Introduction: Navigating the Global Market for pipe float

In an increasingly interconnected global market, sourcing reliable pipe floats can present a significant challenge for B2B buyers in diverse industries such as dredging, mining, and marine construction. These buoyant devices are critical for maintaining the integrity and operational efficiency of submerged pipes, hoses, and cables, yet the variety of options and specifications can overwhelm even the most seasoned procurement professionals. This guide aims to demystify the complexities of the pipe float market, providing insights into various types of floats, their applications, and considerations for supplier vetting.

With a focus on international buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—this comprehensive resource will equip you with the knowledge necessary to make informed purchasing decisions. We will cover essential topics such as material specifications, buoyancy capabilities, and installation techniques, while also addressing critical factors like cost, durability, and regulatory compliance. By understanding the nuances of different float systems and their applications, you can streamline your procurement process and enhance your project outcomes.

Ultimately, this guide serves as a strategic tool to empower B2B buyers in selecting the right flotation solutions tailored to their specific needs, ensuring operational success in challenging environments.

Indice dei contenuti

- Top 7 Pipe Float Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pipe float

- Understanding pipe float Types and Variations

- Key Industrial Applications of pipe float

- 3 Common User Pain Points for ‘pipe float’ & Their Solutions

- Strategic Material Selection Guide for pipe float

- In-depth Look: Manufacturing Processes and Quality Assurance for pipe float

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipe float’

- Comprehensive Cost and Pricing Analysis for pipe float Sourcing

- Alternatives Analysis: Comparing pipe float With Other Solutions

- Essential Technical Properties and Trade Terminology for pipe float

- Navigating Market Dynamics and Sourcing Trends in the pipe float Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pipe float

- Strategic Sourcing Conclusion and Outlook for pipe float

- Disclaimer importante e condizioni d'uso

Understanding pipe float Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Standard Pipe Floats | Made from durable, UV-resistant polyethylene; various sizes available | Dredging, mining, marine construction | Pro: High durability; customizable sizes; easy installation. Contro: Limited to specific pipe diameters. |

| Galleggianti per tubi modulari | Patented modular design; adjustable for various pipe sizes | Oil & gas, water management, aquaculture | Pro: Versatile; reusable; quick setup. Contro: May require additional components for larger systems. |

| Foam-Filled Floats | Foam-filled for added buoyancy; impact-resistant | Marine operations, floating platforms | Pro: Enhanced buoyancy; robust performance. Contro: Heavier than other types; potential for punctures. |

| Hose Floats | Specifically designed for hoses; lightweight and flexible | Agricultural irrigation, aquaculture | Pro: Lightweight; easy to transport. Contro: May not support heavy loads effectively. |

| Stazioni di pompaggio galleggianti | Integrated floats for pump systems; designed for stability | Water treatment, irrigation, construction | Pro: Streamlined design; supports operational efficiency. Contro: Higher upfront cost; may require specific pump types. |

What Are Standard Pipe Floats and Their Applications?

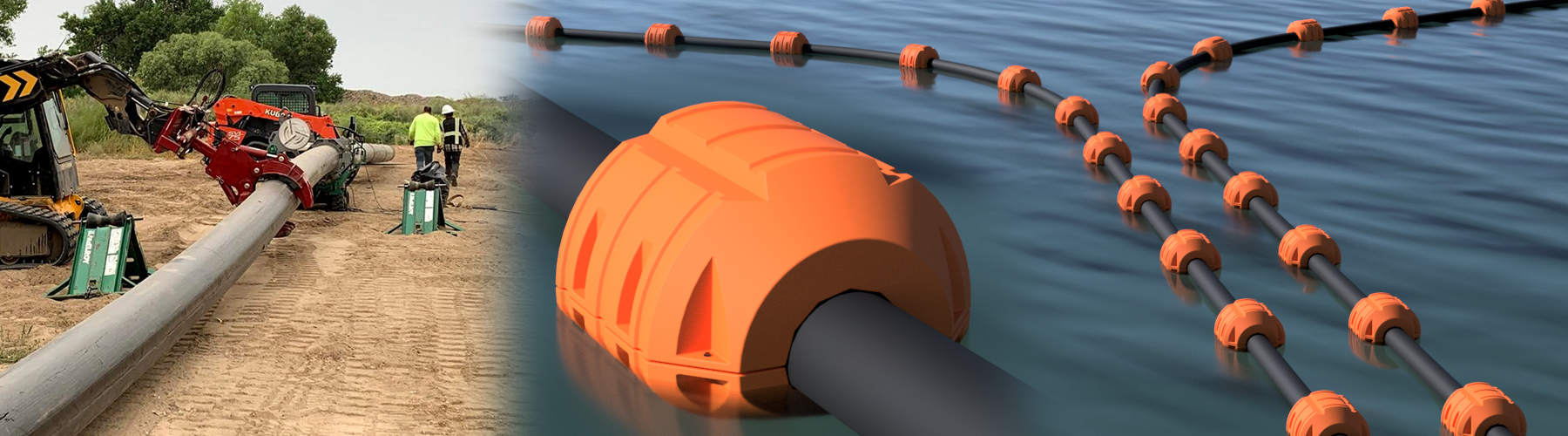

Standard pipe floats are essential for maintaining the buoyancy of pipes in various industrial applications. Constructed from durable, UV-resistant polyethylene, these floats come in multiple sizes to accommodate different pipe diameters. They are widely used in dredging, mining, and marine construction, where they provide reliable support in challenging environments. When considering standard pipe floats, buyers should evaluate the specific diameter and weight requirements of their pipes to ensure optimal performance.

How Do Modular Pipe Floats Enhance Flexibility?

Modular pipe floats feature a patented design that allows for easy adjustment to fit various pipe sizes. This flexibility makes them ideal for applications in oil and gas, water management, and aquaculture. Their reusable nature reduces costs over time, and the quick installation process minimizes downtime on projects. Buyers should consider the adaptability of these floats when planning for projects that may require different pipe sizes or configurations.

What Advantages Do Foam-Filled Floats Offer?

Foam-filled floats are designed to provide enhanced buoyancy and stability, making them suitable for marine operations and floating platforms. Their impact-resistant construction ensures durability in harsh conditions, while the foam filling adds extra buoyancy. Buyers should weigh the benefits of increased stability against the potential for added weight, as these floats can be heavier than their non-foam counterparts.

Why Choose Hose Floats for Specific Applications?

Hose floats are specifically engineered for lightweight hoses, making them ideal for agricultural irrigation and aquaculture applications. Their flexibility allows them to adapt to various environments while remaining easy to transport and install. However, buyers should be cautious about their load-bearing capacity, as hose floats may not support heavier equipment effectively.

How Do Floating Pump Stations Integrate with Operations?

Floating pump stations combine flotation technology with pump systems, providing stability and efficiency in water treatment, irrigation, and construction projects. Their streamlined design facilitates easy deployment and operation in aquatic environments. While they offer significant benefits in terms of operational efficiency, buyers should consider the initial investment and compatibility with existing pump systems when making a purchase.

Key Industrial Applications of pipe float

| Industria/Settore | Specific Application of Pipe Float | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Dredging & Mining | Supporting pipelines and cables in water | Prevents damage to submerged equipment, ensuring operational efficiency and reducing maintenance costs. | Durability in harsh environments, buoyancy specifications, and ease of installation. |

| Costruzione navale | Stabilizing hoses and cables for underwater work | Enhances safety and efficiency by keeping hoses and cables afloat, reducing entanglement risks. | Material resistance to saltwater, UV stability, and modularity for various pipe sizes. |

| Aquaculture | Floating feed and aeration lines | Maintains optimal water flow and prevents feed from sinking, leading to better fish health and growth. | Custom sizing, buoyancy requirements, and environmental sustainability of materials. |

| Oil & Gas | Supporting drilling and production lines | Reduces the risk of operational downtime by ensuring that pipelines remain accessible and functional. | Compliance with industry standards, resistance to corrosive materials, and ease of maintenance. |

| Gestione dell'acqua | Floating pump stations and containment booms | Facilitates effective water management and pollution control, ensuring compliance with environmental regulations. | Specifications for weight capacity, material resilience, and adaptability to various water conditions. |

How is Pipe Float Used in Dredging and Mining Applications?

In dredging and mining, pipe floats are essential for supporting pipelines and cables that transport materials across water. These floats ensure that equipment remains buoyant, preventing damage from submersion and extending the lifespan of costly machinery. Buyers in these sectors should prioritize durability and resistance to harsh environmental factors, such as chemicals and abrasion, while also considering the ease of installation to minimize downtime.

What Role Do Pipe Floats Play in Marine Construction?

In marine construction, pipe floats stabilize hoses and cables used for underwater tasks, such as concrete pouring and infrastructure development. By keeping these components afloat, pipe floats reduce the risk of entanglement and enhance operational safety. Businesses involved in marine construction should focus on sourcing floats that are resistant to saltwater and UV exposure, ensuring longevity and reliability in challenging conditions.

How Are Pipe Floats Beneficial for Aquaculture?

Aquaculture relies on pipe floats to support feeding and aeration lines, which are critical for maintaining healthy aquatic environments. By keeping these lines above water, pipe floats prevent feed from sinking and ensure adequate oxygenation for fish. Buyers in this industry must consider custom sizing and buoyancy specifications to optimize performance, as well as the environmental impact of the materials used in the floats.

Why Are Pipe Floats Important for the Oil and Gas Industry?

In the oil and gas sector, pipe floats are vital for supporting drilling and production lines, ensuring that they remain accessible and functional. This prevents operational downtime and enhances the safety of underwater operations. When sourcing pipe floats, businesses should ensure compliance with industry standards and focus on materials that resist corrosion and wear from harsh operational conditions.

How Do Pipe Floats Assist in Water Management Initiatives?

Pipe floats are utilized in water management for floating pump stations and containment booms, which play a crucial role in controlling water flow and preventing pollution. By ensuring that these systems function effectively, businesses can meet environmental regulations and enhance their operational efficiency. Key considerations for sourcing should include weight capacity, material resilience, and adaptability to varying water conditions.

3 Common User Pain Points for ‘pipe float’ & Their Solutions

Scenario 1: Inconsistent Buoyancy Leading to Equipment Damage

Il problema: A common challenge faced by B2B buyers is ensuring consistent buoyancy during marine operations. Fluctuating water levels or unexpected currents can cause pipes to sink or become entangled, resulting in damage to both the pipes and the associated equipment. This not only leads to costly repairs but can also cause project delays and increase operational risks, particularly in sensitive environments like dredging or oil and gas operations.

Illustrative image related to pipe float

La soluzione: To mitigate the risk of inconsistent buoyancy, buyers should invest in modular pipe floats with adjustable buoyancy features. For instance, selecting products that allow the addition or removal of floats can help accommodate varying pipe diameters and water conditions. It’s essential to choose floats made from durable, UV-resistant materials to ensure longevity and resistance to environmental factors. Additionally, implementing a regular maintenance schedule for inspecting the floats can help identify wear and tear before they become problematic. Buyers should also consider working with suppliers who offer customized solutions tailored to specific project needs, ensuring optimal performance across various conditions.

Scenario 2: Complicated Installation Processes Affecting Efficiency

Il problema: Many B2B buyers experience frustration with complicated installation processes for pipe floats, which can significantly delay project timelines. Complex assembly requirements or the need for specialized tools can result in increased labor costs and hinder the efficiency of operations, particularly in remote or harsh environments where time is of the essence.

La soluzione: To address this issue, buyers should prioritize sourcing pipe floats designed for easy installation. Products that feature a straightforward assembly process, such as those utilizing quick-connect systems or pre-assembled components, can save valuable time and labor costs. Buyers should also consider modular systems that allow for rapid adjustments and reconfigurations as project needs change. Training personnel on installation best practices and utilizing visual aids or instructional materials can further streamline the process. Additionally, choosing suppliers that offer on-site support or installation assistance can help ensure that projects proceed smoothly and efficiently.

Scenario 3: Environmental Impact Concerns and Regulatory Compliance

Il problema: As environmental regulations become more stringent, B2B buyers are increasingly concerned about the ecological impact of the materials used in pipe floats. Many traditional floats can release harmful substances into the water, leading to compliance issues and potential damage to the company’s reputation. This concern is particularly acute in industries like aquaculture and environmental management, where safeguarding ecosystems is paramount.

La soluzione: To navigate these environmental challenges, buyers should seek out eco-friendly pipe floats made from recyclable and VOC-free materials. Suppliers that offer products certified for environmental compliance can provide peace of mind and help mitigate regulatory risks. Implementing a life cycle assessment (LCA) approach when selecting floats can also ensure that the environmental impact is considered from production through disposal. Additionally, establishing partnerships with manufacturers who are committed to sustainable practices can enhance corporate responsibility efforts and align with buyer values in today’s eco-conscious market. Regularly reviewing and updating procurement policies to prioritize sustainability will position companies favorably within their industries.

Strategic Material Selection Guide for pipe float

What Are the Key Properties of Common Materials Used in Pipe Floats?

When selecting materials for pipe floats, B2B buyers must consider various factors such as performance, durability, and environmental compatibility. The most common materials used in manufacturing pipe floats include polyethylene (PE), polypropylene (PP), foam-filled structures, and rubber. Each material has distinct properties that influence its suitability for specific applications.

How Does Polyethylene (PE) Perform in Pipe Floats?

Polyethylene is widely used in pipe floats due to its excellent resistance to UV radiation, chemicals, and moisture. It typically operates effectively within a temperature range of -60°C to 80°C. This material is lightweight yet durable, making it ideal for marine and dredging applications where buoyancy is critical.

Pro: PE floats are cost-effective and easy to manufacture, allowing for a wide range of sizes and designs. They are also recyclable, which appeals to environmentally conscious buyers.

Contro: Although durable, PE can become brittle at extremely low temperatures and may not withstand high-pressure applications as effectively as other materials.

Illustrative image related to pipe float

Impatto sull'applicazione: PE floats are suitable for freshwater and saltwater environments, making them versatile for various industries, including oil and gas, mining, and aquaculture.

What Advantages Does Polypropylene (PP) Offer for Pipe Floats?

Polypropylene is another popular choice for pipe floats, known for its superior chemical resistance and strength. It can withstand temperatures up to 100°C, making it suitable for high-temperature applications.

Pro: PP floats are lightweight and have a high tensile strength, which enhances their durability. They are also resistant to fatigue and have a lower density than PE, providing additional buoyancy.

Illustrative image related to pipe float

Contro: The higher manufacturing complexity and cost associated with PP can be a drawback for budget-sensitive projects. Additionally, it may have limited UV resistance compared to PE.

Impatto sull'applicazione: PP floats are particularly effective in chemical processing industries and environments where exposure to corrosive substances is common.

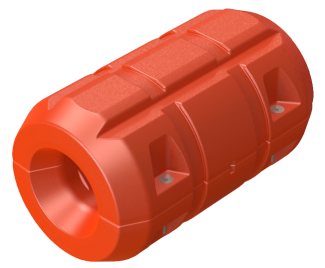

How Do Foam-Filled Structures Enhance Pipe Float Performance?

Foam-filled floats combine the buoyancy of traditional floats with added insulation and impact resistance. These structures are typically made from a robust outer shell, often PE or PP, filled with closed-cell foam.

Illustrative image related to pipe float

Pro: The foam provides additional buoyancy and insulation, making these floats ideal for cold water applications. They also offer enhanced shock resistance, which is beneficial in turbulent marine environments.

Contro: The manufacturing process for foam-filled floats can be more complex and expensive. They may also be less environmentally friendly due to the materials used in foam production.

Impatto sull'applicazione: Foam-filled floats are particularly useful in applications where temperature fluctuations are common, such as in colder climates or offshore environments.

What Role Does Rubber Play in Pipe Float Applications?

Rubber floats are less common but can be effective in specific applications where flexibility and resilience are required. They are often used in environments that require high impact resistance.

Pro: Rubber floats are highly durable and can withstand extreme conditions, including abrasive environments. They are also flexible, allowing for movement without compromising buoyancy.

Contro: The cost of rubber floats tends to be higher, and they may require more maintenance over time due to wear and tear. Additionally, rubber can degrade under prolonged exposure to UV light.

Impatto sull'applicazione: These floats are best suited for industrial applications where high durability is necessary, such as construction sites or areas with heavy machinery.

Summary Table of Material Selection for Pipe Floats

| Materiale | Typical Use Case for Pipe Float | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (basso/medio/alto) |

|---|---|---|---|---|

| Polietilene | Marine and dredging applications | UV and chemical resistance | Brittle at low temperatures | Basso |

| Polipropilene | Chemical processing industries | High tensile strength and temperature tolerance | Higher manufacturing cost | Medio |

| Foam-Filled | Cold water and offshore applications | Enhanced buoyancy and shock resistance | Complex manufacturing process | Alto |

| Rubber | Industrial applications with high impact | Durable and flexible | Higher cost and UV degradation | Alto |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in pipe floats, enabling informed decision-making for specific applications across diverse industries.

Illustrative image related to pipe float

In-depth Look: Manufacturing Processes and Quality Assurance for pipe float

What are the Main Stages in the Manufacturing Process of Pipe Floats?

The manufacturing process of pipe floats involves several critical stages that ensure the final product meets industry standards and client expectations.

Material Preparation

The first stage in manufacturing pipe floats is material preparation. High-density polyethylene (HDPE) is a common choice due to its durability, UV resistance, and recyclability. Suppliers typically source high-quality resin from reputable manufacturers, ensuring that the materials can withstand harsh marine conditions. Before processing, materials undergo stringent quality checks to confirm they meet specifications, including tensile strength and resistance to chemicals.

Forming Techniques

Once materials are prepared, the next step is forming the pipe floats. This can involve techniques such as rotational molding or blow molding, depending on the design requirements.

-

Stampaggio rotazionale: This technique involves placing the raw material in a mold, which is then rotated at high speeds to evenly distribute the material across the mold’s surface. This method allows for the creation of seamless, hollow pipe floats that are both lightweight and strong.

-

Blow Molding: Used for producing hollow shapes, blow molding is ideal for creating complex designs with internal structures. This technique is often employed when additional buoyancy or structural reinforcement is required.

Assembly Process

After forming, the components are assembled. This may involve the integration of features like Clamp Tite™ inserts, which prevent slippage, or the addition of modular sections that allow for customization based on the pipe’s diameter and buoyancy requirements.

Assembly typically requires precise alignment and secure fastening to ensure durability and performance under operational conditions. Automated assembly lines may be employed to enhance efficiency and reduce human error.

Illustrative image related to pipe float

Finishing Touches

The final stage involves finishing processes such as surface treatment and quality checks. This may include UV stabilization treatments to enhance longevity and color application for visibility in marine environments. Additionally, floats are often tested for buoyancy and structural integrity before being packaged for shipment.

How is Quality Assurance Integrated into the Manufacturing Process of Pipe Floats?

Quality assurance (QA) is a vital aspect of the manufacturing process that ensures products meet predefined standards and specifications. For pipe floats, adhering to international standards such as ISO 9001 and industry-specific certifications like CE and API is essential for maintaining product integrity.

What are the Relevant International and Industry-Specific Standards?

ISO 9001 sets the foundation for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements. In addition, CE marking indicates compliance with European health, safety, and environmental protection standards, while API standards apply to specific applications in the oil and gas sector.

Manufacturers targeting B2B buyers in regions like Africa, South America, the Middle East, and Europe must be aware of these standards as they can significantly influence purchasing decisions. Non-compliance can lead to increased costs and project delays.

What are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that pipe floats meet quality and safety standards. Key stages include:

-

Controllo qualità in entrata (CQI): This initial checkpoint involves assessing raw materials upon arrival. Suppliers conduct tests to verify that the materials meet specifications before they proceed to manufacturing.

-

Controllo qualità in corso d'opera (IPQC): During the manufacturing process, regular inspections are conducted to ensure that production parameters remain within specified limits. This might include monitoring temperature, pressure, and material consistency.

-

Controllo qualità finale (CQC): Once manufacturing is complete, the final products undergo rigorous testing. This includes buoyancy tests, structural integrity assessments, and visual inspections to check for defects. Only products that pass these tests are approved for shipment.

What Testing Methods Are Commonly Used for Pipe Floats?

Various testing methods are employed to ensure that pipe floats meet safety and performance standards. Common tests include:

-

Buoyancy Tests: Assess the float’s ability to support weight in water, ensuring it meets the required buoyancy specifications.

-

Impact Resistance Tests: Evaluate how well the float can withstand physical stress, particularly in rugged marine environments.

-

UV Resistance Testing: Determines the float’s ability to resist degradation from prolonged exposure to sunlight, which is crucial for outdoor applications.

-

Chemical Resistance Testing: Assesses how the float performs when exposed to various chemicals, ensuring it maintains integrity in different operational environments.

Come possono gli acquirenti B2B verificare i processi di controllo qualità dei fornitori?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial to mitigating risks associated with product quality and compliance.

Conducting Supplier Audits

One effective method for verifying QC processes is conducting supplier audits. This involves visiting the manufacturing facility to review their processes, quality management systems, and compliance with international standards.

Illustrative image related to pipe float

Richiesta di rapporti sulla qualità

Buyers should also request detailed quality reports that outline the results of various tests conducted on the products. These reports should include information on the materials used, testing procedures, and compliance with relevant standards.

Engaging Third-Party Inspectors

Hiring third-party inspection services can provide an unbiased evaluation of the manufacturing process and final products. These inspectors can perform independent tests and assessments, ensuring that the products meet the required standards before shipment.

What are the Nuances of Quality Control for International Buyers?

International buyers must navigate various nuances when it comes to quality control. Different regions may have specific regulations and expectations regarding product quality.

Understanding Regional Standards

For instance, buyers in Europe may place greater emphasis on CE marking and environmental impact, while those in the Middle East may prioritize compliance with local regulations. Understanding these nuances can help buyers make informed purchasing decisions.

Currency and Logistics Considerations

Additionally, international buyers should be aware of currency fluctuations and logistics challenges that can impact delivery timelines and costs. Clear communication with suppliers regarding these factors can help manage expectations and ensure timely project completion.

Illustrative image related to pipe float

By understanding the manufacturing processes and quality assurance measures for pipe floats, B2B buyers can make informed decisions, ensuring that they procure reliable and high-quality products tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipe float’

When sourcing pipe floats for industrial applications, it is essential to follow a structured approach to ensure that the chosen products meet operational needs while providing value for money. This guide outlines a step-by-step checklist to assist B2B buyers in making informed decisions about procuring pipe floats.

Fase 1: Definire le specifiche tecniche

Clearly outline the technical requirements for your pipe floats, including size, buoyancy, and material. Understanding your project needs—such as the type of fluid being transported, environmental conditions, and installation challenges—will help you select the most suitable products. Look for specifications such as resistance to UV, chemicals, and temperature variations.

Fase 2: Research Supplier Options

Conduct thorough research on potential suppliers, focusing on their product offerings and industry reputation. Review online resources, case studies, and testimonials from other buyers to gain insight into their reliability and product quality. Consider suppliers that specialize in your specific application, whether it be dredging, marine construction, or water management.

Fase 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Verify that they have the necessary certifications and quality control processes in place to ensure that their products meet international standards.

- Check for certifications: Look for ISO or other relevant certifications that indicate adherence to industry standards.

- Assess product warranties: A reliable supplier should offer warranties that reflect confidence in their products.

Passo 4: Richiesta di campioni da testare

Ask suppliers for product samples to test their performance under your specific operational conditions. This step is critical to assess the buoyancy, durability, and ease of installation of the pipe floats. Ensure that the samples are representative of the final product you intend to purchase.

Illustrative image related to pipe float

Passo 5: Compare Pricing and Terms

Once you have identified a shortlist of suppliers, obtain detailed quotations that include pricing, delivery times, and payment terms. Comparing these elements will help you understand the total cost of ownership and make an informed decision. Look for any hidden costs, such as shipping fees or additional charges for customization.

- Evaluate bulk discounts: Inquire about pricing tiers for larger orders that could result in significant savings.

Passo 6: Assess After-Sales Support and Maintenance

Consider the level of after-sales support offered by the supplier. Reliable support can significantly impact the long-term usability of your pipe floats. Check if the supplier provides maintenance services, spare parts availability, and technical assistance when required.

Passo 7: Finalize Your Purchase Agreement

After evaluating all factors, finalize your purchase agreement with the chosen supplier. Ensure that all terms, including delivery schedules, warranty details, and service commitments, are clearly documented. Having a well-defined contract will protect your interests and facilitate smoother transactions.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing pipe floats, ensuring they select products that meet their operational needs while also adhering to budgetary constraints.

Comprehensive Cost and Pricing Analysis for pipe float Sourcing

What Are the Key Cost Components in Pipe Float Manufacturing?

When sourcing pipe floats, understanding the cost structure is crucial for B2B buyers, particularly in international markets like Africa, South America, the Middle East, and Europe. The primary components influencing the overall cost include:

-

I materiali: The choice of materials significantly impacts pricing. High-density polyethylene (HDPE) is commonly used due to its durability and resistance to environmental factors. However, options like foam filling can add to the buoyancy but also to the cost. Buyers should consider the trade-off between material costs and the expected lifespan of the floats.

-

Lavoro: Labor costs can vary greatly depending on the manufacturing region. For instance, countries with lower wage standards may offer more competitive pricing. However, labor quality and expertise in manufacturing specific float designs can also affect the overall price.

-

Spese generali di produzione: This includes costs related to factory operations, maintenance of equipment, and utilities. Efficient manufacturing processes can lead to lower overhead costs, which can be passed on to buyers.

-

Utensili: Custom designs often require specialized tooling, which can increase initial costs. Buyers should evaluate whether investing in custom tooling will yield long-term savings or efficiencies.

-

Controllo qualità (CQ): Comprehensive QC measures ensure the reliability and safety of pipe floats. While this adds to the upfront cost, it can significantly reduce the risk of failures in the field, thus lowering maintenance costs over time.

-

Logistica: Shipping costs are a major consideration, especially for international buyers. Factors such as distance, shipping method, and Incoterms can influence these costs. For example, opting for DAP (Delivered at Place) can simplify logistics but may increase the price.

-

Margine: Suppliers typically apply a margin on top of their costs to achieve profitability. This can vary based on competition and market demand.

How Do Price Influencers Affect Pipe Float Sourcing?

Several factors influence the pricing of pipe floats, and understanding these can lead to more strategic purchasing decisions:

-

Volume/MOQ: Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their project needs while maximizing cost savings.

-

Specifiche e personalizzazione: Custom floats tailored to specific project requirements can increase costs. Buyers should weigh the benefits of customization against standard solutions that may suffice for their needs.

-

Qualità dei materiali e certificazioni: Higher-quality materials and certifications (e.g., ISO standards) often come at a premium but can enhance performance and longevity. Buyers should assess whether the added cost aligns with their operational requirements.

-

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more, but the assurance of quality and service may justify the expense.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can greatly affect the total landed cost. Understanding these terms helps buyers anticipate additional fees and manage budgets effectively.

What Are the Best Negotiation Tips for B2B Buyers?

To achieve favorable pricing on pipe floats, international B2B buyers should consider the following strategies:

-

Sfruttare gli sconti sui volumi: Whenever possible, consolidate orders to qualify for bulk pricing. This can significantly reduce the overall cost per unit.

-

Seek Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the floats, including maintenance, replacement, and potential downtime. Sometimes a higher upfront cost can lead to lower TCO.

-

Understand Market Trends: Keep abreast of market dynamics affecting material costs and supplier pricing strategies. This knowledge can provide leverage during negotiations.

-

Be Open to Alternative Solutions: If a supplier cannot meet your price expectations, consider discussing alternative materials or designs that may reduce costs while still meeting your operational requirements.

-

Request Transparent Pricing: Suppliers should be willing to break down costs, allowing buyers to identify areas for potential negotiation. Understanding the cost structure can empower buyers to negotiate effectively.

Conclusione

While indicative prices for pipe floats can vary based on numerous factors, informed decision-making can lead to cost-effective sourcing strategies. By understanding the nuances of cost components, price influencers, and negotiation tactics, international B2B buyers can optimize their procurement processes and ensure they secure the best value for their investments in pipe floats.

Alternatives Analysis: Comparing pipe float With Other Solutions

Exploring Alternatives to Pipe Floats: What Are Your Options?

In industries such as dredging, mining, and marine construction, effective buoyancy solutions are crucial for operational efficiency. While pipe floats are a popular choice for keeping pipes and cables afloat, several alternatives may also serve similar purposes. Understanding these options can help B2B buyers make informed decisions tailored to their specific project needs. Below, we compare pipe floats against two viable alternatives: Hose Floats and Modular Floating Platforms.

| Aspetto di confronto | Galleggiante per tubi | Hose Floats | Modular Floating Platforms |

|---|---|---|---|

| Prestazioni | High buoyancy for various pipe sizes; withstands harsh conditions | Provides flexibility for hose installations; good for light-duty applications | Supports a variety of equipment; customizable configurations |

| Costo | Moderate cost, varies by size | Typically lower cost | Higher upfront cost due to modular design |

| Facilità di implementazione | Quick installation with minimal tools | Simple installation, often requires straps | Requires assembly; may need additional components |

| Manutenzione | Low maintenance; durable materials | Generally low; may require replacement if damaged | Moderate; periodic checks needed for modular connections |

| Il miglior caso d'uso | Ideal for heavy-duty applications in water management | Suitable for lighter applications like irrigation or drainage | Best for supporting multiple applications, including walkways or pump stations |

In-Depth Examination of Alternatives

Hose Floats

Hose floats are designed primarily to support hoses, making them an excellent choice for lighter applications. Their modular nature allows for flexibility in installation, accommodating various hose sizes. The cost-effectiveness of hose floats makes them appealing for projects with budget constraints. However, they may not withstand the same harsh conditions as pipe floats, limiting their use in more demanding environments such as dredging or deep-sea operations.

Modular Floating Platforms

These platforms provide a versatile solution for supporting not only pipes but also other equipment like pumps and walkways. The customizable design allows for adjustments based on project requirements, making them suitable for a range of applications from water management to recreational uses. While the initial investment is higher than pipe floats, the long-term benefits of durability and adaptability can offset these costs. However, the complexity of assembly might pose challenges for some users, requiring additional time and resources.

Making the Right Choice for Your Needs

When selecting the appropriate flotation solution, B2B buyers should consider their specific project requirements, including environmental conditions, load capacities, and budget constraints. Pipe floats excel in demanding applications where durability and performance are paramount. Conversely, hose floats may be more suitable for lighter tasks, while modular floating platforms offer adaptability for diverse uses. Evaluating these factors will enable buyers to choose the most effective solution for their operational needs, ensuring efficiency and cost-effectiveness in their projects.

Essential Technical Properties and Trade Terminology for pipe float

What Are the Key Technical Properties of Pipe Floats?

When sourcing pipe floats for industrial applications, understanding their technical properties is crucial for ensuring performance and longevity. Here are several critical specifications to consider:

-

Material Grade

Pipe floats are typically made from high-density polyethylene (HDPE) or similar polymers, chosen for their durability and resistance to UV radiation, chemicals, and water. The material’s resistance to environmental factors ensures that the floats maintain their structural integrity over time, which is vital for operations in harsh conditions, such as marine environments. -

Buoyancy Capacity

This is a measure of how much weight the float can support while remaining buoyant. It is essential to match the buoyancy capacity with the weight of the pipes or hoses being supported. Insufficient buoyancy can lead to sinking or instability, which can disrupt operations and result in costly downtime. -

Dimensions and Tolerances

The outer diameter (OD), inner diameter (ID), and length of the pipe floats are critical specifications. These dimensions must align with the pipes or hoses they are intended to support. Tolerances in these measurements ensure a snug fit, which minimizes slippage and enhances stability. Accurate dimensions are particularly important in industries such as dredging and marine construction, where precision affects overall efficiency. -

Impact Resistance

This property refers to the float’s ability to withstand sudden force or shock without breaking. High impact resistance is vital for applications exposed to turbulent waters or heavy machinery. Floats with superior impact resistance reduce the risk of damage and prolong the lifespan of the product, leading to lower replacement and maintenance costs. -

Operating Temperature Range

The temperature range indicates the conditions in which the floats can function effectively. For example, some floats can operate in temperatures ranging from -60°C to 80°C. This specification is crucial for regions with extreme weather conditions, ensuring that the floats will not degrade or lose functionality.

What Are Common Trade Terms Associated with Pipe Floats?

Familiarity with industry terminology can facilitate smoother transactions and enhance communication with suppliers. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital when sourcing pipe floats, as it ensures that the products meet the necessary standards for compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps buyers assess whether a supplier meets their volume needs and budget constraints, particularly when sourcing for large projects. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price offers from suppliers. When buyers issue an RFQ for pipe floats, it allows them to compare pricing and terms from multiple vendors, ensuring they secure the best deal for their requirements. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs and risk management when importing pipe floats. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for project planning, especially in industries where timely delivery is critical to avoid delays and additional costs. -

Customs Clearance

This term involves the process of passing goods through customs so they can enter a country. Buyers should be aware of customs regulations and procedures for pipe floats, as these can affect delivery times and overall project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing pipe floats, ensuring that they select products that meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the pipe float Sector

What Are the Current Market Dynamics and Key Trends in the Pipe Float Sector?

The global pipe float market is witnessing significant growth driven by the increasing demand in various industries such as dredging, mining, and marine construction. As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, navigate these dynamics, it’s crucial to recognize the trends shaping sourcing strategies. Key drivers include technological advancements that enhance the durability and efficiency of pipe floats, such as the introduction of modular designs and eco-friendly materials. The rise of digital platforms for procurement is also transforming how buyers source products, enabling them to compare options and secure competitive pricing efficiently.

Emerging trends indicate a growing preference for custom solutions tailored to specific operational needs, which can maximize efficiency and reduce costs. Additionally, the move towards lightweight, recyclable materials has gained traction, as companies seek to minimize shipping costs and reduce their environmental footprint. The integration of smart technology in flotation systems, allowing for real-time monitoring and maintenance alerts, is another trend gaining momentum. B2B buyers should consider these factors when sourcing pipe floats, as they can lead to enhanced operational efficiency and sustainability.

How Is Sustainability Influencing the Sourcing of Pipe Floats?

Sustainability is becoming a critical consideration in the procurement of pipe floats. With increasing awareness of environmental impacts, buyers are prioritizing products that are made from recyclable and eco-friendly materials. For instance, many manufacturers are adopting polyethylene that is UV resistant and free from volatile organic compounds (VOCs), thus ensuring a lower environmental footprint. This shift is not only beneficial for the planet but also aligns with corporate social responsibility goals that are increasingly important to stakeholders.

Illustrative image related to pipe float

Moreover, ethical sourcing practices are gaining traction, with companies emphasizing transparency in their supply chains. Buyers are encouraged to partner with manufacturers who adhere to sustainable practices, ensuring that materials are sourced responsibly and that labor conditions are ethical. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability. By prioritizing sustainable options, B2B buyers can not only comply with regulatory requirements but also enhance their brand reputation in a market that increasingly values environmental stewardship.

What Is the Historical Context Behind Pipe Float Development?

The evolution of pipe floats can be traced back several decades, initially designed for basic buoyancy in marine applications. Early models were often heavy and cumbersome, limiting their usability across different environments. As industries expanded and the need for efficiency grew, innovations in materials and design began to emerge. The introduction of lightweight, durable polyethylene revolutionized the sector, providing a solution that was not only effective but also easier to install and transport.

Over the years, technological advancements have further refined the functionality of pipe floats. The development of modular systems, for example, has allowed for greater flexibility in application, enabling users to adapt floats to various pipe sizes and configurations. This evolution has positioned pipe floats as essential tools across multiple industries, facilitating improved operational efficiency and safety standards. Understanding this historical context can provide valuable insights for B2B buyers seeking to make informed sourcing decisions in today’s competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of pipe float

-

How do I choose the right pipe float for my project?

Selecting the appropriate pipe float involves considering several key factors, including the diameter and weight of the pipe, the specific environmental conditions (e.g., saltwater, freshwater, temperature), and the float’s buoyancy capacity. Assess the installation requirements and whether a modular or fixed design suits your needs. Additionally, verify the material durability, especially against UV exposure and chemical resistance. Consulting with suppliers who can provide technical specifications and recommendations based on your project details can also enhance your decision-making process. -

What is the best material for pipe floats in harsh environments?

For harsh environments, high-density polyethylene (HDPE) is often the best material choice for pipe floats due to its superior resistance to UV rays, chemicals, and physical impacts. Some floats also utilize foam filling for added buoyancy and insulation against extreme temperatures. When sourcing, look for floats that are specifically designed for marine applications, as they are engineered to withstand the rigors of saltwater and turbulent conditions, ensuring longevity and reliability in your operations. -

How can I ensure quality when sourcing pipe floats internationally?

To ensure quality, start by vetting suppliers through thorough research. Look for manufacturers with certifications that align with international standards (e.g., ISO, ASTM). Request samples to assess material quality and construction. Additionally, consider suppliers who offer warranties or guarantees on their products, as this can indicate confidence in their quality. Engaging third-party inspection services prior to shipping can also provide an added layer of assurance regarding product specifications. -

What are the common payment terms for international pipe float purchases?

Payment terms can vary significantly among suppliers, but common arrangements include letters of credit, upfront deposits, and net payment terms (e.g., 30 or 60 days post-delivery). It’s essential to clarify terms before committing to a purchase, as this can affect cash flow and project timelines. Ensure that payment methods are secure and provide adequate buyer protection. Discussing terms upfront can help avoid misunderstandings and facilitate smoother transactions. -

What are the minimum order quantities (MOQ) for pipe floats?

Minimum order quantities (MOQ) for pipe floats can differ based on the manufacturer and the specific product line. Typically, MOQs may range from a few dozen to several hundred units. When negotiating with suppliers, consider your project needs and budget, as well as potential discounts for bulk orders. If you require a smaller quantity, some suppliers may offer flexibility or allow for mixed orders across different products, which can be beneficial for project diversity. -

Can I customize pipe floats to meet specific project requirements?

Yes, many manufacturers offer customization options for pipe floats, including size, color, buoyancy levels, and additional features like UV protection or foam filling. Customization allows you to tailor floats to your project’s unique specifications and environmental conditions. When discussing customization with suppliers, provide detailed requirements and ask for prototypes or design proofs to ensure they meet your expectations before final production. -

What logistical considerations should I keep in mind when importing pipe floats?

Logistical considerations include shipping methods, lead times, and customs regulations for the specific countries involved. Evaluate the most cost-effective shipping options, whether by sea or air, and factor in potential delays at customs. Ensure that all documentation, including invoices and certificates of origin, is accurate and complete to prevent complications. Working with experienced logistics partners can streamline the import process and help navigate international trade regulations. -

How do I maintain and care for pipe floats to extend their lifespan?

To maintain pipe floats and extend their lifespan, regular inspections for signs of wear, UV damage, or punctures are essential. Clean floats with freshwater after exposure to saltwater or harsh chemicals to prevent degradation. Store them in a shaded, dry area when not in use to minimize UV exposure. Following manufacturer guidelines for maintenance and care can significantly enhance the durability and performance of your floats in various operational conditions.

Top 7 Pipe Float Manufacturers & Suppliers List

1. PipeFloat – Hose Floats and Mooring Buoys

Dominio: pipefloat.com

Registrato: 2011 (14 anni)

Introduzione: {“Hose Floats/Pipe Floats/Cable Floats”: {“material”: “UV resistant PE”, “features”: “Clamp Tite TM inserts to prevent slippage”}, “Mooring Buoys”: {“size range”: “13’’ to 48’’”, “features”: “foam filled, available with eye or rope channel”}, “Regulatory Buoys”: {“alternate names”: “Spar Buoys, Channel Marker Buoys”, “features”: “impact resistant, molded with handles for lifting”}, “Floating Walkw…

2. EZ Connect Floats – Modular Hose and Pipeline Floats

Dominio: ezconnectfloats.com

Registrazione: 2022 (3 anni)

Introduzione: EZ Connect Floats are patented modular one-size-fits-all floats designed to float hoses, pipelines, pipes, cables, and umbilicals. They are made of bright red polyethylene material, ensuring visibility and durability against wear in water and direct sunlight. The floats are reusable for any size diameter of pipe or hose, ranging from 1 to 40 inches. Installation is quick and easy, utilizing corros…

3. Pacific Marine – Pipe and Hose Floats

Dominio: pacificmarine.net

Registered: 1999 (26 years)

Introduzione: This company, Pacific Marine – Pipe and Hose Floats, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. DAE Pumps – Polyethylene Pipe and Hose Floats

Dominio: daepumps.com

Registrato: 2018 (7 anni)

Introduzione: DAE Pumps offre galleggianti ultraresistenti per tubi e manichette in polietilene progettati per applicazioni di dragaggio. Le caratteristiche principali includono:

- Realizzato in polietilene leggero ad alta densità per garantire flessibilità e resistenza agli urti.

– Non-slip fit to cables, hoses, and pipes to prevent slippage and misalignment.

- Elevata resistenza alla corrosione e ai raggi UV per una maggiore durata del prodotto.

– Lightweight for ease of transportation and i…

5. Nautilus – GripTite™ Pipe Floats

Dominio: nautilusfloats.com

Registered: 2012 (13 years)

Introduzione: Nautilus™ Pipe Floats with GripTite™ technology for Pipe, Hose or Cable. Features a multi-faceted gripping surface for enhanced contact area, tapered nose design to reduce drag, available for pipe diameters from 2.5″ – 30″, made of weather resistant polyethylene (HDPE), and designed to replace rusted & damaged steel pontoon floats.

6. Barr Plastics – Neptune Industrial Pipe Floats

Dominio: barrplastics.com

Registrato: 2004 (21 anni)

Introduzione: Neptune Industrial Pipe Floats are designed for dredging, mining, de-watering, pumping, and other industrial projects. They are molded from tough, impact-resistant high-density polyethylene and are foam-filled. Key features include a low profile design for stability and reduced resistance to waves, currents, ice, and winds, ability to withstand sub-zero temperatures, and UV stabilizer for sunlight…

7. Nelco Marine – Neptune Pipe Floats

Dominio: nelcomarine.com

Registered: 2008 (17 years)

Introduzione: {‘product_name’: ‘Neptune Pipe Floats’, ‘application’: ‘Pipeline flotation requirements in dredging, mining, and aggregate applications’, ‘features’: [‘Clamp Tite™ – prevents slippage by compressing the pipeline’, ‘EzGlide™ – tapered ends decrease water and wind resistance’, ‘Solid one piece construction’, ‘Molded-in bolt holes for easy installation’], ‘material’: ‘Impact resistant polyethylene pl…

Strategic Sourcing Conclusion and Outlook for pipe float

What Are the Key Takeaways for B2B Buyers in Pipe Float Sourcing?

In the competitive landscape of pipe float sourcing, understanding the diverse applications and benefits of these products is crucial. Pipe floats serve as essential solutions across industries such as dredging, mining, and marine operations, providing buoyancy and stability that protect submerged equipment while enhancing operational efficiency. When sourcing, prioritize high-quality materials, such as UV-resistant polyethylene, which ensure durability and long-term performance in demanding environments.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing enables international buyers to streamline procurement, reduce costs, and ensure a reliable supply chain. By fostering relationships with reputable manufacturers who offer customizable solutions, you can adapt to specific project requirements, whether in Africa, South America, the Middle East, or Europe. Emphasizing sustainability through the selection of recyclable materials can also align with global environmental standards, adding value to your sourcing strategy.

What’s Next for International Buyers?

Looking ahead, the demand for innovative and adaptable pipe flotation solutions is set to rise. As industries evolve, staying informed about the latest technologies and product offerings will be key to maintaining a competitive edge. Engage with suppliers that offer modular designs and easy installation, which can significantly reduce downtime. Take action today to explore tailored solutions that meet your operational needs and position your business for success in the global market.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to pipe float

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.