Descrizione

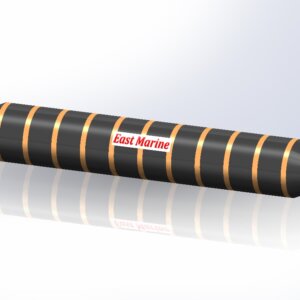

Tubo di scarico in gomma con flangia a sandwich

The sandwich flanged discharge hose is widely used in dredging projects, port construction, and water conservancy works. It is designed to be connected with dredgers for the transportation of slurry, tailings, or other mixed materials, and can be applied in floating pipelines, onshore pipelines, and submarine pipelines.

The hose is made from high-quality natural rubber and synthetic rubber composites, featuring excellent resistance to abrasion, corrosion, and bending. Both ends are equipped with sandwich flanges, enabling easy and efficient installation and disassembly while ensuring reliable system operation.

With outstanding flexibility and pressure-bearing capacity, the hose performs well under complex working conditions and continuous heavy loads, delivering stable and consistent results even in harsh environments.

As a vital component of dredging operations, the steel flanged discharge hose provides safe, efficient, and durable conveying solutions for a wide range of engineering applications.

Specifications:

| Descrizione | Dettaglio |

| Nome del prodotto | Dredging Discharge Rubber Hose with Sandwich Flange |

| Origin | Cina |

| Inner Diameter(ID) | 100-1100mm |

| Length | 500-11800mm |

| Working Pressure(WP) | 0.5-4.2Mpa |

| Burst Pressure(BP) | 1.5-12.6Mpa |

| Flange Type | Sandwich Flange |

| Application | Offshore Dredging Pipeline or other Dredging Project |

Structure:

-

Inner Lining

Black wear and corrosion resistant natural rubber compound, integrated with a wear warning layer to indicate service condition. -

Rinforzo

Multiple layers of high tensile textile reinforcement, ensuring excellent pressure resistance and structural stability. -

Outer Cover

Black weather and abrasion resistant natural rubber, designed for harsh dredging environments and equipped with a warning layer for added safety. -

Flanges

The flange body is made of Q235 carbon steel, with the sealing surface and the inner bore surface in contact with the medium lined with rubber. -

Marking

Clear and durable markings with East Dredging branding or customized customer logo for easy identification of dredging equipment.

Key Benefits and Features

- Designed to handle project loads and materials of up to 16 tons efficiently.

- Suitable for a wide range of projects, especially in ship-building, mining, and manufacturing

- It has a maximum span of up to 36 meters, and, therefore, is suitable if you have a small load-handling space

- Allows for effective control of lifting and trolley speed to suit different project needs

- Provides 3 remote control options f

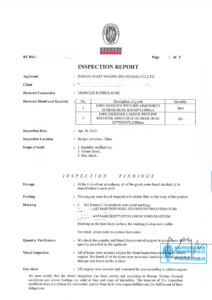

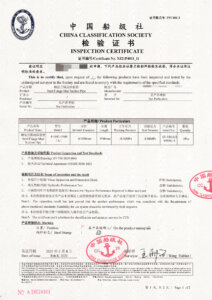

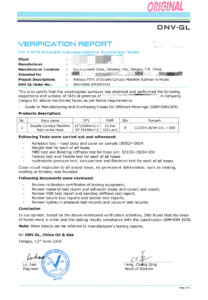

Discharge Rubber Hose Inspection:

To ensure each discharge rubber hose meets the required performance and safety standards, a series of strict inspections and tests are carried out throughout the production process:

-

Raw Material Test: Each batch of raw materials, including natural rubber, tensile textile, and rubber additives, is carefully inspected before entering the warehouse to ensure quality consistency and durability.

-

Hose Dimension Check: The hose’s inner and outer diameters, wall thickness, and flange alignment are measured to confirm they meet design specifications.

-

Weight Check: Each hose is weighed to verify it falls within the acceptable tolerance range, ensuring uniform product quality.

-

Working Pressure Test (if specified): The hose is subjected to pressure testing to confirm its ability to safely withstand the specified working pressure without leakage or deformation.

-

Bending Test (if specified): The hose is tested for flexibility and bending resistance to ensure reliable performance under working conditions.

For additional assurance, we can invite third-party inspection agencies to conduct inspections according to customer requirements.

Discharge Rubber Hose Packaging Information:

To ensure the safety of transporting discharge rubber hoses and maximize loading efficiency, we adopt different packaging methods according to the order quantity:

-

Bulk cargo: Delivered in loose packing to the port and then consolidated into containers.

-

Small-volume cargo: Secured on wooden pallets before being loaded into containers to ensure stability and safety during transportation.

_1000x750-300x225.jpg)

Professional · Efficient · Cost-effective · Environmentally Responsible

Due to the large size and heavy weight of marine and dredging rubber hoses, conventional packaging is generally not used, helping to reduce logistics costs and unnecessary materials.

We apply professional bulk hose packing and loading methods to ensure safe transportation while protecting the hoses, containers, transport equipment, and handling personnel.

With extensive experience in rubber hose manufacturing and global shipment, we ensure safe loading, efficient delivery, and reliable protection throughout the logistics process.