Introduction: Navigating the Global Market for hose pipe high pressure wholesaler

In the fast-paced world of industrial operations, sourcing high-quality high-pressure hoses is crucial for ensuring efficiency and safety across various applications. For B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, the challenge lies not only in identifying reliable suppliers but also in understanding the diverse types of hoses available, their specific applications, and the factors that influence pricing. This comprehensive guide serves as a roadmap for navigating the global market for high-pressure hose pipe wholesalers, offering insights into the different types of hoses, their suitability for various industries, and best practices for supplier vetting.

Within these pages, you will discover an extensive overview of high-pressure hoses, including their construction, performance characteristics, and operational capabilities. We delve into critical applications ranging from agricultural to industrial cleaning, ensuring that you find the right hose for your unique needs. Additionally, the guide provides valuable information on cost considerations, helping you make informed purchasing decisions that align with your business objectives.

By arming yourself with the knowledge presented in this guide, you will be better equipped to engage with suppliers, negotiate favorable terms, and ultimately enhance your operational efficiency. Embrace the opportunity to streamline your sourcing process, minimize risks, and secure high-performance hoses that meet the demands of your industry.

Indice dei contenuti

- Top 6 Hose Pipe High Pressure Wholesaler Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hose pipe high pressure wholesaler

- Understanding hose pipe high pressure wholesaler Types and Variations

- Key Industrial Applications of hose pipe high pressure wholesaler

- 3 Common User Pain Points for ‘hose pipe high pressure wholesaler’ & Their Solutions

- Strategic Material Selection Guide for hose pipe high pressure wholesaler

- In-depth Look: Manufacturing Processes and Quality Assurance for hose pipe high pressure wholesaler

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose pipe high pressure wholesaler’

- Comprehensive Cost and Pricing Analysis for hose pipe high pressure wholesaler Sourcing

- Alternatives Analysis: Comparing hose pipe high pressure wholesaler With Other Solutions

- Essential Technical Properties and Trade Terminology for hose pipe high pressure wholesaler

- Navigating Market Dynamics and Sourcing Trends in the hose pipe high pressure wholesaler Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hose pipe high pressure wholesaler

- Strategic Sourcing Conclusion and Outlook for hose pipe high pressure wholesaler

- Disclaimer importante e condizioni d'uso

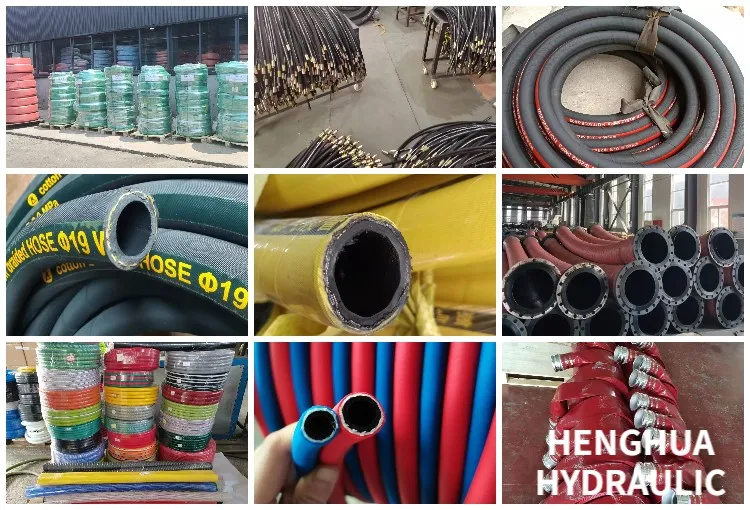

Understanding hose pipe high pressure wholesaler Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Hydraulic Hose | Reinforced construction, high-pressure tolerance | Industrial machinery, automotive | Pro: High durability, wide pressure range. Contro: Can be expensive. |

| Water Blast Hose | Designed for extreme water pressure, often with protective jackets | Cleaning services, construction | Pro: Effective for heavy-duty cleaning. Contro: Limited flexibility. |

| Chemical Transfer Hose | Resistant to various chemicals, often made from specialized materials | Chemical processing, agriculture | Pro: Safe for hazardous materials. Contro: Requires careful selection based on chemical compatibility. |

| Power Washer Hose | Flexible, lightweight, with high-temperature resistance | Power washing, car wash operations | Pro: Easy to handle, versatile. Contro: Shorter lifespan than heavier-duty options. |

| Vacuum Hose | Reinforced for suction applications, often lightweight | Food processing, pharmaceuticals | Pro: Efficient for material handling. Contro: Not suitable for high-pressure applications. |

What Are the Characteristics and Suitability of Hydraulic Hoses for B2B Buyers?

Hydraulic hoses are essential for applications requiring high-pressure fluid transfer, particularly in industrial and automotive settings. Their reinforced construction allows them to withstand significant pressure, making them suitable for machinery and hydraulic systems. When purchasing, buyers should consider factors such as pressure ratings, compatibility with fluids, and the environment in which the hose will operate. Investing in high-quality hydraulic hoses can lead to reduced maintenance costs and improved operational efficiency.

How Do Water Blast Hoses Stand Out for Heavy-Duty Applications?

Water blast hoses are specifically engineered to handle extreme pressures, often exceeding standard hoses. They are typically equipped with protective jackets to enhance durability during demanding cleaning tasks in construction and industrial sectors. While their effectiveness in heavy-duty cleaning is a significant advantage, buyers should be aware of their limited flexibility, which may restrict maneuverability in tight spaces. Proper assessment of pressure requirements and application types is crucial for optimal performance.

Why Are Chemical Transfer Hoses Critical in Certain Industries?

Chemical transfer hoses are designed to handle a variety of chemicals safely, making them indispensable in industries such as chemical processing and agriculture. These hoses are often constructed from specialized materials to ensure resistance to corrosive substances. When selecting chemical transfer hoses, buyers must focus on chemical compatibility and safety certifications to prevent leaks and ensure compliance with industry regulations. The right choice can significantly impact operational safety and efficiency.

What Advantages Do Power Washer Hoses Offer for Cleaning Services?

Power washer hoses are favored for their lightweight and flexible design, making them ideal for various cleaning applications, including car washes and industrial cleaning services. They typically withstand high temperatures and pressures, allowing for effective cleaning without damaging surfaces. However, their lifespan may be shorter than more robust options, which is a consideration for buyers looking for long-term durability. Evaluating the specific cleaning tasks and required pressure ratings is essential for effective use.

In What Scenarios Are Vacuum Hoses Most Effective for B2B Buyers?

Vacuum hoses are tailored for suction applications and are commonly used in industries such as food processing and pharmaceuticals. Their lightweight and reinforced design facilitates efficient material handling. However, these hoses are not suitable for high-pressure applications, making it crucial for buyers to assess their specific needs. When selecting vacuum hoses, factors like diameter, length, and material compatibility should be prioritized to ensure optimal performance in intended applications.

Key Industrial Applications of hose pipe high pressure wholesaler

| Industria/Settore | Specific Application of hose pipe high pressure wholesaler | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Costruzione | Hydraulic systems for heavy machinery | Enhanced operational efficiency and safety | Pressure ratings, compatibility with machinery, durability in harsh environments |

| Agricoltura | High-pressure irrigation systems | Improved water efficiency and crop yield | Resistance to chemicals, UV stability, length options |

| Petrolio e gas | High-pressure fluid transfer for drilling operations | Increased reliability and reduced downtime | Temperature tolerance, material compatibility, certification standards |

| Industrial Cleaning | Power washing and surface preparation | Effective cleaning and maintenance of equipment | Hose flexibility, abrasion resistance, pressure ratings |

| Automotive | Fuel and fluid transfer in manufacturing | Streamlined production processes and safety | Compliance with industry regulations, high-pressure ratings, custom lengths |

How are High-Pressure Hoses Utilized in Construction?

In the construction sector, high-pressure hoses are integral to hydraulic systems used in heavy machinery such as excavators and cranes. These hoses facilitate the transfer of hydraulic fluids, enabling precise control and power for lifting and moving materials. Buyers in this sector must ensure that hoses meet specific pressure ratings and are compatible with their machinery. Additionally, durability against harsh environmental conditions is crucial to prevent equipment failure and maintain safety standards.

What Role Do High-Pressure Hoses Play in Agriculture?

High-pressure hoses are vital for modern irrigation systems in agriculture, allowing for efficient water distribution across large fields. By using these hoses, farmers can optimize water usage, leading to improved crop yields and resource management. Buyers should consider the hose’s resistance to chemicals and UV exposure, ensuring longevity and reliability in diverse climates. Length options are also essential to accommodate various field sizes and irrigation layouts.

How are High-Pressure Hoses Used in Oil & Gas?

In the oil and gas industry, high-pressure hoses are crucial for transferring fluids during drilling operations. These hoses need to withstand extreme pressures and temperatures, ensuring safe and efficient fluid movement. International buyers should prioritize sourcing hoses that meet rigorous industry standards and certifications for safety and performance. Material compatibility with various drilling fluids is also a key consideration to prevent leaks and operational disruptions.

Why are High-Pressure Hoses Important for Industrial Cleaning?

High-pressure hoses are extensively used in industrial cleaning applications, particularly for power washing and surface preparation. They enable effective removal of dirt, grease, and other contaminants from machinery and surfaces, promoting maintenance and operational efficiency. Buyers should look for hoses that offer flexibility and abrasion resistance, as these features enhance usability and longevity in demanding cleaning environments. The pressure ratings must align with the cleaning equipment used to ensure optimal performance.

How Do High-Pressure Hoses Benefit the Automotive Industry?

In the automotive sector, high-pressure hoses are essential for fuel and fluid transfer during the manufacturing process. These hoses streamline production by ensuring safe and efficient movement of various fluids, including fuel, oil, and coolant. Sourcing considerations for automotive applications include compliance with industry regulations and the ability to withstand high pressures. Custom lengths may also be necessary to fit specific manufacturing setups, enhancing operational efficiency and safety.

3 Common User Pain Points for ‘hose pipe high pressure wholesaler’ & Their Solutions

Scenario 1: Inconsistent Quality of High-Pressure Hoses

Il problema: A B2B buyer sourcing high-pressure hoses for industrial applications often encounters inconsistent quality. This inconsistency can lead to failures in critical operations, resulting in downtime, increased maintenance costs, and compromised safety. Buyers may receive hoses that do not meet the specified pressure ratings or are not durable enough for the intended environment, which can be particularly concerning in sectors like oil and gas or construction where reliability is paramount.

La soluzione: To mitigate this issue, buyers should prioritize sourcing from reputable wholesalers with proven track records in the industry. Conduct thorough due diligence by checking for certifications, customer testimonials, and quality assurance processes. Engage directly with manufacturers or wholesalers to understand their production standards and request detailed product specifications. Additionally, consider implementing a sampling process for new suppliers; this allows for testing hoses under real operational conditions before committing to larger orders. Establishing a long-term relationship with a reliable supplier can also lead to improved consistency and performance in the long run.

Scenario 2: Difficulty in Selecting the Right Hose for Specific Applications

Il problema: Many B2B buyers struggle with selecting the correct high-pressure hose for their specific applications due to the wide variety of options available. Each application—whether for hydraulic systems, pressure washing, or chemical transfer—demands hoses that can withstand different pressures, temperatures, and environmental conditions. This can lead to misorders, increased costs, and even project delays as buyers navigate through complex specifications and technical jargon.

Illustrative image related to hose pipe high pressure wholesaler

La soluzione: To ease the selection process, buyers should leverage the expertise of wholesalers who provide tailored consultation services. Before making a purchase, engage with technical support teams that can offer insights into the best hose types based on specific application requirements. Create a checklist of key parameters such as pressure rating, temperature tolerance, and compatibility with fluids being transported. Additionally, consider investing in a hose management system or software that can help track performance and ensure that the right hoses are utilized for each application, thereby reducing the risk of errors.

Scenario 3: Limited Availability of Custom Solutions

Il problema: In many cases, B2B buyers find that off-the-shelf high-pressure hoses do not meet their unique operational needs, leading to frustration. Custom solutions are often necessary for specialized equipment or unconventional applications. However, some wholesalers may lack the capability or willingness to provide such customizations, leaving buyers with inadequate options.

La soluzione: Buyers should seek wholesalers that offer a robust customization program. When evaluating suppliers, inquire about their ability to manufacture hoses tailored to specific dimensions, materials, and pressure ratings. Establish a clear communication line where buyers can articulate their unique requirements, including any industry-specific certifications or compliance standards that must be met. Additionally, consider forming partnerships with suppliers who are open to collaborating on product development; this not only ensures that your unique needs are addressed but also fosters innovation and adaptability in the supply chain. By prioritizing wholesalers who understand the importance of customization, businesses can enhance operational efficiency and effectiveness.

Strategic Material Selection Guide for hose pipe high pressure wholesaler

What Are the Key Materials for High-Pressure Hose Pipes?

When selecting high-pressure hose pipes, the choice of material significantly influences performance, durability, and suitability for specific applications. Here, we analyze four common materials used in high-pressure hoses: rubber, thermoplastic elastomer (TPE), stainless steel, and PVC. Each material has unique properties that cater to different operational needs and environmental conditions.

Illustrative image related to hose pipe high pressure wholesaler

How Does Rubber Perform in High-Pressure Applications?

Rubber is a traditional choice for high-pressure hoses due to its excellent flexibility and resilience. It typically has a high-temperature rating, often ranging from -40°C to +100°C, and can handle pressures up to 15,000 psi, depending on the reinforcement.

Pros: Rubber hoses are durable, resistant to abrasion, and can withstand extreme weather conditions. They are also cost-effective for many applications.

Cons: However, rubber hoses can degrade when exposed to certain chemicals and UV light, making them less suitable for outdoor applications without protective covers. Manufacturing complexity can also increase if specialized formulations are required.

Illustrative image related to hose pipe high pressure wholesaler

Impatto sull'applicazione: Rubber is generally compatible with a wide range of fluids, including oils and fuels, but may not be suitable for aggressive chemicals.

International Considerations: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, as rubber hoses often need to meet specific regulations such as ASTM or DIN.

What Advantages Do Thermoplastic Elastomers Offer?

Thermoplastic elastomers (TPE) are gaining popularity due to their versatility and performance characteristics. TPE hoses can handle temperatures from -60°C to +120°C and are designed to withstand high pressures, often exceeding 10,000 psi.

Pros: TPE offers excellent chemical resistance and flexibility, making it suitable for a variety of applications, including those involving aggressive media. They are also lightweight and can be produced in various colors for identification.

Illustrative image related to hose pipe high pressure wholesaler

Cons: The primary drawback of TPE hoses is their higher cost compared to traditional rubber hoses. Additionally, they may require more complex manufacturing processes.

Impatto sull'applicazione: TPE hoses are ideal for applications involving chemicals, steam, or food-grade materials, making them suitable for diverse industries.

International Considerations: Compliance with regulations such as FDA for food applications and REACH for chemical safety is crucial for international buyers, especially in Europe.

Illustrative image related to hose pipe high pressure wholesaler

Why Choose Stainless Steel for High-Pressure Hoses?

Stainless steel hoses are known for their robustness and durability, often used in industrial applications where high pressure and temperature resistance are essential. They can operate effectively in temperature ranges from -70°C to +600°C and withstand pressures up to 30,000 psi.

Pros: The primary advantage of stainless steel hoses is their exceptional strength and corrosion resistance, making them suitable for harsh environments and aggressive media.

Cons: On the downside, stainless steel hoses are typically more expensive and heavier than other materials, which can complicate installation and handling.

Impatto sull'applicazione: They are particularly effective in oil and gas, chemical processing, and high-temperature applications due to their resistance to corrosion and wear.

International Considerations: Buyers should ensure that the stainless steel used meets international standards such as ASTM A269 or A312, especially for applications in Europe and the Middle East.

What Role Does PVC Play in High-Pressure Hose Applications?

Polyvinyl chloride (PVC) is commonly used for high-pressure hoses in applications like water discharge and agricultural use. PVC hoses can typically handle pressures of up to 3,000 psi and temperatures ranging from -10°C to +60°C.

Pros: PVC hoses are lightweight, flexible, and cost-effective, making them an attractive option for many buyers.

Cons: However, they have limited temperature and pressure ratings compared to rubber or stainless steel. PVC is also less resistant to UV light and certain chemicals.

Impatto sull'applicazione: PVC hoses are suitable for water and non-aggressive fluids but may not be ideal for high-temperature or chemical applications.

International Considerations: Buyers should check for compliance with local safety standards and certifications, especially in regions with stringent regulations like Europe.

Summary Table of Material Selection for High-Pressure Hoses

| Materiale | Typical Use Case for hose pipe high pressure wholesaler | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (basso/medio/alto) |

|---|---|---|---|---|

| Gomma | General industrial applications | Durable and cost-effective | Degrades with chemicals and UV exposure | Basso |

| Thermoplastic Elastomer | Chemical processing, food-grade applications | Eccellente resistenza chimica | Higher cost and manufacturing complexity | Medio |

| Acciaio inox | Oil and gas, high-temperature applications | Exceptional strength and corrosion resistance | Costo e peso maggiori | Alto |

| PVC | Water discharge, agricultural use | Lightweight and flexible | Limited pressure and temperature ratings | Basso |

This guide provides a comprehensive overview of materials for high-pressure hoses, enabling international B2B buyers to make informed decisions based on their specific requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hose pipe high pressure wholesaler

What Are the Main Stages of Manufacturing High-Pressure Hose Pipes?

The manufacturing process of high-pressure hose pipes involves several critical stages to ensure that the final product meets the rigorous demands of various industries. These stages typically include material preparation, forming, assembly, and finishing.

-

Preparazione del materiale: The first step involves selecting the appropriate raw materials, which can include rubber, thermoplastics, and reinforcement materials such as steel wire or polyester yarn. These materials must be sourced from reputable suppliers to ensure quality. The materials are then cut to size and prepared for the subsequent stages, ensuring they meet the required specifications for pressure ratings and flexibility.

-

Formazione: This stage involves the shaping of the hose. Techniques such as extrusion and braiding are commonly used. Extrusion allows for continuous lengths of hose to be formed, while braiding adds strength through interwoven layers of reinforcement. The choice of technique depends on the intended application of the hose, with considerations for pressure tolerance and flexibility.

-

Montaggio: Once the hose is formed, it undergoes assembly, where fittings, couplings, and end connections are attached. This step is crucial as it determines the compatibility of the hose with various systems. Precision in this stage ensures that there are no leaks or failures during operation.

-

Finitura: The final stage of manufacturing involves applying protective coatings and conducting any necessary surface treatments. This can include abrasion-resistant layers or UV protection, depending on the application. The finishing process also includes cutting the hose to the required lengths and performing quality checks before the product is packaged for distribution.

What Quality Assurance Standards Are Relevant for High-Pressure Hoses?

Quality assurance is vital in the manufacturing of high-pressure hoses, especially for international B2B buyers who require consistent quality. Several international and industry-specific standards are relevant in this context.

-

ISO 9001: This international standard outlines the criteria for a quality management system. Adhering to ISO 9001 ensures that manufacturers have consistent processes in place for maintaining quality throughout the production cycle.

-

Marchio CE: For products sold in the European Economic Area, CE marking indicates compliance with safety and environmental protection standards. It is crucial for B2B buyers in Europe to verify that their suppliers have this certification.

-

Standard API: The American Petroleum Institute (API) sets standards for products used in the oil and gas industry, including high-pressure hoses. Compliance with API standards is particularly important for buyers in sectors that require high-performance materials.

How Are Quality Control Checkpoints Implemented in Hose Manufacturing?

Quality Control (QC) is implemented at various checkpoints throughout the manufacturing process to ensure that the hoses meet the necessary standards and specifications. Common QC checkpoints include:

-

Controllo qualità in entrata (CQI): This initial checkpoint involves inspecting raw materials upon arrival. It ensures that all materials meet specified quality criteria before they are used in production.

-

Controllo qualità in corso d'opera (IPQC): During the manufacturing process, continuous monitoring is conducted to identify any deviations from quality standards. This includes checks on dimensions, pressure ratings, and the integrity of assemblies.

-

Controllo qualità finale (CQC): After the manufacturing process, each batch of hoses undergoes rigorous testing. This includes pressure testing, burst testing, and abrasion resistance testing to confirm that the products meet or exceed industry standards.

What Testing Methods Are Commonly Used for High-Pressure Hoses?

To ensure reliability and safety, various testing methods are employed in the quality assurance process for high-pressure hoses:

-

Test idrostatici: This method involves filling the hose with water and pressurizing it to check for leaks or weaknesses. It simulates the conditions the hose will experience in real-world applications.

-

Burst Testing: In this test, the hose is subjected to pressures well above its rated limits to determine the point of failure. This provides insights into the safety margins of the hose.

-

Abrasion Testing: This method assesses the hose’s resistance to wear and tear, which is critical for applications involving rough handling or exposure to harsh environments.

Come possono gli acquirenti B2B verificare i processi di controllo qualità dei fornitori?

B2B buyers, particularly those in international markets, must take proactive steps to verify the quality control processes of their suppliers. Here are some strategies:

-

Conduct Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows them to assess the manufacturing processes, quality control measures, and compliance with relevant standards firsthand.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including any certifications and results from recent testing. This transparency is crucial for establishing trust.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is especially valuable for buyers in regions where they cannot easily visit the manufacturing site.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances regarding quality control and certification when sourcing high-pressure hoses:

-

Regional Standards Compliance: Buyers should be aware of the specific standards and regulations applicable in their regions. For instance, while CE marking is essential in Europe, other regions may have different requirements.

-

Cultural and Communication Barriers: Effective communication is key when dealing with suppliers from different cultures. Buyers should ensure that there is a clear understanding of quality expectations and compliance requirements.

-

Logistical Considerations: The logistics of international shipping can complicate quality assurance. Buyers should factor in potential delays and variations in product quality due to transportation conditions.

In conclusion, understanding the manufacturing processes and quality assurance measures for high-pressure hoses is essential for B2B buyers looking to ensure reliability and performance in their applications. By focusing on these aspects, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose pipe high pressure wholesaler’

To assist B2B buyers in navigating the procurement of high-pressure hoses, this guide provides a structured checklist designed to ensure comprehensive evaluation and selection of suppliers. The high-pressure hose market is complex, and understanding the key factors involved can lead to more informed decisions that align with operational needs.

Fase 1: Definire le specifiche tecniche

Before you initiate contact with suppliers, clarify the technical requirements of your high-pressure hoses. This includes determining the pressure ratings, diameter, material compatibility, and intended application (e.g., hydraulic systems, industrial cleaning, or construction). Having precise specifications helps in narrowing down suppliers who can meet your specific needs.

- Pressure Ratings: Identify the maximum pressure your hoses will encounter.

- Material Compatibility: Ensure the hose material can withstand the chemicals or substances it will transport.

Fase 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential wholesalers. Utilize industry directories, trade shows, and online platforms to find suppliers with a solid reputation in high-pressure hoses. Pay attention to their market presence in regions relevant to your operations, such as Africa, South America, the Middle East, and Europe.

Illustrative image related to hose pipe high pressure wholesaler

- Industry Directories: Platforms like ThomasNet and industry-specific websites can provide valuable supplier insights.

- Trade Shows: Attending relevant trade shows offers opportunities to meet suppliers and evaluate their offerings firsthand.

Fase 3: Evaluate Supplier Certifications and Compliance

It is essential to verify that potential suppliers adhere to industry standards and possess necessary certifications. This ensures that the products meet safety and quality benchmarks, which is especially critical in high-pressure applications.

- ISO Certifications: Look for suppliers with ISO certifications that indicate quality management systems.

- Industry Compliance: Ensure compliance with local and international regulations relevant to your industry.

Passo 4: Request Samples and Technical Data Sheets

Once you have shortlisted potential suppliers, request samples of their high-pressure hoses along with technical data sheets. Analyzing samples allows you to assess the quality and suitability of the hoses for your intended applications.

- Performance Testing: Check if the samples meet your pressure and temperature requirements.

- Technical Data Sheets: These documents should provide detailed information on material properties, pressure ratings, and application guidelines.

Passo 5: Assess Pricing and Payment Terms

When comparing suppliers, pricing is a key factor, but it should not be the only one. Analyze the total cost of ownership, including shipping, taxes, and any potential import duties. Also, review payment terms and conditions to ensure they align with your budgeting and cash flow strategies.

- Bulk Discounts: Inquire about pricing structures for bulk purchases.

- Payment Flexibility: Look for suppliers offering favorable payment terms, such as credit options or installment plans.

Passo 6: Check References and Customer Feedback

Before finalizing your supplier, reach out to their existing customers for feedback. Understanding their experiences can provide insights into the supplier’s reliability, product quality, and customer service.

- Testimonials: Look for reviews or case studies related to similar applications.

- Direct Communication: Consider contacting references directly to ask specific questions about their experiences.

Passo 7: Finalize Contracts and Terms of Service

Once you have selected a supplier, ensure that all agreements are clearly documented. Review the contract terms, including delivery timelines, warranty conditions, and service agreements, to avoid misunderstandings later on.

- Legal Review: Consider having legal counsel review the contract, especially if it involves significant investment.

- Clear Terms: Ensure all terms are transparent, particularly regarding liability and dispute resolution.

By following these steps, B2B buyers can streamline their sourcing process for high-pressure hoses, ensuring they partner with suppliers that meet their technical and operational requirements.

Comprehensive Cost and Pricing Analysis for hose pipe high pressure wholesaler Sourcing

What Are the Key Cost Components in High Pressure Hose Wholesaling?

When sourcing high-pressure hoses, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

I materiali: The quality of raw materials, such as rubber, synthetic fibers, and reinforcement materials, significantly impacts the cost. Higher-grade materials enhance durability and performance but come at a premium.

-

Lavoro: Labor costs vary depending on the region and the skill level required for manufacturing. In areas with higher labor costs, such as Europe, the overall pricing may be elevated compared to regions with lower labor expenses.

-

Spese generali di produzione: This includes costs related to utilities, facilities, and equipment maintenance. Efficient production processes can reduce overhead costs, influencing the final pricing of hoses.

-

Utensili: Custom tooling for specialized hose designs can add to the initial cost. However, investing in quality tooling may lead to better precision and lower defect rates, offering long-term savings.

-

Controllo qualità (CQ): Stringent QC processes are essential, particularly for high-pressure applications where safety is paramount. These processes add to the overall cost but are necessary for maintaining quality standards and certifications.

-

Logistica: Transporting hoses from manufacturers to wholesalers involves freight and shipping costs. International logistics can add complexity and expenses, particularly when considering customs duties and tariffs.

-

Margine: Wholesalers typically apply a markup to cover their operational costs and profit margins. Understanding the average markup can help buyers gauge fair pricing.

What Factors Influence Pricing for High Pressure Hoses?

Several factors can influence the pricing of high-pressure hoses:

-

Volume/MOQ: Higher order volumes often result in lower per-unit costs. Buyers should consider negotiating Minimum Order Quantities (MOQ) to achieve better pricing.

-

Specifiche e personalizzazione: Custom hoses tailored for specific applications can incur additional costs. Buyers should balance the need for customization with budget constraints.

-

Qualità dei materiali e certificazioni: Hoses that meet international quality standards (e.g., ISO, ASTM) or specific industry certifications may command higher prices. Buyers should ensure that the required certifications align with their operational needs.

-

Fattori di fornitura: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge a premium for their proven quality and service, but this can lead to fewer operational disruptions.

-

Incoterms: Understanding the Incoterms used in the transaction is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall cost structure and the buyer’s responsibilities.

What Tips Can Help Buyers Optimize Costs?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, strategic sourcing is key:

-

Negotiate Pricing and Terms: Leverage volume discounts and flexible payment terms. Building long-term relationships with suppliers can lead to better pricing and service.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and operational efficiency. A higher upfront cost might be justified by longer service life and lower replacement needs.

-

Understand Pricing Nuances: Be aware of regional pricing differences and the impact of currency fluctuations. Understanding local market conditions can aid in making informed purchasing decisions.

-

Engage in Market Research: Regularly assess market trends and competitor pricing. Keeping abreast of industry developments can provide leverage in negotiations and sourcing strategies.

Disclaimer on Indicative Prices

Prices for high-pressure hoses can vary widely based on market conditions, specific requirements, and supplier negotiations. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing hose pipe high pressure wholesaler With Other Solutions

Exploring Alternatives to Hose Pipe High Pressure Wholesalers

In the competitive landscape of industrial applications, selecting the right solution for high-pressure needs is crucial for operational efficiency. While hose pipe high pressure wholesalers provide specialized products tailored for demanding tasks, there are alternative solutions that buyers should consider. This analysis compares high-pressure hoses with other viable methods, helping international B2B buyers make informed decisions based on performance, cost, and application suitability.

Illustrative image related to hose pipe high pressure wholesaler

| Aspetto di confronto | Hose Pipe High Pressure Wholesaler | Alternative 1: Hydraulic Systems | Alternative 2: Pneumatic Systems |

|---|---|---|---|

| Prestazioni | High pressure handling, versatile across industries | Excellent for heavy-duty applications, consistent pressure | Suitable for lighter tasks, quick response time |

| Costo | Moderate to high, depending on specifications | Generally higher initial investment; cost-effective in long-term | Lower initial costs, but ongoing air supply expenses |

| Facilità di implementazione | Requires specific fittings and setup | Complex setup, requires skilled labor | Easier to implement; less technical knowledge needed |

| Manutenzione | Regular inspections needed; long lifespan with proper care | High maintenance due to hydraulic fluid and components | Low maintenance; air systems are less prone to leaks |

| Il miglior caso d'uso | Industrial cleaning, construction, and manufacturing | Heavy machinery operations, automotive applications | Light construction, quick repairs, and automotive service |

What Are the Advantages and Disadvantages of Hydraulic Systems?

Hydraulic systems utilize pressurized fluid to perform tasks, making them ideal for heavy-duty applications. They offer robust performance and can handle significant loads, which is essential in industries like manufacturing and construction. However, they require a higher initial investment and skilled personnel for installation and maintenance, which may not be feasible for all businesses. Additionally, hydraulic fluid management can lead to high maintenance costs due to potential leaks and fluid replacements.

How Do Pneumatic Systems Compare?

Pneumatic systems operate using compressed air, providing a quick response time and ease of implementation. They are generally lower in initial costs compared to hydraulic systems, making them attractive for smaller operations or less intensive applications. However, they are best suited for lighter tasks and may not deliver the same power as hydraulic systems or high-pressure hoses. Ongoing costs associated with air supply and compressor maintenance can add up, impacting overall efficiency.

Come possono gli acquirenti B2B scegliere la soluzione giusta?

When considering the optimal solution for high-pressure applications, B2B buyers should evaluate their specific needs, including the nature of tasks, budget constraints, and operational capabilities. A hose pipe high pressure wholesaler offers specialized products tailored for demanding environments, making them ideal for industrial cleaning and construction. Conversely, hydraulic systems are suited for heavy machinery, while pneumatic systems may serve well in lighter, quick-response scenarios.

Ultimately, the choice hinges on balancing performance requirements with cost considerations and ease of implementation. By conducting a thorough analysis of their unique operational demands and leveraging this comparison, buyers can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for hose pipe high pressure wholesaler

What Are the Key Technical Properties of High-Pressure Hoses?

When sourcing high-pressure hoses, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some of the most critical properties to consider:

-

Grado del materiale

High-pressure hoses are typically made from materials such as rubber, thermoplastic, or composite materials. The choice of material affects durability, flexibility, and resistance to environmental factors like abrasion and temperature. Selecting the right material grade ensures that the hose can withstand the specific pressures and conditions of your application, reducing the risk of failure and downtime. -

Pressione nominale

The pressure rating indicates the maximum pressure the hose can safely handle. It is essential to choose hoses with pressure ratings that exceed the demands of your application. This factor is particularly important in industries such as construction and oil and gas, where unexpected pressure spikes can occur. A hose with a higher pressure rating increases safety and longevity. -

Intervallo di temperatura

Each hose type has a specified operating temperature range, which indicates the temperatures it can withstand without losing performance or integrity. Understanding the temperature requirements of your application is vital for preventing hose degradation, which can lead to leaks or ruptures, especially in extreme environments. -

Reinforcement Type

Many high-pressure hoses include reinforcement layers, such as steel wire or textile braids, which enhance their strength and flexibility. The type of reinforcement affects the hose’s ability to withstand pressure and its resistance to kinking and abrasion. A well-reinforced hose is essential for applications that involve frequent movement or harsh conditions. -

Burst Pressure

This specification indicates the pressure at which the hose will fail or burst. It’s crucial to have a clear understanding of burst pressure for safety reasons, especially in high-stakes environments. A hose with a high burst pressure relative to its working pressure provides an additional safety margin.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry terminology is essential for effective communication and negotiation in the high-pressure hose market. Here are some key terms:

Illustrative image related to hose pipe high pressure wholesaler

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for ensuring compatibility and quality in hose applications. -

MOQ (quantità minima d'ordine)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for budget-conscious buyers, as it impacts inventory levels and cash flow. Knowing the MOQ helps in planning purchases effectively. -

RFQ (Richiesta di offerta)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. This term is essential for B2B transactions as it helps streamline the purchasing process and ensures that all potential suppliers are evaluated on the same criteria. -

Incoterms (Termini commerciali internazionali)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international transactions, as they clarify who bears the risk and cost at various stages of shipping. -

Fittings and Couplings

These components are used to connect hoses to machinery or other hoses. Understanding the types and specifications of fittings and couplings is critical for ensuring compatibility and leak-free performance in high-pressure applications.

Conclusione

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the essential technical properties and terminology of high-pressure hoses can significantly enhance procurement strategies. By focusing on material grades, pressure ratings, and common trade terms, buyers can make informed decisions that ensure safety, efficiency, and long-term value in their operations.

Navigating Market Dynamics and Sourcing Trends in the hose pipe high pressure wholesaler Sector

What are the Current Market Dynamics and Key Trends in the High-Pressure Hose Sector?

The high-pressure hose market is experiencing robust growth driven by several global factors, including industrial expansion, increased demand for automation, and advancements in manufacturing technologies. Key industries such as construction, oil and gas, agriculture, and automotive are major consumers of high-pressure hoses. In regions like Africa and South America, rapid urbanization and infrastructure development are significant drivers, while in Europe and the Middle East, the focus is on enhancing existing infrastructure and adopting advanced technologies.

Emerging trends in B2B sourcing include the integration of digital platforms for procurement, enabling buyers to compare products and prices efficiently. E-commerce has reshaped how wholesalers operate, with a shift towards online marketplaces that enhance accessibility for international buyers. Additionally, the adoption of Industry 4.0 technologies, such as IoT and AI, is transforming supply chain management, offering predictive analytics for inventory and demand forecasting. Buyers from regions like Germany and Saudi Arabia are increasingly looking for suppliers that can provide not only competitive pricing but also rapid delivery times and customization options to meet specific operational needs.

How is Sustainability Influencing Sourcing Decisions in the High-Pressure Hose Market?

Sustainability has become a critical consideration in the sourcing decisions of B2B buyers within the high-pressure hose sector. The environmental impact of manufacturing processes, particularly in terms of waste generation and resource consumption, has prompted wholesalers to adopt more sustainable practices. This includes the use of eco-friendly materials and processes that minimize carbon footprints.

Ethical sourcing is also gaining prominence, with buyers seeking suppliers who can demonstrate transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) are increasingly important for companies looking to align with global sustainability goals. Suppliers that offer ‘green’ materials, such as hoses made from recycled or biodegradable components, are becoming more appealing to buyers committed to corporate social responsibility. By prioritizing sustainability, wholesalers can enhance their brand reputation while meeting the evolving expectations of international buyers.

What is the Historical Context of the High-Pressure Hose Industry?

The high-pressure hose industry has evolved significantly over the past several decades, transitioning from basic rubber hoses to advanced multi-layered designs that offer enhanced durability and performance. Initially, hoses were primarily used in industrial applications, but with technological advancements, their utility has expanded across various sectors, including agriculture, automotive, and construction.

The introduction of synthetic materials in the 1970s marked a turning point, allowing for hoses that could withstand higher pressures and harsher environments. Today, manufacturers are leveraging cutting-edge technologies such as composite materials and reinforced structures to produce hoses that are not only high-performing but also lightweight and flexible. This evolution reflects the industry’s responsiveness to the diverse needs of international markets, ensuring that B2B buyers have access to innovative solutions tailored to their specific applications.

Frequently Asked Questions (FAQs) for B2B Buyers of hose pipe high pressure wholesaler

-

How do I choose the right high-pressure hose for my application?

Selecting the appropriate high-pressure hose depends on several factors, including the specific application, pressure requirements, and environmental conditions. Assess the maximum pressure and temperature your application demands, and ensure the hose is rated accordingly. Consider material compatibility with the fluids being transported, whether it’s water, oil, or chemicals. Additionally, check for features like abrasion resistance and flexibility. Consulting with suppliers who offer technical support can provide valuable insights to ensure you make an informed decision. -

What are the common materials used in high-pressure hoses?

High-pressure hoses are typically made from materials such as rubber, thermoplastic elastomer (TPE), and PVC, each offering unique benefits. Rubber hoses are known for their durability and flexibility, making them suitable for a variety of applications. TPE hoses provide excellent resistance to chemicals and high temperatures, while PVC hoses are lightweight and cost-effective. The choice of material should align with the intended application, pressure ratings, and environmental factors to ensure optimal performance and longevity. -

What are the minimum order quantities (MOQ) for high-pressure hoses?

Minimum order quantities (MOQ) can vary significantly between suppliers and depend on factors such as the type of hose and customization options. Generally, wholesalers may set MOQs ranging from 50 to 500 units. It is advisable to discuss MOQs directly with potential suppliers, especially if you are interested in bulk purchases or have specific requirements. Some suppliers may offer flexibility on MOQs for regular customers or larger contracts, so negotiating based on your business needs can be beneficial. -

How can I ensure quality when sourcing high-pressure hoses internationally?

To ensure quality when sourcing high-pressure hoses internationally, start by vetting suppliers through thorough research. Look for manufacturers with certifications such as ISO 9001 or industry-specific standards. Request samples to assess the quality firsthand and inquire about their quality assurance processes. Establish clear communication regarding specifications, testing protocols, and warranties. Additionally, consider using third-party inspection services to verify product quality before shipment, especially when dealing with larger orders. -

What payment terms are typically offered by high-pressure hose wholesalers?

Payment terms can vary widely among wholesalers, but common practices include net 30, 60, or 90 days following delivery, or payment in advance for new customers. Some suppliers may offer discounts for early payments or bulk purchases. It’s essential to clarify payment methods accepted (e.g., bank transfers, letters of credit) and any additional fees that may apply. Establishing a good relationship with the supplier can often lead to more favorable terms, so consider discussing payment options that align with your cash flow needs. -

How does logistics work for international shipments of high-pressure hoses?

Logistics for international shipments typically involves multiple steps, including customs clearance, freight forwarding, and delivery to your location. It’s crucial to understand the shipping methods available (air, sea, or land) and their respective costs and delivery times. Work with suppliers who have experience in international shipping to navigate customs requirements effectively. Additionally, consider insurance options for your shipments to protect against potential damages or losses during transit, ensuring a smoother logistics experience. -

Can I customize high-pressure hoses to meet my specific needs?

Yes, many wholesalers offer customization options for high-pressure hoses, including variations in length, diameter, fittings, and material composition. Customization can help you meet specific application requirements or industry standards. When discussing customization, provide clear specifications and any relevant testing certifications needed. Be prepared to discuss lead times, as custom orders may take longer to fulfill than standard products. Collaborating closely with your supplier will help ensure that your customized hoses perform effectively in your intended applications. -

What industries commonly use high-pressure hoses, and what are their applications?

High-pressure hoses are utilized across various industries, including construction, agriculture, automotive, and manufacturing. In construction, they are often used for power washing, concrete spraying, and hydraulic applications. Agriculture relies on high-pressure hoses for irrigation and chemical spraying. In the automotive industry, they are essential for hydraulic systems and cleaning equipment. Understanding the specific applications within your industry can guide you in selecting the right type of high-pressure hose for your operations.

Top 6 Hose Pipe High Pressure Wholesaler Manufacturers & Suppliers List

1. Dultmeier – High Pressure Hose

Dominio: dultmeier.com

Registered: 1996 (29 years)

Introduzione: High Pressure Hose designed for demanding applications including power washer hose and sewer jetting hose. Features include multi-layer reinforcement for maximum pressure handling, abrasion-resistant outer coating, high-temperature resistance, and burst-resistant design. Offers a wide range of pressure ratings, extended service life, and flexible handling. Applicable in various industries such as …

2. Hose Warehouse – 5-Day Delivery

Dominio: hosewarehouse.com

Registrato: 2012 (13 anni)

Introduzione: This company, Hose Warehouse – 5-Day Delivery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. SPIR STAR® – Ultra-High-Pressure Hoses and Accessories

Dominio: spirstar.de

Introduzione: SPIR STAR® manufactures ultra-high-pressure thermoplastic hoses with spiralized steel wire reinforcements, suitable for pressure ranges from 250 bar (3,600 psi) to 4,000 bar (58,000 psi) and inner diameters from 3 mm to 32 mm. The product range includes high-pressure valves, adapters, tubing, and couplings. The company serves various industries including waterjet, oil & gas, hydrogen, hydraulic, a…

4. HydroMaxx® – High Pressure Lay Flat Discharge Hose

Dominio: flexiblepvc.net

Registrato: 2010 (15 anni)

Introduzione: High Pressure Lay Flat Discharge Hose – HydroMaxx®

Key Product Details:

– Available Diameters: 1.5″, 2″, 3″, 4″, 6″

– Lengths: 100 ft and 300 ft rolls

– Item Numbers and Prices:

– RLF112100: 1.5″ Dia x 100 ft – $79.99

– RLF112300: 1.5″ Dia x 300 ft – $219.99

– RLF200100: 2″ Dia x 100 ft – $99.99

– RLF200300: 2″ Dia x 300 ft – $279.99

– RLF300100: 3″ Dia x 100 ft – $199.99

– RLF300300:…

5. Aeroflex – High Pressure Hoses & PTFE Hose Assemblies

Dominio: aeroflexindia.com

Registered: 2002 (23 years)

Introduzione: High Pressure Hoses & PTFE Hose Assemblies from Aeroflex Industries are designed for extreme working pressures, suitable for liquid and gas transfer in outer space or underwater applications. Key features include:

– Made from premium quality stainless steel with heavier wall thickness and hydro-formed design.

– Corrosion-resistant, capable of withstanding pressures up to 2800 bar (40,000 psi).

– A…

6. Flexible Rubber Hoses – High Pressure Hydraulic Hose

Dominio: flexiblerubberhoses.com

Registered: 2015 (10 years)

Introduzione: High Pressure Hydraulic Hose manufacturer; Products include 2SN High Pressure Hydraulic Hose, DIN EN 853 1SN High Pressure Hydraulic Hose, 5/16″ SAE 100 R1 AT Hydraulic Rubber Hose, DN10 Custom Hydraulic Hose, I.D. 1″ Hydraulic Rubber Hoses, I.D. 1/4″ Hydraulic Hose, Black High Pressure Hydraulic Pipe, EN 853 1SN High Pressure Hydraulic Hose with Single Steel Wire Reinforcement, 3/8″ Two Wire Brai…

Strategic Sourcing Conclusion and Outlook for hose pipe high pressure wholesaler

In the competitive landscape of high-pressure hose distribution, strategic sourcing emerges as a cornerstone for success. By focusing on quality, reliability, and supplier partnerships, B2B buyers can ensure they secure hoses that meet rigorous industry standards while also optimizing their supply chain efficiencies. Understanding the diverse applications—from industrial cleaning to agricultural needs—allows wholesalers to tailor their offerings, ensuring they address specific market demands.

Illustrative image related to hose pipe high pressure wholesaler

Investing in high-pressure hoses not only enhances operational performance but also mitigates risks associated with equipment failure and downtime. Buyers should prioritize suppliers who provide comprehensive support, including technical assistance and customized solutions, to navigate the complexities of this sector effectively.

As we look to the future, international B2B buyers from Africa, South America, the Middle East, and Europe should actively seek out innovative suppliers who leverage advanced materials and manufacturing technologies. This proactive approach will not only foster long-term partnerships but also position businesses to capitalize on emerging market opportunities. Embrace the potential of strategic sourcing today—your operations depend on it.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Illustrative image related to hose pipe high pressure wholesaler

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.