Introduction: Navigating the Global Market for flexible pipeline

In the rapidly evolving energy landscape, sourcing flexible pipeline solutions has become a pivotal challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As industries face increasing demands for efficiency and adaptability in oil and gas production, understanding the nuances of flexible pipeline systems is essential. This guide serves as a comprehensive resource, covering various types of flexible pipes, their applications, and the critical factors to consider when vetting suppliers.

From risers and jumpers to flowlines, flexible pipelines provide solutions that address complex technical challenges, such as harsh seabed conditions and high-pressure environments. Buyers will gain insights into cost-effective options, installation timelines, and the importance of durability and reliability in flexible pipe systems. Moreover, this guide offers a strategic framework for making informed purchasing decisions, ensuring that organizations can navigate the global market effectively.

By equipping buyers with actionable knowledge about the benefits and applications of flexible pipelines, this guide empowers stakeholders to optimize their procurement strategies, enhance operational efficiency, and ultimately drive sustainable growth in their respective markets. Whether you are in Brazil, Nigeria, or anywhere else, understanding the flexible pipeline landscape is crucial to achieving success in today’s competitive environment.

Indice dei contenuti

- Top 8 Flexible Pipeline Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for flexible pipeline

- Understanding flexible pipeline Types and Variations

- Key Industrial Applications of flexible pipeline

- 3 Common User Pain Points for ‘flexible pipeline’ & Their Solutions

- Strategic Material Selection Guide for flexible pipeline

- In-depth Look: Manufacturing Processes and Quality Assurance for flexible pipeline

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘flexible pipeline’

- Comprehensive Cost and Pricing Analysis for flexible pipeline Sourcing

- Alternatives Analysis: Comparing flexible pipeline With Other Solutions

- Essential Technical Properties and Trade Terminology for flexible pipeline

- Navigating Market Dynamics and Sourcing Trends in the flexible pipeline Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of flexible pipeline

- Strategic Sourcing Conclusion and Outlook for flexible pipeline

- Disclaimer importante e condizioni d'uso

Understanding flexible pipeline Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Flexible Pipe Riser | High-pressure resistance, excellent bending capabilities | Deepwater oil and gas extraction | Pro: Faster installation, adaptable; Contro: Higher initial costs. |

| Integrated Production Bundle | Modular design with thermal insulation and monitoring | Hydrocarbon transport in challenging conditions | Pro: Enhanced flow assurance; Contro: Complexity in design and installation. |

| Freestanding Hybrid Riser | Vertical steel structure with buoyancy support | Deepwater production systems | Pro: Stability in harsh conditions; Contro: Requires significant upfront investment. |

| Flexible Flowlines | Leak-proof thermoplastic barriers, corrosion-resistant layers | Subsea fluid transport | Pro: Versatile and reusable; Contro: Limited lifespan in extreme conditions. |

| Riser Integrity Management | Advanced monitoring systems for structural integrity | Asset management in subsea environments | Pro: Proactive maintenance; Contro: Ongoing operational costs. |

What Are the Key Characteristics of Flexible Pipe Risers?

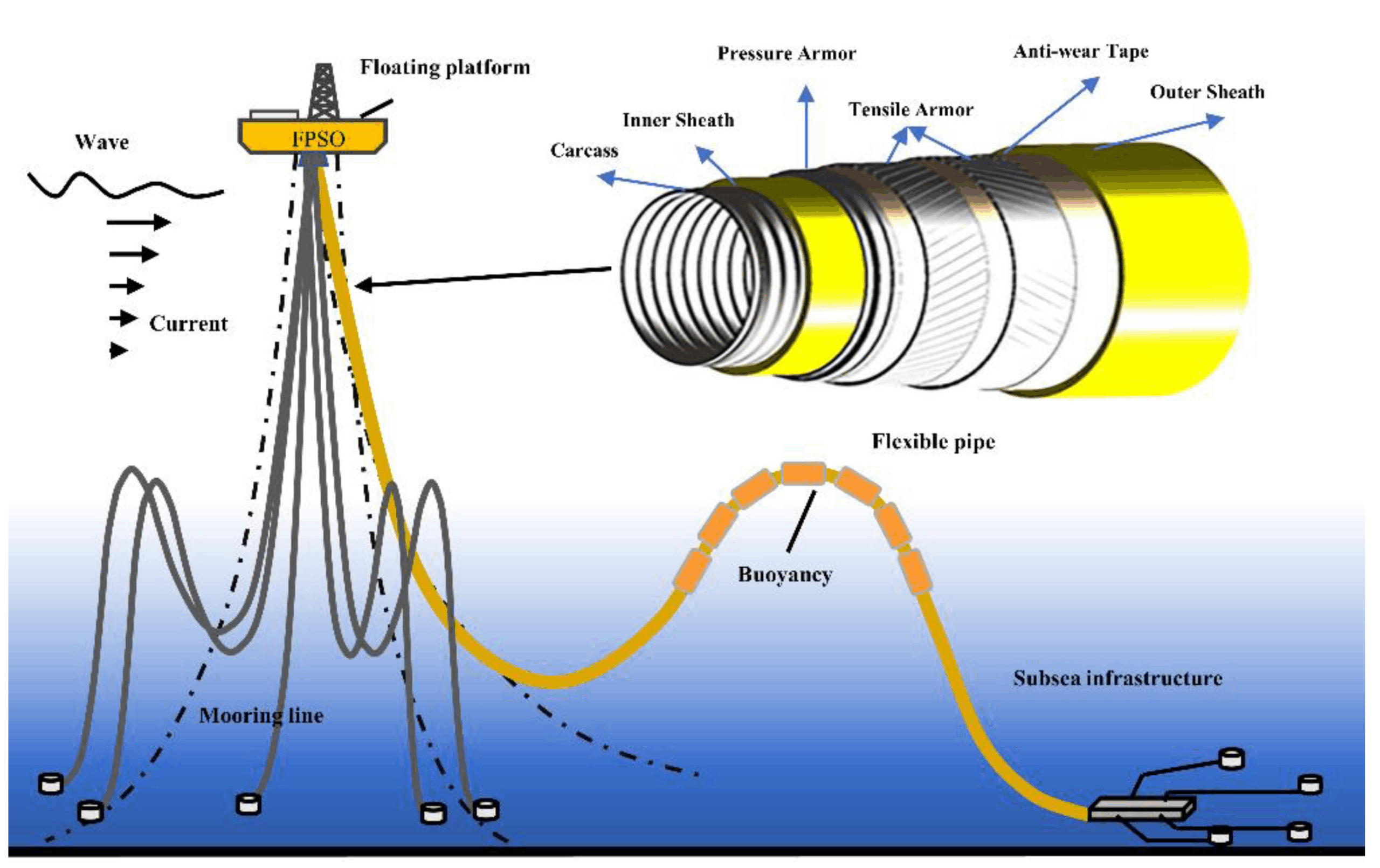

Flexible pipe risers are engineered to withstand high pressures and dynamic conditions, making them ideal for deepwater oil and gas extraction. Their excellent bending capabilities allow for flexibility in installation, significantly reducing the time required for deployment. When considering this option, buyers should evaluate the initial investment against long-term operational savings, as the quicker installation can lead to earlier production starts.

How Does the Integrated Production Bundle Enhance Subsea Operations?

The Integrated Production Bundle (IPB) is a sophisticated solution that integrates multiple functionalities, including thermal insulation and real-time monitoring. This modular design allows for customized adaptations to meet specific field development requirements, making it suitable for challenging subsea environments. Buyers should weigh the benefits of enhanced flow assurance against the complexity and potential costs of installation and maintenance.

Why Choose a Freestanding Hybrid Riser for Deepwater Production?

Freestanding Hybrid Risers provide a stable solution for deepwater production by combining a vertical steel structure with buoyancy support. This design is particularly effective in harsh marine environments, ensuring reliable connectivity and flow. However, potential buyers must consider the significant upfront costs and the need for robust foundation structures to support this system.

What Advantages Do Flexible Flowlines Offer for Subsea Fluid Transport?

Flexible flowlines are designed with leak-proof thermoplastic barriers and corrosion-resistant layers, making them suitable for transporting various fluids in subsea applications. Their versatility allows for reuse in different fields, providing a sustainable option for operators. However, buyers should be cautious of the limitations in lifespan, particularly in extreme conditions where wear and tear may occur more rapidly.

How Does Riser Integrity Management Improve Operational Efficiency?

Riser Integrity Management systems utilize advanced monitoring technology to ensure the structural integrity of risers over their operational life. This proactive approach allows for timely maintenance and reduces the risk of costly failures. While this system adds ongoing operational costs, the benefits of enhanced safety and efficiency can justify the investment, particularly for companies operating in challenging subsea environments.

Key Industrial Applications of flexible pipeline

| Industria/Settore | Specific Application of Flexible Pipeline | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Petrolio e gas | Subsea Riser Systems | Enhances production efficiency in deepwater environments | Ensure high-pressure and corrosion resistance; consider local regulations. |

| Gestione dell'acqua | Water Transfer and Distribution Systems | Reduces installation time and lowers operational costs | Assess flexibility for diverse terrains; evaluate environmental impacts. |

| Energia rinnovabile | Offshore Wind Farm Connections | Facilitates reliable fluid transport for energy generation | Look for adaptability to harsh marine conditions and ease of installation. |

| Trattamento chimico | Transport of Hazardous Materials | Provides leak-proof and safe transfer solutions | Ensure compliance with safety standards and consider monitoring capabilities. |

| Miniere | Slurry Transport Systems | Improves efficiency in transporting materials over challenging terrain | Focus on durability and resistance to wear; evaluate the ability for retrieval and reuse. |

How Are Flexible Pipelines Used in the Oil & Gas Industry?

In the oil and gas sector, flexible pipelines are crucial for subsea riser systems. These systems transport hydrocarbons from the seabed to surface facilities, particularly in deepwater environments where traditional rigid pipes may fail. Flexible pipelines mitigate issues related to seabed topography and dynamic riser movements, thereby enhancing production efficiency. Buyers should prioritize sourcing materials that offer high pressure and corrosion resistance, as well as compliance with local regulations to ensure safe operations.

What Role Do Flexible Pipelines Play in Water Management?

Flexible pipelines are increasingly used in water transfer and distribution systems. Their adaptability allows for quick installation in various terrains, significantly reducing operational costs. These pipelines are particularly beneficial for regions facing water scarcity, as they ensure efficient transportation from sources to consumers. Buyers must consider the environmental impact of installation and assess the pipeline’s ability to withstand local climate conditions, ensuring long-term reliability.

How Are Flexible Pipelines Beneficial for Renewable Energy Projects?

In renewable energy, especially offshore wind farms, flexible pipelines facilitate the transport of various fluids, including cooling water and hydraulic fluids. Their design allows for easy integration into dynamic environments, ensuring reliable connections between turbines and support vessels. International buyers should focus on the pipelines’ adaptability to harsh marine conditions and the efficiency of their installation processes, which can significantly reduce project timelines.

Why Are Flexible Pipelines Essential in Chemical Processing?

Flexible pipelines are vital for the safe transport of hazardous materials in chemical processing. Their leak-proof design ensures the secure transfer of corrosive or high-pressure fluids, minimizing environmental risks. Buyers in this sector should prioritize sourcing options that meet strict safety standards, including advanced monitoring capabilities to detect leaks or structural integrity issues early on.

How Do Flexible Pipelines Enhance Mining Operations?

In mining, flexible pipelines are utilized for slurry transport systems, allowing for efficient movement of materials over challenging terrains. Their durability and resistance to wear make them ideal for harsh mining environments. Buyers should focus on the pipelines’ ability for retrieval and reuse, which can reduce costs and enhance sustainability. Evaluating the product’s adaptability to local geological conditions is also crucial for successful operations.

3 Common User Pain Points for ‘flexible pipeline’ & Their Solutions

Scenario 1: Navigating Installation Delays in Challenging Environments

Il problema: In the oil and gas sector, B2B buyers often face significant installation delays when deploying traditional rigid pipelines, especially in challenging environments like deepwater or rough seabeds. These delays can stem from the extensive time required for offshore welding and assembly, leading to increased Total Expenditure (TOTEX) and potential project overruns. Buyers are under pressure to meet production timelines, and any delay can result in financial losses and missed market opportunities.

La soluzione: To effectively mitigate installation delays, buyers should consider flexible pipeline systems designed for rapid deployment. These systems are manufactured onshore and can be delivered ready to install, significantly reducing the need for offshore welding. For instance, opting for a modular design that incorporates leak-proof thermoplastic barriers and corrosion-resistant steel wires allows for quicker assembly and enhanced flexibility. Additionally, engaging with experienced suppliers who offer comprehensive installation support can further streamline the process. By prioritizing suppliers with proven track records in deploying flexible pipelines in similar environments, companies can ensure faster execution and improved operational reliability.

Scenario 2: Managing Integrity and Health Monitoring of Flexible Pipelines

Il problema: As offshore operations expand into deeper waters and more corrosive environments, maintaining the integrity of flexible pipelines becomes a paramount concern for B2B buyers. A lack of robust monitoring can lead to undetected damage, resulting in costly repairs and potential environmental hazards. Buyers often find it challenging to monitor the health of their pipeline systems effectively, particularly when operating under extreme conditions, such as high pressures or temperatures.

La soluzione: Implementing advanced monitoring systems is essential for managing the integrity of flexible pipelines. Buyers should prioritize solutions that include real-time monitoring technology, such as Distributed Temperature Sensing (DTS) and online fatigue analysis. These systems can provide early warnings of potential issues, such as damage to the outer sheath or loss of tensile armor wire integrity. By integrating these monitoring solutions with a proactive maintenance strategy, companies can respond to issues before they escalate, ensuring continued operational efficiency and compliance with environmental regulations. Collaborating with suppliers who provide integrated integrity management services can further enhance pipeline reliability and reduce lifecycle costs.

Scenario 3: Balancing Cost-Effectiveness with Environmental Sustainability

Il problema: B2B buyers are increasingly pressured to balance cost-effectiveness with sustainability in their pipeline choices. Traditional rigid pipelines can be expensive and environmentally taxing due to their single-use nature and the extensive resources required for installation and decommissioning. Buyers often struggle to find solutions that meet both budgetary constraints and environmental responsibilities.

La soluzione: Flexible pipelines offer a sustainable alternative that can be reused and redeployed across multiple projects, thus reducing overall material waste and environmental impact. Buyers should explore modular flexible pipeline systems that can be tailored for specific field requirements and easily retrieved for future use. Additionally, engaging with suppliers who prioritize sustainable practices in their manufacturing processes, such as using recyclable materials and minimizing carbon footprints, can align operational goals with environmental responsibilities. By adopting flexible pipelines, companies can achieve significant cost savings while enhancing their reputation as environmentally conscious operators in the industry.

Strategic Material Selection Guide for flexible pipeline

When selecting materials for flexible pipelines, it’s crucial to consider the specific properties, advantages, and limitations of each material. The right choice can significantly impact performance, durability, and cost-effectiveness, especially for international B2B buyers operating in diverse environments such as Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in flexible pipelines.

What Are the Key Properties of Polyethylene (PE) in Flexible Pipelines?

Polyethylene (PE) is widely used in flexible pipelines due to its excellent chemical resistance and low density. It can withstand temperatures up to 60°C and pressures around 10 bar, making it suitable for various applications. Its inherent flexibility allows for easy installation and adaptability to different environments.

Pros: PE is lightweight, cost-effective, and resistant to corrosion, making it ideal for transporting water and non-aggressive fluids. It is also relatively easy to manufacture and install.

Cons: However, PE has limitations in high-temperature applications and is not suitable for transporting hydrocarbons or aggressive chemicals. Its mechanical strength is lower compared to other materials, which may lead to increased wear in challenging environments.

Impatto sull'applicazione: PE is best suited for non-corrosive media and lower pressure applications, making it a common choice for water supply systems.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like Brazil and Nigeria, where infrastructure may vary, understanding local regulations is vital.

How Does Polyvinyl Chloride (PVC) Perform in Flexible Pipeline Applications?

Polyvinyl Chloride (PVC) is another popular material for flexible pipelines, known for its excellent chemical resistance and durability. PVC can handle temperatures up to 70°C and pressures up to 16 bar.

Illustrative image related to flexible pipeline

Pros: PVC is highly resistant to corrosion and is an economical option for various applications, particularly in construction and drainage systems. Its rigidity provides good structural integrity.

Cons: On the downside, PVC is less flexible than PE, making installation more challenging in complex layouts. It also has limitations in high-temperature applications and can become brittle over time when exposed to UV light.

Impatto sull'applicazione: PVC is ideal for transporting water, sewage, and other non-aggressive fluids, but it is not suitable for high-pressure or high-temperature applications.

Considerazioni per gli acquirenti internazionali: Buyers must verify compliance with local standards and consider the environmental impact of PVC, especially in regions with stringent regulations.

What Are the Advantages of Steel in Flexible Pipeline Systems?

Steel, particularly carbon steel and stainless steel, is renowned for its strength and durability. It can withstand high pressures (up to 100 bar) and temperatures (up to 300°C), making it suitable for various demanding applications.

Illustrative image related to flexible pipeline

Pros: Steel offers superior mechanical properties, making it ideal for transporting hydrocarbons and other aggressive media. Its durability ensures a long service life, reducing maintenance costs.

Cons: The primary drawback is its susceptibility to corrosion, which necessitates protective coatings or the use of stainless steel, increasing manufacturing complexity and cost. Additionally, steel is heavier, complicating installation.

Impatto sull'applicazione: Steel is best suited for high-pressure and high-temperature applications, particularly in oil and gas sectors.

Considerazioni per gli acquirenti internazionali: Buyers should be aware of compliance with international standards and the need for corrosion protection, especially in humid or saline environments common in regions like the Middle East.

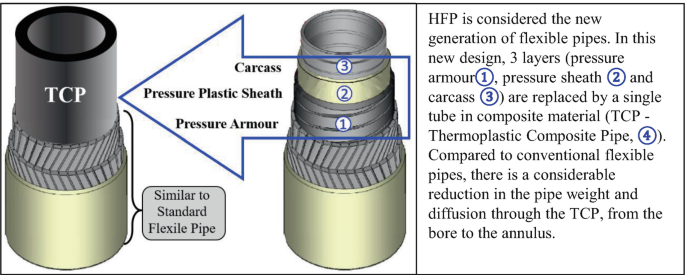

How Does Composite Material Enhance Flexible Pipeline Performance?

Composite materials, often made of a combination of thermoplastics and reinforced fibers, are increasingly used in flexible pipelines due to their lightweight and high strength-to-weight ratio. They can handle pressures up to 30 bar and temperatures around 80°C.

Pros: Composites are resistant to corrosion and offer excellent flexibility, making them suitable for complex installations. Their lightweight nature reduces transportation and installation costs.

Cons: However, composites can be more expensive than traditional materials and may require specialized manufacturing processes. Additionally, their long-term durability under extreme conditions is still being evaluated.

Impatto sull'applicazione: Composites are ideal for applications requiring high flexibility and resistance to aggressive media, particularly in offshore environments.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that composite materials meet local certifications and standards, particularly in regions with strict environmental regulations.

Summary Table of Material Selection for Flexible Pipelines

| Materiale | Typical Use Case for flexible pipeline | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (basso/medio/alto) |

|---|---|---|---|---|

| Polyethylene (PE) | Water supply systems | Lightweight and cost-effective | Limited in high-temperature applications | Basso |

| Polyvinyl Chloride (PVC) | Construction and drainage systems | Economical and corrosion-resistant | Less flexible, can become brittle | Basso |

| Acciaio | Oil and gas transportation | Superior strength and durability | Suscettibile alla corrosione | Alto |

| Composito | Offshore applications | Lightweight and flexible | Costi più elevati e produzione specializzata | Medio |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to optimize their flexible pipeline systems, ensuring they make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for flexible pipeline

What Are the Key Stages in the Manufacturing Process of Flexible Pipelines?

The manufacturing of flexible pipelines involves several critical stages that ensure the final product meets the rigorous demands of subsea and offshore applications. These stages include material preparation, forming, assembly, and finishing.

Preparazione del materiale: Quali sono i materiali utilizzati?

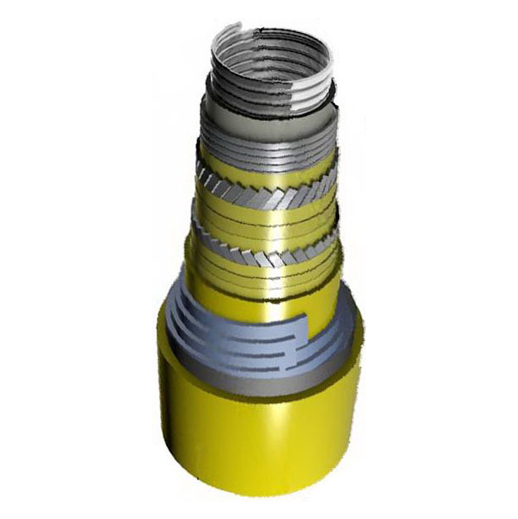

The first step in manufacturing flexible pipelines is material preparation. This typically involves the selection of high-performance materials that can withstand extreme conditions. Flexible pipes are constructed using multiple layers, including leak-proof thermoplastic barriers and corrosion-resistant steel wires. These materials are chosen for their ability to provide high pressure resistance and excellent bending characteristics.

Manufacturers often employ advanced techniques such as polymer compounding and steel wire coating to enhance the properties of the base materials. This preparation phase is crucial, as the quality of the raw materials directly influences the durability and reliability of the final product.

How Are Flexible Pipelines Formed?

Once materials are prepared, the next stage is forming. This involves the extrusion of thermoplastic layers and the winding of steel wires around a central core. The helical winding technique used in this process allows the pipe to maintain flexibility while providing the necessary structural integrity.

Key techniques in this stage include:

- Extrusion: For creating the thermoplastic barrier layers that provide leak-proof properties.

- Helical Winding: A method that intertwines steel wires to enhance pressure resistance and flexibility.

These forming techniques are designed to ensure that each layer can interact effectively while maintaining its individual properties.

What Does the Assembly Process Entail?

The assembly stage brings together the various components produced during the forming phase. This is where the individual layers are combined to create the final flexible pipeline structure. Manufacturers must ensure precise alignment and secure bonding between layers to prevent any future operational issues.

Illustrative image related to flexible pipeline

During assembly, advanced technologies such as automated welding and quality control systems are often employed to enhance efficiency and minimize human error. This stage may also include the integration of additional features, such as sensors for real-time monitoring of pipeline conditions.

How Is Finishing Performed in Flexible Pipeline Production?

The finishing stage involves final inspections and treatments to enhance the pipeline’s performance and longevity. This may include surface treatments to improve corrosion resistance and the application of protective coatings.

Additionally, the finishing process often incorporates thorough quality checks to ensure that the product meets all specified requirements and standards before it is packaged for delivery.

What Quality Assurance Measures Are Implemented in Flexible Pipeline Manufacturing?

Quality assurance (QA) is a vital component of the flexible pipeline manufacturing process, ensuring that products meet both international standards and industry-specific requirements.

Which International Standards Are Relevant for Quality Control?

Manufacturers of flexible pipelines must adhere to several international standards, including:

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring consistent quality in products and services.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: The American Petroleum Institute provides specific standards for pipeline manufacturing, particularly in the oil and gas industry.

These standards serve as benchmarks for quality and safety, providing buyers with assurance regarding the reliability of their purchased products.

What Are the Checkpoints in the Quality Control Process?

The quality control process typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial check assesses the quality of raw materials before they enter the production process.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing ensure that each stage adheres to quality standards, minimizing defects.

- Final Quality Control (FQC): A comprehensive inspection of the finished product, verifying that it meets all specifications and standards before shipment.

These checkpoints are crucial for maintaining the integrity of the manufacturing process and ensuring that any potential issues are addressed promptly.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers employ a range of testing methods to ensure that flexible pipelines can withstand the conditions they will face in the field. Common testing methods include:

- Hydrostatic Testing: To assess the pressure resistance of the pipeline.

- Tensile Testing: To determine the strength and flexibility of the materials used.

- Leak Testing: To ensure that no leaks are present in the finished product.

These testing methods provide critical data on the performance capabilities of the pipelines, offering peace of mind to B2B buyers.

Illustrative image related to flexible pipeline

Come possono gli acquirenti B2B verificare il controllo qualità dei fornitori?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, it is essential to verify the quality control measures of suppliers. Here are some actionable strategies:

What Role Do Audits and Reports Play?

Conducting regular audits of suppliers can provide insights into their quality control processes. Buyers should request access to audit reports and certifications that demonstrate compliance with relevant standards. This transparency helps buyers assess the reliability of their suppliers.

How Important Are Third-Party Inspections?

Utilizing third-party inspection services can further enhance confidence in the quality of flexible pipelines. Independent inspectors can provide objective assessments of manufacturing processes and product quality, ensuring that all specifications are met.

What Are the Specific QC Considerations for International Buyers?

International buyers should be aware of potential nuances in quality control, such as regional standards and regulations that may differ from their own. Understanding these differences is crucial for ensuring compliance and quality assurance throughout the supply chain.

In summary, the manufacturing processes and quality assurance measures for flexible pipelines are designed to meet the stringent demands of subsea applications. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring the reliability and performance of their pipeline systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flexible pipeline’

To assist B2B buyers in procuring flexible pipeline solutions, this step-by-step guide outlines essential actions to ensure successful sourcing. By following these steps, you can make informed decisions that align with your operational needs and project requirements.

Fase 1: Definire le specifiche tecniche

Before initiating the sourcing process, it is crucial to clearly outline your technical requirements. This includes understanding the operating environment, such as pressure, temperature, and the types of fluids being transported. Having detailed specifications helps in matching the right flexible pipeline solutions that can withstand the unique challenges of your project.

- Consider material requirements: Identify if you need corrosion-resistant materials or specific layers for insulation.

- Outline performance metrics: Define expectations regarding flexibility, pressure tolerance, and durability.

Fase 2: Ricerca di potenziali fornitori

Conduct thorough research to identify suppliers who specialize in flexible pipelines. Look for companies with proven track records in your geographical region, especially those familiar with local regulations and environmental conditions.

Illustrative image related to flexible pipeline

- Leverage industry reports: Utilize market analysis reports to identify key players in the flexible pipeline market.

- Explore online platforms: Check professional networks and industry forums for supplier recommendations and reviews.

Fase 3: Valutare le certificazioni dei fornitori

Verification of supplier certifications is a critical step in ensuring the quality and safety of the products. Look for certifications that adhere to international standards, such as ISO 9001 for quality management systems.

- Check for industry-specific certifications: Certifications from organizations like DNV GL or ABS can indicate a supplier’s capability to meet stringent industry requirements.

- Confirm compliance with local regulations: Ensure that the suppliers are compliant with the local laws and environmental guidelines relevant to your project.

Passo 4: Request Technical Proposals

Once you have shortlisted potential suppliers, request detailed technical proposals. These proposals should include product specifications, installation methodologies, and maintenance plans.

- Assess customization options: Inquire about how adaptable the solutions are to meet your specific needs.

- Evaluate installation timelines: Understanding the expected timeframes for installation can impact your project schedules significantly.

Passo 5: Conduct Site Visits and Assess Capabilities

If possible, visit the manufacturing facilities of your shortlisted suppliers. This will provide insight into their production capabilities, quality control processes, and overall operational standards.

- Inspect equipment and technology: Evaluate the technology used in the manufacturing process to ensure it aligns with your quality expectations.

- Meet with technical teams: Discuss your project requirements with their engineering teams to gauge their expertise and responsiveness.

Passo 6: Review Terms and Conditions

Before finalizing the contract, carefully review all terms and conditions. Pay attention to warranties, service agreements, and any clauses related to liability and compliance.

Illustrative image related to flexible pipeline

- Negotiate favorable terms: Ensure that the contract includes provisions for timely delivery and clear performance guarantees.

- Understand penalty clauses: Be aware of any penalties for non-compliance or delays, which could impact your project timeline.

Passo 7: Establish a Communication Plan

Effective communication is vital throughout the procurement process and beyond. Set up a clear communication plan that includes regular updates and points of contact.

- Define communication channels: Decide whether to use emails, project management tools, or regular meetings for updates.

- Ensure transparency: Encourage open dialogue regarding any issues that may arise during the project.

By following these steps, you can streamline your procurement process for flexible pipelines, ensuring that you choose the best solutions for your operational needs while minimizing risks and costs.

Comprehensive Cost and Pricing Analysis for flexible pipeline Sourcing

What Are the Key Cost Components in Flexible Pipeline Sourcing?

When sourcing flexible pipelines, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

I materiali: Flexible pipelines are typically constructed from multiple layers, including thermoplastic barriers and corrosion-resistant steel wires. The quality and type of materials significantly influence costs. For instance, high-pressure resistant materials may command a premium, while standard materials could reduce upfront expenses.

-

Lavoro: Labor costs encompass the workforce involved in manufacturing, installation, and maintenance. Skilled labor is often required for specialized tasks, such as welding and quality inspections, which can drive up costs.

-

Spese generali di produzione: This includes indirect costs related to production, such as utilities, equipment depreciation, and facility maintenance. A manufacturer with advanced technology may have higher overhead but can offer better efficiency and reliability.

-

Utensili: Custom tooling for specific projects can increase initial costs, but it may also enhance efficiency and reduce lead times in the long run.

-

Quality Control: Ensuring the integrity and durability of flexible pipelines is essential, particularly in challenging environments. Enhanced QC processes can add to costs but are vital for minimizing the risk of failures and associated costs.

-

Logistica: The transportation of flexible pipes can be complex, especially for international shipments. Costs may vary based on distance, shipping method, and the handling of oversized or heavy items.

-

Margine: Supplier margins will vary based on market conditions, competition, and the supplier’s reputation. Higher margins may be justified by superior quality or service.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of flexible pipelines, and understanding these can help buyers make informed decisions.

-

Volume e quantità minima d'ordine (MOQ): Larger orders often lead to bulk discounts. Buyers should assess their needs and negotiate accordingly to benefit from economies of scale.

-

Specifiche e personalizzazione: Customized solutions tailored to specific project requirements typically incur higher costs. Buyers should evaluate whether off-the-shelf options could meet their needs to save on expenses.

-

Materiali e certificazioni di qualità: The choice of materials, including certifications for quality and compliance, can significantly impact pricing. High-quality materials with certifications may be more expensive but offer long-term reliability.

-

Fattori di fornitura: The supplier’s experience, technological capabilities, and geographic location can affect pricing. Established suppliers with a track record of reliability may charge higher prices, but they often provide better service and product assurance.

-

Incoterms: Understanding the terms of delivery, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial. Different Incoterms can affect the overall cost structure and responsibilities regarding shipping and handling.

What Are Effective Buyer Tips for Cost Efficiency in Flexible Pipeline Procurement?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency.

-

Negoziazione: Strong negotiation skills can lead to better pricing and terms. Buyers should be prepared with market research to support their positions.

-

Costo totale di proprietà (TCO): Focus on TCO rather than just initial purchase price. Consider long-term factors such as installation costs, maintenance, and potential downtime when evaluating proposals.

-

Leverage Local Suppliers: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times. Local suppliers may also have a better understanding of regional regulations and challenges.

-

Stay Informed About Market Trends: Keeping abreast of industry trends, technological advancements, and changes in material costs can help buyers anticipate price fluctuations and make timely purchasing decisions.

-

Request Multiple Quotes: Gathering quotes from various suppliers allows for comparison, ensuring competitive pricing and better negotiation leverage.

Disclaimer

Prices for flexible pipelines can vary significantly based on numerous factors, including market conditions, supplier practices, and project specifications. The information provided here is intended for guidance and may not reflect actual pricing. Buyers are encouraged to conduct thorough market research and obtain detailed quotes tailored to their specific needs.

Alternatives Analysis: Comparing flexible pipeline With Other Solutions

Understanding Alternative Solutions for Subsea Pipeline Needs

When evaluating subsea pipeline solutions, it’s essential to consider various alternatives to flexible pipelines. Flexible pipelines are known for their adaptability and efficiency, but several other technologies can also serve similar purposes in the oil and gas industry. In this analysis, we will compare flexible pipelines with rigid steel pipelines and umbilicals, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Aspetto di confronto | Flexible Pipeline | Rigid Steel Pipeline | Umbilicals |

|---|---|---|---|

| Prestazioni | High flexibility, excellent for dynamic environments | Good for stable, fixed installations | Supports multiple functions (power, control, fluids) |

| Costo | Higher initial investment but lower installation costs | Lower upfront costs but higher installation and maintenance | Moderate cost, depending on complexity |

| Facilità di implementazione | Quick installation, minimal offshore welding | Longer installation times, more complex logistics | Requires careful planning and integration |

| Manutenzione | Low maintenance due to robust design; easy to monitor | Moderate to high maintenance; susceptible to corrosion | Regular inspections needed; complex repairs |

| Il miglior caso d'uso | Ideal for deepwater and challenging terrains | Suitable for shallow waters and stable seabeds | Best for integrated operations requiring multiple services |

In-Depth Look at Alternative Solutions

Rigid Steel Pipeline

Rigid steel pipelines have been the traditional choice for subsea installations. They are known for their strength and durability, making them suitable for stable environments where ground conditions are predictable. The initial cost of rigid steel pipelines is often lower than that of flexible pipelines; however, they typically incur higher installation costs due to the need for extensive welding and more complex logistical planning. Additionally, their maintenance can be challenging as they are more susceptible to corrosion and require regular inspections.

Umbilicals

Umbilicals are specialized lines that integrate multiple functions, such as power supply, control lines, and fluid transport. They provide a comprehensive solution for subsea operations but come with a moderate cost that can vary significantly based on their complexity. Umbilicals are particularly useful in environments where integrated operations are necessary, allowing for efficient management of multiple services. However, their installation requires meticulous planning to ensure proper integration, and maintenance can be complicated due to the diverse functions they serve.

Making the Right Choice for Your Subsea Pipeline Needs

Choosing the right pipeline solution hinges on several factors, including the specific operational environment, budget constraints, and long-term maintenance considerations. Flexible pipelines offer unparalleled adaptability and ease of installation, making them ideal for dynamic and challenging subsea conditions. In contrast, rigid steel pipelines might be more cost-effective for stable environments, while umbilicals provide a versatile solution for integrated operations.

B2B buyers should assess their unique project requirements, including site conditions and operational goals, to select the most appropriate technology. Conducting a thorough cost-benefit analysis and consulting with industry experts can further refine decision-making, ensuring a successful investment in subsea infrastructure.

Essential Technical Properties and Trade Terminology for flexible pipeline

What Are the Key Technical Properties of Flexible Pipelines?

Flexible pipelines are essential in modern subsea developments, offering several advantages over traditional rigid systems. Here are some critical technical properties that buyers should consider:

Illustrative image related to flexible pipeline

-

Grado del materiale

Flexible pipelines are typically constructed from a combination of thermoplastics and corrosion-resistant steel wires. The specific material grades determine the pipeline’s resistance to pressure, temperature, and corrosive substances. Understanding the material grade is crucial for ensuring that the pipeline can withstand the operational conditions of the intended environment, especially in regions with high H2S content or dense CO2. -

Pressione nominale

The pressure rating indicates the maximum pressure the pipeline can safely handle. This specification is vital for applications involving high-pressure hydrocarbons, as it directly impacts the safety and longevity of the system. Buyers must assess their operational requirements to choose a pipeline that meets or exceeds these pressure demands. -

Bending Radius

The bending radius refers to the smallest radius a flexible pipeline can be bent without compromising its structural integrity. This property is essential for installations in complex underwater topographies, where sharp turns may be necessary. A smaller bending radius allows for more adaptable field layouts, which can lead to reduced installation time and costs. -

Thermal Insulation

Many flexible pipelines include thermal insulation layers to maintain the temperature of the transported fluids. This is particularly important in deepwater applications where temperature variations can significantly impact fluid behavior and production efficiency. Effective thermal insulation can enhance flow assurance and reduce energy costs associated with heating. -

Recovery and Reusability

The ability to recover and redeploy flexible pipelines offers significant economic benefits. This property allows operators to use the same infrastructure for multiple projects or during decommissioning phases, reducing the overall capital expenditure. Understanding the recovery protocols is essential for efficient project planning. -

Integrity Monitoring Systems

Advanced monitoring systems are often integrated into flexible pipelines to track structural integrity in real time. These systems can detect issues such as damage to the outer sheath or loss of tensile strength, allowing for proactive maintenance and minimizing the risk of costly failures. Buyers should consider the availability and reliability of these systems when selecting a flexible pipeline solution.

Which Trade Terminology Should B2B Buyers Understand in the Flexible Pipeline Industry?

Understanding industry terminology is crucial for effective communication and decision-making. Here are some common terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the flexible pipeline sector, buyers often engage with OEMs to procure customized solutions that meet specific operational requirements. -

MOQ (quantità minima d'ordine)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For flexible pipelines, MOQs can significantly affect project budgeting and planning. Buyers should clarify MOQ with suppliers to ensure that their procurement strategies align with their operational needs. -

RFQ (Richiesta di offerta)

An RFQ is a formal document that buyers use to request price quotes from suppliers for specific products or services. This process is essential for ensuring competitive pricing and evaluating potential vendors in the flexible pipeline market. -

Incoterms (Termini commerciali internazionali)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, including the delivery points, risk transfer, and cost responsibilities. Familiarity with Incoterms is crucial for smooth negotiations and contract execution in global supply chains. -

TOTEX (Total Expenditure)

TOTEX is a financial term that encompasses all costs associated with the lifecycle of an asset, including capital and operational expenditures. Understanding TOTEX is vital for buyers as it helps in evaluating the long-term cost-effectiveness of flexible pipeline solutions compared to traditional alternatives. -

Flow Assurance

Flow assurance refers to the management of the flow of fluids in pipelines, ensuring that they can be transported effectively under varying conditions. This concept is particularly relevant in flexible pipelines, where thermal insulation and material properties play a critical role in maintaining optimal fluid flow.

By grasping these technical properties and industry terms, international B2B buyers can make more informed decisions when selecting flexible pipeline solutions tailored to their specific operational challenges.

Navigating Market Dynamics and Sourcing Trends in the flexible pipeline Sector

What Are the Current Market Dynamics and Key Trends in the Flexible Pipeline Sector?

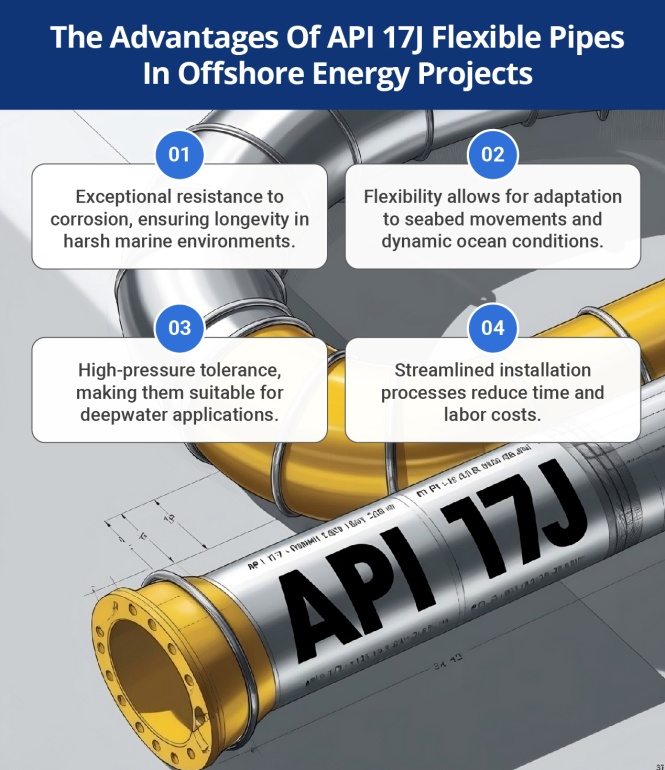

The flexible pipeline sector is undergoing transformative changes driven by increasing demand for efficient energy transportation and the need for sustainable solutions. Global drivers such as the rise in offshore oil and gas exploration, particularly in regions like Africa and South America, are propelling the market forward. Flexible pipelines are favored for their adaptability in challenging environments, including deep waters and rough terrains, making them essential in the evolving energy landscape.

Illustrative image related to flexible pipeline

Emerging B2B technology trends include the integration of advanced monitoring systems and digital solutions that enhance pipeline integrity and operational efficiency. Companies are increasingly investing in smart technologies, such as Distributed Temperature Sensing (DTS) and real-time monitoring systems, which provide real-time data on pipeline performance and health. This trend is particularly relevant for international buyers who seek to optimize asset management and reduce operational risks.

In terms of sourcing trends, there is a notable shift towards modular and adaptable solutions. Manufacturers are now offering flexible pipes that can be customized to meet specific field requirements, thereby reducing Total Cost of Ownership (TOTEX) and installation time. Furthermore, the market is witnessing an emphasis on local sourcing strategies, which not only minimize transportation costs but also align with regional content regulations, particularly in developing markets like Brazil and Nigeria.

How Is Sustainability Influencing the Sourcing of Flexible Pipelines?

Sustainability is increasingly becoming a focal point in the flexible pipeline sector, influencing both sourcing decisions and product design. The environmental impact of traditional pipeline materials and practices has led to a shift towards more sustainable alternatives. Flexible pipelines are designed to be reusable and recyclable, offering a lower carbon footprint compared to conventional steel pipelines.

Ethical sourcing practices are gaining traction among B2B buyers, with a growing emphasis on supply chain transparency and responsible material sourcing. Companies are seeking suppliers that adhere to stringent environmental standards and possess green certifications. This includes the use of eco-friendly materials and the implementation of sustainable manufacturing processes.

Moreover, the demand for “green” certifications is on the rise. Buyers are increasingly looking for suppliers who can demonstrate compliance with international environmental standards and showcase their commitment to sustainability. This trend not only enhances brand reputation but also aligns with the global push towards corporate social responsibility, making it a vital consideration for international B2B buyers.

How Has the Flexible Pipeline Sector Evolved Over Time?

The evolution of flexible pipelines dates back to the early 1970s when they were first introduced as a viable alternative to rigid steel pipelines. Initially developed for shallow waters, advancements in technology have allowed flexible pipelines to be adapted for deepwater applications and harsh environments, significantly expanding their use in offshore oil and gas exploration.

Over the decades, the design and manufacturing processes have evolved to incorporate innovative materials and technologies that enhance performance and reliability. Key developments include the integration of leak-proof thermoplastic barriers and corrosion-resistant steel layers, which have improved the durability and flexibility of these systems. This evolution has been driven by the industry’s need for more efficient and adaptable solutions, catering to the demands of complex subsea developments.

Today, flexible pipelines are recognized for their superior dynamic performance and the ability to mitigate installation risks, making them a critical component of modern energy infrastructure. As the industry continues to face challenges related to environmental impact and operational efficiency, flexible pipelines are poised to play an increasingly significant role in the sustainable energy landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of flexible pipeline

-

How do I solve challenges with installation in rough seabed conditions?

To address installation challenges in rough seabed environments, flexible pipeline systems are designed to adapt to complex topographies. Their lightweight nature and flexibility allow for easier maneuverability, reducing the need for extensive anchoring or support structures. Collaborating with suppliers who specialize in flexible pipes can provide tailored solutions, including advanced monitoring systems that ensure integrity during installation. Utilizing locally available expertise in regions like Africa or South America can also streamline the installation process, ensuring that local conditions are accounted for effectively. -

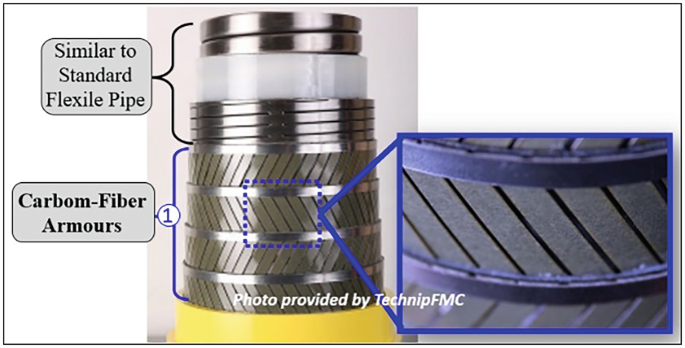

What is the best flexible pipeline solution for high-pressure applications?

For high-pressure applications, particularly in subsea environments, flexible pipes featuring multiple layers of leak-proof thermoplastic barriers and corrosion-resistant steel wires are optimal. These configurations allow for high-pressure resistance while maintaining flexibility, which is crucial for dynamic environments. Suppliers like TechnipFMC and Baker Hughes offer specialized products designed to handle challenging fluids and extreme temperatures, making them suitable for applications in deepwater oil and gas extraction or other high-pressure scenarios. -

How can I ensure the quality and reliability of flexible pipelines?

To ensure the quality and reliability of flexible pipelines, it is essential to conduct thorough supplier vetting. Look for manufacturers with a proven track record in flexible pipe technology and certifications that adhere to international standards. Additionally, inquire about their quality assurance processes, including testing protocols and monitoring systems for structural integrity. Engaging with suppliers who provide detailed documentation on their manufacturing processes and offer warranties on their products can further enhance your confidence in their reliability. -

What are the minimum order quantities (MOQ) for flexible pipelines?

Minimum order quantities for flexible pipelines can vary significantly between suppliers, depending on their production capabilities and the complexity of the order. Typically, larger orders may attract better pricing and availability, while smaller orders might incur additional costs. It is advisable to discuss your specific project requirements with potential suppliers to negotiate favorable terms that align with your operational needs. This dialogue can also help identify any opportunities for bulk purchasing discounts. -

What payment terms should I expect when sourcing flexible pipelines internationally?

Payment terms for international transactions involving flexible pipelines often depend on the supplier’s policies and the buyer’s creditworthiness. Common terms include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Understanding the currency exchange risks and potential tariffs associated with cross-border trade is crucial. It’s best to clarify these terms during negotiations to avoid misunderstandings and ensure a smooth transaction process. -

What customization options are available for flexible pipeline systems?

Flexible pipeline systems can often be customized to meet specific project requirements, including variations in diameter, length, and pressure ratings. Suppliers like Baker Hughes and TechnipFMC offer modular designs that allow for tailored solutions based on the unique needs of a project, including adaptations for different fluid types and environmental conditions. Engaging in early discussions with your supplier about customization options can lead to better alignment with your operational goals. -

How do I manage logistics for international shipping of flexible pipelines?

Managing logistics for international shipping of flexible pipelines requires careful planning and coordination with your supplier. Ensure that you understand the shipping methods available, including air freight for expedited delivery or sea freight for larger shipments. It’s important to clarify the incoterms (e.g., FOB, CIF) to determine responsibilities for shipping costs and risk. Working with logistics partners experienced in handling industrial equipment can also facilitate smoother customs clearance and delivery processes, particularly in regions with complex regulations. -

What are the best practices for maintaining flexible pipeline integrity?

Maintaining the integrity of flexible pipelines involves regular monitoring and inspections to detect potential issues early. Implementing advanced monitoring systems, such as Distributed Temperature Sensing (DTS) or real-time fatigue analysis, can provide valuable data on the pipeline’s condition. Establishing a routine maintenance schedule and working closely with the supplier for integrity management services can enhance operational safety and prolong the lifespan of the pipelines. Training your personnel in proper handling and maintenance techniques is also crucial for minimizing risks and ensuring efficient operation.

Top 8 Flexible Pipeline Manufacturers & Suppliers List

1. Baker Hughes – Flexible Pipe Systems

Dominio: bakerhughes.com

Registered: 1996 (29 years)

Introduzione: Flexible pipe systems from Baker Hughes are designed for subsea applications, providing advanced solutions for oil and gas operations. They offer enhanced flexibility and reliability, ensuring efficient transportation of hydrocarbons in challenging environments. The systems are engineered to meet the demands of deepwater and ultra-deepwater projects, contributing to improved project success and op…

2. TechnipFMC – Flexible Pipes

Dominio: technipfmc.com

Registered: 2016 (9 years)

Introduzione: TechnipFMC is the world leader in the design and manufacture of flexible pipes, which consist of multiple layers including leakproof thermoplastic barriers and corrosion-resistant steel wires. Key features include high-pressure resistance, excellent bending characteristics, flexibility, and superior dynamic performance. The modular construction allows for adaptability to diverse subsea development…

3. SoluForce – Flexible High-Pressure Pipes

Dominio: soluforce.com

Registrato: 2000 (25 anni)

Introduzione: SoluForce offers flexible pipes for high-pressure hydrocarbons, designed for various applications including oil and gas flow lines, gas pipelines, and high-pressure water injection pipelines. Key product features include:

– Pipe Types: Light, Classic, Heavy, High Temperature (HT), and Gas Tight (GT).

– Light: Reinforced with synthetic fiber, LCLRCRT ranging from 36 bar/522 psi to 45 bar/653 psi….

4. ScienceDirect – Flexible Pipe

Dominio: sciencedirect.com

Registrato: 1997 (28 anni)

Introduzione: Flexible pipe is a configurable product made up of several independent layers, commonly used for risers, flowlines, and jumpers in offshore operations. It has a higher unit cost compared to carbon steel pipes, limiting its application to special scenarios and smaller quantities. Flexible pipes can be applied in water depths down to 8,000 ft, high pressures up to 10,000 psi, and high temperatures a…

5. NOV – Flexible Pipe Solutions

Dominio: nov.com

Registered: 1995 (30 years)

Introduzione: Flexible Pipe products from NOV deliver proven, innovative, and high-performance technology suitable for shallow and deep-water applications.

6. Syensqo – High-Performance Flexible Pipe Materials

Dominio: syensqo.com

Registered: 2023 (2 years)

Introduzione: Syensqo offers high-performing materials for flexible pipes used in the oil and gas industry, including reinforced thermoplastic pipes, flexible risers, flowlines, and fluid transfer lines. These materials are designed to withstand harsh conditions such as extreme temperatures, high-pressure environments, and corrosive fluid mixtures. Syensqo’s thermoplastic composites and specialty polymers provi…

7. Flexpipe Systems – Flexible High-Pressure Pipe Solutions

Dominio: flexpipesystems.com

Registered: 2001 (24 years)

Introduzione: Flexpipe Products: 1. Flexpipe: Spoolable, flexible pipe designed for high pressure, abrasion, and corrosion resistance. Diameters: 2″-6″. Pressure ratings: 300, 750, and 1,500 psi. 2. Flexpipe HT: Spoolable, flexible pipe for continuous service temperatures up to 180°F (82°C). Diameters: 2″-6″. Pressure ratings: 750 and 1,500 psi. 3. Flexcord: High-strength steel-cord reinforced flexible pipe for…

8. FlexSteel – Spoolable Pipeline Technology

Dominio: flexsteelpipe.com

Registrato: 2008 (17 anni)

Introduzione: FlexSteel is a spoolable pipeline technology that combines the strength of steel with the corrosion resistance of HDPE. It is designed to be highly corrosion-resistant and more durable than other flexible pipe options, providing superior life-cycle performance and value. Key features include long lengths, high-pressure capability, and a unique combination of flexibility and durability. FlexSteel p…

Strategic Sourcing Conclusion and Outlook for flexible pipeline

What Are the Key Benefits of Strategic Sourcing for Flexible Pipelines?

In conclusion, the strategic sourcing of flexible pipelines presents invaluable advantages for B2B buyers operating in dynamic and challenging environments. These advanced systems are not only designed to enhance operational efficiency but also to reduce total expenditure (TOTEX) and installation time significantly. By opting for flexible pipelines, companies can navigate complex subsea terrains and maintain reliable connectivity even in extreme conditions, ensuring optimal flow and production.

How Can International Buyers Leverage Flexible Pipeline Solutions?

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for adaptable and sustainable pipeline solutions will only grow. Strategic sourcing enables businesses to not only select the best products but also to engage with suppliers who offer innovative monitoring systems and comprehensive support services. This positions companies to proactively manage risks, maintain pipe integrity, and enhance overall project execution.

Illustrative image related to flexible pipeline

What’s Next for B2B Buyers in the Flexible Pipeline Market?

Looking ahead, international B2B buyers should prioritize partnerships with leading manufacturers that emphasize research and development in flexible pipeline technologies. By doing so, they will be better equipped to meet the challenges of future projects while optimizing both performance and cost-effectiveness. Engage with your suppliers today to explore how flexible pipelines can elevate your operations and contribute to a more sustainable energy future.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.