Introduction : Naviguer sur le marché mondial des tubes PEHD

Dans le paysage en évolution rapide du développement des infrastructures, l'approvisionnement en tuyaux en polyéthylène haute densité (PEHD) présente à la fois des défis et des opportunités pour les acheteurs internationaux B2B. Grâce à leur remarquable durabilité, leur résistance à la corrosion et leur polyvalence, les tuyaux en PEHD sont de plus en plus utilisés pour diverses applications, notamment la distribution d'eau, les réseaux d'égouts et les conduites de gaz. Toutefois, la complexité de l'approvisionnement en ce matériau essentiel peut être déconcertante, en particulier pour les entreprises de régions telles que l'Afrique, l'Amérique du Sud, le Moyen-Orient et l'Europe, y compris le Brésil et l'Allemagne.

Ce guide complet vise à démystifier le marché mondial des tuyaux en PEHD en explorant ses différents types, applications et avantages. Nous nous pencherons sur les éléments essentiels à prendre en compte lors de l'examen des fournisseurs, en fournissant des indications sur la manière d'identifier les fabricants et les distributeurs de bonne réputation. En outre, nous analyserons les facteurs de coût, afin d'aider les acheteurs à comprendre les structures de prix et à négocier efficacement. En fournissant aux acheteurs B2B les connaissances nécessaires pour prendre des décisions d'achat éclairées, ce guide permet aux entreprises d'améliorer leurs projets d'infrastructure tout en garantissant la conformité avec les réglementations et les normes locales.

Que vous cherchiez à étendre votre chaîne d'approvisionnement ou à trouver des partenaires fiables pour votre prochain projet, il est essentiel de comprendre les nuances du marché des tubes PEHD. Ce guide est votre feuille de route pour naviguer avec succès dans les complexités de l'approvisionnement en tubes PEHD dans un marché mondial interconnecté, conduisant en fin de compte à de meilleurs résultats de projet et à un succès à long terme.

Table des matières

- Liste des 4 meilleurs fabricants et fournisseurs de tubes Hdpe

- Introduction : Naviguer sur le marché mondial des tubes PEHD

- Comprendre les types et les variations des tuyaux PEHD

- Principales applications industrielles des tuyaux en PEHD

- 3 points de douleur courants pour les utilisateurs de 'HDPE Pipe' et leurs solutions

- Guide de sélection stratégique des matériaux pour les tubes PEHD

- Regard approfondi : Procédés de fabrication et assurance qualité pour les tubes PEHD

- Guide pratique d'approvisionnement : Liste de contrôle étape par étape pour "Tube PEHD" (HDPE Pipe)

- Analyse complète des coûts et des prix pour l'approvisionnement en tubes PEHD

- Analyse des alternatives : Comparaison du tube PEHD avec d'autres solutions

- Propriétés techniques essentielles et terminologie commerciale pour les tubes PEHD

- Naviguer dans la dynamique du marché et les tendances en matière d'approvisionnement dans le secteur des tuyaux en PEHD

- Foire aux questions (FAQ) pour les acheteurs B2B de tuyaux en PEHD

- Conclusion et perspectives en matière d'approvisionnement stratégique pour les tubes en PEHD

- Avis de non-responsabilité et conditions d'utilisation

Comprendre les types et les variations des tuyaux PEHD

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Tube PEHD à fusion bout à bout | Forte intégrité des joints grâce à la fusion thermique | Distribution d'eau, approvisionnement en gaz | Pour : Tolérance à la pression élevée ; Cons : L'installation nécessite un équipement spécialisé. |

| Tube PEHD électrofusion | Utilise le courant électrique pour fusionner les joints | Applications industrielles, gestion des eaux usées | Pour : Connexions fiables ; Cons : Coût d'installation plus élevé. |

| Tube enroulé en PEHD | Flexible, peut être facilement transporté et installé | Systèmes d'irrigation et de drainage | Pour : Léger ; Cons : Options de diamètre limitées. |

| Tube PEHD à paroi structurée | Résistance accrue avec un profil léger | Gestion des eaux pluviales, systèmes d'assainissement | Pour : Rentable pour les applications de grand diamètre ; Cons : Peut nécessiter un soutien supplémentaire dans certaines conditions. |

| Tuyau MDPE (polyéthylène de densité moyenne) | Densité intermédiaire, convient aux applications gazières | Distribution de gaz, conduites d'eau à basse pression | Pour : Bonne flexibilité ; Cons : Ne convient pas aux applications à haute pression. |

Quelles sont les caractéristiques des tuyaux PEHD soudés bout à bout ?

Les tuyaux PEHD à fusion bout à bout se caractérisent par leur capacité à créer des joints solides et étanches grâce à un processus de fusion thermique. Ce type de tuyau est couramment utilisé dans des applications nécessitant une pression élevée et une grande durabilité, telles que la distribution d'eau municipale et les conduites d'alimentation en gaz naturel. Lors de l'achat, les acheteurs doivent tenir compte de la disponibilité de l'équipement de fusion et du personnel qualifié, car l'installation nécessite des compétences spécialisées.

Comment fonctionne le tuyau PEHD électrofusé ?

Les tuyaux PEHD électrofusionnés utilisent un courant électrique pour chauffer et fusionner les joints des tuyaux, ce qui permet d'obtenir une connexion robuste et fiable. Cette méthode est particulièrement avantageuse pour les environnements industriels et la gestion des eaux usées, où l'intégrité des joints est cruciale. Les acheteurs B2B doivent évaluer le coût total de possession, y compris l'équipement et la formation, car l'investissement initial peut être plus élevé que pour les méthodes traditionnelles.

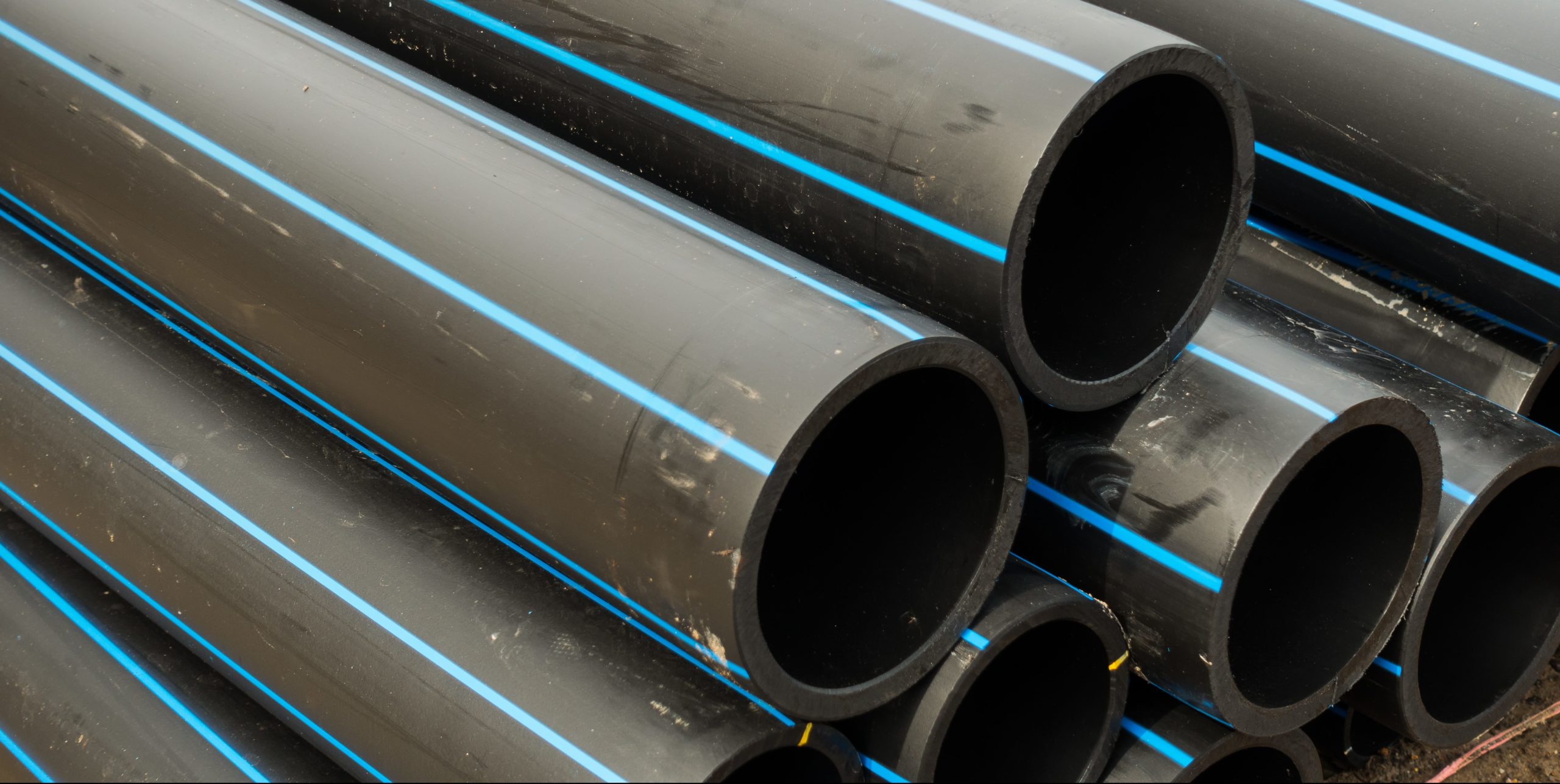

Image d'illustration relative au tuyau PEHD

Pourquoi le tube enroulé en PEHD est-il idéal pour certaines applications ?

Le tuyau spiralé en PEHD est connu pour sa flexibilité et sa facilité de transport, ce qui le rend idéal pour des applications telles que les systèmes d'irrigation et de drainage. Sa conception légère permet une installation rapide, ce qui réduit les coûts de main-d'œuvre. Toutefois, les acheteurs doivent être conscients que les tuyaux enroulés peuvent être limités en termes de diamètre et qu'ils ne sont souvent pas adaptés aux applications à haute pression.

Pourquoi choisir le tube PEHD à paroi structurée pour les besoins de grands diamètres ?

Les tuyaux en PEHD à paroi structurée offrent une résistance accrue tout en conservant un profil léger, ce qui en fait un choix économique pour les applications de grand diamètre telles que la gestion des eaux pluviales et les systèmes d'égouts. Ce type de tuyau permet de réduire considérablement les coûts des matériaux. Les acheteurs doivent tenir compte de l'environnement d'installation, car un support supplémentaire peut être nécessaire dans certaines conditions pour assurer la stabilité.

Quels sont les avantages du tube MDPE dans la distribution du gaz ?

Les tuyaux en polyéthylène de moyenne densité (MDPE) sont conçus pour la distribution de gaz et les conduites d'eau à basse pression. Il offre une bonne flexibilité et une bonne résistance à la fissuration sous contrainte, ce qui le rend adapté à divers environnements. Toutefois, il est important que les acheteurs sachent que le MDPE n'est pas conçu pour les applications à haute pression, ce qui peut limiter son utilisation dans certains projets. Il est essentiel de comprendre ces spécifications pour prendre des décisions d'achat éclairées.

Image d'illustration relative au tuyau PEHD

Principales applications industrielles des tuyaux en PEHD

| Industrie/secteur | Applications spécifiques du tube PEHD | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Gestion de l'eau | Systèmes de distribution d'eau potable | Garantit la sécurité de l'approvisionnement en eau potable, la durabilité et la résistance à la corrosion | Conformité aux normes locales et internationales pour l'eau potable, disponibilité de différents diamètres et niveaux de pression |

| Agriculture | Systèmes d'irrigation | Distribution efficace de l'eau, réduction de l'évaporation et augmentation du rendement des cultures | L'approvisionnement en tuyaux qui peuvent résister à l'exposition aux UV et aux conditions du sol, la compatibilité avec l'infrastructure d'irrigation existante. |

| Pétrole et gaz | Transport par pipeline | Haute résistance à la corrosion et aux produits chimiques, légèreté pour une manipulation plus aisée | Respect des règles de sécurité, disponibilité de l'équipement de fusion pour l'installation et garantie d'une pression nominale appropriée. |

| La construction | Systèmes de drainage | Gestion efficace des eaux pluviales, prévention des inondations et de l'érosion des sols | Prise en compte des réglementations environnementales locales, des exigences en matière de taille des tuyaux et de la compatibilité avec les systèmes de drainage existants. |

| Télécommunications | Conduit pour câbles à fibres optiques | Protection des câbles, souplesse d'installation et réduction des coûts de maintenance | Disponibilité d'options de tuyaux flexibles et durables, compatibilité avec divers types de câbles et conformité aux normes industrielles |

Comment le tuyau PEHD est-il utilisé dans la gestion de l'eau et quels sont les problèmes qu'il résout ?

Dans le secteur de la gestion de l'eau, les tuyaux en PEHD sont principalement utilisés pour les systèmes de distribution d'eau potable. Leur résistance élevée à la corrosion et à la lixiviation chimique garantit que l'eau reste propre à la consommation. Cette application répond à des problèmes critiques tels que le vieillissement des infrastructures et les risques de contamination, ce qui fait du PEHD un choix privilégié pour les municipalités et les autorités chargées de la gestion de l'eau. Les acheteurs doivent tenir compte de la conformité aux réglementations et normes locales, ainsi que de la disponibilité de différents diamètres et pressions nominales pour répondre aux exigences spécifiques des projets.

Quel est le rôle des tuyaux en PEHD dans les systèmes d'irrigation agricole ?

Dans l'agriculture, les tuyaux en PEHD sont essentiels pour les systèmes d'irrigation modernes. Ils facilitent l'acheminement efficace de l'eau vers les cultures, en réduisant considérablement les pertes d'eau dues à l'évaporation et aux fuites. Cette application permet non seulement d'améliorer le rendement des cultures, mais aussi de promouvoir une utilisation durable de l'eau, ce qui est crucial dans les régions confrontées à une pénurie d'eau. Les acheteurs B2B de ce secteur doivent se concentrer sur l'approvisionnement en tuyaux qui peuvent résister à l'exposition aux UV et aux conditions de sol difficiles, tout en assurant la compatibilité avec l'infrastructure d'irrigation existante.

Quels sont les avantages du tube HDPE pour le transport des oléoducs et des gazoducs ?

L'industrie pétrolière et gazière utilise des tuyaux en PEHD pour transporter divers fluides en raison de leur résistance exceptionnelle à la corrosion et aux produits chimiques. Cette application est essentielle pour maintenir l'intégrité des pipelines et minimiser les fuites, qui peuvent entraîner des risques pour l'environnement et des pertes financières. Les acheteurs doivent s'assurer que les tuyaux achetés sont conformes aux réglementations de sécurité strictes et aux normes industrielles, tout en tenant compte de la disponibilité d'équipements de fusion pour une installation et une maintenance efficaces.

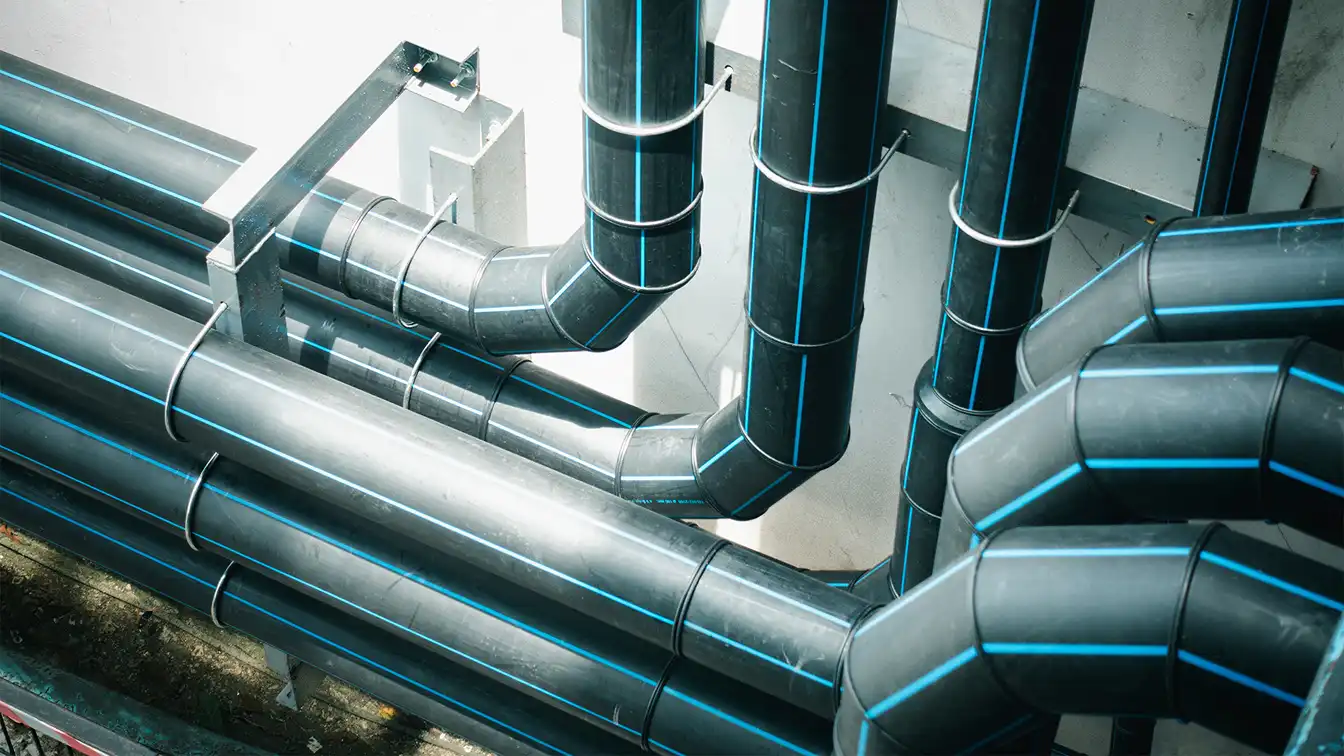

Pourquoi les tuyaux en PEHD sont-ils utilisés dans les systèmes de drainage des constructions ?

Dans la construction, les tuyaux en PEHD sont largement utilisés dans les systèmes de drainage pour gérer efficacement les eaux pluviales. Leur légèreté et leur durabilité permettent une installation facile et une performance à long terme, ce qui prévient les inondations et l'érosion des sols. Cette application est particulièrement importante dans les projets de développement urbain où un drainage efficace est essentiel. Les acheteurs doivent tenir compte des réglementations environnementales locales et de la compatibilité des tuyaux avec les systèmes de drainage existants afin de garantir des performances optimales.

Image d'illustration relative au tuyau PEHD

Comment les tuyaux en PEHD soutiennent-ils l'infrastructure des télécommunications ?

Dans le domaine des télécommunications, les tuyaux en PEHD servent de conduits pour les câbles à fibres optiques, offrant une protection essentielle contre les dommages physiques et les facteurs environnementaux. Leur flexibilité facilite l'installation et réduit les coûts de maintenance, ce qui en fait une option intéressante pour les entreprises de télécommunications qui étendent leurs réseaux. Lorsqu'ils s'approvisionnent en tubes PEHD pour cette application, les acheteurs doivent s'assurer de la compatibilité avec les différents types de câbles et de la conformité avec les normes industrielles afin de garantir la fiabilité de l'infrastructure de communication.

3 points de douleur courants pour les utilisateurs de 'HDPE Pipe' et leurs solutions

Scénario 1 : Qualité inégale d'un fournisseur à l'autre

Le problème : Les acheteurs B2B sont souvent confrontés au problème de l'incohérence de la qualité lorsqu'ils s'approvisionnent en tubes PEHD auprès de différents fournisseurs. Cela peut entraîner des retards dans les projets, des coûts imprévus dus à des retouches, voire des risques pour la sécurité. Par exemple, un acheteur du secteur de la construction peut commander des tuyaux en PEHD pour un projet de distribution d'eau à grande échelle, avant de constater que les tuyaux reçus ont une épaisseur ou une résistance à la traction différente de ce qui avait été spécifié. De telles divergences compliquent non seulement l'installation, mais peuvent également compromettre l'intégrité de l'ensemble du système.

La solution : Pour limiter ce risque, les acheteurs doivent mettre en place des protocoles d'assurance qualité rigoureux lorsqu'ils s'approvisionnent en tuyaux PEHD. Commencez par effectuer des recherches approfondies sur les fournisseurs potentiels, en vous concentrant sur leur réputation, leurs normes de fabrication et leur conformité aux certifications de qualité internationales telles que l'ISO 9001. Demandez des échantillons du tuyau pour effectuer des tests internes de résistance à la pression et de durabilité avant de passer une commande en gros. En outre, envisagez de faire appel à des services d'inspection tiers pour vérifier que les produits répondent aux spécifications requises avant d'être expédiés. Cette approche proactive peut garantir que la qualité des tuyaux PEHD reste constante, ce qui permet en fin de compte de faciliter l'exécution des projets et d'améliorer la sécurité.

Scénario 2 : Difficultés d'installation et de fusion

Le problème : La complexité de l'installation des tuyaux PEHD, en particulier en ce qui concerne les techniques de fusion telles que la fusion bout à bout et l'électrofusion, est un autre point de douleur commun aux acheteurs B2B. De nombreux projets nécessitent un équipement spécialisé et un personnel qualifié pour assurer une connexion correcte. Un acheteur qui gère la modernisation d'un réseau d'eau municipal peut constater que son équipe ne possède pas les compétences nécessaires pour appliquer correctement ces méthodes de fusion, ce qui entraîne des fuites et des retards potentiels dans le projet.

Image d'illustration relative au tuyau PEHD

La solution : Pour relever ce défi, les acheteurs doivent investir dans des programmes de formation pour leurs équipes d'installation ou s'associer à des entrepreneurs expérimentés spécialisés dans l'installation de tuyaux en PEHD. Les fournisseurs de tuyaux PEHD proposent souvent des sessions de formation ou des ressources qui décrivent les meilleures pratiques en matière de techniques de fusion. En outre, il faut envisager de louer ou d'acheter l'équipement de fusion approprié auprès de fournisseurs réputés, en veillant à ce qu'il réponde aux exigences spécifiques du projet. En dotant les équipes des connaissances et des outils nécessaires à une installation correcte, les acheteurs peuvent réduire considérablement la probabilité d'erreurs d'installation et assurer la longévité du réseau de pipelines.

Scénario 3 : Préoccupations et réglementations environnementales

Le problème : Avec la prise de conscience mondiale des problèmes environnementaux, les acheteurs B2B dans des régions comme l'Europe et l'Amérique du Sud sont de plus en plus contraints de se conformer à des réglementations environnementales strictes concernant l'utilisation de matériaux tels que le PEHD. Cela peut créer des incertitudes quant à la durabilité de leur chaîne d'approvisionnement, en particulier pour les projets qui impliquent la gestion de l'eau potable ou des eaux usées. Un acheteur peut s'inquiéter de l'impact environnemental de l'approvisionnement en tuyaux PEHD, craignant une réaction négative de la part des parties prenantes ou des organismes de réglementation.

La solution : Pour répondre à ces préoccupations, les acheteurs doivent s'approvisionner en priorité en tuyaux PEHD certifiés pour leur conformité environnementale, par exemple ceux qui répondent aux exigences fixées par des organisations telles que l'Agence de protection de l'environnement (EPA) ou le règlement REACH de l'Union européenne. Faites appel à des fournisseurs qui peuvent fournir une documentation sur l'impact environnemental de leurs processus de production et sur la recyclabilité de leurs produits. En outre, envisagez d'investir dans des tuyaux en PEHD fabriqués à partir de matériaux recyclés, qui peuvent renforcer les efforts en matière de développement durable. En adoptant une approche d'approvisionnement respectueuse de l'environnement, les acheteurs garantissent non seulement la conformité aux réglementations, mais se positionnent également comme des acteurs responsables sur le marché, ce qui peut améliorer la réputation de leur marque et la confiance des parties prenantes.

Guide de sélection stratégique des matériaux pour les tubes PEHD

Quelles sont les principales propriétés des matériaux utilisés pour les tuyaux en PEHD ?

Les tuyaux en polyéthylène haute densité (PEHD) sont principalement utilisés dans diverses applications, notamment la distribution d'eau, les systèmes d'égouts et les gazoducs. Il est essentiel pour les acheteurs B2B de comprendre les différents matériaux utilisés dans la fabrication des tuyaux en PEHD, en particulier lorsqu'ils prennent en compte la performance, le coût et la conformité aux normes internationales.

Comment les différentes compositions de matériaux affectent-elles les performances des tuyaux en PEHD ?

-

Polyéthylène haute densité (PEHD)

– Propriétés principales: Le PEHD présente d'excellentes caractéristiques de température et de pression, allant généralement de -40°F à 140°F (-40°C à 60°C) et peut supporter des pressions allant jusqu'à 200 psi ou plus, en fonction de l'épaisseur de la paroi.

– Avantages et inconvénients: Le PEHD est très durable, résistant à la corrosion et a une longue durée de vie. Cependant, son processus de fabrication peut être complexe et entraîner des coûts initiaux plus élevés que pour d'autres matériaux.

– Impact sur l'application: Le PEHD est compatible avec une large gamme de fluides, y compris l'eau potable, les eaux usées et divers produits chimiques, ce qui le rend adapté à diverses applications.

– Considérations pour les acheteurs internationaux: La conformité aux normes telles que ASTM D3350 et ISO 4427 est cruciale. Les acheteurs de régions comme l'Europe et le Moyen-Orient doivent s'assurer que les produits sont conformes aux réglementations et certifications locales. -

Chlorure de polyvinyle (PVC)

– Propriétés principales: Les tuyaux en PVC peuvent supporter des températures allant jusqu'à 60°C (140°F) et des pressions similaires à celles du PEHD, mais ils sont moins flexibles.

– Avantages et inconvénients: Le PVC est rentable et facile à installer, mais il n'a pas la résistance chimique et la flexibilité du PEHD, ce qui le rend moins adapté à certaines applications.

– Impact sur l'application: Le PVC est couramment utilisé pour les systèmes de drainage et d'irrigation, mais il peut ne pas convenir pour les applications à haute pression ou celles impliquant des produits chimiques agressifs.

– Considérations pour les acheteurs internationaux: La conformité aux normes ASTM D1785 et DIN 8061 est essentielle, en particulier dans des régions comme l'Allemagne, où des réglementations strictes sont appliquées. -

Polypropylène (PP)

– Propriétés principales: Les tuyaux en PP peuvent fonctionner à des températures plus élevées, jusqu'à 82°C (180°F), et offrent une excellente résistance à la corrosion chimique.

– Avantages et inconvénients: Le PP offre une résistance chimique supérieure et est léger, mais il peut être plus cher et ne pas être performant dans les applications à haute pression.

– Impact sur l'application: Idéal pour le transport de produits chimiques et les applications industrielles, le PP est moins utilisé pour la distribution d'eau.

– Considérations pour les acheteurs internationaux: Les acheteurs doivent vérifier la conformité avec les normes pertinentes telles que ASTM F2389 et s'assurer de la compatibilité avec les réglementations locales dans leurs régions respectives. -

Polyéthylène réticulé (PEX)

– Propriétés principales: Les tuyaux PEX peuvent résister à des températures allant jusqu'à 93°C et à des pressions d'environ 80 psi, ce qui les rend adaptés aux applications d'eau chaude et d'eau froide.

– Avantages et inconvénients: Le PEX est flexible et facile à installer, ce qui réduit le besoin de raccords. Cependant, il peut ne pas convenir aux applications extérieures en raison de sa sensibilité aux UV.

– Impact sur l'application: Le PEX est couramment utilisé dans la plomberie résidentielle mais n'est pas forcément idéal pour les applications industrielles.

– Considérations pour les acheteurs internationaux: La conformité à des normes telles que la norme ASTM F876 est nécessaire et les acheteurs doivent s'assurer que le matériau est approuvé pour une utilisation dans leurs applications spécifiques.

Tableau récapitulatif de la sélection des matériaux pour les tuyaux en PEHD

| Matériau | Cas d'utilisation typique d'un tuyau PEHD | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Polyéthylène haute densité (PEHD) | Distribution d'eau, systèmes d'égouts | Grande durabilité, résistance à la corrosion | Processus de fabrication complexe | Moyen |

| Chlorure de polyvinyle (PVC) | Drainage, systèmes d'irrigation | Rentable, facile à installer | Résistance chimique limitée | Faible |

| Polypropylène (PP) | Transport de produits chimiques, utilisation industrielle | Excellente résistance chimique | Coût plus élevé, moins adapté à la haute pression | Haut |

| Polyéthylène réticulé (PEX) | Plomberie résidentielle | Flexibilité et facilité d'installation | La sensibilité aux UV limite l'utilisation en extérieur | Moyen |

Ce guide stratégique de sélection des matériaux fournit des informations précieuses aux acheteurs B2B dans diverses régions, leur permettant de prendre des décisions éclairées lorsqu'ils s'approvisionnent en tubes PEHD pour leurs applications spécifiques.

Regard approfondi : Procédés de fabrication et assurance qualité pour les tubes PEHD

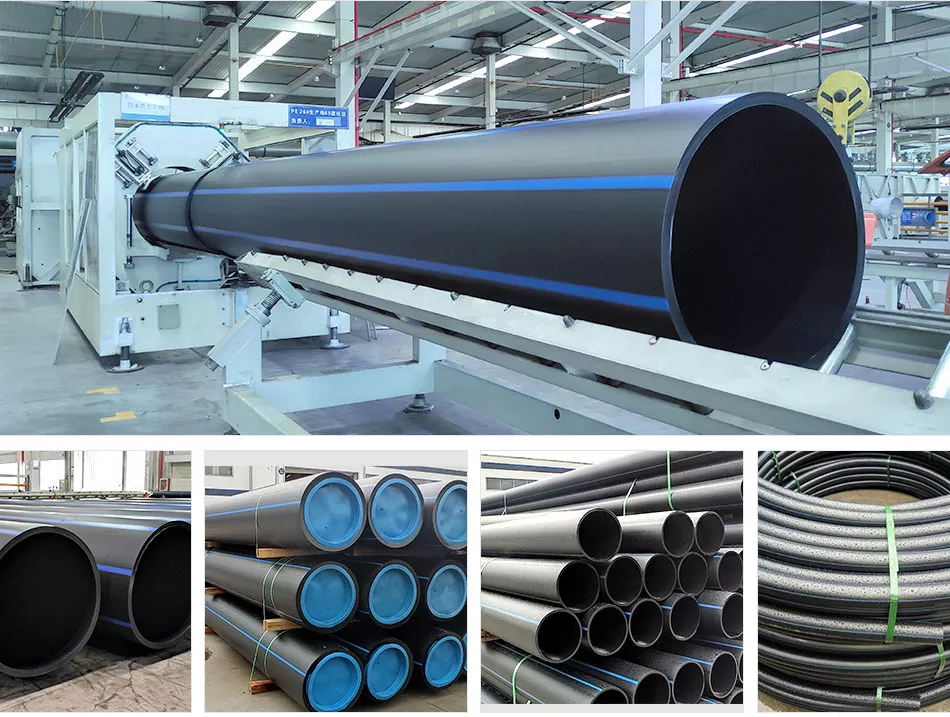

Quelles sont les principales étapes du processus de fabrication des tuyaux en PEHD ?

La fabrication de tuyaux en polyéthylène haute densité (PEHD) comporte plusieurs étapes critiques qui garantissent que le produit final est conforme aux normes industrielles et aux spécifications du client. Les principales étapes sont la préparation des matériaux, le formage, l'assemblage et la finition.

Préparation du matériel

Le processus commence par la sélection d'une résine PEHD de haute qualité, provenant généralement de fournisseurs réputés. La résine est ensuite mélangée à des additifs pour améliorer les propriétés telles que la résistance aux UV, la couleur et la résistance aux chocs. Cette étape peut également impliquer la granulation de la résine pour faciliter sa manipulation au cours des processus ultérieurs.

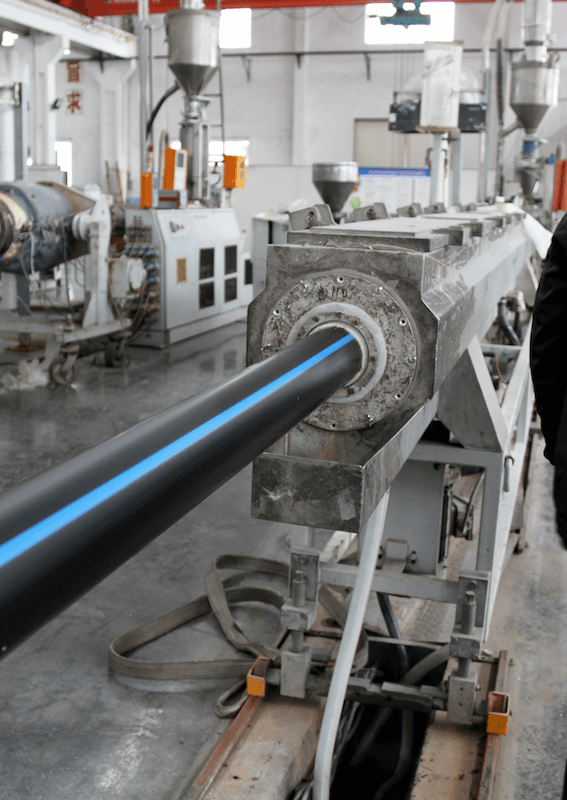

Image d'illustration relative au tuyau PEHD

Techniques de formage

Une fois préparée, la résine PEHD est mise en forme par différentes méthodes, notamment l'extrusion et le moulage par injection. Dans le cas de l'extrusion, la résine est chauffée et forcée à travers une filière pour créer des longueurs continues de tuyaux. Le moulage par injection, quant à lui, est utilisé pour les raccords et les composants plus petits, la résine fondue étant injectée dans des moules. Les deux techniques nécessitent un contrôle précis de la température et de la pression afin de garantir une qualité constante du produit.

Assemblée

Après le formage, il peut être nécessaire d'assembler les tuyaux et les raccords. Pour ce faire, on utilise souvent les techniques de fusion bout à bout ou de fusion par emboîtement, qui consistent à chauffer les extrémités des tuyaux et à les assembler sous pression. Pour les projets plus importants, on peut également recourir à l'électrofusion, où un courant électrique chauffe les raccords et les tuyaux, assurant ainsi une liaison sûre.

Procédés de finition

L'étape finale consiste à refroidir, couper et inspecter les tuyaux pour détecter d'éventuels défauts. Cette étape peut inclure la finition de la surface et l'application de revêtements protecteurs. Chaque tuyau est généralement marqué avec des informations importantes telles que la taille, la pression nominale et la date de fabrication, ce qui garantit la traçabilité tout au long de son cycle de vie.

Comment l'assurance qualité est-elle mise en œuvre dans la production de tubes PEHD ?

L'assurance qualité (AQ) est essentielle dans la fabrication des tuyaux en PEHD pour répondre aux normes internationales et spécifiques à l'industrie. Le processus comprend plusieurs points de contrôle et méthodes d'essai qui garantissent la fiabilité et la sécurité d'utilisation du produit final.

Normes internationales pour l'assurance qualité

Pour maintenir une production de haute qualité, les fabricants adhèrent souvent à des normes internationales telles que la norme ISO 9001, qui définit les exigences d'un système de gestion de la qualité. Cette certification garantit que les entreprises fournissent en permanence des produits qui répondent aux exigences des clients et de la réglementation. En outre, les certifications industrielles spécifiques telles que le marquage CE (pour les produits vendus en Europe) et les normes API (pour les applications pétrolières et gazières) sont essentielles pour les acheteurs B2B dans différentes régions.

Points de contrôle de la qualité

Le contrôle de la qualité (CQ) est généralement divisé en trois points de contrôle principaux : Le contrôle de la qualité à l'arrivée (IQC), le contrôle de la qualité en cours de fabrication (IPQC) et le contrôle de la qualité finale (FQC).

-

CQI: Il s'agit d'inspecter les matières premières à leur arrivée afin de s'assurer qu'elles répondent aux normes de qualité spécifiées. Toute matière non conforme est rejetée ou mise en quarantaine.

-

IPQC: Au cours de la fabrication, les processus sont contrôlés afin de garantir la cohérence et le respect des spécifications. Il peut s'agir d'échantillonner et de tester régulièrement les dimensions des tuyaux, les pressions nominales et les propriétés des matériaux.

-

FQC: L'étape de l'inspection finale consiste à vérifier que les produits finis ne présentent pas de défauts et qu'ils sont conformes à toutes les normes réglementaires. Il s'agit notamment de tester la résistance à la pression, la résistance aux chocs et la fissuration sous contrainte due à l'environnement.

Quelles sont les méthodes d'essai couramment utilisées pour l'assurance qualité des tubes PEHD ?

Plusieurs méthodes d'essai sont utilisées pour garantir la qualité et les performances des tuyaux en PEHD :

-

Essais hydrostatiques: Cette méthode consiste à remplir la conduite d'eau et à la mettre sous pression pour vérifier l'étanchéité et l'intégrité de la structure.

-

Contrôle dimensionnel: Mesure du diamètre, de l'épaisseur de la paroi et de la longueur des tuyaux pour s'assurer qu'ils sont conformes aux tolérances spécifiées.

-

Essai de résistance à la fissuration sous contrainte dans l'environnement (ESCR): Il s'agit d'évaluer la capacité du tuyau à résister aux facteurs environnementaux susceptibles de provoquer des fissures au fil du temps.

-

Tests d'impact: L'évaluation de la capacité du tube à résister à des impacts soudains, ce qui est crucial pour les applications dans des environnements difficiles.

Comment les acheteurs B2B peuvent-ils vérifier les processus de contrôle de la qualité des fournisseurs ?

Pour les acheteurs internationaux B2B, en particulier dans des régions comme l'Afrique, l'Amérique du Sud, le Moyen-Orient et l'Europe, il est essentiel de vérifier les processus de contrôle de la qualité d'un fournisseur pour garantir la fiabilité des produits. Voici les mesures que les acheteurs peuvent prendre :

Image d'illustration relative au tuyau PEHD

-

Audits des fournisseurs: Les audits sur place des fournisseurs potentiels permettent aux acheteurs d'évaluer directement les capacités de fabrication, les processus de contrôle qualité et la conformité aux normes internationales.

-

Demande de documentation sur l'assurance de la qualité: Les acheteurs doivent demander des documents décrivant les processus d'assurance qualité du fournisseur, y compris les certifications, les rapports d'inspection et les résultats des tests. Cela permet de vérifier le respect de normes telles que la norme ISO 9001 et d'autres.

-

Inspections par des tiers: Le recours à des services d'inspection par des tiers indépendants peut fournir une évaluation impartiale des produits et des processus du fournisseur, ajoutant ainsi une couche supplémentaire d'assurance.

-

Test d'échantillons: Demander des échantillons de tubes PEHD pour des tests indépendants peut aider les acheteurs à confirmer que les produits répondent aux normes de performance et de qualité spécifiées avant d'effectuer des achats en gros.

Quelles sont les particularités du contrôle de la qualité pour les acheteurs internationaux B2B ?

Lorsqu'ils s'approvisionnent en tubes PEHD au niveau international, les acheteurs doivent être conscients de certaines nuances dans le contrôle de la qualité qui peuvent affecter leurs décisions d'achat :

-

Comprendre les normes régionales: Les réglementations relatives à la qualité et aux spécifications des tubes PEHD peuvent varier d'un pays à l'autre. Les acheteurs doivent se familiariser avec les normes locales de leurs marchés cibles pour s'assurer de leur conformité.

-

Barrières culturelles et linguistiques: Des problèmes de communication peuvent survenir lorsque l'on traite avec des fournisseurs de différentes régions. Il est essentiel d'établir des attentes claires en ce qui concerne les normes de qualité et les processus d'inspection.

-

Considérations logistiques: Les conditions de transport et de stockage peuvent avoir un impact sur la qualité des tubes PEHD. Les acheteurs doivent discuter de ces aspects avec les fournisseurs pour s'assurer que les produits restent dans des conditions optimales tout au long de la chaîne d'approvisionnement.

En conclusion, la compréhension des processus de fabrication et des protocoles d'assurance qualité pour les tubes HDPE est cruciale pour les acheteurs B2B. En se concentrant sur ces éléments, les entreprises peuvent s'assurer qu'elles se procurent des produits fiables qui répondent à leurs besoins spécifiques tout en adhérant aux normes internationales.

Guide pratique d'approvisionnement : Liste de contrôle étape par étape pour "Tube PEHD" (HDPE Pipe)

Dans le paysage concurrentiel des achats interentreprises, l'acquisition de tuyaux en polyéthylène haute densité (PEHD) nécessite une approche structurée pour garantir la qualité, la conformité et la rentabilité. Ce guide présente une liste de contrôle étape par étape conçue pour rationaliser le processus d'approvisionnement des acheteurs dans différentes régions, notamment en Afrique, en Amérique du Sud, au Moyen-Orient et en Europe.

Image d'illustration relative au tuyau PEHD

Étape 1 : Définir les spécifications techniques

Avant d'entamer le processus d'approvisionnement, définissez clairement les spécifications techniques du tuyau PEHD dont vous avez besoin. Il s'agit notamment des dimensions, des pressions nominales et des applications prévues (par exemple, distribution d'eau, gazoducs). Des spécifications précises vous aideront à communiquer vos exigences aux fournisseurs potentiels et vous permettront de recevoir des produits qui répondent à vos besoins opérationnels.

Étape 2 : Recherche et identification de fournisseurs fiables

Effectuer des recherches approfondies pour identifier les fournisseurs potentiels spécialisés dans les tuyaux PEHD. Utilisez les répertoires de l'industrie, les salons professionnels et les plateformes en ligne pour dresser une liste de candidats. Concentrez-vous sur les fournisseurs jouissant d'une solide réputation sur votre marché cible et sur ceux qui ont démontré leur expérience dans votre domaine d'application spécifique.

Étape 3 : Évaluer les fournisseurs potentiels

Avant de s'engager avec un fournisseur, il est essentiel de le passer au crible. Demandez des profils d'entreprise, des études de cas et des références d'acheteurs d'un secteur ou d'une région similaire. Soyez attentif à ses capacités de production, à ses processus d'assurance qualité et à ses délais de livraison pour vous assurer qu'ils correspondent à vos attentes.

Étape 4 : Vérifier les certifications des fournisseurs

Assurez-vous que les fournisseurs que vous avez sélectionnés détiennent les certifications nécessaires et respectent les normes internationales, telles que ISO 9001 ou ASTM. Ces certifications sont des indicateurs des systèmes de gestion de la qualité et de la fiabilité des produits. En outre, vérifiez la conformité aux réglementations locales de votre région, car cela peut avoir une incidence sur la réussite de votre projet.

Étape 5 : Demander des échantillons et effectuer des tests de qualité

Une fois les fournisseurs présélectionnés, demandez des échantillons de leurs tuyaux PEHD pour les inspecter. Effectuez des tests de qualité pour évaluer la durabilité, la flexibilité et la résistance des tuyaux aux facteurs environnementaux. Cette étape est essentielle pour confirmer que les produits répondent à vos spécifications et aux normes industrielles avant de passer une commande en gros.

Étape 6 : Négocier les conditions et les prix

Engagez des discussions sur les prix, les modalités de paiement et les calendriers de livraison. Assurez-vous de bien comprendre le coût total de possession, y compris les frais d'expédition, les droits de douane et les éventuels tarifs douaniers. Visez un accord mutuellement bénéfique qui permette une certaine souplesse pour les commandes futures, en particulier si vous prévoyez d'étendre vos activités.

Étape 7 : Établir un canal de communication clair

Enfin, établissez un canal de communication clair avec le fournisseur que vous avez choisi. Des mises à jour régulières sur l'état de la production, le suivi des expéditions et les problèmes éventuels peuvent améliorer considérablement le processus d'achat. L'établissement d'un protocole de communication fiable contribuera à bâtir un partenariat solide et à faciliter les transactions futures.

Image d'illustration relative au tuyau PEHD

En suivant cette liste de contrôle structurée, les acheteurs B2B peuvent garantir un processus d'approvisionnement en tubes PEHD plus efficace et plus efficient, ce qui se traduira en fin de compte par des projets réussis et une efficacité opérationnelle accrue.

Analyse complète des coûts et des prix pour l'approvisionnement en tubes PEHD

Comprendre la structure des coûts et la dynamique des prix de l'approvisionnement en tubes HDPE est crucial pour les acheteurs B2B internationaux, en particulier ceux qui opèrent sur des marchés divers tels que l'Afrique, l'Amérique du Sud, le Moyen-Orient et l'Europe. Cette analyse se penchera sur les différentes composantes des coûts, les facteurs influençant les prix et les conseils pratiques permettant aux acheteurs d'optimiser leur processus d'approvisionnement.

Quels sont les principaux éléments de coût des tubes PEHD ?

-

Matériaux: Le principal facteur de coût est la matière première elle-même, le polyéthylène haute densité. Les prix peuvent fluctuer en fonction des cours mondiaux du pétrole, car le PEHD est un dérivé du pétrole. En outre, la qualité de la résine peut avoir un impact significatif sur les prix, les matériaux de qualité supérieure étant plus chers.

-

Travail: Les coûts de main-d'œuvre varient en fonction de la région et des pratiques de fabrication. Dans les pays où le coût de la main-d'œuvre est moins élevé, comme certains pays d'Afrique et d'Amérique du Sud, les fabricants peuvent être en mesure d'offrir des prix plus compétitifs. Cependant, la main-d'œuvre qualifiée pour l'assurance qualité et les processus de fusion des tuyaux peut augmenter les coûts.

-

Frais généraux de fabrication: Il s'agit des coûts associés au fonctionnement de l'usine, tels que les services publics, l'entretien et les dépenses administratives. Des processus de fabrication efficaces peuvent contribuer à minimiser ces frais généraux.

-

Outillage: Le coût des moules et des machines pour la production de tuyaux représente un investissement important. L'outillage sur mesure pour des dimensions ou des conceptions de tuyaux spécifiques peut entraîner des coûts initiaux plus élevés, mais les économies d'échelle peuvent réduire les coûts unitaires pour les commandes plus importantes.

-

Contrôle de la qualité (CQ): S'assurer que les tuyaux répondent aux normes et aux certifications de l'industrie engendre des coûts. Les acheteurs devraient s'adresser à des fournisseurs qui accordent la priorité au contrôle de qualité, car cela permet d'éviter des problèmes coûteux lors de l'installation et de l'exploitation.

-

Logistique: Les frais de transport peuvent varier considérablement en fonction de la distance entre le fournisseur et l'acheteur et de la méthode d'expédition choisie. Les acheteurs internationaux doivent également tenir compte des droits de douane et des taxes à l'importation, qui peuvent augmenter le coût total.

-

Marge: Les marges des fournisseurs dépendent de leurs coûts opérationnels, des conditions du marché et de la concurrence. La compréhension des marges habituelles sur le marché du PEHD peut faciliter la négociation.

Comment les facteurs d'influence des prix affectent-ils les coûts des tuyaux en PEHD ?

-

Volume et quantité minimale de commande (QMC): Des commandes plus importantes entraînent généralement des coûts unitaires moins élevés en raison des économies d'échelle. Les acheteurs doivent négocier les QMo pour s'aligner sur les besoins de leur projet sans encourir de coûts de stocks excédentaires.

-

Spécifications et personnalisation: Les spécifications personnalisées - telles que le diamètre, la pression nominale et la couleur - peuvent augmenter les coûts. Les produits standard ont tendance à être moins chers, les acheteurs doivent donc évaluer si la personnalisation est nécessaire pour leur application.

-

Qualité des matériaux et certifications: Les tuyaux qui répondent aux normes internationales (ISO, ASTM, etc.) sont souvent plus chers. Cependant, investir dans des produits certifiés peut se traduire par des économies à long terme en réduisant le risque de défaillance.

-

Facteurs liés au fournisseur: La réputation et la fiabilité du fournisseur peuvent avoir une incidence sur les prix. Les fournisseurs établis peuvent pratiquer des prix plus élevés en raison de leur qualité et de leur service éprouvés, tandis que les nouveaux venus peuvent proposer des prix plus bas pour gagner des parts de marché.

-

Incoterms: Il est essentiel pour les acheteurs internationaux de comprendre les conditions d'expédition et de livraison (par exemple, FOB, CIF). Les incoterms déterminent qui supporte les risques et les coûts aux différents stades du processus d'expédition, ce qui influe sur la tarification globale.

Quels conseils peuvent aider les acheteurs à négocier de meilleurs prix ?

-

Optimiser le coût total de possession (TCO): Lors des négociations, il ne faut pas seulement considérer le prix d'achat, mais aussi le coût total de possession, qui comprend les coûts de maintenance, d'efficacité opérationnelle et d'immobilisation potentielle. La présentation d'une analyse du coût total de possession peut justifier un prix initial plus élevé si les économies à long terme sont évidentes.

-

Négocier les conditions: Engagez des discussions avec les fournisseurs sur les conditions de paiement, les calendriers de livraison et les remises en cas de paiement anticipé ou de commandes groupées. La flexibilité dans ces domaines peut permettre de réaliser d'importantes économies.

-

Recherche sur les tendances du marché: Comprendre les conditions actuelles du marché peut donner plus de poids aux acheteurs lors des négociations. Le fait d'être informé des tendances des prix des matériaux, des fluctuations de la demande et des capacités des fournisseurs peut avoir un effet de levier.

-

Explorer plusieurs fournisseurs: Ne vous contentez pas du premier devis. L'obtention de plusieurs offres permet une meilleure comparaison et de meilleures possibilités de négociation. Cela permet également d'identifier les fournisseurs qui font preuve de souplesse en matière de prix et de conditions.

-

Envisager des fournisseurs locaux: Pour les acheteurs de régions telles que l'Afrique et l'Amérique du Sud, s'approvisionner auprès de fabricants locaux permet de réduire les frais d'expédition et les délais de livraison, ce qui peut constituer un avantage concurrentiel par rapport aux fournisseurs internationaux.

En conclusion, une compréhension approfondie de la structure des coûts, des facteurs d'influence et des stratégies de négociation permettra aux acheteurs B2B de prendre des décisions éclairées en matière d'approvisionnement en tubes PEHD. Gardez à l'esprit que les prix peuvent fluctuer en fonction des conditions du marché et qu'il est essentiel de se tenir au courant des tendances de l'industrie pour maximiser l'efficacité de l'approvisionnement.

Analyse des alternatives : Comparaison du tube PEHD avec d'autres solutions

Explorer les alternatives au tube PEHD : Une comparaison complète

Dans le domaine des solutions de tuyauterie, les tuyaux en polyéthylène haute densité (PEHD) sont réputés pour leur durabilité, leur flexibilité et leur résistance à la corrosion. Cependant, lorsque les acheteurs B2B évaluent leurs options, il est essentiel de prendre en compte les différentes alternatives susceptibles de mieux répondre aux exigences de projets spécifiques. Cette analyse compare les tuyaux en PEHD à deux autres solutions viables : Les tuyaux en PVC (chlorure de polyvinyle) et les tuyaux en PRV (plastique renforcé de verre), en se concentrant sur la performance, le coût, la facilité de mise en œuvre, la maintenance et les meilleurs cas d'utilisation.

| Aspect comparatif | Tube PEHD | Tuyau en PVC | Tube en PRV |

|---|---|---|---|

| Performance | Excellente flexibilité et durabilité | Bonne résistance chimique, rigide | Rapport résistance/poids élevé |

| Coût | Coût modéré ; le prix varie en fonction de la catégorie | Coût initial généralement moins élevé | Investissement initial plus élevé |

| Facilité de mise en œuvre | Modéré ; nécessite des outils spécialisés | Facile à manipuler et à installer | L'installation nécessite une main d'œuvre qualifiée |

| Maintenance | Peu d'entretien ; résistant à l'usure | Modéré ; peut devenir cassant avec le temps | Faible ; résistant à la corrosion |

| Meilleur cas d'utilisation | Approvisionnement en eau et applications industrielles | Plomberie et drainage résidentiels | Traitement chimique et systèmes à haute pression |

Quels sont les avantages et les inconvénients des tuyaux en PVC par rapport au PEHD ?

Le tuyau en PVC est une alternative populaire, en particulier pour les applications de plomberie résidentielles et commerciales. Son coût initial plus faible le rend intéressant pour les projets à budget serré. Le PVC est léger, ce qui facilite son transport et son installation, et il offre une bonne résistance à toute une série de produits chimiques. Cependant, le PVC peut se fragiliser avec le temps, notamment lorsqu'il est exposé au soleil ou à des températures extrêmes, ce qui peut entraîner des fissures ou des cassures. Si le PVC convient à de nombreuses applications, il n'est pas aussi performant que le PEHD dans les environnements où la flexibilité et la résistance aux chocs sont essentielles.

Comment les tuyaux en PRV se situent-ils par rapport au PEHD en termes de performance et de coût ?

Les tuyaux en plastique renforcé de verre (PRV) constituent une autre alternative, en particulier dans les scénarios nécessitant des matériaux légers et très résistants. Le PRV présente un rapport résistance/poids impressionnant, ce qui le rend idéal pour les applications à haute pression et les environnements où les matériaux traditionnels risquent d'échouer. Cependant, les tuyaux en PRV ont généralement un coût initial plus élevé que le PEHD et le PVC. L'installation peut également nécessiter des compétences spécialisées, ce qui peut augmenter le coût total du projet. Le PRV est très résistant à la corrosion et a une longue durée de vie, ce qui en fait un choix solide pour le traitement chimique et d'autres applications exigeantes.

Faire le bon choix : comment déterminer la meilleure solution de tuyauterie pour vos besoins

Lors de la sélection de la bonne solution de tuyauterie, les acheteurs B2B doivent prendre en compte plusieurs facteurs, notamment l'application spécifique, les contraintes budgétaires et les exigences de performance à long terme. Les tuyaux en PEHD excellent dans les applications exigeant flexibilité et résistance aux contraintes environnementales, tandis que le PVC est souvent privilégié pour son rapport coût-efficacité et sa facilité d'installation dans les environnements résidentiels. Les tuyaux en PRV peuvent être le meilleur choix pour les systèmes à haute pression ou les environnements corrosifs, malgré leur coût plus élevé. En fin de compte, la décision doit être guidée par une évaluation approfondie des besoins du projet, en veillant à ce que la solution de tuyauterie choisie corresponde à la fois aux exigences immédiates et aux objectifs opérationnels à long terme.

Propriétés techniques essentielles et terminologie commerciale pour les tubes PEHD

Quelles sont les principales propriétés techniques du tube PEHD ?

Les tuyaux en polyéthylène haute densité (PEHD) sont essentiels dans diverses applications, notamment l'approvisionnement en eau, les eaux usées et les processus industriels. La compréhension des propriétés essentielles des tuyaux en PEHD peut influencer de manière significative les décisions d'achat et les résultats des projets.

-

Qualité des matériaux: Les tuyaux en PEHD sont classés en fonction de leur qualité de matériau, communément définie par des normes telles que la norme ASTM D3350. Les qualités les plus courantes sont le PE4710 et le PE100. Le grade a un impact sur la solidité, la durabilité et la résistance du tuyau aux facteurs environnementaux. Pour les acheteurs B2B, le choix du grade de matériau approprié garantit que le tuyau peut résister aux pressions et températures spécifiques de l'application envisagée.

-

Pression nominale (PSI): La pression nominale indique la pression interne maximale que le tuyau peut supporter en toute sécurité. Les indices les plus courants sont 160 PSI et 200 PSI. Un indice de pression plus élevé indique une plus grande résistance et une meilleure adéquation aux applications exigeantes, ce qui en fait un facteur essentiel pour déterminer l'adéquation du tuyau à un projet donné.

-

Diamètre et épaisseur de la paroi: Les tuyaux en PEHD sont disponibles en différents diamètres et épaisseurs de paroi, généralement mesurés en pouces. Le diamètre extérieur (OD) et le diamètre intérieur (ID) sont essentiels pour la compatibilité avec les raccords et les connexions. L'épaisseur de la paroi influe également sur la pression nominale et la résistance globale du tuyau. Les acheteurs doivent tenir compte de ces spécifications pour garantir une installation et une fonctionnalité correctes au sein de l'infrastructure existante.

-

Résistance aux produits chimiques et à la corrosion: Le PEHD présente une excellente résistance à une large gamme de produits chimiques, ce qui le rend adapté au transport de divers fluides, notamment l'eau potable et les produits chimiques industriels. Cette propriété est essentielle pour les acheteurs dans des secteurs tels que l'agriculture, l'exploitation minière et la construction, où les substances transportées peuvent être corrosives ou dangereuses.

-

Tolérance de température: Les tuyaux en PEHD fonctionnent généralement dans une plage de température comprise entre -40°F et 140°F (-40°C et 60°C). La compréhension de la tolérance à la température est essentielle pour les applications susceptibles de subir des conditions extrêmes, afin de garantir la longévité et la fiabilité du système de tuyauterie.

Quels sont les termes commerciaux courants relatifs au tube PEHD ?

La connaissance de la terminologie commerciale est essentielle pour une communication et une négociation efficaces dans les transactions interentreprises liées aux tuyaux en PEHD.

-

OEM (Original Equipment Manufacturer): Ce terme désigne les entreprises qui produisent des pièces ou des équipements susceptibles d'être commercialisés par un autre fabricant. Dans le contexte des tuyaux en PEHD, les OEM peuvent fournir des tuyaux conçus spécifiquement pour être intégrés dans des systèmes plus importants. Les acheteurs doivent tenir compte des spécifications des OEM pour s'assurer de la compatibilité.

-

MOQ (Minimum Order Quantity): Ce terme définit le plus petit nombre d'unités qu'un fournisseur est prêt à vendre. Il est essentiel de comprendre le MOQ pour la planification du budget et la gestion des stocks, en particulier pour les projets de grande envergure qui nécessitent des quantités importantes de tuyaux en PEHD.

-

RFQ (Request for Quotation): Un appel d'offres est un document formel que les acheteurs utilisent pour solliciter des offres de prix auprès des fournisseurs pour des produits ou services spécifiques. Sur le marché des tuyaux en PEHD, la soumission d'un appel d'offres aide les acheteurs à obtenir des prix et des conditions compétitifs, ce qui leur permet de prendre des décisions d'achat en toute connaissance de cause.

-

Incoterms (termes commerciaux internationaux): Il s'agit de règles internationalement reconnues qui définissent les responsabilités des acheteurs et des vendeurs dans les transactions internationales. La connaissance des Incoterms peut aider les acheteurs à comprendre les coûts d'expédition, les risques et les responsabilités, ce qui est crucial pour l'importation transfrontalière de tuyaux en PEHD.

-

SDR (Standard Dimension Ratio): Le DTS est une mesure du rapport entre le diamètre du tube et l'épaisseur de sa paroi. Elle est essentielle pour déterminer la pression nominale et l'adéquation de l'application des tuyaux PEHD. Les acheteurs doivent évaluer le DTS lorsqu'ils choisissent des tuyaux pour des projets spécifiques afin de s'assurer qu'ils répondent aux exigences opérationnelles.

En comprenant ces propriétés techniques et ces termes commerciaux, les acheteurs B2B peuvent prendre des décisions éclairées qui s'alignent sur les besoins de leurs projets et leurs stratégies d'approvisionnement, ce qui aboutit finalement à des résultats positifs dans leurs projets de tuyaux en PEHD.

Naviguer dans la dynamique du marché et les tendances en matière d'approvisionnement dans le secteur des tuyaux en PEHD

Quelles sont les principales dynamiques et tendances du marché qui ont un impact sur le secteur des tubes PEHD ?

Le marché des tuyaux en PEHD connaît une croissance substantielle, stimulée par la demande croissante de solutions de tuyauterie durables et résistantes à la corrosion dans divers secteurs tels que l'approvisionnement en eau, l'irrigation et la gestion des eaux usées. Au niveau mondial, l'évolution vers le développement d'infrastructures, en particulier dans les marchés émergents d'Afrique, d'Amérique du Sud et du Moyen-Orient, stimule le besoin de tuyaux en PEHD. En outre, l'Europe se concentre sur le remplacement des infrastructures vieillissantes, ce qui crée des opportunités pour les fournisseurs de produits PEHD.

Les avancées technologiques façonnent également la dynamique du marché. L'intégration de l'automatisation et de l'analyse des données dans les processus de fabrication améliore l'efficacité et réduit les coûts de production. En outre, l'adoption de plateformes B2B en ligne pour le sourcing et l'approvisionnement permet aux acheteurs d'accéder plus facilement à une plus large gamme de produits PEHD, de comparer les prix et d'évaluer les fournisseurs. Les solutions de commerce électronique sont particulièrement importantes pour les acheteurs internationaux, car elles rationalisent le processus d'achat et facilitent les transactions transfrontalières.

Parmi les nouvelles tendances, on note une préférence croissante pour les solutions personnalisées, adaptées aux exigences spécifiques des projets. Les acheteurs recherchent des fournisseurs capables d'offrir des services spécialisés, tels que la fusion et la fabrication de tuyaux, qui répondent à des besoins d'installation uniques. Alors que la concurrence sur le marché s'intensifie, les fournisseurs qui mettent l'accent sur la qualité, l'innovation et le service à la clientèle sont susceptibles d'acquérir un avantage concurrentiel.

Comment la durabilité et l'approvisionnement éthique façonnent-ils l'industrie des tuyaux en PEHD ?

La durabilité devient une considération essentielle pour les acheteurs B2B dans le secteur des tuyaux en PEHD. L'impact environnemental des matières plastiques a conduit à un examen plus approfondi des pratiques de production et de l'approvisionnement en matériaux. Les entreprises privilégient désormais les fournisseurs qui s'engagent à réduire leur empreinte carbone et à utiliser des matériaux recyclés. Cette évolution répond non seulement aux exigences réglementaires, mais aussi à la demande croissante des consommateurs pour des produits respectueux de l'environnement.

L'approvisionnement éthique est tout aussi important, car les acheteurs cherchent à s'assurer que leurs chaînes d'approvisionnement sont exemptes de pratiques de travail contraires à l'éthique et d'atteintes à l'environnement. Les certifications telles que la norme ISO 14001 pour la gestion de l'environnement et l'utilisation de matériaux PEHD recyclés deviennent des critères essentiels pour les décisions d'achat. Les fournisseurs qui peuvent fournir des preuves de leurs pratiques et certifications en matière de développement durable ont plus de chances d'attirer les acheteurs internationaux qui accordent de l'importance à la transparence et à la responsabilité des entreprises.

En outre, la tendance croissante aux pratiques d'économie circulaire influence la conception des produits et les processus de fabrication. Les fabricants étudient les moyens de rendre les tuyaux PEHD plus recyclables et réutilisables, ce qui permet non seulement de réduire les déchets, mais aussi d'améliorer la proposition de valeur globale pour les acheteurs B2B.

Image d'illustration relative au tuyau PEHD

Quel est le contexte historique du développement des tubes PEHD ?

Le développement des tuyaux en PEHD remonte aux années 1950, lorsque ce matériau a été introduit pour la première fois en tant qu'alternative viable aux solutions de tuyauterie traditionnelles. D'abord utilisé pour la distribution de gaz, le PEHD, de par sa légèreté et sa durabilité, a rapidement été adopté pour diverses applications, notamment pour l'approvisionnement en eau et les systèmes d'égouts. Au fil des décennies, les progrès des techniques de fabrication et de la science des matériaux ont amélioré les caractéristiques de performance des tuyaux en PEHD, les rendant de plus en plus populaires dans de nombreux secteurs.

À la fin du 20e siècle, le développement des infrastructures s'est intensifié à l'échelle mondiale, ce qui a entraîné une forte augmentation de la demande de tuyaux en PEHD. Leur capacité à résister aux conditions environnementales difficiles et à la corrosion en a fait un choix privilégié pour de nombreux projets de construction. Aujourd'hui, l'industrie des tuyaux en PEHD continue d'évoluer, sous l'impulsion de l'innovation technologique et de l'importance croissante accordée à la durabilité et à l'approvisionnement éthique. Cette évolution reflète la capacité d'adaptation de l'industrie aux besoins changeants du marché et aux considérations environnementales, ce qui garantit sa pertinence dans le paysage moderne de la construction.

Foire aux questions (FAQ) pour les acheteurs B2B de tuyaux en PEHD

-

1. Comment puis-je m'assurer de la qualité des tubes PEHD avant de les acheter ?

Pour garantir la qualité, demandez des échantillons aux fournisseurs potentiels et examinez les certifications telles que ISO, ASTM ou d'autres normes pertinentes. Effectuez des inspections sur place si possible, ou faites appel à des services d'assurance qualité tiers pour vérifier les processus de fabrication et l'intégrité des matériaux. En outre, renseignez-vous sur les antécédents du fournisseur et les commentaires des clients pour évaluer sa fiabilité et ses pratiques en matière de contrôle de la qualité. -

2. Quelles sont les principales spécifications à prendre en compte lors de l'approvisionnement en tubes PEHD ?

Les principales spécifications comprennent le diamètre du tuyau, la pression nominale (par exemple, SDR, DR) et l'application prévue (par exemple, eau potable, eaux usées ou distribution de gaz). En outre, il convient d'évaluer la qualité du matériau (par exemple, PE100, PE80) et la conformité aux réglementations locales. La compréhension de ces spécifications permet de s'assurer que les tuyaux PEHD répondent aux exigences et aux performances attendues de votre projet. -

3. Quel est le délai de livraison habituel pour les commandes de tuyaux en PEHD ?

Les délais de livraison peuvent varier considérablement en fonction de facteurs tels que la taille de la commande, les exigences de personnalisation et la localisation du fournisseur. En général, les commandes standard peuvent prendre de 2 à 4 semaines, tandis que les commandes personnalisées peuvent prendre plus de temps, jusqu'à 8 semaines ou plus. Confirmez toujours les délais de livraison avec les fournisseurs et tenez compte des retards potentiels dans la logistique, en particulier pour les envois internationaux. -

4. Comment puis-je négocier des conditions de paiement favorables avec mes fournisseurs ?

Pour négocier des conditions de paiement favorables, établissez une relation solide avec vos fournisseurs en démontrant votre fiabilité en tant qu'acheteur. Discutez d'options telles que le paiement à la livraison, les lettres de crédit ou les paiements échelonnés. Le fait de proposer un volume de commande plus important ou un contrat à long terme peut également inciter les fournisseurs à offrir de meilleures conditions. Veillez à ce que toutes les conditions soient clairement consignées dans le contrat d'achat afin d'éviter tout malentendu. -

5. Quelles sont les quantités minimales de commande (QMC) pour les tuyaux en PEHD ?

Les quantités minimales de commande peuvent varier selon le fournisseur et le type de produit. En général, les quantités minimales de commande pour les tuyaux en PEHD vont de 500 à 1 000 mètres ou plus, en fonction du diamètre du tuyau et des spécifications. Il est conseillé de discuter de vos besoins directement avec les fournisseurs, car ils peuvent être disposés à accepter des commandes plus petites, en particulier pour les clients réguliers ou les grands projets. -

6. Comment puis-je contrôler efficacement les fournisseurs lorsque je m'approvisionne en tubes PEHD au niveau international ?

Commencez par effectuer des recherches approfondies sur les fournisseurs potentiels, notamment sur leur historique, leurs certifications et les commentaires de leurs clients. Utilisez des plateformes telles que LinkedIn pour entrer en contact avec des professionnels du secteur et recueillir des informations. Demandez des références à d'anciens clients et envisagez d'organiser des visites sur place ou des réunions virtuelles pour évaluer leurs activités. Vérifiez qu'ils respectent les normes de qualité internationales pour vous assurer de leur fiabilité. -

7. Quelles sont les considérations logistiques à prendre en compte lors de l'importation de tubes PEHD ?

Lorsque vous importez des tuyaux en PEHD, tenez compte de facteurs tels que les méthodes de transport (aérien ou maritime), les réglementations douanières et les droits de douane potentiels. Collaborez avec un transitaire fiable qui comprend les nuances de l'expédition internationale. En outre, tenez compte des délais de dédouanement et de transport local pour vous assurer que les délais de votre projet restent intacts. -

8. Existe-t-il des options de personnalisation pour les tubes PEHD ?

Oui, de nombreux fournisseurs proposent des options de personnalisation telles que des longueurs, des diamètres et des pressions nominales spécifiques adaptés aux besoins de votre projet. En outre, vous pouvez demander des couleurs, des marquages ou des raccords spécifiques pour répondre aux exigences de votre système. Discutez de vos besoins de personnalisation avec les fournisseurs dès le début du processus d'approvisionnement pour vous assurer qu'ils peuvent répondre efficacement à vos spécifications.

Liste des 4 meilleurs fabricants et fournisseurs de tubes Hdpe

1. Fourniture de PEHD - Tuyau de fusion en polyéthylène

Domaine : hdpesupply.com

Enregistré : 2009 (16 ans)

Introduction : Tuyau de fusion en polyéthylène - Tuyau en polyéthylène HDPE noir

2. JMEagle - Advanced Pipe Solutions

Domaine : jmeagle.com

Enregistré : 2007 (18 ans)

Introduction : Application : Convient aux systèmes de transmission municipaux et industriels pour l'eau potable, les égouts, les drains, l'exploitation minière, l'irrigation et l'eau recyclée. Avantages : Excellentes performances et longue durée de vie, taux de fuite nul grâce aux joints soudés bout à bout, grande résistance à la corrosion et aux intempéries, durée de vie prévue d'au moins 100 ans, légèreté et souplesse pour une installation facile, convient aux tremblements de terre...

3. Clôture PowerFlex - Tuyaux d'eau en PEHD

Domaine : powerflexfence.com

Enregistré : 2006 (19 ans)

Introduction : Tuyau d'eau HDPE - Tuyau en polyéthylène haute densité

- Fabriqué aux États-Unis

- Homologué NSF-61 pour l'eau potable

- Disponible en bobines et en rouleaux

- Dimensionnement flexible : 1″ à 4″ IPS - SDR 11 en bobine ou en rouleau de longueurs variables ; des tailles plus importantes sont disponibles sur demande dans le cadre de commandes en vrac.

- Convient à la distribution d'eau pour le bétail, l'eau potable, la géothermie, l'eau de récupération, l'eau d'admission, l'eau brute et les eaux usées ...

4. ISCO - Tubes et raccords en PEHD

Domaine : isco-pipe.com

Enregistré : 1995 (30 ans)

Introduction : ISCO propose une gamme complète de produits et de services en polyéthylène haute densité (PEHD) :

1. **Tuyau PEHD** : Disponible en grands diamètres jusqu'à 136 ou 157 pouces, conçu pour diverses applications.

2. **Raccords** : Le plus grand distributeur, fabricant et constructeur de raccords PEHD en Amérique du Nord, construits pour satisfaire ou dépasser les normes ASTM.

3. **PEHD haute température** : PlatinumStripe® PE-...

Conclusion et perspectives en matière d'approvisionnement stratégique pour les tubes en PEHD

En conclusion, l'approvisionnement stratégique en tuyaux PEHD présente des opportunités significatives pour les acheteurs B2B internationaux, en particulier sur les marchés émergents tels que l'Afrique, l'Amérique du Sud, le Moyen-Orient et les régions établies telles que l'Europe. Les avantages des tuyaux en PEHD, notamment leur durabilité, leur résistance à la corrosion et leur facilité d'installation, en font un choix idéal pour diverses applications, des systèmes d'eau potable aux utilisations industrielles. En s'appuyant sur des pratiques d'approvisionnement stratégiques, les entreprises peuvent garantir un approvisionnement régulier en produits de haute qualité tout en optimisant les coûts et en favorisant des relations à long terme avec les fournisseurs.

Image d'illustration relative au tuyau PEHD

Alors que la demande de solutions d'infrastructures durables continue d'augmenter au niveau mondial, il est crucial de rester à l'avant-garde des tendances du marché et d'investir dans des fournisseurs fiables. Les entreprises devraient privilégier les fournisseurs qui respectent les normes de qualité internationales et proposent des solutions innovantes adaptées aux besoins locaux.

Pour l'avenir, nous encourageons les acheteurs internationaux à s'engager activement auprès des fournisseurs et à explorer les possibilités de collaboration. En se concentrant sur l'approvisionnement stratégique, les entreprises peuvent améliorer leur efficacité opérationnelle, réduire les risques et contribuer au développement durable dans leurs régions respectives. L'avenir de l'approvisionnement en tubes PEHD est prometteur, et il est temps d'en tirer parti.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Important Disclaimer

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.