Introduction: Navigating the Global Market for offshore dredging

In the ever-evolving landscape of global trade and environmental sustainability, sourcing reliable offshore dredging services poses a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe seek to enhance infrastructure, manage sedimentation, and protect coastal ecosystems, understanding the intricacies of offshore dredging becomes imperative. This comprehensive guide delves into the various types of dredging projects, from environmental remediation to offshore trenching, highlighting their applications and the specialized equipment involved.

Moreover, it addresses critical factors such as supplier vetting, cost considerations, and technological advancements that influence purchasing decisions. By equipping buyers with actionable insights and expert knowledge, this guide empowers decision-makers to navigate the complexities of the offshore dredging market confidently. Whether you are in Vietnam tackling coastal erosion or in Nigeria planning a major infrastructure project, understanding these elements will facilitate informed choices, ensuring that your dredging needs are met efficiently and effectively.

With a focus on best practices and industry standards, this resource serves as a vital tool for optimizing procurement strategies and fostering sustainable partnerships in the offshore dredging sector.

Indice dei contenuti

- Top 4 Offshore Dredging Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for offshore dredging

- Understanding offshore dredging Types and Variations

- Key Industrial Applications of offshore dredging

- 3 Common User Pain Points for ‘offshore dredging’ & Their Solutions

- Strategic Material Selection Guide for offshore dredging

- In-depth Look: Manufacturing Processes and Quality Assurance for offshore dredging

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore dredging’

- Comprehensive Cost and Pricing Analysis for offshore dredging Sourcing

- Alternatives Analysis: Comparing offshore dredging With Other Solutions

- Essential Technical Properties and Trade Terminology for offshore dredging

- Navigating Market Dynamics and Sourcing Trends in the offshore dredging Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of offshore dredging

- Strategic Sourcing Conclusion and Outlook for offshore dredging

- Disclaimer importante e condizioni d'uso

Understanding offshore dredging Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Environmental Dredging | Focuses on removal of pollutants and sediments | Environmental restoration, cleanup projects | Pro: Enhances ecosystem health; Contro: Can be costly and time-consuming. |

| Offshore Trenching | Creates precise trenches for infrastructure | Installation of pipelines, cables, and utilities | Pro: Protects critical infrastructure; Contro: Requires specialized equipment and expertise. |

| Sand and Gravel Dredging | Extracts materials for construction | Construction projects, aggregate supply | Pro: Provides essential building materials; Contro: Environmental impacts must be managed. |

| Maritime Dredging | Maintains navigable waterways | Port maintenance, harbor deepening | Pro: Ensures safe navigation; Contro: Ongoing maintenance required. |

| Dam Dredging | Removes sediment buildup around dams | Water quality management, hydroelectric projects | Pro: Improves water storage capacity; Contro: Can disrupt local ecosystems. |

What Are the Characteristics of Environmental Dredging?

Environmental dredging is specifically designed to target and remove harmful pollutants and sediments from water bodies. This type of dredging is crucial for projects aimed at restoring ecosystems or cleaning contaminated sites. B2B buyers should consider the project’s environmental impact, regulatory requirements, and the technology used for pollutant removal. While it can be expensive and labor-intensive, the long-term benefits to ecosystem health and compliance with environmental regulations often justify the investment.

How Does Offshore Trenching Support Infrastructure?

Offshore trenching involves the excavation of precise trenches in the seabed, primarily for the installation of underwater infrastructure like pipelines and cables. This technique is vital in protecting these installations from physical hazards. B2B buyers should evaluate the dredging company’s expertise, the technology used for trenching, and the environmental considerations associated with seabed disturbance. While this method enhances the longevity and security of essential utilities, it requires specialized equipment and skilled personnel, which can increase project costs.

Why Is Sand and Gravel Dredging Important for Construction?

Sand and gravel dredging focuses on extracting these materials from the seabed for use in construction projects. Given the rising demand for building materials, this type of dredging is essential for supplying the construction industry. Buyers should assess the sourcing and sustainability of materials, as well as the dredging methods employed. While it provides critical resources, environmental considerations must be managed to minimize disruption to marine ecosystems.

What Role Does Maritime Dredging Play in Navigable Waterways?

Maritime dredging is essential for maintaining the depth and navigability of waterways, ports, and harbors. This type of dredging ensures that vessels can safely navigate and that ports can accommodate larger ships. B2B buyers should consider the frequency of dredging required, the impact on local marine life, and the costs associated with ongoing maintenance. Although it is vital for economic activity, continuous dredging can lead to environmental challenges that must be addressed.

How Does Dam Dredging Contribute to Water Management?

Dam dredging focuses on removing sediment buildup around dams to enhance water quality and storage capacity. This type of dredging is critical for maintaining hydroelectric power generation and ensuring clean water supply. B2B buyers should evaluate the potential environmental impact and the technology used for sediment removal. While effective in improving dam functionality, it can disrupt local ecosystems and require careful planning and execution to mitigate adverse effects.

Key Industrial Applications of offshore dredging

| Industria/Settore | Specific Application of Offshore Dredging | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Petrolio e gas | Pipeline Trenching for Subsea Infrastructure | Ensures safe installation and longevity of pipelines | Advanced positioning systems, environmental compliance |

| Costruzione | Sand and Gravel Extraction for Building Materials | Provides essential raw materials for construction | Quality of materials, transportation logistics |

| Environmental Services | Remediation of Contaminated Marine Areas | Restores ecosystems and meets regulatory standards | Expertise in environmental regulations, specialized equipment |

| Coastal Protection | Beach Nourishment and Dune Restoration | Mitigates erosion and enhances tourism potential | Local environmental impact assessments, project scale |

| Maritime Transport | Maintenance Dredging of Ports and Harbors | Ensures navigability and safety for maritime traffic | Regular maintenance schedules, equipment reliability |

How is Offshore Dredging Used in the Oil and Gas Sector?

In the oil and gas industry, offshore dredging is primarily utilized for pipeline trenching, which is essential for the installation of subsea infrastructure. Dredging creates precise trenches on the seabed, ensuring that pipelines are securely buried to protect them from environmental hazards, such as fishing activities and vessel anchors. For international B2B buyers, particularly those in Africa and the Middle East, sourcing dredging services requires attention to advanced positioning technology and compliance with environmental regulations to ensure safe and efficient operations.

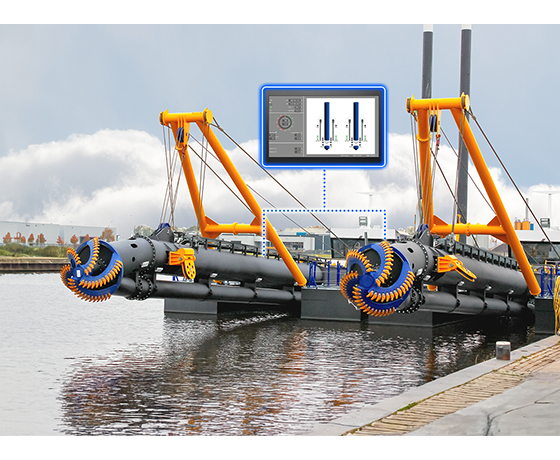

Illustrative image related to offshore dredging

What Role Does Offshore Dredging Play in Construction?

Offshore dredging significantly contributes to the extraction of sand and gravel, fundamental materials in construction projects. This process involves dredging operations that target specific seabed areas to harvest these materials, which are crucial for concrete and other building applications. Buyers from South America and Europe must consider the quality of dredged materials, as well as logistics for transporting them to construction sites, to ensure project timelines and budgets are maintained.

How is Offshore Dredging Applied in Environmental Services?

Environmental services leverage offshore dredging for the remediation of contaminated marine areas, a critical process for restoring ecosystems affected by pollutants. Dredgers are employed to selectively remove harmful sediments, thus improving water quality and restoring marine habitats. Buyers in this sector, especially in regions like Africa and Europe, should prioritize suppliers with expertise in environmental regulations and specialized dredging equipment capable of handling delicate restoration tasks.

What is the Importance of Coastal Protection through Offshore Dredging?

Coastal protection projects utilize offshore dredging for beach nourishment and dune restoration, vital for combating erosion and maintaining coastal ecosystems. This application not only protects infrastructure but also enhances the tourism appeal of coastal areas. International buyers, particularly in regions prone to coastal degradation, should focus on sourcing dredging solutions that include local environmental impact assessments to ensure sustainable practices are followed during project execution.

Illustrative image related to offshore dredging

How Does Offshore Dredging Support Maritime Transport?

In the maritime transport sector, offshore dredging is essential for maintaining navigability in ports and harbors. Regular dredging operations remove sediment buildup, ensuring safe passage for vessels and preventing accidents. For B2B buyers involved in maritime logistics, reliability in dredging operations is crucial. They should consider sourcing partners who can provide consistent maintenance schedules and reliable equipment to minimize disruptions in shipping activities.

3 Common User Pain Points for ‘offshore dredging’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance in Offshore Dredging Projects

Il problema:

B2B buyers often face the daunting task of ensuring that offshore dredging projects comply with an array of local and international regulations. This can be particularly challenging for companies operating in multiple countries, such as those in Africa and South America, where regulations may vary significantly. The risk of non-compliance can lead to project delays, hefty fines, or even the suspension of operations, creating a ripple effect that impacts budgets and timelines.

La soluzione:

To navigate the complex regulatory landscape, it is crucial for buyers to engage with local experts who specialize in dredging regulations. Start by conducting thorough research to identify the specific environmental regulations that apply to your project’s location. Collaborating with local environmental consultants can provide insights into permitting processes, necessary environmental impact assessments, and potential compliance hurdles. Additionally, consider developing a checklist of regulatory requirements tailored to each project. This proactive approach not only helps streamline the permitting process but also fosters good relationships with local authorities, enhancing project credibility and trust.

Scenario 2: Managing Environmental Concerns During Dredging Operations

Il problema:

Environmental impact is a significant concern in offshore dredging, especially when projects are located near sensitive ecosystems. Buyers may encounter resistance from environmental groups or local communities if they fail to demonstrate a commitment to sustainable practices. This can lead to public relations challenges, project delays, and increased scrutiny from regulatory bodies, ultimately affecting the bottom line.

Illustrative image related to offshore dredging

La soluzione:

Implementing an environmental management plan (EMP) is essential for addressing these concerns effectively. Start by conducting a comprehensive environmental impact assessment (EIA) to identify potential risks to marine life and habitats. Utilize this information to develop mitigation strategies, such as scheduling dredging activities during off-peak seasons for wildlife or employing specialized dredging equipment that minimizes sediment disturbance. Additionally, maintaining transparency with stakeholders by providing regular updates on environmental monitoring and mitigation efforts can help build trust and mitigate opposition. Engaging with local communities early in the project planning phase can also foster collaboration and support, making it easier to navigate environmental challenges.

Scenario 3: Ensuring Project Efficiency and Cost Control in Offshore Dredging

Il problema:

Cost overruns and inefficiencies are common pain points in offshore dredging projects, often resulting from unforeseen complications such as equipment breakdowns or inaccurate project assessments. These challenges can lead to increased labor costs, extended timelines, and a strain on resources, making it difficult for buyers to maintain profitability.

La soluzione:

To enhance efficiency and control costs, buyers should invest in advanced project management and dredging technologies. Utilizing GPS and real-time monitoring systems can improve the accuracy of dredging operations and reduce the likelihood of rework. Additionally, employing predictive maintenance strategies for dredging equipment can minimize downtime and extend the lifespan of machinery. Consider conducting thorough pre-project assessments to identify potential risks and allocate resources more effectively. Collaborating with experienced dredging contractors who have a proven track record of managing similar projects can also provide valuable insights and help streamline operations. By prioritizing planning and utilizing technology, buyers can significantly enhance project efficiency and keep costs in check.

Strategic Material Selection Guide for offshore dredging

What Are the Key Materials Used in Offshore Dredging?

When selecting materials for offshore dredging, it is essential to consider their properties, advantages, disadvantages, and their specific applications. Here, we analyze four common materials used in offshore dredging: steel, aluminum, high-density polyethylene (HDPE), and concrete.

How Does Steel Perform in Offshore Dredging Applications?

Steel is one of the most widely used materials in dredging equipment due to its strength and durability. Key properties include high tensile strength, excellent impact resistance, and a temperature rating that can handle extreme conditions. However, steel is susceptible to corrosion, particularly in marine environments, which can lead to increased maintenance costs over time.

Illustrative image related to offshore dredging

Pros: Steel’s durability makes it suitable for heavy-duty applications, and it can withstand significant wear and tear. Its availability and relatively low cost compared to other metals make it a popular choice among contractors.

Cons: The primary disadvantage is its susceptibility to corrosion, necessitating protective coatings or treatments, which can add to manufacturing complexity and costs. Additionally, the weight of steel can complicate transportation and installation.

International buyers, particularly from regions like Africa and South America, should consider compliance with ASTM standards for steel quality. Corrosion-resistant coatings may also be necessary to meet local environmental regulations.

What Role Does Aluminum Play in Offshore Dredging?

Aluminum is increasingly being used in dredging applications due to its lightweight and corrosion-resistant properties. It has a lower density than steel, making it easier to transport and handle. Aluminum can withstand a range of temperatures and is often used in components that require high strength-to-weight ratios.

Pros: The primary advantage of aluminum is its resistance to corrosion, making it ideal for marine environments. Its lightweight nature reduces fuel consumption during transportation and operation.

Cons: The main drawback is its higher cost compared to steel, which can be a limiting factor for budget-conscious projects. Additionally, aluminum may not be as durable as steel in high-impact applications, leading to potential wear issues.

Illustrative image related to offshore dredging

For international buyers, especially in Europe and the Middle East, compliance with JIS and DIN standards is crucial. Buyers should also consider the specific applications where aluminum’s lightweight properties can provide operational efficiencies.

How Is High-Density Polyethylene (HDPE) Used in Offshore Dredging?

High-density polyethylene (HDPE) is a versatile plastic material that is gaining traction in dredging applications, particularly for pipe systems. Its key properties include excellent chemical resistance, low moisture absorption, and a high strength-to-density ratio. HDPE can perform well under various temperature and pressure conditions.

Pros: HDPE’s resistance to corrosion and chemicals makes it suitable for transporting dredged materials without degradation. Its lightweight nature also simplifies installation and reduces transportation costs.

Cons: However, HDPE may not withstand extreme temperatures as effectively as metals, and its long-term durability in high-stress applications can be a concern. Additionally, the initial manufacturing costs can be higher than traditional materials.

Illustrative image related to offshore dredging

International buyers should be aware of compliance with ASTM standards for HDPE products and consider local preferences for materials. The growing demand for environmentally friendly materials may also influence purchasing decisions.

What Are the Benefits of Using Concrete in Offshore Dredging?

Concrete is commonly used in dredging applications for creating stable structures such as piers, docks, and underwater foundations. Its key properties include high compressive strength and durability, making it suitable for heavy loads and harsh marine conditions.

Pros: Concrete’s durability and resistance to wear make it ideal for long-term applications. It can also be formed into various shapes, offering flexibility in design.

Illustrative image related to offshore dredging

Cons: The primary disadvantage is its weight, which can complicate transportation and installation. Additionally, concrete can be susceptible to cracking under certain environmental conditions, leading to maintenance challenges.

For international buyers, particularly in regions like Africa and South America, understanding local regulations regarding concrete quality and environmental impact is essential. Compliance with relevant standards can ensure project success.

Summary Table of Material Selection for Offshore Dredging

| Materiale | Typical Use Case for Offshore Dredging | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (basso/medio/alto) |

|---|---|---|---|---|

| Acciaio | Structural components, dredging equipment | Elevata resistenza e durata | Suscettibile alla corrosione | Medio |

| Aluminum | Lightweight dredging equipment, piping | Corrosion resistance, lightweight | Higher cost, less durable than steel | Alto |

| High-Density Polyethylene (HDPE) | Dredging pipes, flexible connections | Chemical resistance, lightweight | Limited temperature tolerance, higher initial costs | Medio |

| Concrete | Piers, docks, underwater foundations | High compressive strength, durable | Heavy, potential cracking issues | Medio |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their project requirements and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for offshore dredging

What Are the Key Stages in the Manufacturing Process of Offshore Dredging Equipment?

The manufacturing process of offshore dredging equipment involves several critical stages, each designed to ensure that the final product meets the rigorous demands of marine environments. Understanding these stages can help B2B buyers assess the quality and suitability of equipment for their projects.

Material Preparation: What Materials Are Used in Dredging Equipment?

The first stage involves selecting the right materials, which is crucial for durability and performance. Offshore dredging equipment is typically constructed from high-strength steel and corrosion-resistant alloys. These materials are chosen for their ability to withstand harsh marine conditions, including saltwater exposure and extreme pressures.

Once the materials are selected, they undergo processes such as cutting and machining to create components that meet specific design requirements. This stage may also involve sourcing specialized materials, such as composite materials for lightweight applications or rubber for seals and gaskets.

How Are Dredging Equipment Components Formed?

The forming stage involves several techniques to shape the prepared materials into functional components. Common methods include:

- Welding: High-precision welding techniques, such as MIG and TIG welding, are employed to join metal parts. This process must adhere to strict quality standards to ensure the structural integrity of the equipment.

- Casting and Forging: Some components, like pumps and impellers, may be cast or forged to achieve the necessary strength and durability. These processes allow for the creation of complex shapes that are essential for efficient operation.

- Machining: Precision machining is used to fine-tune components, ensuring they meet exact specifications. This may involve CNC machining, which allows for intricate designs and high repeatability.

What Is Involved in the Assembly of Offshore Dredging Equipment?

The assembly stage is where individual components come together to form the complete dredging system. This process typically involves:

- Component Integration: Skilled technicians carefully assemble components, ensuring that all parts fit together correctly and function as intended. This includes integrating hydraulic systems, pumps, and control mechanisms.

- System Testing: Once assembled, the entire system undergoes initial testing to ensure that all components work harmoniously. This may include hydraulic pressure tests, operational tests, and safety checks.

Why Is Finishing Important in Dredging Equipment Manufacturing?

The finishing stage enhances the performance and aesthetics of the dredging equipment. Key activities in this stage include:

- Surface Treatment: Components are often treated with protective coatings to prevent corrosion and wear. Techniques such as galvanization or powder coating are commonly used to enhance durability.

- Quality Checks: Final inspections ensure that all components meet design specifications and quality standards. This may involve visual inspections, dimensional checks, and functional tests.

What International Standards and Quality Assurance Practices Are Relevant for Offshore Dredging?

Quality assurance (QA) is critical in the manufacturing process of offshore dredging equipment. Adhering to international standards ensures that products are reliable and safe for use in marine environments.

Illustrative image related to offshore dredging

Which International Standards Should B2B Buyers Look For?

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to demonstrate their commitment to quality and continuous improvement.

- CE Marking: This certification indicates compliance with European safety, health, and environmental protection standards, making it crucial for buyers in Europe.

- API Standards: The American Petroleum Institute (API) sets standards for equipment used in the oil and gas industry, which is often relevant for dredging projects involving subsea installations.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are vital throughout the manufacturing process to ensure that every piece of equipment meets the required standards.

What Are the Main QC Checkpoints?

-

Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to ensure they meet specified standards. This includes checking for material certifications and physical attributes.

-

In-Process Quality Control (IPQC): During manufacturing, various inspections are conducted at critical stages to catch defects early. This may involve monitoring welding techniques, machining tolerances, and assembly integrity.

-

Final Quality Control (FQC): The final inspection occurs once the equipment is fully assembled. This includes comprehensive testing to verify functionality, safety, and compliance with industry standards.

What Common Testing Methods Are Used for Dredging Equipment?

To verify the quality of dredging equipment, several testing methods are commonly employed:

- Hydraulic Testing: Ensures that hydraulic systems operate under pressure without leaks.

- Load Testing: Validates that the equipment can handle expected operational loads.

- Functional Testing: Confirms that all systems, including control mechanisms and safety features, operate correctly.

Come possono gli acquirenti B2B verificare il controllo qualità dei fornitori?

B2B buyers need to take proactive steps to ensure that their suppliers maintain high-quality standards. Here are some effective methods:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This may include reviewing their certifications and production facilities.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certifications.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the equipment and manufacturing practices.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certifications:

-

Regulatory Compliance: Different countries have varying regulations regarding dredging equipment. Buyers should ensure that suppliers are compliant with local laws and standards.

-

Cultural Considerations: Understanding cultural differences in business practices can help in establishing effective communication with suppliers, particularly regarding quality expectations.

-

Language Barriers: Clear communication is crucial in quality assurance. Buyers may consider working with suppliers who can provide documentation and support in their preferred language.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when procuring offshore dredging equipment, ensuring that they receive products that meet their operational needs and comply with international standards.

Illustrative image related to offshore dredging

Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore dredging’

To assist B2B buyers in navigating the complexities of offshore dredging procurement, this guide provides a structured checklist. Each step is designed to ensure a thorough evaluation of your project needs and potential suppliers, ultimately leading to a successful dredging operation.

Fase 1: Define Your Project Requirements

Understanding the specific needs of your offshore dredging project is essential. Consider factors such as the type of dredging (e.g., environmental remediation, pipeline trenching), project scale, and timeline. This clarity will help you communicate effectively with suppliers and ensure they can meet your technical and operational demands.

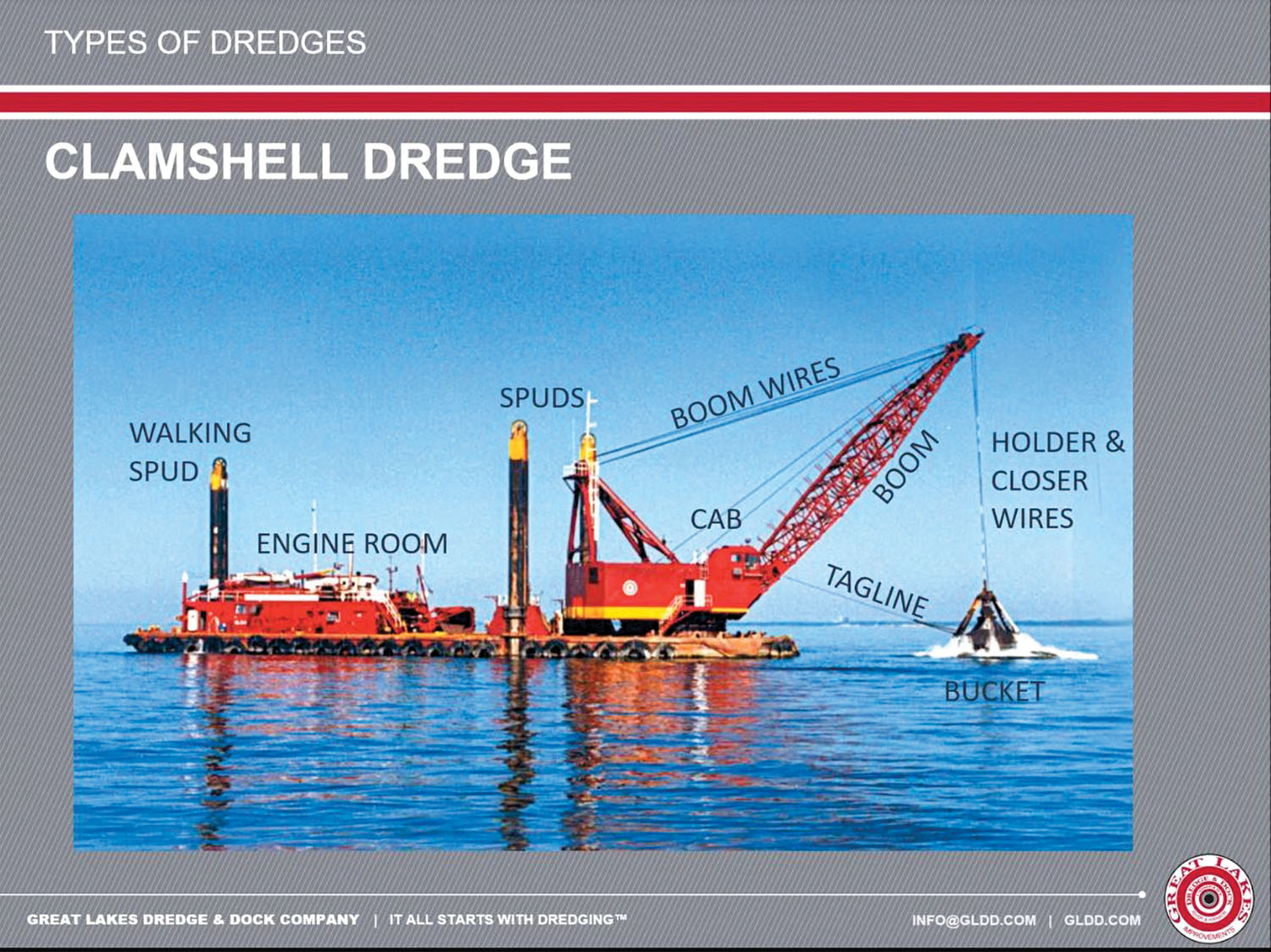

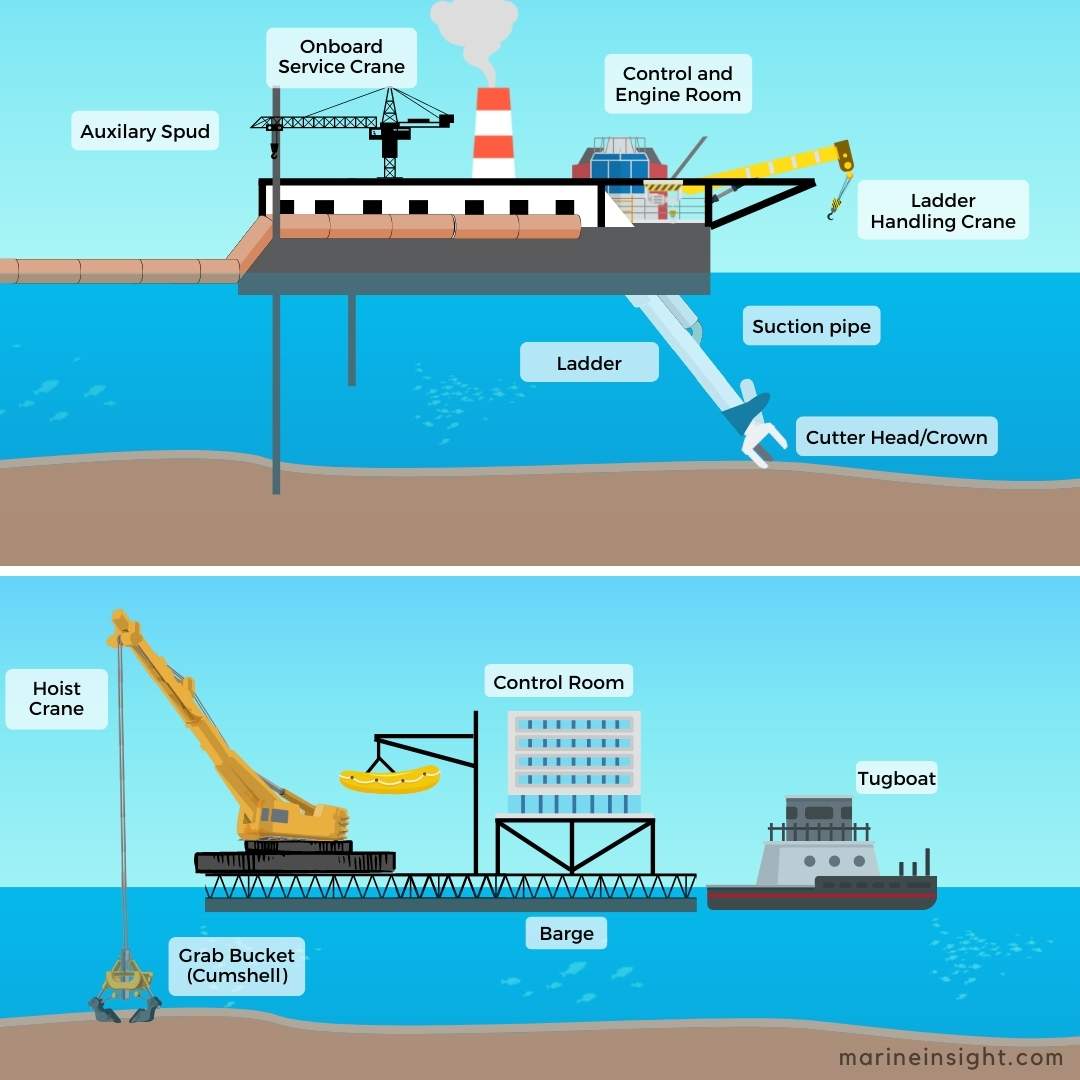

Fase 2: Research Available Dredging Technologies

Offshore dredging employs various technologies suited for different applications. Familiarize yourself with the types of dredgers, such as cutter suction dredgers and trailing suction hopper dredgers, to determine which is best for your project. Consider their capabilities in terms of material handling, depth range, and efficiency to ensure alignment with your project goals.

Illustrative image related to offshore dredging

Fase 3: Valutare i potenziali fornitori

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with proven experience in offshore dredging and a robust portfolio of completed projects, as this indicates their ability to manage complexities and deliver results.

Passo 4: Verify Compliance and Certifications

Ensure that potential suppliers adhere to relevant regulations and industry standards. Certifications such as ISO 9001 for quality management and environmental management certifications indicate a commitment to excellence and sustainability. This step is vital for mitigating risks associated with environmental compliance and operational safety.

Passo 5: Assess Equipment Availability and Maintenance

Inquire about the availability and condition of dredging equipment. Well-maintained, modern equipment is crucial for efficiency and safety in offshore operations. Check whether the supplier has a regular maintenance program and access to backup equipment to minimize downtime during the project.

Illustrative image related to offshore dredging

Passo 6: Request Detailed Proposals

Once you’ve narrowed down your list of suppliers, request detailed proposals that outline their approach to your project. Proposals should include timelines, cost estimates, and methodologies. This transparency allows for better comparisons and helps you gauge each supplier’s understanding of your project needs.

Passo 7: Negotiate Contract Terms and Conditions

Before finalizing your agreement, carefully review and negotiate contract terms. Pay attention to aspects such as payment schedules, delivery timelines, liability clauses, and performance guarantees. Clear terms will protect your interests and set expectations for both parties, facilitating a smoother project execution.

By following this structured checklist, B2B buyers can make informed decisions when sourcing offshore dredging services, ensuring that their projects are executed efficiently and successfully.

Comprehensive Cost and Pricing Analysis for offshore dredging Sourcing

What Are the Key Cost Components in Offshore Dredging?

Understanding the cost structure of offshore dredging is crucial for B2B buyers, especially when planning large-scale projects. The primary cost components include:

-

I materiali: This encompasses the raw materials necessary for dredging operations, such as fuel, dredging equipment, and maintenance supplies. The choice of materials can significantly affect the overall cost, as more durable and specialized equipment may lead to higher initial expenses but lower long-term maintenance costs.

-

Lavoro: Skilled labor is essential for efficient dredging operations. Costs can vary based on geographic location and labor availability. In regions such as Africa or South America, labor costs may be lower, but the availability of trained personnel can be a challenge.

-

Spese generali di produzione: This includes costs associated with the operation and maintenance of dredging vessels and equipment. Factors like depreciation, insurance, and facility costs contribute to this overhead, impacting pricing structures.

-

Tooling and Equipment: The type of dredging equipment—ranging from small, portable dredgers to large, specialized vessels—will influence costs. Higher-capacity and technologically advanced equipment often comes with a premium but can enhance efficiency.

-

Controllo qualità (CQ): Ensuring that dredging operations meet environmental and safety standards can incur additional costs. Investments in quality control systems and certifications can lead to long-term savings by minimizing risks and potential fines.

-

Logistica: Transportation of equipment and materials to and from the dredging site can be significant, especially in remote areas. Efficient logistics planning can help reduce these costs, but they remain a crucial factor in the overall pricing structure.

-

Margine: Suppliers typically add a profit margin to their costs, which can vary widely based on market demand, competition, and operational efficiencies.

How Do Price Influencers Affect Offshore Dredging Costs?

Several factors can influence the pricing of offshore dredging services:

-

Volume e quantità minima d'ordine (MOQ): Larger projects often benefit from economies of scale, leading to lower per-unit costs. Negotiating for bulk pricing can yield significant savings.

-

Specifiche e personalizzazione: Customized solutions tailored to specific project requirements can increase costs. Buyers should assess whether standard solutions can meet their needs to avoid unnecessary expenses.

-

Materiali e certificazioni di qualità: The choice of materials and the level of certification required can affect pricing. Higher quality and environmentally certified materials often come at a premium but can lead to better project outcomes.

-

Fattori di fornitura: The reputation and reliability of the supplier can impact costs. Established suppliers may charge more but offer better service and support, reducing the risk of project delays.

-

Incoterms: Understanding the delivery terms (Incoterms) is vital for international buyers. These terms dictate the responsibilities of buyers and sellers regarding transportation, insurance, and tariffs, all of which can significantly influence total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Offshore Dredging?

-

Effective Negotiation Strategies: Engage suppliers early in the planning process to negotiate favorable terms. Being transparent about project requirements and timelines can lead to better pricing and service agreements.

-

Evaluating Total Cost of Ownership (TCO): Beyond initial costs, consider the long-term implications of your purchase. Assess maintenance, operational efficiency, and the potential for downtime when evaluating suppliers.

-

Understanding Pricing Nuances for International Buyers: International transactions often involve additional costs such as tariffs and taxes. Familiarize yourself with local regulations in regions like Africa or the Middle East to avoid unexpected expenses.

-

Leveraging Local Knowledge: Local suppliers may offer competitive pricing and a better understanding of regional challenges, such as environmental regulations and logistical considerations. Building relationships with local firms can enhance project success.

-

Monitoring Market Trends: Stay informed about fluctuations in material costs and labor rates. This knowledge can provide leverage during negotiations and help in making timely purchasing decisions.

Disclaimer on Indicative Prices

Pricing for offshore dredging services can vary significantly based on numerous factors, including project scope, location, and market conditions. It is advisable to obtain multiple quotes and conduct thorough due diligence to ensure competitive pricing aligned with your project requirements.

Illustrative image related to offshore dredging

Alternatives Analysis: Comparing offshore dredging With Other Solutions

In the realm of maritime and environmental projects, choosing the right solution for sediment removal and seabed management is critical. Offshore dredging is a well-known method, but there are alternative solutions that may better suit certain projects based on specific requirements. This section provides a comparative analysis of offshore dredging against other viable methods, helping B2B buyers make informed decisions.

| Aspetto di confronto | Offshore Dredging | Mechanical Excavation | Hydrovac Excavation |

|---|---|---|---|

| Prestazioni | High precision and depth control for underwater infrastructure | Effective for shallow areas, limited in depth | High precision, but slower process |

| Costo | Moderate to high, depending on equipment and project scale | Generally lower for shallow projects | Higher due to specialized equipment |

| Facilità di implementazione | Requires specialized vessels and technology | Simple machinery; easy to mobilize | Requires skilled operators and specific conditions |

| Manutenzione | Regular equipment servicing needed | Lower maintenance, simpler machinery | High maintenance on hydrovac systems |

| Il miglior caso d'uso | Offshore infrastructure, environmental remediation | Shallow water projects, land clearing | Sensitive sites, urban areas with utilities |

What Are the Advantages and Disadvantages of Mechanical Excavation Compared to Offshore Dredging?

Mechanical excavation involves the use of excavators and other heavy machinery to remove sediments and debris from waterways. Its primary advantage lies in its lower cost and ease of mobilization for shallow water projects. However, it is limited in terms of depth and precision, making it less suitable for offshore applications where specific environmental and structural requirements must be met. Additionally, mechanical excavation can disturb the surrounding ecosystem more than offshore dredging, which often employs controlled techniques.

How Does Hydrovac Excavation Compare to Offshore Dredging?

Hydrovac excavation utilizes high-pressure water and vacuum systems to remove soil, making it ideal for delicate projects in urban environments or areas with existing utilities. This method offers high precision and minimizes disturbance to the surrounding area, similar to offshore dredging. However, it tends to be more expensive and requires skilled operators. The speed of hydrovac excavation is generally slower compared to offshore dredging, which can impact project timelines. It is best used in sensitive sites where traditional methods may pose risks to underground utilities or ecosystems.

Illustrative image related to offshore dredging

How Can B2B Buyers Determine the Right Solution for Their Needs?

When selecting between offshore dredging and its alternatives, B2B buyers should carefully evaluate their specific project requirements. Factors such as project location, environmental impact, budget constraints, and desired outcomes should all influence the decision-making process. Offshore dredging may be the optimal choice for complex, deep-water projects requiring precision, while mechanical excavation could be more cost-effective for shallow areas. Conversely, hydrovac excavation is best suited for sensitive urban environments where minimizing disruption is paramount. By understanding the strengths and limitations of each method, buyers can choose the most appropriate solution to meet their objectives efficiently and effectively.

Essential Technical Properties and Trade Terminology for offshore dredging

What Are the Key Technical Properties in Offshore Dredging?

Understanding the technical specifications of dredging equipment is crucial for B2B buyers involved in offshore projects. Here are several key properties that influence performance and operational efficiency:

1. Grado del materiale

The material grade of a dredger refers to the quality and composition of the materials used in its construction, such as steel or composite materials. High-grade materials ensure durability and resistance to corrosion, especially in harsh marine environments. For buyers, selecting equipment made from superior materials can lead to lower maintenance costs and extended lifespan, enhancing overall project profitability.

2. Dredging Depth Capacity

This specification indicates the maximum depth at which a dredger can effectively operate. Different projects require varying dredging depths; for instance, deep-sea dredging operations may necessitate equipment capable of reaching depths of over 30 meters. Understanding this capacity helps B2B buyers match the right equipment to their specific project needs, ensuring operational efficiency and compliance with environmental regulations.

3. Pumping Capacity

Pumping capacity is a measure of the volume of material a dredger can remove per unit of time, usually quantified in cubic meters per hour. A higher pumping capacity translates to faster project completion times, which can significantly reduce labor and operational costs. Buyers should assess their project timelines and budget constraints when evaluating dredgers based on this property.

Illustrative image related to offshore dredging

4. Suction Velocity

Suction velocity is the speed at which the dredging equipment can draw in sediment and debris. This metric is critical for maximizing efficiency and minimizing operational delays. It is particularly important in projects where sediment removal must be performed swiftly to avoid environmental disruptions or to maintain navigable waterways. Buyers should inquire about suction velocity to ensure they meet project deadlines.

5. Tolerance Levels

Tolerance levels refer to the precision with which dredging equipment can operate, particularly in relation to the depth and width of the dredged area. Equipment with tighter tolerance levels can minimize environmental impact and ensure compliance with regulatory standards. For B2B buyers, selecting dredgers that maintain these tolerances can help in securing necessary permits and avoiding costly fines.

6. Fuel Efficiency

Fuel efficiency measures how effectively a dredger utilizes fuel during operations. Given the high operational costs associated with dredging, equipment that offers better fuel efficiency can significantly lower overall project expenses. Buyers should consider this property when evaluating equipment, as it directly influences long-term operational costs.

What Are Common Trade Terms in Offshore Dredging?

Navigating the dredging industry requires familiarity with specific jargon and trade terminology. Here are some key terms that B2B buyers should understand:

Illustrative image related to offshore dredging

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the dredging industry, understanding OEM relationships can help buyers identify reputable suppliers and ensure they are purchasing high-quality, reliable equipment.

2. MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For buyers, understanding MOQ is vital for budget management and inventory planning, particularly when sourcing specialized dredging equipment.

3. RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ can help in comparing multiple suppliers, ensuring they receive competitive pricing and favorable terms for their dredging projects.

4. Incoterms (Termini commerciali internazionali)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global transactions. Familiarity with these terms is crucial for B2B buyers involved in international dredging projects, as they dictate shipping costs, risk, and delivery responsibilities.

Illustrative image related to offshore dredging

5. Dredging Cycle Time

This term refers to the duration required to complete one cycle of dredging activity, from excavation to disposal of dredged materials. Understanding cycle time helps buyers estimate project timelines and resource allocation effectively.

6. Environmental Impact Assessment (EIA)

An EIA is a process that evaluates the potential environmental effects of a proposed dredging project. B2B buyers should prioritize projects that include a comprehensive EIA to minimize environmental risks and ensure compliance with local regulations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers in the offshore dredging sector can make more informed decisions that enhance project outcomes and promote sustainable practices.

Navigating Market Dynamics and Sourcing Trends in the offshore dredging Sector

What Are the Current Market Dynamics and Key Trends in Offshore Dredging?

The offshore dredging sector is experiencing significant shifts driven by a combination of global economic factors, technological advancements, and environmental considerations. Key market drivers include the increasing demand for infrastructure development in emerging economies, particularly in Africa and South America, where urbanization and population growth necessitate enhanced maritime infrastructure. Similarly, in regions like the Middle East and Europe, the need for coastal protection and environmental remediation projects is growing, spurred by climate change and rising sea levels.

Emerging B2B technology trends are reshaping how dredging projects are executed. For instance, the integration of advanced positioning systems, sonar technologies, and automation in dredging equipment is enhancing accuracy and operational efficiency. These innovations not only reduce project timelines but also minimize environmental impacts, which is crucial for compliance in regions with stringent regulations. Moreover, the utilization of data analytics and IoT (Internet of Things) solutions enables real-time monitoring of dredging operations, allowing for proactive adjustments to project parameters.

International B2B buyers must navigate these dynamics by focusing on reliable partnerships with dredging service providers that emphasize technological competence and adherence to environmental standards. As the market evolves, sourcing strategies should incorporate flexibility to adapt to regulatory changes and emerging best practices in dredging operations.

How Can Sustainability and Ethical Sourcing Impact Offshore Dredging Projects?

The environmental impact of offshore dredging is a critical concern that influences sourcing decisions among B2B buyers. Projects often disturb marine ecosystems, and as such, ethical sourcing practices have become paramount. Companies are increasingly expected to demonstrate their commitment to sustainable practices, which includes employing dredging methods that minimize ecological disruption and promote habitat restoration.

Investing in ‘green’ certifications and materials is a growing trend in the offshore dredging sector. These certifications signal a company’s adherence to environmental management standards, which can enhance reputation and marketability. Furthermore, utilizing eco-friendly dredging equipment and techniques, such as sediment management systems that reduce the release of contaminants, is becoming essential for compliance and securing project approvals.

For B2B buyers, partnering with suppliers who prioritize sustainability not only aligns with corporate social responsibility goals but also positions them favorably in competitive bids. As regulatory frameworks tighten globally, the focus on sustainability and ethical sourcing will continue to reshape procurement strategies in the offshore dredging market.

What Is the Historical Context of Offshore Dredging for B2B Buyers?

The history of offshore dredging traces back to the early industrial revolution when the need for navigable waterways and ports became paramount for trade and commerce. Initially, dredging was performed manually or with rudimentary tools, but as maritime trade expanded, so did the technology. The introduction of steam-powered dredgers in the 19th century revolutionized the industry, allowing for deeper and more efficient excavation.

In recent decades, the evolution of dredging technology has accelerated dramatically, driven by advancements in engineering and environmental science. The development of specialized dredging vessels equipped with sophisticated navigational tools and automation has transformed offshore dredging into a highly technical field. Today, B2B buyers benefit from a wealth of options and innovations that enhance project outcomes while addressing regulatory and environmental challenges.

Understanding this historical context not only provides insight into the sector’s evolution but also emphasizes the importance of choosing experienced partners who can navigate the complexities of modern offshore dredging projects effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of offshore dredging

-

How do I ensure the quality of dredging services for my project?

To ensure quality in dredging services, it is essential to vet potential suppliers thoroughly. Look for companies with proven experience in offshore projects, positive client testimonials, and certifications from relevant authorities. Request case studies that demonstrate their past performance, especially in similar environments to your project. Additionally, consider conducting site visits or audits of their equipment and operations to assess their capabilities firsthand. Establishing clear communication about your project requirements and expectations will also help maintain quality throughout the dredging process. -

What are the key factors to consider when selecting a dredging contractor?

When selecting a dredging contractor, consider their experience, equipment capabilities, and safety record. Evaluate their specialization in the specific type of dredging you require, such as environmental remediation or offshore trenching. Additionally, assess their financial stability and references from previous clients, particularly in your region. It’s also crucial to understand their project management approach, including timelines, logistics, and contingency plans. Engaging in detailed discussions about project scope and expectations will help ensure alignment with your business goals. -

What are the common payment terms for offshore dredging contracts?

Payment terms for offshore dredging contracts can vary widely, but they often include an upfront deposit, progress payments based on milestones, and a final payment upon project completion. It is advisable to negotiate terms that align with project timelines and deliverables. Ensure that the payment schedule is clearly defined in the contract to avoid disputes. Additionally, consider including performance-based incentives to motivate timely and high-quality work. Always review the financial stability of the contractor, as this can impact their ability to meet payment obligations and project deadlines. -

How can I customize dredging services to fit my specific project needs?

Customization of dredging services often involves discussing your unique project requirements with potential contractors. This may include specific dredging depths, environmental considerations, and timelines. Many dredging companies offer tailored solutions, such as specialized equipment or techniques, to address unique challenges. It is essential to communicate your project goals and constraints clearly. Request proposals that outline how they can adapt their services to meet your needs, and ensure that the contractor has the flexibility to adjust their approach as required throughout the project. -

What logistics should I consider for international dredging projects?

Logistics for international dredging projects encompass transportation of equipment, scheduling of operations, and compliance with local regulations. Evaluate the proximity of your project site to supply chains and ports to minimize transportation costs. Understand the customs and import/export regulations of the countries involved, as these can impact timelines and budgets. Additionally, consider potential environmental regulations that may affect dredging operations. Collaborating with local partners or logistics experts can facilitate smoother operations and ensure compliance with all legal requirements. -

What are the minimum order quantities (MOQ) for dredging equipment and services?

Minimum order quantities (MOQ) for dredging services can vary by contractor and project scope. Typically, for specialized dredging equipment rentals, the MOQ may depend on the type of equipment and duration of use. For larger projects, contractors may offer flexible arrangements based on project needs rather than strict MOQs. It’s beneficial to discuss your project requirements with potential suppliers to negotiate terms that work for both parties. Always ensure that the contract reflects any agreed-upon MOQs to avoid misunderstandings during project execution. -

What quality assurance measures should I expect from dredging contractors?

Quality assurance measures from dredging contractors should include adherence to industry standards, regular equipment maintenance, and safety protocols. Expect contractors to have a quality management system in place that includes monitoring and reporting on project progress, environmental impact assessments, and compliance with local regulations. Additionally, they should provide documentation of inspections and maintenance records for their equipment. Regular communication and progress updates throughout the project are essential to ensure that quality standards are maintained. -

How do environmental regulations impact offshore dredging projects?

Environmental regulations play a crucial role in offshore dredging projects, often dictating the methods and equipment used. Contractors must comply with local and international environmental laws designed to protect marine ecosystems. This may include conducting environmental impact assessments (EIAs) prior to project initiation, implementing measures to minimize disruption to marine life, and adhering to guidelines for waste disposal. Engaging with local regulatory bodies and environmental experts during project planning can help ensure compliance and reduce the risk of delays or fines associated with non-compliance.

Top 4 Offshore Dredging Manufacturers & Suppliers List

1. Yelp – General Contractors & Construction Services

Dominio: yelp.com

Registrato: 2003 (22 anni)

Introduzione: General Contractors, Dredging and Construction Services

2. Great Lakes Dredge & Dock – Dredging Solutions

Dominio: gldd.com

Registrato: 1997 (28 anni)

Introduzione: Great Lakes Dredge & Dock Corporation (GLDD) is North America’s leading dredging contractor, specializing in channel and port maintenance, channel deepening and port expansion, coastal protection and restoration, land reclamation, and work on rivers, lakes, and reservoirs. GLDD operates a diverse fleet of equipment including trailing suction hopper dredges, cutter suction dredges, mechanical dredg…

3. Indeed – Offshore Dredging Jobs

Dominio: indeed.com

Registrato: 1998 (27 anni)

Introduzione: This company, Indeed – Offshore Dredging Jobs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Ouco Industry – Dredging Solutions

Dominio: ouco-industry.com

Registrato: 2018 (7 anni)

Introduzione: Dredging is an underwater excavation activity that involves the removal of sediments such as sand, silt, and rock debris from the beds of oceans, rivers, and lakes. The extracted material is transported and deposited at a new location for various uses. Dredging serves to ensure navigability of water areas, create new waterways, remove accumulated sediment, protect water quality, and support reclam…

Strategic Sourcing Conclusion and Outlook for offshore dredging

In navigating the complexities of offshore dredging, strategic sourcing emerges as a pivotal element for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. By understanding the various types of dredging projects—from environmental remediation to pipeline trenching—companies can better align their procurement strategies with their operational needs. This alignment not only enhances project efficiency but also ensures compliance with environmental regulations and mitigates risks associated with sediment management.

The value of strategic sourcing lies in its ability to foster long-term partnerships with experienced dredging service providers. Such collaborations enable access to the latest technology and specialized equipment, ensuring that projects are executed with precision and minimal environmental impact. As global demand for dredging services continues to rise, particularly in regions facing infrastructure development and environmental challenges, it becomes increasingly vital for buyers to prioritize sourcing strategies that are both sustainable and cost-effective.

Illustrative image related to offshore dredging

Looking ahead, international B2B buyers should seize the opportunity to engage with established dredging companies that offer tailored solutions and innovative approaches. By doing so, they can not only enhance their operational capabilities but also contribute to the sustainable management of marine resources. Embrace strategic sourcing today to ensure your projects are positioned for success in the evolving landscape of offshore dredging.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.