Article Contents

Engineering Insight: Dredging Project

Technical Imperatives in Dredging Project Execution for TSHDs and CSDs

Dredging projects represent complex, high-stakes engineering undertakings where operational continuity and efficiency are paramount. The success of Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs) hinges critically on the performance reliability of their fluid transfer systems, particularly the suction and discharge hoses. These components operate under extreme, multi-vector stresses: cyclic flexing from vessel motion and wave action, intense abrasive wear from sediment-laden slurries often exceeding 60% solids by weight, significant internal pressure fluctuations, and constant exposure to corrosive marine environments. A single hose failure during critical project phases—such as deep-sea trailing or confined channel excavation—triggers immediate operational paralysis, incurring severe financial penalties through vessel downtime, missed contractual milestones, and costly emergency repairs. Consequently, the technical specification, material science, and structural integrity of dredging hoses are not merely operational considerations but fundamental determinants of project feasibility, schedule adherence, and overall economic viability.

TSHDs impose unique demands on suction hoses, requiring exceptional flexibility to accommodate the dynamic hose ladder movement during trailing operations while maintaining structural integrity against collapse under deep-water vacuum conditions and abrasion from coarse seabed materials. Conversely, CSD discharge hoses face extreme abrasion resistance requirements at the cutter head discharge point, handling high-velocity, high-density slurries under significant pressure, often requiring multi-layer reinforcement to prevent premature wear-through. Both applications necessitate hoses engineered with precise elastomer formulations for cut/tear resistance, optimized textile or wire reinforcement architectures for pressure containment and kink resistance, and robust coupling systems capable of withstanding constant mechanical shock loads. Adherence to stringent international standards like CEDA guidelines and ISO 14310 is non-negotiable for mitigating catastrophic failure risks in these high-consequence environments.

East Marine leverages its position as a core technical supplier within the dredging sector, backed by a dedicated engineering cohort exceeding 150 professionals specializing in marine rubber compounding, finite element analysis (FEA), and hydraulic system dynamics. Our 0.68 million square meter integrated manufacturing facility, operating under ISO 9001 certification and active WEDA/CEDA membership since our 2007 founding, enables rigorous in-house validation of every hose assembly against project-specific operational profiles. This deep engineering capability ensures solutions are not merely compliant but proactively optimized for the distinct hydrodynamic and abrasive challenges presented by TSHD suction ladder deployment or CSD high-pressure discharge circuits, directly contributing to enhanced dredger uptime and project margin protection.

The following table outlines critical technical parameters differentiating hose requirements for primary dredger types:

Parameter | TSHD Suction Hose | CSD Discharge Hose

Internal Pressure Rating | 10-15 bar (dynamic vacuum/pressure cycles) | 16-25+ bar (steady high pressure)

Abrasion Resistance (DIN 53516) | 80-100 mm³ loss (coarse sand/rock) | 60-80 mm³ loss (high-concentration abrasive slurry)

Minimum Bend Radius | 8-10x ID (critical for ladder articulation) | 6-8x ID (space-constrained discharge lines)

Reinforcement | Multi-spiral wire/textile for collapse resistance | Heavy-duty textile/wire braid for pressure/abrasion

Typical Slurry Density | 1.3-1.6 g/cm³ | 1.5-2.0+ g/cm³

Advanced Manufacturing Process

Advanced Manufacturing and Precision Vulcanization in Dredging Hose Production at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted name in marine and dredging solutions since 2007, the manufacturing of high-performance suction and discharge rubber hoses is executed with uncompromising precision. Our 0.68 million square meter state-of-the-art factory in China serves as the backbone of our production capabilities, housing 18 fully integrated production lines dedicated to the development of reinforced rubber hoses engineered for the most demanding dredging environments.

The core of our manufacturing excellence lies in the vulcanization process—a critical phase where raw rubber compounds are transformed into durable, high-tensile materials capable of withstanding extreme pressure, abrasive slurries, and continuous flexing. Our advanced autoclave and press-vulcanization systems ensure uniform cross-linking of polymer chains, enhancing the hose’s mechanical strength, flexibility, and resistance to degradation from seawater, UV exposure, and chemical contaminants. Each hose undergoes precisely controlled temperature and pressure cycles, monitored in real time to meet strict performance benchmarks.

Prior to vulcanization, multi-layer construction is meticulously assembled. This includes a wear-resistant inner tube, high-strength textile or steel reinforcement layers, and a weather- and abrasion-resistant outer cover. The reinforcement architecture is tailored to application-specific requirements, whether for trailing suction hopper dredgers, cutter suction dredgers, or floating pipeline systems. Our engineering team leverages finite element analysis (FEA) to optimize layer adhesion and stress distribution, ensuring maximum fatigue life under dynamic operational loads.

Quality assurance is embedded at every stage of production. As an ISO 9001-certified manufacturer and proud member of WEDA and CEDA, East Marine adheres to international standards for design, process control, and traceability. Each hose batch undergoes rigorous testing, including hydrostatic pressure validation, adhesion strength measurement, dimensional inspection, and elongation-to-break analysis. Non-destructive testing (NDT) methods are employed to detect internal defects, while final products are laser-stamped with unique serial identifiers for full lifecycle tracking.

Our scalable production infrastructure, supported by automated material handling and digital process monitoring, allows for rapid turnaround without compromising consistency. The integration of lean manufacturing principles across the 18 production lines ensures efficient resource utilization and minimal environmental impact.

East Marine’s commitment to technical innovation and operational integrity positions us as a strategic partner for global dredging contractors seeking reliable, high-capacity hose solutions backed by industrial-grade quality and engineering depth.

| Parameter | Specification |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 specialized lines |

| Vulcanization Method | Autoclave & press-vulcanization |

| Quality Standard | ISO 9001:2015 |

| Test Pressure Capability | Up to 4.0 MPa (customizable) |

| Reinforcement Types | Textile braid, spiral steel, wire helix |

| Intervallo di temperatura | -30°C to +85°C (standard compounds) |

| Custom Lengths | Up to 50 meters per joint (spliced options) |

| Traceability System | Laser serial marking with batch documentation |

Critical Applications

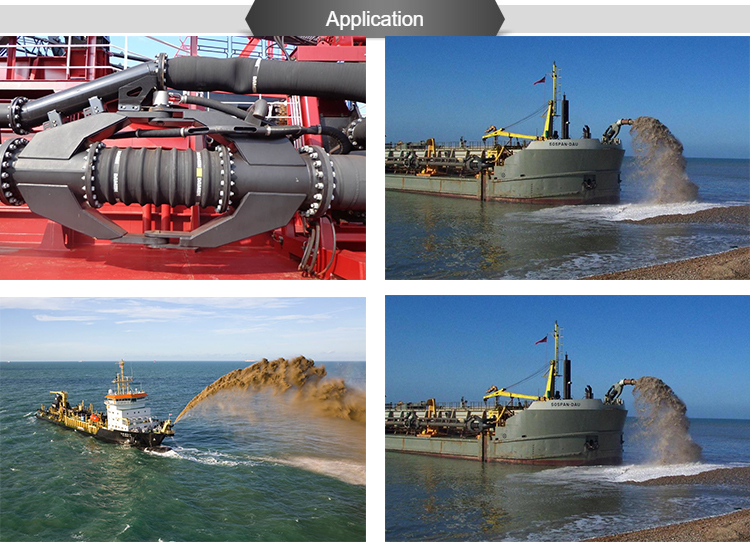

Global Project Applications for Dredging Rubber Hoses

Dredging projects form the backbone of critical global infrastructure development and resource management, demanding highly engineered rubber hoses capable of withstanding extreme operational environments. East Marine, leveraging its 0.68 million square meter manufacturing facility and deep expertise since 2007, supplies robust suction and discharge hoses essential across three primary application domains. These domains underscore the indispensable role of advanced elastomeric solutions in shaping coastlines, accessing energy resources, and creating new landmasses.

Traditional capital and maintenance dredging for port and harbor development represents a fundamental application. Deepening navigation channels, constructing new berths, and maintaining existing infrastructure require continuous, high-volume transfer of sand, silt, and clay. Our hoses, designed for relentless abrasion resistance and flexibility under dynamic vessel movement, ensure operational continuity in these demanding maritime settings. Equally vital is the offshore oil and gas sector, where dredging supports subsea pipeline trenching, platform foundation preparation, and seabed leveling. Here, hoses must resist not only abrasive sediments but also potential exposure to hydrocarbons and saltwater corrosion, necessitating specialized compound formulations validated through rigorous ISO 9001-certified quality processes. The most visually transformative application occurs in large-scale land reclamation projects. Nations across Southeast Asia and the Middle East, including Singapore and the UAE, rely on massive dredging operations to create new urban, industrial, and tourism zones. These megaprojects involve moving colossal sediment volumes over extended distances and durations, placing immense stress on hose systems where failure carries significant cost and schedule implications.

East Marine’s commitment to meeting these diverse global challenges is reinforced by our active membership in both the Central Dredging Association (CEDA) and the World Organization of Dredging Associations (WEDA). This strategic engagement ensures our engineering team remains at the forefront of evolving industry best practices, environmental standards, and technical specifications. We translate this knowledge directly into product design, focusing on longevity, safety, and operational efficiency for our clients. The following table outlines key technical parameters defining our dredging hose performance envelope across these critical applications.

| Parameter | Typical Range/Value | Relevance to Global Projects |

|---|---|---|

| Working Pressure | 16 – 40 bar (232 – 580 psi) | Handles high head losses in long discharge lines |

| Intervallo di temperatura | -30°C to +80°C (-22°F to +176°F) | Suitable for Arctic to tropical operations |

| Resistenza all'abrasione | > 100 mm³ (DIN 53516) | Critical for sand/clay transfer in all domains |

| Bend Radius (Min) | 6x Nominal ID | Enables maneuverability on dredgers & pipelines |

| Cover Compound | Specialized NR/BR/SBR Blend | Resists seawater, ozone, UV, hydrocarbons |

| Rinforzo | High-Tensile Steel Wire | Ensures pressure integrity & kink resistance |

Our engineering team confirms that successful project execution globally hinges on hose systems exceeding baseline specifications. East Marine’s integration of advanced materials science, adherence to international standards, and practical field experience—validated through our CEDA/WEDA participation—delivers the reliability required for projects where downtime is not an option. From deepwater energy infrastructure to the creation of new sovereign land, our hoses are engineered to perform under the most exacting conditions, supporting sustainable development worldwide.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: East Marine vs. Industry Competitors

In the demanding environment of dredging operations, the performance and reliability of suction and discharge hoses are critical to project efficiency, safety, and cost-effectiveness. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted member of WEDA and CEDA, delivers high-performance rubber hoses engineered for superior durability and operational consistency. With over 15 years of specialized manufacturing experience since 2007 and a 0.68 million square meter production facility, East Marine applies stringent ISO9001-certified quality controls to ensure every hose meets or exceeds international standards.

This technical comparison evaluates key performance parameters of dredging rubber hoses—Inner Diameter, Working Pressure, Burst Pressure, and Bending Radius—comparing East Marine’s flagship dredging hose series with average specifications from general market competitors. These metrics directly influence hose selection for offshore, riverine, and land reclamation dredging projects where resistance to abrasion, flexibility, and pressure integrity are paramount.

East Marine’s dredging hoses are constructed using high-tensile braided steel reinforcement and premium-grade synthetic rubber compounds, optimized for resistance to sand, silt, and continuous flexing. This advanced construction translates into higher working pressures, enhanced safety margins, and longer service life under harsh conditions. In contrast, many competitor hoses utilize standard textile or spiral wire reinforcement, which often results in reduced pressure tolerance and greater susceptibility to kinking and collapse.

The data below reflects standardized test conditions per ISO 14310 and API 7K guidelines, with measurements averaged across common hose sizes used in medium to large-scale dredging operations (ranging from 8 to 24 inches in inner diameter).

| Inner Diameter (inches) | Working Pressure (bar) – East Marine | Working Pressure (bar) – Competitors | Burst Pressure (bar) – East Marine | Burst Pressure (bar) – Competitors | Bending Radius (mm) – East Marine | Bending Radius (mm) – Competitors |

|---|---|---|---|---|---|---|

| 8 | 16 | 12 | 64 | 48 | 650 | 750 |

| 12 | 15 | 11 | 60 | 44 | 800 | 950 |

| 16 | 14 | 10 | 56 | 40 | 1,000 | 1,200 |

| 20 | 13 | 9 | 52 | 36 | 1,250 | 1,500 |

| 24 | 12 | 8 | 48 | 32 | 1,500 | 1,800 |

East Marine’s engineering advantage is evident in the 25–50% higher working pressure ratings and a consistent 4:1 safety factor between burst and working pressure, exceeding industry norms. Additionally, the reduced bending radius across all diameters allows for tighter routing in confined dredge spreads, minimizing installation time and reducing the risk of flow restriction due to kinking. These performance characteristics are validated through in-house hydraulic pulse testing and real-world deployment in major dredging projects across Southeast Asia, the Middle East, and Africa.

For engineering contractors and dredging operators, selecting a hose with optimized pressure handling and flexibility directly impacts uptime and operational safety. East Marine’s technical superiority, backed by comprehensive testing and global field performance, positions its dredging hoses as the preferred choice for mission-critical applications.

Partner with East Marine

Conclusion: Engineering Reliability for Demanding Dredging Operations

In the high-stakes environment of modern dredging projects, the performance and longevity of suction and discharge hoses directly impact operational efficiency, project timelines, and total cost of ownership. East Marine, operating as a specialized subsidiary of Jiangsu Huashen Special Rubber Products, delivers engineered rubber hose solutions designed explicitly for the abrasive, high-pressure, and corrosive challenges inherent in marine and inland dredging. Our commitment extends beyond manufacturing to providing comprehensive technical partnership, ensuring your pipeline system operates reliably under the most demanding conditions, minimizing downtime and maximizing productivity. With a foundation built over 17 years of dedicated marine rubber expertise, our ISO 9001-certified processes and 0.68 million square meter manufacturing facility guarantee consistent quality and scalability for projects of any magnitude. As active members of WEDA and CEDA, we remain at the forefront of industry standards and technological advancements.

Our technical proficiency is validated across hundreds of global dredging projects, from cutter suction dredgers to trailing suction hopper dredgers and land reclamation operations. The following table summarizes the core performance characteristics achievable with our standard and custom-engineered dredging hoses, reflecting our adherence to rigorous international testing protocols.

| Parameter | Standard Range | Custom Range Capability | Test Standard Reference |

|---|---|---|---|

| Working Pressure | 10 – 25 bar | Up to 40 bar | ISO 14306 |

| Vacuum Resistance | Full Vacuum (0.98 bar) | Enhanced Stability | ISO 1307 |

| Intervallo di temperatura | -20°C to +80°C | -30°C to +100°C | ISO 188 |

| Cover Material | Natural Rubber (NR) | NR/BR/SBR Blends | ASTM D2000 |

| Rinforzo | High-Tensile Steel Wire | Multi-Spiral Configs | ISO 1307 |

| Resistenza all'abrasione | > 100 mm³ loss | Optimized Compound | ISO 4649 |

Initiate Your Project Partnership with East Marine

Securing the optimal hose solution requires collaboration between your project engineers and our technical specialists. East Marine provides dedicated engineering support throughout the project lifecycle – from initial system design consultation and hydraulic analysis to on-site installation guidance and long-term performance monitoring. Our Singapore branch ensures responsive regional support for critical projects across Southeast Asia, the Indian subcontinent, and the broader Asia-Pacific region, offering localized expertise and rapid logistical coordination. Do not compromise on a component as critical as your dredging hose system. Contact our global technical team today to discuss your specific project requirements, pressure profiles, sediment characteristics, and environmental conditions. We will provide a tailored solution backed by comprehensive testing data and a proven track record in complex marine operations.

Contact East Marine for Technical Consultation and Project Support:

Engage directly with our dredging hose engineering specialists via WhatsApp at +86-13806109365 for immediate technical discussion or project status updates. For detailed inquiries, specifications, and formal quotations, email our dedicated dredging solutions team at hsdredging@eastmarine.tech. Reference your project name and key operational parameters to expedite our response. Our Singapore branch stands ready to support regional deployments, ensuring seamless integration and commissioning. Partner with East Marine – where decades of specialized marine rubber engineering deliver the reliability your dredging project demands. Let us provide the robust, high-performance hose solution that keeps your operation moving.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.