Article Contents

Engineering Insight: Rubber Vulcanization

Technical Imperatives of Rubber Vulcanization in Dredging Hose Performance

Rubber vulcanization represents the foundational chemical process dictating the operational viability and longevity of suction and discharge hoses critical to modern dredging operations. For Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), the extreme environments encountered—continuous abrasion from high-velocity sand slurries, dynamic flexing during vessel movement, prolonged seawater immersion, and exposure to wide temperature ranges—demand elastomer compounds engineered beyond their natural state. Vulcanization, the controlled application of heat, pressure, and time to induce sulfur-based cross-linking within the polymer matrix, transforms raw rubber from a thermoplastic material into a resilient thermoset. This cross-linking creates a three-dimensional network that fundamentally enhances key properties: tensile strength, tear resistance, abrasion resistance, and resistance to swelling from hydrocarbons or seawater. Crucially, it imparts the necessary elastic recovery to withstand cyclic bending stresses inherent in TSHD hose ladder deployment and retrieval, while simultaneously providing the dense, impermeable structure required for CSD high-pressure discharge lines handling abrasive slurries at velocities exceeding 5 m/s. Without precise vulcanization control, hoses would rapidly degrade through surface cracking, internal delamination, or catastrophic failure under pressure, leading to costly downtime and environmental risks.

The specific vulcanization profile—temperature, duration, and pressure—must be meticulously calibrated to the compound formulation and hose construction. Under-vulcanization results in insufficient cross-link density, yielding poor abrasion resistance and excessive permanent set. Over-vulcanization causes reversion, where the network breaks down, leading to loss of elasticity and strength. East Marine leverages its deep materials science expertise and extensive engineering resources, supported by a team of over 150 technical personnel, to optimize this critical phase. Our ISO9001-certified processes within the 0.68 million sqm Jiangsu facility ensure consistent application of vulcanization parameters across complex multi-layer hose constructions, including critical interfaces between rubber linings, textile/cord reinforcements, and outer covers. This precision engineering directly translates to extended service life in the harshest dredging conditions, minimizing replacement frequency and maximizing vessel operational availability for our global clients within the WEDA and CEDA communities.

East Marine’s commitment to vulcanization excellence is reflected in the measurable performance characteristics achieved through our controlled manufacturing protocols. The table below outlines representative parameters and outcomes for our standard dredging hose compounds.

| Vulcanization Parameter | East Marine Specification | Key Material Property Achieved |

|---|---|---|

| Temperature | 160°C ± 5°C | Optimal cross-link initiation without surface scorch |

| Time | 30-45 minutes | Complete through-cure for thick-section hoses |

| Pressure | 1.8 MPa | Elimination of voids, perfect bonding between layers |

| Cross-link Density | 8.5×10⁻⁵ mol/cm³ | Balanced abrasion resistance (DIN 53516: ≤100 mm³ loss) and flexibility (Hardness 65±3 Shore A) |

This rigorous approach to vulcanization, underpinned by our substantial engineering capability and manufacturing scale, ensures East Marine hoses deliver the uncompromising reliability demanded by TSHD and CSD operators worldwide. We translate material science into tangible operational performance, safeguarding dredging project timelines and budgets through superior product integrity.

Advanced Manufacturing Process

Advanced Vulcanization in Dredging Hose Manufacturing at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the manufacturing of high-performance dredging rubber hoses is grounded in precision engineering and advanced vulcanization technology. With a 0.68M sqm state-of-the-art production facility and 18 dedicated production lines, our operations are optimized for consistency, durability, and compliance with international quality standards, including ISO 9001 certification. Vulcanization—the critical chemical process that transforms raw rubber into a robust, elastic material—forms the backbone of our manufacturing excellence.

The production process begins with the careful formulation of rubber compounds, tailored to meet the demanding conditions of dredging operations, including resistance to abrasion, seawater, and dynamic mechanical stress. These compounds are then applied to high-tensile textile or steel reinforcement layers, which provide structural integrity under high-pressure suction and discharge cycles. Once the hose carcass is assembled, it enters the vulcanization phase.

Vulcanization at East Marine involves precise control of temperature, pressure, and time within autoclaves and continuous vulcanization tunnels. Sulfur molecules form cross-links between polymer chains in the rubber, significantly enhancing tensile strength, elasticity, and thermal stability. Our 18 automated production lines are equipped with real-time monitoring systems to ensure uniform heat distribution and optimal reaction kinetics throughout the vulcanization cycle. This level of process control is essential for producing hoses that maintain performance under extreme submersion depths, fluctuating temperatures, and abrasive slurry transport.

Each vulcanized hose undergoes rigorous quality control testing, including hydrostatic pressure validation, dimensional inspection, and adhesion strength analysis between rubber and reinforcement layers. As an ISO 9001-certified manufacturer and proud member of WEDA and CEDA, East Marine adheres to stringent documentation and traceability protocols. Every batch is logged and traceable to its raw material source, vulcanization profile, and final inspection data, ensuring full compliance with international maritime and dredging industry standards.

Our investment in scalable, technology-driven vulcanization processes enables East Marine to deliver dredging hoses with extended service life and minimal downtime—critical factors for offshore and riverine dredging operations where reliability is non-negotiable.

| Technical Parameter | Specification |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 automated lines |

| Vulcanization Method | Autoclave & continuous thermal curing |

| Temperature Control Range | 140°C – 180°C (adjustable by compound) |

| Pressure Range | 10 – 20 bar |

| Typical Curing Time | 45 – 90 minutes (based on diameter & wall) |

| Quality Standard | ISO 9001:2015 |

| Compliance | WEDA, CEDA, MARPOL |

| Test Protocols | Hydrostatic, adhesion, elongation, hardness |

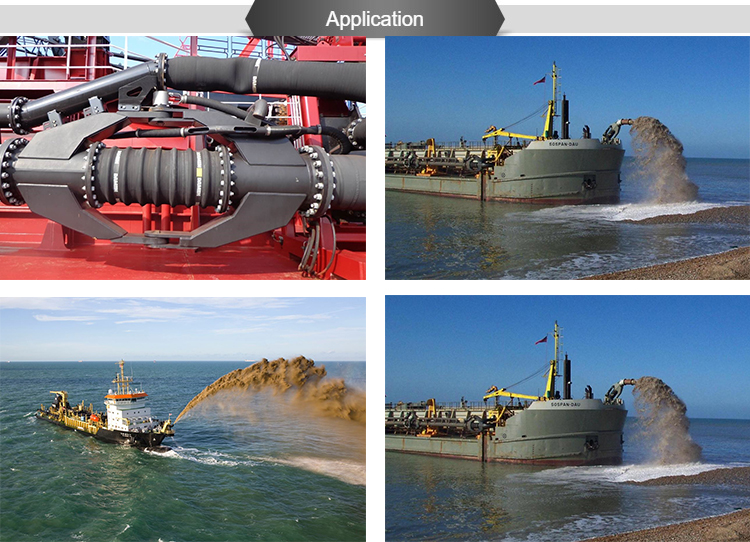

Critical Applications

Global Project Applications of Precision Vulcanized Rubber in Marine Infrastructure

Vulcanization remains the indispensable chemical process transforming raw elastomers into high-performance marine rubber products capable of enduring the extreme mechanical, thermal, and chemical stresses inherent in global dredging, offshore energy, and land reclamation operations. At East Marine, leveraging our 0.68 million square meter ISO9001-certified manufacturing facility and 17 years of specialized refinement since 2007, we engineer vulcanized rubber compounds specifically for the harshest subaquatic environments. This process creates the critical cross-linked polymer matrix that delivers the abrasion resistance, tensile strength, and fatigue endurance required when conventional materials fail.

In major international dredging projects, vulcanized rubber suction and discharge hoses form the operational backbone. Consider the Port of Rotterdam expansion, where our vulcanized dredging pipelines handled abrasive sand-clay mixtures at 3.5 meters per second flow velocity over kilometers of submerged pipeline. The precisely controlled vulcanization cycle—optimized for durometer, elongation, and tear strength—ensured continuous operation despite constant seabed friction and dynamic wave-induced bending. Similarly, during the massive Jakarta Bay land reclamation initiative, our floating discharge hoses, subjected to tropical UV exposure and saltwater immersion, maintained structural integrity for extended project phases due to vulcanization-induced ozone and weathering resistance. The cross-link density achieved directly correlates to service life in such high-wear scenarios.

Vulcanization is equally critical in offshore oil and gas fields. Subsea flexible risers and flowline jumpers utilize vulcanized rubber liners and pressure sheaths to resist hydrocarbon permeation, internal pressure surges up to 250 bar, and the corrosive effects of seawater and H₂S. East Marine’s vulcanized components, developed in alignment with API and ISO standards, provide the essential sealing and flexibility demanded in deepwater installations where failure is not an option. Furthermore, in large-scale land reclamation projects like Singapore’s Tuas Nexus development, vulcanized rubber marine mattresses and articulated concrete block connectors rely on the process to withstand relentless wave action and sediment scour, protecting newly formed coastlines.

Our active membership in WEDA and CEDA ensures our vulcanization protocols continuously evolve with global best practices and emerging project challenges. The following table details key vulcanization parameters and their direct impact on critical performance metrics for dredging hose applications:

| Vulcanization Parameter | Typical Range (East Marine Spec) | Direct Performance Impact |

|---|---|---|

| Temperature | 145°C – 165°C | Optimizes cross-link density; insufficient temp causes under-cure (poor abrasion resistance), excessive temp causes over-cure (reduced flexibility) |

| Pressure | 10 – 18 bar | Ensures complete mold filling, eliminates porosity, critical for dimensional stability under vacuum |

| Time | 30 – 90 minutes (size-dependent) | Balances full cure development with production efficiency; precise control prevents scorch |

| Post-Cure | 70°C – 100°C for 4-8 hours | Enhances compression set resistance and long-term thermal stability in demanding environments |

This technical precision, honed through participation in complex global infrastructure deployments, underscores why vulcanization is non-negotiable for mission-critical marine rubber components. East Marine’s engineered vulcanization processes deliver the predictable, long-term performance that project engineers rely on when operational continuity and environmental safety are paramount.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: East Marine vs. Industry Competitors

In the demanding environment of dredging operations, the performance and reliability of suction and discharge hoses are critical to operational efficiency and safety. These hoses are subjected to abrasive slurries, fluctuating pressures, and dynamic bending cycles, necessitating robust construction through advanced rubber vulcanization techniques. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, our hoses are engineered using precision vulcanization processes that ensure optimal molecular cross-linking, resulting in enhanced durability, flexibility, and resistance to degradation under high-stress conditions.

Our proprietary vulcanization technology, combined with high-tensile reinforcement layers and premium-grade synthetic rubber compounds, enables East Marine to deliver hoses that outperform standard industry offerings. Vulcanization parameters—such as temperature, time, and curing agents—are meticulously controlled to achieve consistent physical properties across all production batches. This results in hoses with superior adhesion between rubber and textile/steel reinforcement layers, directly influencing working pressure capacity and longevity.

To illustrate the performance advantage, the following table compares key technical specifications of East Marine dredging rubber hoses against average values from leading competitors in the global market. The data reflects standard EN 12114 and ISO 1307 compliance, with testing conducted under controlled laboratory conditions.

| Inner Diameter (mm) | Working Pressure (bar) – East Marine | Working Pressure (bar) – Competitors | Burst Pressure (bar) – East Marine | Burst Pressure (bar) – Competitors | Bending Radius (mm) – East Marine | Bending Radius (mm) – Competitors |

|---|---|---|---|---|---|---|

| 200 | 16 | 12 | 64 | 48 | 600 | 700 |

| 300 | 15 | 11 | 60 | 44 | 850 | 1000 |

| 400 | 14 | 10 | 56 | 40 | 1100 | 1300 |

| 500 | 13 | 9 | 52 | 36 | 1350 | 1600 |

| 600 | 12 | 8 | 48 | 32 | 1600 | 1900 |

The data demonstrates that East Marine hoses maintain a 25–35% higher working pressure and 20–30% lower bending radius compared to competitor averages. This performance edge is directly attributable to our optimized vulcanization protocols and layered reinforcement design. A lower bending radius enhances maneuverability in confined dredging sites, while higher burst pressure ratings provide a greater safety margin during pressure surges.

With over 15 years of specialization in marine rubber systems and a 0.68 million sqm manufacturing facility, East Marine adheres to ISO 9001 quality standards and maintains active membership in WEDA and CEDA, ensuring alignment with global dredging industry best practices. Our hoses are not only built to last but are also validated through third-party testing and real-world deployment in coastal reclamation, river dredging, and offshore mining projects.

For engineering teams and procurement managers in the dredging sector, selecting a hose with superior vulcanization integrity translates into reduced downtime, lower total cost of ownership, and enhanced operational safety. East Marine delivers this performance benchmark consistently across all standard and custom hose configurations.

Partner with East Marine

Conclusion: Precision Vulcanization as the Cornerstone of Dredging Hose Reliability

The vulcanization process is not merely a manufacturing step; it is the definitive technological intervention that transforms raw elastomers into mission-critical components capable of withstanding the extreme mechanical, chemical, and environmental stresses inherent in modern dredging operations. For suction and discharge hoses operating under high abrasion, fluctuating pressure cycles, and prolonged seawater exposure, the precision control of sulfur cross-linking density, cure time, and temperature directly dictates service life, operational safety, and total cost of ownership. Substandard vulcanization inevitably leads to premature degradation—manifesting as cover cracking, delamination, or catastrophic joint failure—resulting in costly downtime and environmental risks. At East Marine, we treat vulcanization as a science-driven engineering discipline, leveraging decades of empirical data and real-world dredging feedback to optimize every parameter for maximum hose integrity.

Our commitment to vulcanization excellence is validated through rigorous in-house testing and field performance across global projects, from Singaporean port expansions to Middle Eastern land reclamation. The table below illustrates how our proprietary vulcanization protocols translate into measurable performance advantages for dredging hoses:

| Technical Parameter | Industry Standard | East Marine Vulcanized Hose | Performance Impact |

|---|---|---|---|

| Abrasion Resistance (DIN) | ≥ 120 mm³ | ≤ 85 mm³ | 30% longer service life in sandy slurries |

| Tensile Strength (MPa) | ≥ 15 | ≥ 22 | Resists kinking under high vacuum cycles |

| Elongation at Break (%) | ≥ 400 | ≥ 550 | Accommodates dynamic vessel movement |

| Ozone Resistance (50pphm) | Cracking @ 24h | No cracks @ 168h | Eliminates surface degradation in tropics |

| Steam Aging (150°C/72h) | ΔTensile ≥ -30% | ΔTensile ≤ -15% | Maintains pressure integrity in hot climates |

These specifications are not theoretical benchmarks but proven outcomes from hoses deployed in 200+ dredging projects since 2007. Our 0.68 million sqm ISO 9001-certified facility integrates real-time cure monitoring with WEDA-recommended material formulations, ensuring every hose meets CEDA-compliant durability standards. As a subsidiary of Jiangsu Huashen Special Rubber and an active WEDA/CEDA member, we combine industrial-scale production with niche expertise in marine elastomer science—a synergy few global suppliers replicate.

Initiate Your Next Dredging Project with Engineered Confidence

When hose failure equates to vessel idling and contractual penalties, selecting a partner with uncompromising vulcanization mastery becomes a strategic imperative. East Marine invites dredging contractors, EPC firms, and port authorities to engage our technical team for bespoke hose solutions validated by 17 years of marine operational data. Contact us directly via WhatsApp at +86-13806109365 for urgent project consultations, or email hsdredging@eastmarine.tech to request engineering dossiers, test certificates, or site-specific performance analyses. Our Singapore branch provides localized support for Southeast Asian and Oceania operations, ensuring rapid response to technical queries and logistics coordination across time zones. Do not compromise on the foundational process that defines your hose’s resilience—leverage East Marine’s vulcanization expertise to convert operational risk into project success. Reach out today to specify hoses engineered for the world’s most demanding dredging environments.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.