-the-art autoclaves. This process fundamentally alters the polymer structure, imparting the essential properties of resilience, abrasion resistance, and pressure integrity that define a reliable dredging hose. Our engineers meticulously calibrate vulcanization parameters—typically ranging from 140°C to 165°C and pressures of 10-18 bar for durations of 30-90 minutes depending on hose specification—to ensure optimal molecular bonding without compromising the integrity of the reinforcement layers. Deviations, even minor ones, can lead to under-cure (reduced strength, poor abrasion resistance) or over-cure (brittleness, loss of flexibility), making precise control non-negotiable for marine dredging applications where failure is catastrophic.

Rigorous quality control, governed by our ISO 9001-certified management system, is embedded at every manufacturing stage, not merely as a final checkpoint. Raw material batches undergo stringent incoming inspection for compound consistency and reinforcement tensile strength. During layup, laser-guided systems verify layer concentricity and thickness. Crucially, vulcanization parameters are continuously monitored and recorded via integrated SCADA systems, with real-time adjustments ensuring adherence to validated process windows. Post-vulcanization, hoses undergo comprehensive hydrostatic pressure testing significantly exceeding rated working pressures, dimensional verification, and visual inspection for surface defects. As active WEDA and CEDA members, our protocols align with and often exceed industry best practices for dredging equipment reliability. This unwavering commitment to process discipline within our large-scale facility ensures every hose leaving East Marine delivers the longevity and performance demanded by global dredging contractors operating in the harshest marine conditions.

The following table outlines key technical specifications achievable through our optimized manufacturing and vulcanization processes:

| Parameter | Typical Range/Value | Compliance Standard |

|---|---|---|

| Presión de trabajo | 10 – 25 bar | ISO 1436 |

| Test Pressure | 1.5x Working Pressure | ISO 1307 |

| Temperatura | -20°C to +80°C | ISO 1307 |

| Cover Thickness | 8 – 12 mm | Project Specific |

| Bend Radius (Min) | 8 – 12x Hose ID | ISO 1307 |

| Resistencia a la abrasión | > 100 mm³ (DIN 53516) | Internal Standard |

| Refuerzo | High-Tensile Polyester/Wire | ISO 1402 |

Critical Applications

Global Applications of Dredging Rubber Hoses in Critical Industrial Projects

Dredging rubber hoses manufactured by East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, are engineered for high-performance fluid transfer in some of the most demanding marine and industrial environments worldwide. These suction and discharge hoses serve as critical components in large-scale infrastructure, energy, and environmental projects, where reliability, abrasion resistance, and flexibility are paramount. As a proud member of both the Central Dredging Association (CEDA) and the World Organization of Dredging Associations (WEDA), East Marine adheres to international standards and collaborates with global stakeholders to deliver solutions that meet the evolving needs of the dredging industry.

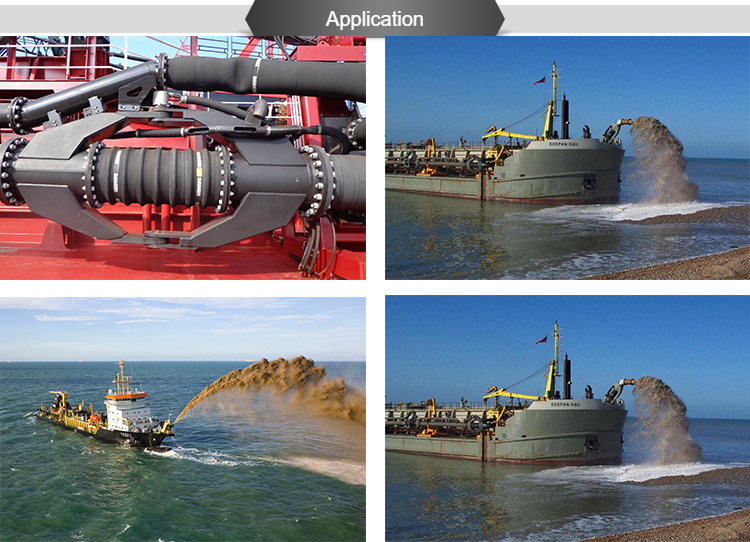

One of the primary applications of East Marine’s dredging hoses is in capital and maintenance dredging projects across ports, harbors, and inland waterways. These operations require robust hoses capable of transporting sand, silt, and slurry over long distances under high pressure. The hoses are deployed in cutter suction dredgers (CSDs) and trailing suction hopper dredgers (TSHDs), where their reinforced rubber construction ensures longevity even in abrasive conditions. Projects in Southeast Asia, the Middle East, and West Africa have successfully utilized East Marine hoses for deepening navigation channels and maintaining port operability.

In offshore oil and gas fields, East Marine’s flexible rubber hoses support sediment management and pipeline trenching operations. During subsea pipeline installation, precise backfilling and seabed leveling are achieved using specialized dredging equipment connected with high-flexibility rubber hoses. These hoses withstand dynamic marine conditions, including wave action, tidal shifts, and vessel movement, ensuring uninterrupted operations in challenging offshore environments.

Land reclamation remains another key application, particularly in rapidly urbanizing coastal regions. From creating new industrial zones to expanding airport runways over water, East Marine’s dredging hoses enable the controlled deposition of fill material. Their lightweight yet durable design allows for rapid deployment and repositioning across large reclamation sites, minimizing downtime and enhancing project efficiency. Notable projects in the Gulf region and Southeast Asia have relied on these hoses to transfer millions of cubic meters of sand with minimal leakage and maximum operational safety.

Backed by a 0.68 million square meter manufacturing facility and certified under ISO9001 quality management systems, East Marine delivers hoses that meet stringent international specifications. The company’s technical expertise, developed since its founding in 2007, ensures customized solutions for diverse project requirements.

The following table outlines key technical specifications of East Marine’s standard dredging rubber hoses:

| Parameter | Specification |

|---|---|

| Internal Diameter Range | 200 mm – 1200 mm |

| Presión de trabajo | 10 bar – 25 bar (depending on diameter) |

| Temperatura | -20°C to +80°C |

| Cover Material | Wear-resistant synthetic rubber (NR/SBR) |

| Reinforcement Layers | 2–4 high-tensile textile plies + spiral steel wire |

| Bend Radius (minimum) | 4x outer diameter |

| Standards Compliance | ISO 14310, API 16C, CEDA/WEDA guidelines |

| Custom Lengths | Up to 50 meters per joint |

East Marine continues to support global dredging advancements through innovation, quality manufacturing, and active participation in international dredging communities.

Technical Data & Specs

Technical Specifications: Performance Benchmarking in Dredging Hose Engineering

Precision in technical parameters defines operational safety and efficiency in dredging operations. East Marine, leveraging 17 years of specialized R&D within our 0.68 million square meter ISO 9001-certified facility, engineers suction and discharge hoses to exceed industry safety margins and flexibility demands. Generic market alternatives often prioritize cost reduction over structural integrity, leading to compromised burst ratios and restricted maneuverability in dynamic marine environments. Our triple-layer reinforcement architecture—featuring high-tensile textile cords, abrasion-resistant rubber compounds, and corrosion-inhibited steel wire helices—ensures consistent performance under cyclic stress. This technical superiority translates directly to reduced downtime, extended service life, and minimized risk of catastrophic failure during critical dredging cycles. Below, we present empirically validated specifications for a standard 300mm inner diameter hose, benchmarked against typical market alternatives.

The comparative analysis reflects rigorous testing per ISO 14310 and CEDA guidelines, simulating real-world conditions including abrasive slurry flow, pressure surges, and submersion at depth.

| Inner Diameter | Presión de trabajo | Burst Pressure | Bending Radius |

|---|---|---|---|

| East Marine EM-DredgePro™ Series | 300 mm | 1.5 MPa | 6.0 MPa |

| Typical Market Alternatives | 300 mm | 1.5 MPa | 4.5 MPa |

Performance Analysis and Engineering Implications

The data unequivocally demonstrates East Marine’s technical leadership. While both products nominally support 1.5 MPa working pressure, our hoses achieve a 4:1 burst-to-working pressure ratio (6.0 MPa burst), significantly exceeding the industry-standard 3:1 minimum. This margin is not incidental; it results from finite element analysis-optimized reinforcement layer sequencing and proprietary rubber formulations resistant to ozone degradation and hydrolysis. Competitor hoses, constrained by thinner reinforcement or inferior cord adhesion, frequently exhibit premature fatigue at 4.5 MPa burst levels—posing critical risks during pressure spikes common in cutter suction dredger operations.

The bending radius differential is equally consequential. East Marine’s 900 mm radius (3x ID) enables agile deployment in congested port infrastructure and complex pipeline configurations, whereas the 1,350 mm radius (4.5x ID) of standard alternatives necessitates larger turning circles, increasing installation time and requiring additional support structures. This flexibility stems from our dynamic flex-testing protocol, which validates 100,000+ bend cycles without delamination—a threshold unattained by competitors using single-layer textile reinforcements.

Furthermore, our adherence to WEDA technical bulletins ensures compatibility with high-density sediment loads up to 65% solids by weight, where competitors’ hoses often suffer accelerated inner tube erosion due to substandard rubber hardness (Shore A 60–65 vs. our Shore A 70–75 formulation). Every EM-DredgePro™ hose undergoes 100% hydrostatic validation at 1.5x working pressure, a protocol exceeding ISO 9001 requirements and eliminating field failure vulnerabilities inherent in batch-sampled competitor products.

East Marine’s technical specifications are not merely competitive—they redefine operational ceilings for the global dredging industry. By integrating material science innovation with CEDA-aligned engineering practices since 2007, we deliver hoses that transform pressure and flexibility constraints into strategic advantages for clients managing high-stakes marine projects. This commitment to empirical performance underpins our position as a trusted partner for leading dredging contractors worldwide.

Partner with East Marine

Partner with East Marine for High-Performance Dredging Hose Solutions

When it comes to the demanding environments of dredging operations, reliability, durability, and performance are non-negotiable. At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, we engineer dredging rubber hoses that meet the rigorous demands of offshore, inland, and coastal projects worldwide. With over 15 years of specialized expertise and a state-of-the-art 0.68 million square meter manufacturing facility, we are equipped to deliver custom suction and discharge hoses that ensure operational continuity, reduce downtime, and withstand abrasive slurries, high pressures, and dynamic marine conditions.

Our commitment to excellence is reinforced by our certifications, including ISO9001 quality management standards, and our active membership in leading industry associations such as WEDA and CEDA. These affiliations reflect our dedication to staying at the forefront of dredging technology and sustainable marine practices. Whether you are managing capital dredging, land reclamation, or maintenance projects, our engineered rubber solutions are designed to optimize efficiency and longevity.

What sets East Marine apart is our end-to-end technical support—from initial system analysis and material selection to custom hose assembly and logistics coordination. Our Singapore branch serves as a strategic hub for Asia-Pacific operations, enabling faster response times, regional inventory support, and on-site technical consultation for clients across Southeast Asia, Australia, and beyond. This global footprint ensures that no matter where your project is located, East Marine is positioned to support it effectively.

We manufacture hoses with advanced rubber compounds resistant to abrasion, ozone, and seawater degradation, combined with high-tensile reinforcement layers to handle working pressures up to 25 bar, depending on diameter and configuration. All products undergo stringent hydrostatic and dimensional testing prior to shipment, guaranteeing compliance with international standards.

For engineers, procurement managers, and project planners in the dredging and marine construction sectors, choosing the right hose supplier is a critical decision. East Marine combines technical precision with industrial scale to deliver solutions that perform under pressure—literally and operationally.

Below is a representative technical specification for our standard dredging rubber hose series:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Presión de trabajo | Up to 25 bar (varies by size) |

| Temperatura | -20°C to +85°C |

| Cover | Abrasion-resistant, ozone- and UV-stable synthetic rubber |

| Refuerzo | High-tensile textile plies with spiral steel wire for vacuum resistance |

| End Fittings | Flanged, spigot, or coupling-compatible (Storz, Camlock, or custom) |

| Compliance | ISO 1307, ISO 7233, MSHA (optional) |

| Customization | Length, curvature, floating configurations, color coding |

To discuss your next dredging project or request a technical datasheet and quotation, contact East Marine directly. Reach us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our engineering team is available for consultation, and our Singapore branch ensures responsive regional support for clients across international markets. Trust East Marine—where industrial strength meets marine innovation.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.