Article Contents

Engineering Insight: Vulcanized Ribber

Technical Importance of Vulcanized Rubber in Dredging Hoses for TSHD and CSD Operations

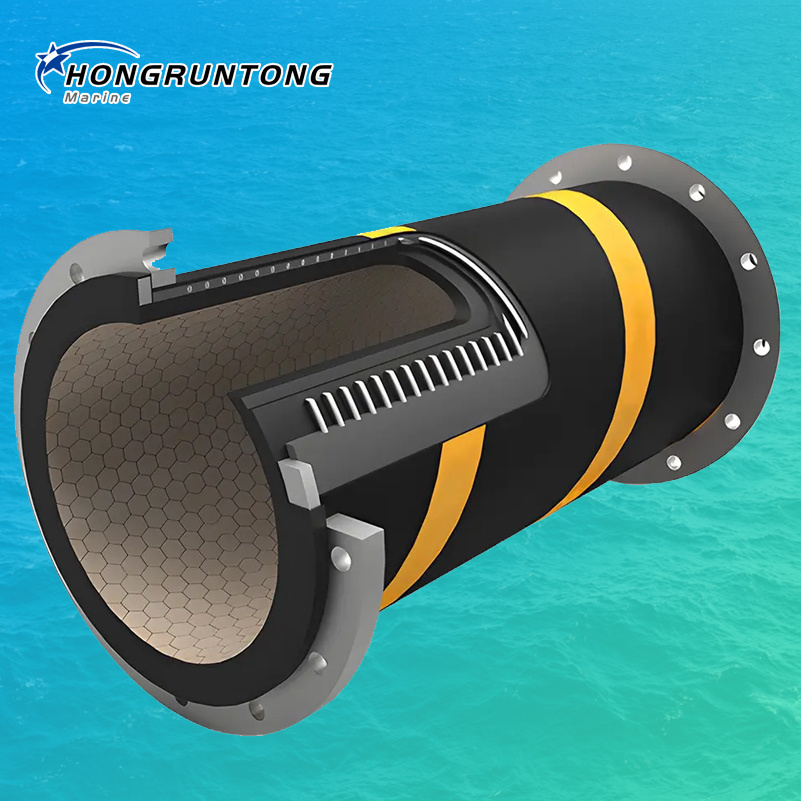

In the demanding environment of hydraulic dredging, the integrity and performance of suction and discharge hoses are critical to operational efficiency and safety. Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD) operate under extreme mechanical stress, abrasive slurries, and fluctuating pressure conditions, necessitating the use of high-performance materials in hose construction. Among these, vulcanized rubber stands as a cornerstone technology, delivering unmatched durability, flexibility, and resistance to degradation in marine applications.

Vulcanization, a chemical process pioneered by Charles Goodyear, involves cross-linking rubber polymer chains using sulfur under heat and pressure. This transformation fundamentally enhances the elastomeric properties of natural and synthetic rubber compounds. In dredging hoses, vulcanized rubber provides superior tensile strength, abrasion resistance, and resilience against repeated flexing—essential attributes when hoses are deployed in dynamic offshore environments. The process also improves resistance to oil, ozone, and weathering, ensuring prolonged service life even under continuous exposure to seawater and suspended sediments.

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the application of vulcanized rubber is engineered to meet the rigorous demands of modern dredging fleets. With over 150 skilled employees, including dedicated R&D engineers and quality assurance specialists, the company maintains full control over the vulcanization process—from compound formulation to final curing. This vertical integration ensures consistent material performance and compliance with international standards, including ISO 9001 certification. As a member of WEDA and CEDA, East Marine aligns its technical development with global industry best practices, supporting clients with hoses that deliver reliability and reduced downtime.

The vulcanized rubber layers in East Marine’s dredging hoses are precision-calibrated to balance flexibility with structural integrity. Multi-layer constructions incorporate fabric or wire reinforcement sandwiched between vulcanized rubber linings, creating a composite that resists collapse under vacuum and expansion under high pressure. The interlayer adhesion achieved through steam autoclave vulcanization ensures that the hose behaves as a single, cohesive unit, minimizing delamination risks during prolonged use.

The following table outlines key technical properties of East Marine’s vulcanized rubber used in dredging hoses:

| Property | Test Standard | Typical Value |

|---|---|---|

| Tensile Strength | ISO 37 | ≥18 MPa |

| Elongation at Break | ISO 37 | ≥450% |

| Abrasion Loss (DIN) | ISO 4649 | ≤90 mm³ |

| Hardness (Shore A) | ISO 48 | 60–70 |

| Adhesion Strength (Rubber to Fabric) | ISO 2623 | ≥8 N/mm |

| Operating Temperature Range | — | -30°C to +80°C |

These specifications reflect the optimized performance envelope achieved through East Marine’s advanced vulcanization protocols and in-house engineering expertise. By combining material science with industrial-scale manufacturing capability across a 0.68 million sqm facility, the company delivers dredging solutions that meet the evolving needs of global maritime infrastructure projects.

Advanced Manufacturing Process

Precision Vulcanization: Engineering Durability in Dredging Hose Manufacturing

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member since 2007, the vulcanization process represents the critical transformation where raw rubber compounds achieve the structural integrity and performance essential for demanding dredging operations. Our 0.68 million square meter integrated manufacturing facility, housing 18 dedicated production lines, leverages advanced vulcanization technology under stringent ISO 9001 quality management to produce suction and discharge hoses capable of withstanding extreme abrasion, high pressure, and corrosive marine environments. This phase is far more than simple curing; it is a precisely controlled chemical reaction that cross-links polymer chains, optimizing the rubber’s mechanical properties for the specific rigors of dredging.

The process begins with meticulous pre-vulcanization preparation. Compounded rubber mixes, formulated for optimal abrasion resistance, flexibility, and adhesion to textile or wire reinforcements, are calendared, extruded, and assembled into hose blanks with exacting dimensional control. These blanks are then loaded into state-of-the-art horizontal or radial autoclaves. Here, the core vulcanization reaction occurs under precisely regulated conditions of time, temperature (typically 140°C to 180°C), and internal pressure (exceeding the hose’s maximum working pressure). Our automated control systems ensure uniform heat distribution and pressure application throughout the entire hose structure, preventing defects like porosity, under-cure, or over-cure which compromise performance and lifespan. The specific vulcanization profile – duration, temperature ramp rates, and pressure levels – is meticulously engineered for each hose construction and compound, validated through extensive R&D and historical performance data.

Post-vulcanization, rigorous quality control protocols mandated by our ISO 9001 certification system commence immediately. Hoses undergo comprehensive dimensional checks, visual inspection for surface defects, and critical hydrostatic pressure testing at 1.5 times the specified maximum working pressure. Destructive testing on representative samples from each batch verifies tensile strength, elongation at break, tear resistance, and adhesion strength between rubber and reinforcement layers, ensuring compliance with international standards like ISO 1436 and project-specific requirements. This systematic approach, executed across our high-capacity 18-line production environment, guarantees that every meter of East Marine dredging hose delivers the consistent, field-proven reliability demanded by global dredging contractors operating in the harshest conditions.

The following table outlines key performance characteristics achieved through our optimized vulcanization process for standard dredging hose constructions:

| Parameter | Typical Value Range | Test Standard | Significance for Dredging |

|---|---|---|---|

| Maximum Working Pressure | 10 – 25 bar | ISO 1402 | Handles high-pressure slurry discharge |

| Proof Pressure | 1.5 x MWP | ISO 1402 | Ensures safety margin against pressure spikes |

| Minimum Burst Pressure | ≥ 3 x MWP | ISO 1402 | Critical safety factor for operational safety |

| Intervallo di temperatura | -20°C to +80°C | ISO 37 | Maintains flexibility in diverse climates |

| Abrasion Resistance (DIN) | ≤ 120 mm³ | DIN 53516 | Extends service life in abrasive sediment |

| Adhesion Strength | ≥ 8 kN/m (rubber-reinforcement) | ISO 3601-1 | Prevents delamination under stress |

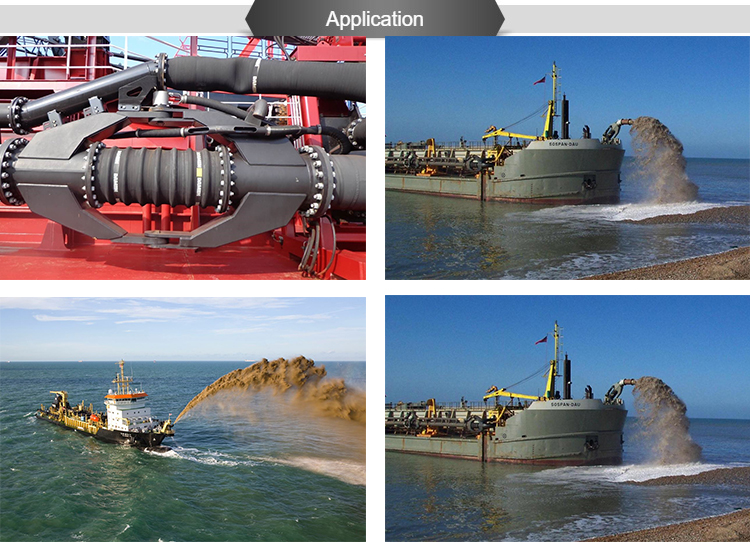

Critical Applications

Global Applications of Vulcanized Rubber in Dredging and Marine Infrastructure Projects

Vulcanized rubber, particularly in the form of high-performance dredging hoses, plays a pivotal role in large-scale marine and offshore operations worldwide. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, our engineered vulcanized rubber solutions are deployed across critical infrastructure projects that demand durability, flexibility, and resistance to abrasive and corrosive environments. With over 15 years of industry experience since our founding in 2007, and as an active member of both the Central Dredging Association (CEDA) and the World Organization for Dredging (WEDA), we align our product development with global best practices and technical standards.

One of the primary applications of vulcanized rubber hoses is in hydraulic dredging operations. These hoses are essential for transporting slurry—comprising sand, silt, and water—from the seabed to onshore processing or deposition sites. Whether in capital dredging for port expansions or maintenance dredging to ensure navigational safety, our reinforced rubber hoses withstand high internal pressures and abrasive particulate flow. Projects in Southeast Asia, the Middle East, and West Africa have successfully utilized our suction and discharge hoses in riverine and coastal environments where reliability under continuous operation is non-negotiable.

In offshore oil and gas fields, vulcanized rubber hoses support subsea operations including sediment removal around platform foundations, pipeline trenching, and decommissioning activities. The oil-resistant and seawater-stable compounds we use ensure long service life even under fluctuating temperatures and mechanical stress. These hoses are often deployed via trailing suction hopper dredgers (TSHDs) or cutter suction dredgers (CSDs), where dynamic movement and submersion depth require materials with superior elasticity and tensile strength—qualities inherent in properly vulcanized rubber.

Land reclamation projects, such as those seen in the UAE, Singapore, and the Maldives, represent another major application domain. In these endeavors, vast quantities of sand are pumped over long distances—sometimes exceeding 5 kilometers—requiring hoses that can endure prolonged exposure to UV radiation, wave action, and mechanical abrasion at connection points. Our floating hose systems, constructed with vulcanized rubber and high-tenacity textile reinforcements, provide the necessary buoyancy and structural integrity. The vulcanization process ensures seamless bonding between rubber layers and reinforcing plies, eliminating delamination risks under cyclic loading.

East Marine’s commitment to quality is reinforced through ISO9001 certification and a 0.68 million square meter manufacturing facility in Jiangsu, enabling scalable production without compromising precision. Our participation in CEDA and WEDA ensures ongoing collaboration with global dredging leaders, allowing us to contribute to and benefit from technical advancements in marine engineering.

The following table outlines key technical specifications of our standard dredging hoses:

| Parameter | Value |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (varies by size) |

| Intervallo di temperatura | -20°C to +85°C |

| Resistenza all'abrasione | >100 mm³ (DIN 53516) |

| Reinforcement Layer | High-tenacity polyester or nylon |

| Cover Compound | Natural rubber blend, ozone resistant |

| Certification | ISO9001, CEDA/WEDA compliant |

Technical Data & Specs

Technical Specifications: Precision Engineering in Dredging Hose Performance

As a leading manufacturer within the WEDA and CEDA networks with ISO 9001 certification and over 17 years of specialized R&D since 2007, East Marine (Jiangsu Huashen Special Rubber Products) understands that dredging hose performance hinges on rigorously defined technical parameters. Generic industry specifications often fail to address the extreme abrasion, pressure cycling, and dynamic flexing inherent in modern dredging operations. Our vulcanized rubber suction and discharge hoses are engineered using proprietary compound formulations and advanced multi-stage vulcanization processes within our 680,000 sqm facility, resulting in demonstrable performance advantages over conventional offerings. Critical evaluation must focus on the interplay between inner diameter, working pressure, burst pressure, and bending radius – factors directly impacting operational safety, efficiency, and total cost of ownership. Below is a comparative analysis reflecting typical high-duty cycle dredging hose specifications for common nominal sizes, based on standardized testing protocols per ISO 14310 and CEDA guidelines.

The data presented represents achievable performance benchmarks for hoses designed for continuous heavy-duty dredging applications. Actual specifications may vary based on specific project requirements and material construction.

Inner Diameter (mm) Working Pressure (bar) Burst Pressure (bar) Bending Radius (mm)

East Marine Vulcanized Hose 400 16 ≥ 64 1,800

Industry Standard Competitor Hose 400 14 ≥ 42 2,200

East Marine Vulcanized Hose 600 12 ≥ 48 2,700

Industry Standard Competitor Hose 600 10 ≥ 30 3,300

East Marine Vulcanized Hose 800 10 ≥ 40 3,600

Industry Standard Competitor Hose 800 8 ≥ 24 4,400

East Marine’s engineering superiority is quantifiable in three critical areas. Firstly, our hoses consistently achieve a minimum 4:1 burst-to-working pressure ratio, exceeding the common industry minimum of 3:1. This translates to a significantly enhanced safety margin during pressure surges or transient events common in dredge pump operations, directly mitigating rupture risks and associated downtime or environmental hazards. Secondly, the superior flexibility inherent in our vulcanized rubber compound, developed through precise control of the curing process, delivers a demonstrably tighter bending radius across all diameters. A reduced bending radius, such as 1,800mm versus 2,200mm for a 400mm ID hose, is not merely a specification; it enables more compact pipeline layouts in confined dredging areas, reduces stress concentrations at flange connections during vessel movement, and minimizes energy loss due to flow restriction in bends – directly improving pumping efficiency and reducing fuel consumption. Thirdly, the higher working pressure ratings at equivalent diameters allow for greater slurry throughput or longer pipeline reaches without necessitating larger, heavier, and more expensive hose sections, optimizing capital expenditure and operational flexibility.

These performance differentiators stem from East Marine’s foundational commitment to material science and process control. Our ISO 9001-certified manufacturing leverages decades of specialized experience in marine rubber compounding, ensuring consistent vulcanization density and adhesion between rubber layers and reinforcement plies. This rigorous approach results in hoses that deliver not only superior immediate performance but also extended service life under the most abrasive and demanding dredging conditions, ultimately providing a lower cost-per-cubic-meter dredged. For project engineers specifying critical dredging infrastructure, these technical benchmarks are essential for ensuring operational reliability and maximizing project ROI. Consult East Marine’s engineering team for application-specific validation and performance data.

Partner with East Marine

Conclusion: Engineered for Performance, Backed by Global Expertise

When it comes to dredging operations, the reliability of your suction and discharge systems directly impacts project timelines, operational costs, and overall efficiency. Vulcanized rubber hoses represent a critical component in this ecosystem, where the fusion of advanced rubber compounds and precision engineering determines longevity and performance under extreme conditions. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we have dedicated over 15 years to perfecting the science of vulcanization and reinforcement in dredging hoses, ensuring every product meets the rigorous demands of marine and inland excavation environments.

Our vulcanized rubber hoses are manufactured in a 0.68 million square meter state-of-the-art facility, leveraging proprietary rubber formulations and multi-layer reinforcement technologies. Each hose undergoes stringent quality control protocols aligned with ISO9001 standards, ensuring resistance to abrasion, UV degradation, ozone exposure, and high-pressure fatigue. As active members of WEDA and CEDA, we remain at the forefront of industry innovation, collaborating with engineers and contractors worldwide to refine hose performance in real-world dredging scenarios.

What sets East Marine apart is not only our technical capability but also our global support infrastructure. With a strategic branch located in Singapore, we provide rapid response times, localized technical assistance, and streamlined logistics across Southeast Asia, the Middle East, Africa, and beyond. Whether you are operating a cutter suction dredger in a coastal reclamation project or managing aggregate transfer in a riverbed mining operation, our team ensures your hose systems are optimized for maximum uptime and minimal maintenance.

We invite engineering firms, dredging contractors, and procurement managers to engage with our technical team for project-specific solutions. From custom hose assembly configurations to on-site performance audits, East Marine delivers end-to-end support tailored to your operational requirements.

Technical Specifications – Vulcanized Rubber Dredging Hoses

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (varies by diameter) |

| Intervallo di temperatura | -20°C to +85°C |

| Cover Material | Natural Rubber / SBR Blend, UV & Ozone Resistant |

| Reinforcement Layers | 2–4 Ply High-Tensile Synthetic Fabric + Steel Wire Helix |

| Resistenza all'abrasione | >100 mm³ (DIN ISO 4649) |

| Bend Radius (Min) | 6x Nominal Diameter |

| Standards Compliance | ISO 1431, ISO 1817, ISO 8033 |

| Certificazioni | ISO9001, WEDA & CEDA Industry Member |

For immediate technical consultation or quotation requests, contact our global support team via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our Singapore branch ensures responsive coordination for clients across key maritime and dredging hubs. Partner with East Marine — where industrial durability meets engineered precision.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.