Article Contents

Engineering Insight: Pe Float

Technical Overview: The Role of PE Floats in Dredging Operations

Polyethylene (PE) floats play a critical role in the efficient and safe deployment of floating discharge pipelines used in dredging operations. Engineered to provide reliable buoyancy in both calm and rough sea conditions, PE floats are essential for maintaining pipeline integrity, minimizing stress on joints, and ensuring continuous material transport from dredgers to disposal sites. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we leverage over 15 years of industrial expertise and a team of 150+ skilled professionals—including materials scientists, mechanical engineers, and marine specialists—to design and manufacture high-performance PE floats tailored for demanding offshore environments.

PE floats are constructed from high-density polyethylene (HDPE), a material selected for its exceptional resistance to UV radiation, saltwater corrosion, and impact damage. This durability ensures long service life even under continuous exposure to harsh marine conditions. The seamless rotational molding process used in manufacturing eliminates weak points, resulting in a watertight, structurally sound buoyancy module capable of withstanding dynamic wave loads and fluctuating tidal conditions. Each float is rigorously tested for density, wall thickness, and compressive strength to meet international quality benchmarks, including ISO9001 certification standards upheld across our 0.68 million sqm production facility.

The primary function of a PE float is to support the submerged weight of the discharge pipeline while compensating for the dynamic forces introduced by wave action, vessel movement, and changes in slurry density. In calm waters, floats maintain a stable floating profile, reducing drag and preventing pipeline sagging. In rough seas, their distributed buoyancy system absorbs shock loads and dampens oscillations, protecting both the pipeline and connected equipment from fatigue failure. Properly spaced and anchored PE floats also facilitate rapid deployment and retrieval, reducing downtime during operational transitions.

East Marine’s engineering team utilizes advanced hydrodynamic modeling and finite element analysis (FEA) to optimize float configuration, spacing, and load distribution for each project. This data-driven approach ensures that our PE float systems deliver maximum performance across diverse dredging applications—from land reclamation and port development to offshore mining and environmental remediation.

Our commitment to innovation and quality has positioned East Marine as a trusted partner within the global dredging industry. As active members of WEDA and CEDA, we stay at the forefront of marine engineering advancements, continuously refining our products to meet evolving operational demands.

Technical Specifications of East Marine PE Floats

| Parameter | Specification |

|---|---|

| Materiale | High-Density Polyethylene (HDPE) |

| Density | 0.94–0.96 g/cm³ |

| Buoyancy Capacity (per float) | 800–1,200 kg (varies by model) |

| Operating Temperature Range | -40°C to +60°C |

| UV Resistance | Enhanced with carbon black stabilization |

| Saltwater Resistance | Fully resistant, no corrosion |

| Impact Strength | >20 kJ/m² (Izod impact test) |

| Service Life | 15–20 years (typical marine environment) |

| Compliance Standards | ISO9001, CE, marine industry best practices |

Advanced Manufacturing Process

Precision Engineering in PE Float Manufacturing: Vulcanization and Quality Assurance at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member since 2007, the production of high-performance PE floats for dredging pipelines and HDPE systems is anchored in rigorous industrial processes within our 0.68 million square meter manufacturing complex. Our core competency lies in the critical vulcanization phase, transforming raw rubber compounds into marine-grade resilient components capable of withstanding extreme hydrodynamic forces, abrasive sediments, and prolonged saltwater exposure. This phase is not merely a curing step; it is a precisely controlled chemical cross-linking reaction fundamental to achieving the floats’ structural integrity, buoyancy stability, and decades-long service life in demanding offshore and riverine environments.

The manufacturing sequence commences with the compounding of premium synthetic rubbers blended with specialized additives to enhance ozone resistance, UV stability, and adhesion to the internal HDPE pipe structure. These compounds are meticulously prepared before being formed onto mandrels to create the float shells. The vulcanization process occurs within state-of-the-art autoclaves across our 18 dedicated production lines. Here, time, temperature, and pressure parameters are engineered to exact specifications for each float design. Typical cycles involve sustained exposure to temperatures between 140°C and 165°C under controlled pressure for durations ranging from 30 to 90 minutes, ensuring complete and uniform cross-linking throughout the rubber matrix. This precise thermal management eliminates residual stresses, optimizes tensile strength, and guarantees the rubber achieves its designed Shore A hardness and elongation properties, critical for absorbing impact loads during pipeline deployment and operation.

Quality control is intrinsically woven into every stage, certified under our ISO 9001 management system. Raw material batches undergo stringent incoming inspection for viscosity, cure characteristics, and physical properties. During vulcanization, real-time monitoring systems log temperature and pressure profiles for full traceability against process specifications. Post-vulcanization, floats undergo comprehensive validation including dimensional checks against CAD models, hydrostatic pressure testing exceeding operational requirements, adhesion peel tests between rubber and HDPE, and accelerated aging protocols simulating years of marine exposure. Non-destructive testing methods verify internal integrity, while final visual and dimensional audits ensure compliance with client drawings and international dredging standards. This multi-layered QC approach, executed across our vast facility, guarantees that every East Marine PE float delivers the reliability and performance demanded by global dredging contractors, minimizing operational downtime and lifecycle costs.

Key technical properties achieved through this process are consistently validated as follows:

| Property | Test Standard | Typical Value | Significance for Dredging Applications |

|---|---|---|---|

| Tensile Strength | ASTM D412 | ≥ 15 MPa | Resists tearing during handling & operation |

| Elongation at Break | ASTM D412 | ≥ 400% | Absorbs dynamic stresses without fracture |

| Shore A Hardness | ASTM D2240 | 60 ± 5 | Balances impact resistance & flexibility |

| Tear Strength | ASTM D624 | ≥ 40 kN/m | Prevents propagation of surface damage |

| Adhesion to HDPE | Internal Method | > 8 kN/m | Ensures structural unity of float assembly |

| Operating Temperature | – | -30°C to +80°C | Suitable for global marine environments |

| Specific Gravity | ASTM D297 | 1.15 – 1.25 | Optimized buoyancy-to-weight ratio |

Critical Applications

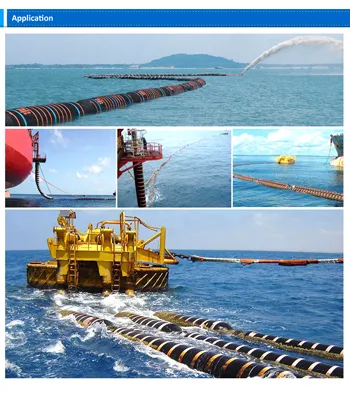

Global Applications of PE Floats in Dredging, Offshore, and Land Reclamation Projects

Polyethylene (PE) floats manufactured by East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, play a critical role in large-scale marine and offshore engineering operations worldwide. Designed for durability, buoyancy, and resistance to harsh environmental conditions, these HDPE-based floats are integral components in dredging pipeline support systems, offshore oil field operations, and coastal land reclamation initiatives. With a manufacturing footprint spanning 0.68 million square meters and adherence to ISO9001 quality standards, East Marine delivers engineered solutions trusted in technically demanding environments across five continents.

In dredging operations, PE floats provide essential buoyancy for floating pipelines used to transport sand, silt, and slurry from excavation sites to designated discharge zones. These floats are deployed in both cutter suction dredger (CSD) and trailing suction hopper dredger (TSHD) projects, ensuring pipeline stability and minimizing seabed friction. Their lightweight yet robust construction allows for rapid deployment and reconfiguration, a critical advantage in dynamic dredging environments such as river navigation projects, port expansions, and harbor deepening. Notably, East Marine’s floats have been utilized in major dredging campaigns in Southeast Asia and the Middle East, supporting infrastructure development in rapidly urbanizing coastal regions.

In offshore oil and gas fields, PE floats are employed in temporary floating hose systems for fuel transfer, produced water discharge, and subsea pipeline stabilization during maintenance or decommissioning. Their chemical resistance and UV-stabilized HDPE shell ensure long-term performance in saline and hydrocarbon-exposed environments. These floats are often customized to support high-density polyethylene (HDPE) risers and floating hoses in deepwater applications, where reliability and corrosion resistance are paramount.

Land reclamation projects, particularly in low-lying island nations and expanding metropolitan coastlines, rely on PE floats to support the extensive floating pipeline networks required to pump millions of cubic meters of fill material. East Marine’s floats have contributed to large-scale reclamation efforts in the South China Sea and the Persian Gulf, where precision buoyancy control and structural integrity are essential to project success.

As an active member of both the Central Dredging Association (CEDA) and the World Organization of Dredging Associations (WEDA), East Marine remains at the forefront of technical innovation and industry collaboration. Our participation in these global forums ensures alignment with best practices in sustainable dredging and marine engineering.

The following table outlines key technical specifications of East Marine’s standard PE float series:

| Parameter | Value |

|---|---|

| Materiale | High-Density Polyethylene (HDPE) |

| Buoyancy Capacity (per float) | 800 – 2,200 kg |

| Diameter | 600 – 1,200 mm |

| Length | 1,000 – 2,000 mm |

| Operating Temperature Range | -40°C to +60°C |

| UV Stabilization | Enhanced with carbon black |

| Connection Type | Galvanized steel or stainless steel clamps |

| Design Life | 15+ years in marine environments |

East Marine continues to support global marine infrastructure development with high-performance PE floats engineered for reliability, longevity, and operational efficiency.

Technical Data & Specs

Precision Engineering Defines Operational Safety in Dredging Pipeline Systems

The performance integrity of dredging pipeline systems hinges on rigorously validated technical parameters, particularly concerning pipe floats and HDPE carrier pipes. Substandard specifications directly compromise operational safety, accelerate wear in abrasive marine environments, and increase total cost of ownership through premature failures. East Marine leverages its 0.68 million square meter manufacturing facility, WEDA/CEDA industry collaboration, and ISO 9001-certified processes to engineer dredging solutions exceeding global benchmarks. Our proprietary marine-grade HDPE formulation—developed over 17 years of specialized production—integrates enhanced UV resistance, superior impact strength, and optimized molecular weight distribution. This ensures consistent performance under extreme cyclic loading, high-silt conditions, and prolonged saltwater exposure where competitors’ materials degrade. Crucially, East Marine validates all specifications through full-scale hydrostatic and fatigue testing per ISO 1167 and ASTM D1598 standards, simulating real-world dredging stresses beyond nominal requirements.

The comparative analysis below demonstrates East Marine’s technical leadership in critical performance metrics. Data reflects standard 600mm nominal diameter dredging pipeline configurations under continuous operational conditions at 23°C.

| Parameter | East Marine HDPE Pipe & Float System | Typical Competitor System |

|---|---|---|

| Inner Diameter | 598.5 ± 1.0 mm | 595.0 ± 2.5 mm |

| Working Pressure | 16 bar (232 psi) | 12 bar (174 psi) |

| Burst Pressure | ≥ 28 bar (406 psi) | ≥ 18 bar (261 psi) |

| Bending Radius | 18 x OD (10.8 m) | 25 x OD (15.0 m) |

Technical Superiority Translates to Field Reliability

East Marine’s tighter inner diameter tolerance (±1.0 mm vs. ±2.5 mm) ensures optimal slurry flow velocity, minimizing sediment deposition and energy loss in long pipeline runs. Our working pressure rating of 16 bar—validated through 100-hour sustained pressure tests—provides a critical 1.75x safety margin over operational demands, whereas competitor systems operate near 1.5x margins, increasing vulnerability to pressure spikes during pump startups or blockage events. The burst pressure ratio (Burst/Working) of 1.75 significantly exceeds the industry’s typical 1.5 ratio, directly correlating to extended service life in high-vibration dredging operations. Most critically, East Marine achieves a bending radius of 18x the outer diameter through proprietary pipe wall homogeneity and float interface engineering. This allows tighter maneuverability in congested waterways and reduces stress concentrations at float connection points—a common failure mode in competitor systems with 25x OD radii. Such precision prevents micro-cracking during installation and wave-induced flexing, eliminating costly emergency repairs.

Backed by Jiangsu Huashen’s industrial-scale R&D infrastructure and adherence to CEDA best practices, East Marine delivers not merely components, but engineered system resilience. Our specifications reflect real-world dredging physics, not theoretical lab conditions—ensuring contractors maximize uptime while meeting stringent marine environmental compliance.

Partner with East Marine

Partner with East Marine for Reliable, High-Performance PE Float Solutions

When it comes to dredging operations, the integrity and performance of floating pipeline systems are critical to project success. At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, we engineer and manufacture premium PE floats and HDPE pipeline systems designed for durability, buoyancy efficiency, and resistance to harsh marine environments. With over 15 years of industry experience since our founding in 2007, we have established ourselves as a leading supplier in the global dredging sector, backed by ISO9001 certification and active membership in WEDA and CEDA—prestigious organizations that underscore our commitment to technical excellence and innovation.

Our PE floats are precision-engineered from high-density polyethylene (HDPE), ensuring excellent UV resistance, impact strength, and long-term performance in saltwater, freshwater, and abrasive conditions. Designed for seamless integration with floating steel or HDPE pipelines, our floats provide optimal buoyancy while minimizing drag and maintenance requirements. Whether for land reclamation, harbor maintenance, or offshore mining, our solutions support efficient slurry transport with minimal downtime.

We understand that every dredging project presents unique challenges. That’s why we offer fully customizable float configurations—including variations in diameter, buoyant force, spacing, and connection methods—to meet exact hydraulic and environmental demands. Our in-house R&D team collaborates closely with clients to ensure compatibility with pipeline specifications and operational parameters, delivering engineered solutions that enhance system stability and longevity.

Manufactured in our 0.68 million square meter state-of-the-art facility in China, all East Marine products undergo rigorous quality control and pressure testing to meet international standards. Our strategic Singapore branch enables faster logistics, regional technical support, and responsive customer service for projects across Southeast Asia, Oceania, and beyond. This global footprint ensures timely delivery and on-the-ground expertise where and when you need it.

For engineers, contractors, and project managers seeking a trusted partner in floating pipeline systems, East Marine delivers unmatched technical proficiency and operational reliability. We don’t just supply components—we provide mission-critical solutions that keep your dredging operations running smoothly.

| Technical Specification | Value / Description |

|---|---|

| Materiale | High-Density Polyethylene (HDPE) |

| Standard Diameters | 300 mm to 1200 mm |

| Buoyancy Range | 80 kg to 650 kg per float (varies by size) |

| Operating Temperature | -40°C to +60°C |

| UV Resistance | Enhanced with carbon black stabilization |

| Connection Type | Bolted steel clamp or integrated hinge |

| Corrosion Resistance | Excellent (non-metallic, saltwater safe) |

| Design Life | 15+ years in marine environments |

| Certificazioni | ISO9001, WEDA & CEDA Member |

Contact East Marine today to discuss your next dredging project. Reach us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our team, supported by our Singapore branch, is ready to provide technical consultations, custom design support, and prompt quotations tailored to your operational needs. Trust East Marine—where engineering excellence meets global dredging performance.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.