Introduction: Navigating the Global Market for hard suction hose fire

In today’s global marketplace, sourcing hard suction hoses for fire applications poses significant challenges for B2B buyers, especially when it comes to identifying reliable suppliers and ensuring product quality. As industries across Africa, South America, the Middle East, and Europe prioritize safety and efficiency, understanding the nuances of hard suction hoses becomes crucial. This comprehensive guide delves into various types of hard suction hoses, their applications in firefighting, and key factors to consider during the procurement process.

Navigating the complexities of supplier vetting, pricing structures, and product specifications can be daunting. Buyers must evaluate not only the technical aspects of hoses—such as material durability, bend radius, and coupling types—but also the logistical considerations like lead times and shipping costs. This guide empowers international B2B buyers by providing actionable insights and best practices, enabling them to make informed purchasing decisions that align with their specific operational needs.

From understanding the differences between PVC and heavy-duty options to recognizing the importance of compliance with international standards, this resource equips buyers with the knowledge necessary to enhance their firefighting capabilities. Whether you are in the heart of Vietnam or Germany, our guide serves as a pivotal tool to navigate the global market for hard suction hoses, ensuring that you secure the best products for your organization’s needs.

Indice dei contenuti

- Top 4 Hard Suction Hose Fire Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hard suction hose fire

- Understanding hard suction hose fire Types and Variations

- Key Industrial Applications of hard suction hose fire

- 3 Common User Pain Points for ‘hard suction hose fire’ & Their Solutions

- Strategic Material Selection Guide for hard suction hose fire

- In-depth Look: Manufacturing Processes and Quality Assurance for hard suction hose fire

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hard suction hose fire’

- Comprehensive Cost and Pricing Analysis for hard suction hose fire Sourcing

- Alternatives Analysis: Comparing hard suction hose fire With Other Solutions

- Essential Technical Properties and Trade Terminology for hard suction hose fire

- Navigating Market Dynamics and Sourcing Trends in the hard suction hose fire Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hard suction hose fire

- Strategic Sourcing Conclusion and Outlook for hard suction hose fire

- Disclaimer importante e condizioni d'uso

Understanding hard suction hose fire Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Standard Hard Suction Hose | Rigid construction, typically made from PVC or rubber | Firefighting, industrial water transfer | Pro: Durable, reliable performance. Contro: Heavier than alternatives. |

| Lightweight PVC Suction Hose | Lighter, flexible, often less expensive | Emergency services, small-scale firefighting | Pro: Easy to handle, cost-effective. Contro: Less durable than heavy-duty options. |

| Camlock Suction Hose | Quick-connect couplings for fast setup | Fire departments, construction sites | Pro: Time-saving connection, versatile. Contro: May require additional fittings. |

| Heavy-Duty Hard Suction Hose | Reinforced with extra layers for high pressure | High-demand firefighting, industrial applications | Pro: Excellent pressure resistance, long lifespan. Contro: Higher cost. |

| Tubo di aspirazione in PVC trasparente | Il materiale trasparente consente il monitoraggio visivo del flusso | Water rescue operations, filtration systems | Pro: Easy flow visibility, lightweight. Contro: Susceptible to UV damage without protection. |

What are the Characteristics of Standard Hard Suction Hose?

Standard hard suction hoses are typically constructed from durable materials such as PVC or rubber. These hoses are designed to withstand rigorous conditions and are essential for applications like firefighting and industrial water transfer. When purchasing, buyers should consider the hose’s pressure ratings, compatibility with existing equipment, and whether the weight aligns with their operational needs.

How Does Lightweight PVC Suction Hose Differ?

Lightweight PVC suction hoses are favored for their flexibility and ease of handling, making them ideal for emergency services and smaller firefighting operations. Their cost-effectiveness is a significant advantage, but buyers should weigh this against potential durability issues. It is essential to assess the specific operational requirements and whether a lighter hose will meet the demands of their applications.

What Advantages Does Camlock Suction Hose Offer?

Camlock suction hoses feature quick-connect couplings that facilitate rapid setup, an invaluable asset in emergency situations. Commonly used by fire departments and on construction sites, these hoses enhance operational efficiency. Buyers must consider the additional fittings that may be required and ensure compatibility with their existing systems to maximize the benefits of this type.

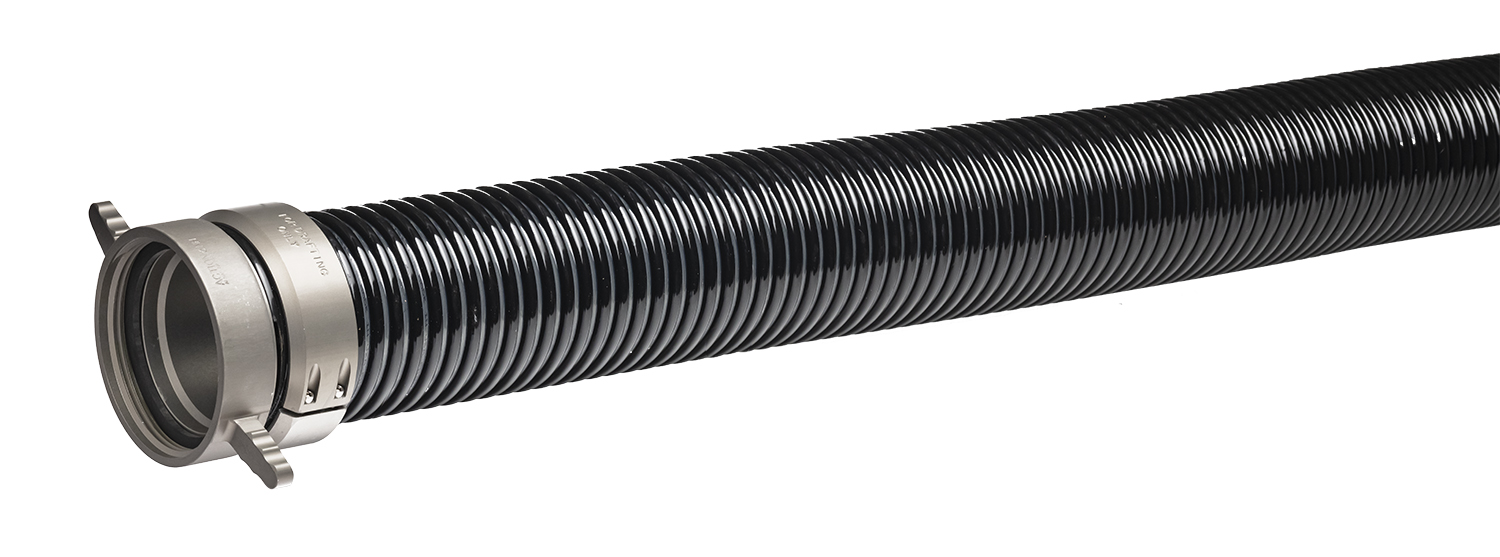

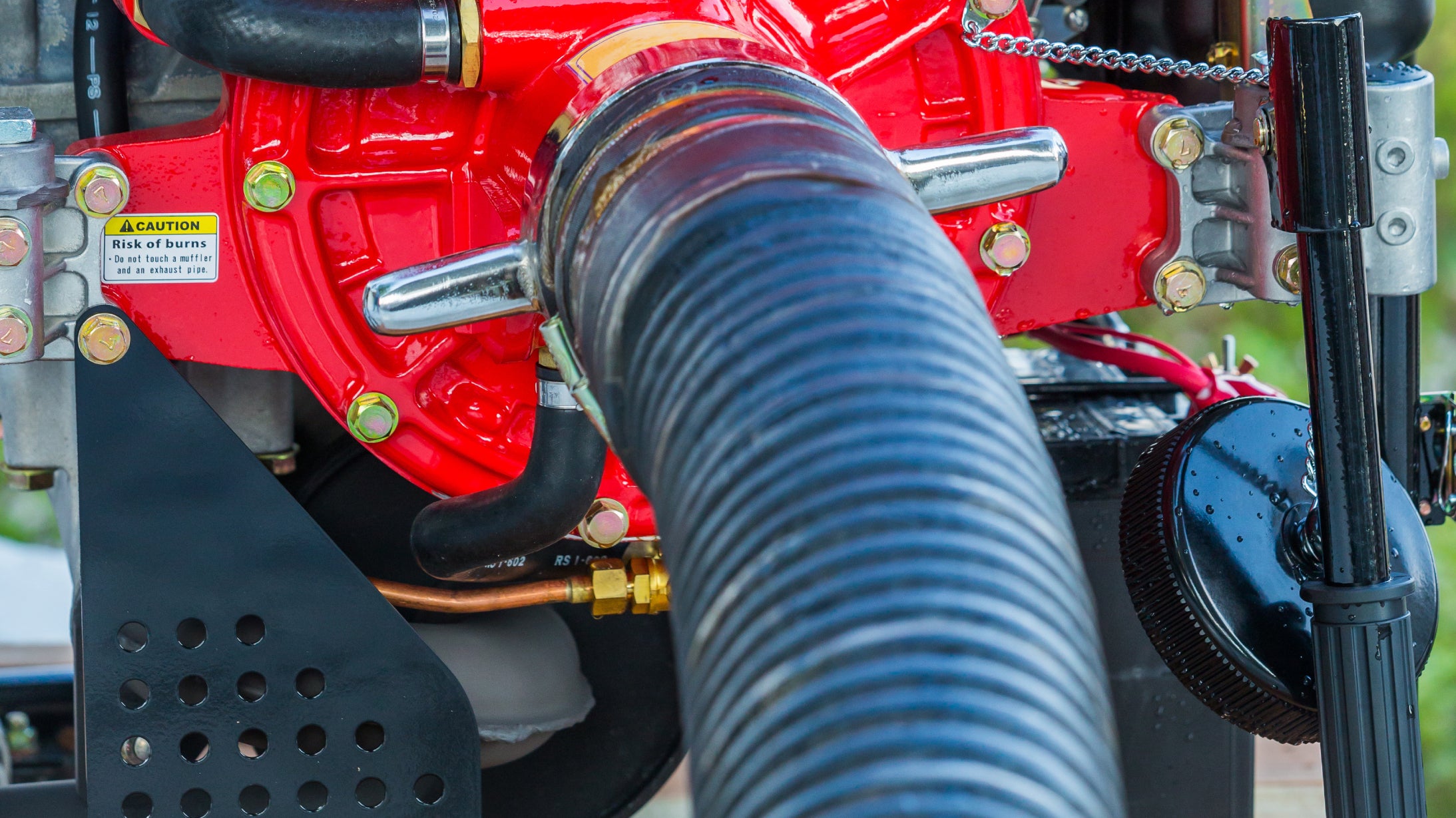

Illustrative image related to hard suction hose fire

Why Choose Heavy-Duty Hard Suction Hose?

Heavy-duty hard suction hoses are reinforced to handle high-pressure environments, making them suitable for demanding firefighting scenarios and industrial applications. While these hoses offer exceptional durability and longevity, they come at a higher price point. Buyers should evaluate their specific needs, including pressure requirements and potential long-term savings from investing in more robust equipment.

What are the Benefits of Clear PVC Suction Hose?

Clear PVC suction hoses allow for easy visual monitoring of water flow, which is particularly beneficial in water rescue operations and filtration systems. Their lightweight nature makes them easy to handle, but buyers must be cautious of UV exposure, which can degrade the material over time. When considering this option, it is crucial to assess the environment in which the hose will be used and whether additional protective measures are necessary.

Key Industrial Applications of hard suction hose fire

| Industria/Settore | Specific Application of hard suction hose fire | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Firefighting Services | Water extraction from natural sources (ponds, rivers) | Provides reliable water supply for firefighting operations | Ensure hose durability and resistance to UV and abrasion |

| Agricoltura | Irrigation and water transfer from open sources | Efficient water sourcing during droughts or for crop irrigation | Consider hose length, diameter, and coupling compatibility |

| Costruzione | Dewatering construction sites | Prevents flooding and maintains site safety | Assess pressure ratings and flexibility for tight spaces |

| Miniere | Emergency water supply for fire control | Enhances safety and compliance in mining operations | Evaluate compatibility with existing fire suppression systems |

| Industrial Facilities | Water transfer for fire suppression systems | Ensures quick response during fire emergencies | Look for hoses with high flow rates and robust construction |

How is Hard Suction Hose Used in Firefighting Services?

In firefighting services, hard suction hoses are crucial for extracting water from unpressurized sources like ponds or rivers. This application is vital in rural areas where hydrants may not be readily available. The hoses must be robust, capable of withstanding harsh environmental conditions, and resistant to UV damage. For international buyers, particularly in regions like Africa and South America, sourcing hoses that meet local firefighting standards and are compatible with existing equipment is essential to ensure effective fire response.

What Role Does Hard Suction Hose Play in Agriculture?

Agricultural applications leverage hard suction hoses for irrigation, especially in regions facing water scarcity. By drawing water from nearby rivers or lakes, farmers can ensure efficient crop irrigation, reducing dependency on municipal water supplies. Buyers should consider the hose’s weight, flexibility, and compatibility with various fittings to facilitate ease of use in diverse agricultural settings, particularly in developing regions where infrastructure may be limited.

How is Hard Suction Hose Beneficial for Construction?

In construction, hard suction hoses are employed for dewatering sites to prevent flooding, which can impede progress and create safety hazards. These hoses help maintain a dry work environment, ensuring compliance with safety regulations. When sourcing hoses for construction applications, buyers should focus on pressure ratings, flexibility for maneuvering around obstacles, and durability to withstand rough handling on job sites.

What is the Importance of Hard Suction Hose in Mining Operations?

Mining operations utilize hard suction hoses for emergency water supply during fire incidents. Given the high-risk environment, having reliable water access is crucial for safety and compliance with industry regulations. Buyers in the mining sector need to assess the compatibility of hoses with existing fire suppression systems, ensuring they can handle the specific demands of their operations, especially in remote locations where resources are limited.

How Do Industrial Facilities Benefit from Hard Suction Hose?

Industrial facilities use hard suction hoses as part of their fire suppression systems to quickly transfer water to areas at risk of fire. This ensures a rapid response, minimizing damage and enhancing safety. When sourcing these hoses, businesses should prioritize high flow rates, robust construction, and the ability to integrate seamlessly with existing firefighting infrastructure, particularly in regions where industrial standards may vary.

3 Common User Pain Points for ‘hard suction hose fire’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Hard Suction Hoses

Il problema: B2B buyers often struggle with sourcing hard suction hoses that can withstand harsh environmental conditions, particularly in regions with extreme weather, such as Africa and the Middle East. Many suppliers offer hoses that may be cost-effective but compromise on durability, leading to premature wear and failure during critical firefighting operations. This not only affects the performance of firefighting efforts but can also lead to increased costs due to frequent replacements and downtime.

La soluzione: When sourcing hard suction hoses, prioritize suppliers that offer high-quality materials designed for durability and weather resistance. Look for hoses made from UV-resistant PVC or reinforced synthetic materials that can handle temperature fluctuations and exposure to the elements. It’s also advisable to request samples to test for flexibility and sturdiness. Ensure that the hoses meet international standards such as NFPA 1961, which guarantees their reliability. Establishing long-term relationships with reputable manufacturers can also provide better access to durable options and favorable pricing.

Illustrative image related to hard suction hose fire

Scenario 2: Inefficient Water Flow Due to Hose Design

Il problema: Another common issue faced by B2B buyers is the inefficiency in water flow when using hard suction hoses. Many hoses have suboptimal designs that can lead to kinks or restrictions in flow, particularly in tight spaces or during rapid deployment. This inefficiency can significantly hinder firefighting efforts, especially in emergencies where every second counts.

La soluzione: To mitigate this issue, buyers should consider investing in hard suction hoses that feature advanced engineering, such as those with a tighter bend radius and smooth interior linings. Hoses like the Flex-Lite Suction Hose are designed to offer exceptional flexibility and a 24% tighter bend radius, reducing the chances of kinking during use. Additionally, ensure that couplings are made from high-grade materials, as durable couplings can help maintain a consistent water flow. Regularly inspect and maintain hoses by removing any debris or obstructions that could impede water flow, and train teams on proper handling techniques to minimize damage during deployment.

Scenario 3: Challenges with Compatibility and Standardization

Il problema: B2B buyers often encounter compatibility issues with hard suction hoses, especially when integrating new hoses into existing firefighting equipment. These challenges can arise from varying diameters, coupling types, or hose materials, leading to delays in response times and increased operational costs. Furthermore, in regions where multiple fire departments may use different systems, standardization becomes a significant concern.

La soluzione: To address compatibility issues, it is crucial to conduct a thorough assessment of existing firefighting equipment and their specifications before purchasing new hoses. Standardize on a specific diameter and coupling type across all units to ensure interoperability. Engage with suppliers who provide custom solutions or can advise on standardization practices. Additionally, consider purchasing hoses that offer versatile coupling options, such as camlock or threaded fittings, to facilitate easier integration into different systems. Regular training and clear documentation on the compatibility of hoses with existing equipment can also help streamline operations and enhance overall efficiency.

Strategic Material Selection Guide for hard suction hose fire

When selecting materials for hard suction hoses used in firefighting, it is essential to consider various factors such as performance characteristics, cost, and application suitability. Below, we analyze four common materials used in the manufacture of hard suction hoses, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

What are the Key Properties of PVC for Hard Suction Hoses?

Polyvinyl Chloride (PVC) is a popular material for hard suction hoses due to its lightweight and cost-effective nature. PVC hoses generally have a temperature rating of up to 150°F (65°C) and can handle moderate pressure levels, typically around 150 psi. They are resistant to corrosion and chemicals, making them suitable for various water sources.

Pro: PVC hoses are affordable and lightweight, which simplifies transportation and handling. Their flexibility allows for easier maneuverability in tight spaces.

Contro: However, PVC hoses can be less durable than other materials, particularly in extreme temperatures or prolonged UV exposure. They may not be suitable for high-pressure applications, limiting their use in certain firefighting scenarios.

Impatto sull'applicazione: PVC hoses are ideal for transferring water from unpressurized sources such as ponds or rivers, but they may not withstand the rigors of heavy-duty firefighting operations.

Considerazioni per gli acquirenti internazionali: Compliance with standards such as ASTM D1785 is crucial. Buyers in regions like Africa and South America should also consider local climate conditions that may affect the hose’s longevity.

How Does Rubber Compare for Hard Suction Hoses?

Gomma is another common material used for hard suction hoses, known for its excellent flexibility and durability. Rubber hoses can typically withstand higher temperatures (up to 200°F or 93°C) and pressures (up to 250 psi), making them suitable for more demanding applications.

Pro: The durability of rubber hoses makes them highly suitable for rugged environments. They are resistant to abrasion and can handle a variety of media, including water with debris.

Contro: On the downside, rubber hoses tend to be heavier and more expensive than PVC options, which could impact shipping costs and handling.

Impatto sull'applicazione: Rubber hoses are ideal for heavy-duty firefighting operations where high pressure and temperature resistance are necessary.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that rubber hoses meet international standards such as ISO 9001. In regions like Europe, compliance with DIN standards is also essential.

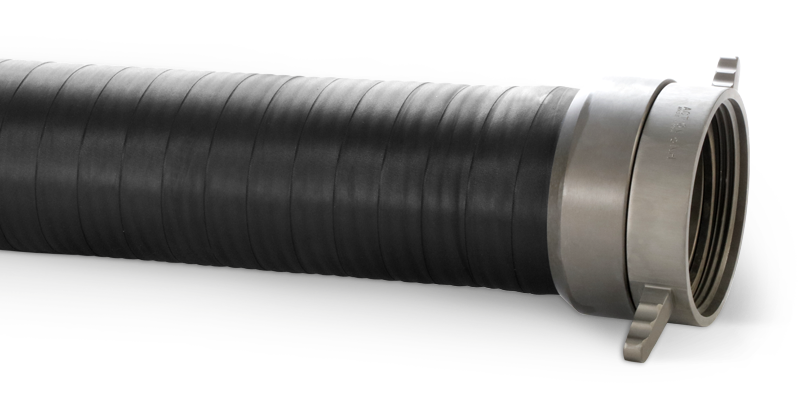

Illustrative image related to hard suction hose fire

What are the Benefits of Using Polyurethane in Hard Suction Hoses?

Poliuretano is a high-performance material that offers excellent abrasion resistance and flexibility. These hoses can operate effectively in a temperature range of -40°F to 180°F (-40°C to 82°C) and can handle pressures up to 300 psi.

Pro: The lightweight nature of polyurethane hoses makes them easy to handle, while their durability ensures a longer lifespan. They are also resistant to UV rays and chemicals.

Contro: The primary downside is the higher cost compared to PVC and rubber hoses, which may deter budget-conscious buyers.

Impatto sull'applicazione: Polyurethane hoses are particularly suitable for applications requiring high flexibility and durability, making them ideal for firefighting in challenging environments.

Considerazioni per gli acquirenti internazionali: Buyers should verify compliance with relevant standards such as JIS and ASTM. Additionally, understanding local market preferences in regions like the Middle East can aid in selection.

What Makes Aluminum a Viable Option for Hard Suction Hoses?

Aluminum, while not a traditional hose material, is often used for fittings and couplings in hard suction hoses. It offers excellent strength-to-weight ratio and corrosion resistance.

Pro: Aluminum fittings are lightweight and provide a secure connection, enhancing the overall performance of the hose.

Contro: However, aluminum is not suitable as a primary hose material due to its rigidity and potential for corrosion under certain conditions.

Impatto sull'applicazione: Aluminum fittings improve the efficiency of hard suction hoses but should be combined with flexible hose materials for optimal performance.

Considerazioni per gli acquirenti internazionali: Ensure that aluminum components meet military specifications for durability. Buyers should also consider the availability of compatible fittings in their regions.

Summary Table

| Materiale | Typical Use Case for hard suction hose fire | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (basso/medio/alto) |

|---|---|---|---|---|

| PVC | Water transfer from ponds or rivers | Lightweight and cost-effective | Less durable under extreme conditions | Basso |

| Gomma | Heavy-duty firefighting operations | High durability and pressure resistance | Heavier and more expensive | Medio |

| Poliuretano | Challenging environments requiring flexibility | Eccellente resistenza all'abrasione | Higher cost | Alto |

| Aluminum | Hose fittings and couplings | Leggero e resistente alla corrosione | Not suitable as primary hose material | Medio |

This strategic material selection guide provides essential insights for B2B buyers to make informed decisions when sourcing hard suction hoses for firefighting applications.

In-depth Look: Manufacturing Processes and Quality Assurance for hard suction hose fire

The manufacturing process and quality assurance for hard suction hoses play a critical role in ensuring product reliability and performance, especially in emergency situations where lives may depend on the equipment’s effectiveness. This section provides an in-depth overview of the stages involved in producing hard suction hoses, the quality control measures implemented, and insights for B2B buyers navigating the international market.

What Are the Main Stages in the Manufacturing Process of Hard Suction Hoses?

Material Preparation: What Types of Materials Are Used?

The manufacturing of hard suction hoses typically begins with the selection of high-quality materials. Common materials include PVC (polyvinyl chloride) and various rubber compounds, chosen for their durability, flexibility, and resistance to environmental factors such as UV rays and abrasion. The material preparation stage involves sourcing these raw materials from reputable suppliers, often adhering to international standards to ensure consistency and reliability.

How Are Hard Suction Hoses Formed?

After material preparation, the next stage is forming the hose. This process may involve extrusion, where heated material is forced through a die to create a continuous tube. For some hoses, especially those requiring specific structural properties, a molding process might be used. This involves shaping the material into the desired configuration while ensuring that the internal diameter meets performance specifications.

What Is the Assembly Process Like?

The assembly stage incorporates the addition of couplings, which are crucial for connecting hoses to pumps or other firefighting equipment. Couplings can be made from aluminum or other robust metals to enhance durability. Techniques such as crimping or welding are often used to ensure a secure fit, preventing leaks during operation. Attention to detail during assembly is vital, as any imperfection could compromise the hose’s performance.

What Finishing Techniques Are Commonly Applied?

Once the hose is assembled, it undergoes finishing processes, which may include surface treatment to enhance resistance to chemicals and UV exposure. Additionally, branding, labeling, and protective coatings are applied to ensure visibility and compliance with safety standards. This stage is crucial for preparing the hose for its intended use, particularly in environments where visibility and identification are critical.

How Is Quality Assurance Implemented in Hard Suction Hose Production?

What International Standards Guide Quality Control?

Quality assurance in hard suction hose manufacturing is guided by international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that the manufacturer has established processes that meet customer and regulatory requirements. In addition, industry-specific certifications such as CE marking in Europe or API standards for the oil and gas industry may also apply, depending on the intended use of the hoses.

Illustrative image related to hard suction hose fire

Quali sono i principali punti di controllo della qualità?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage ensures that raw materials meet specified standards before production begins. Inspections may include physical and chemical testing to verify material properties.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples may be tested to monitor consistency and performance. This stage helps identify any deviations from quality standards early on, allowing for immediate corrective actions.

-

Final Quality Control (FQC): Once production is complete, the finished products undergo rigorous testing. This includes pressure testing, visual inspections for defects, and performance evaluations to ensure that the hoses meet or exceed industry specifications.

What Testing Methods Are Commonly Used?

Testing methods for hard suction hoses include hydrostatic testing, which measures the hose’s ability to withstand internal pressure, and vacuum testing, which assesses its suction capabilities. Additionally, hoses may be subjected to environmental testing to evaluate their performance under various conditions, such as temperature fluctuations and exposure to chemicals.

Come possono gli acquirenti B2B verificare il controllo qualità dei fornitori?

What Should Buyers Look for in Supplier Audits and Reports?

B2B buyers should seek suppliers who are transparent about their quality assurance processes. This includes providing access to audit reports, certifications, and documentation of compliance with international standards. Suppliers should also be open to third-party inspections, which can provide an unbiased assessment of their quality control practices.

How Do Quality Control Certifications Vary by Region?

For international buyers, understanding regional quality control nuances is essential. For instance, in Europe, CE certification is mandatory for many products, indicating compliance with safety and environmental regulations. In contrast, buyers in Africa and South America may encounter different local regulations that can affect product quality and safety standards. It is vital for buyers to familiarize themselves with these regional requirements to ensure they are sourcing compliant products.

What Role Does Third-Party Inspection Play?

Engaging third-party inspection services can provide an additional layer of assurance for B2B buyers. These inspections can occur at various stages of the manufacturing process, from material sourcing to final production. Third-party inspectors can validate the manufacturer’s claims regarding quality and compliance, offering peace of mind to buyers concerned about product reliability.

Conclusion: Why Is Quality Assurance Vital for Hard Suction Hoses?

For B2B buyers, particularly those operating in critical sectors like firefighting, understanding the manufacturing processes and quality assurance measures for hard suction hoses is paramount. By prioritizing suppliers who adhere to rigorous quality standards and providing transparent documentation, buyers can ensure they procure reliable, high-performance hoses that meet their operational needs. Whether in Africa, South America, the Middle East, or Europe, a commitment to quality can significantly impact safety and efficiency in emergency response situations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hard suction hose fire’

When sourcing hard suction hoses for fire applications, it’s crucial to follow a structured approach to ensure that you select the right products that meet your operational needs. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

Fase 1: Definire le specifiche tecniche

Begin by outlining the specific requirements for the hard suction hose, including diameter, length, and material. Different applications may demand varying specifications; for instance, a heavier-duty hose may be required for rugged environments, while a lighter option could suffice for less demanding situations. Consider factors such as flexibility, pressure ratings, and resistance to UV and abrasion.

Fase 2: Research and Identify Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies that specialize in fire safety equipment and have a solid reputation in the industry. Utilize platforms like trade shows, online directories, and industry associations to find reliable suppliers. Be sure to check for their geographical reach, especially if you are sourcing from regions like Africa or South America.

Fase 3: Valutare i potenziali fornitori

Before making a commitment, it’s essential to vet your shortlisted suppliers. Request company profiles, case studies, and references from buyers within similar industries or regions. This step not only validates the supplier’s credibility but also provides insight into their customer service and product quality.

- Check Certifications: Ensure that the suppliers comply with international standards, such as NFPA (National Fire Protection Association) regulations, which guarantee the safety and reliability of their products.

- Assess Product Range: A supplier with a diverse product range may offer better solutions tailored to your specific needs.

Passo 4: Request Samples

Don’t hesitate to ask for samples of the hard suction hoses you are considering. Testing the hoses in your operational environment can help you assess their performance, flexibility, and durability. This step is vital for understanding how the hoses will function under real-world conditions.

Passo 5: Compare Pricing and Terms

Once you have gathered samples, compare pricing among your shortlisted suppliers. Keep an eye on the total cost of ownership, including shipping, taxes, and any potential import duties, particularly when sourcing internationally. Also, evaluate payment terms and warranty options to ensure you are making a financially sound decision.

Passo 6: Negotiate Contracts

When you’ve identified a preferred supplier, it’s time to negotiate the contract. Discuss delivery timelines, bulk order discounts, and after-sales support. Clear communication at this stage can prevent misunderstandings later on and ensure that you receive a product that meets your expectations.

Passo 7: Plan for After-Sales Support

Finally, ensure that your supplier offers robust after-sales support. This includes warranty services, maintenance advice, and availability of spare parts. A reliable support system can greatly enhance the longevity and performance of your hard suction hoses, ultimately safeguarding your investment.

By following this checklist, you can streamline your sourcing process for hard suction hoses and ensure that you choose a product that not only meets your specifications but also supports your operational needs effectively.

Comprehensive Cost and Pricing Analysis for hard suction hose fire Sourcing

What Are the Key Cost Components in Hard Suction Hose Pricing?

When analyzing the pricing structure for hard suction hoses, various cost components come into play. The primary elements include:

-

I materiali: The choice of materials significantly affects the cost. Common materials include PVC, rubber, and reinforced fabrics, with PVC often being more cost-effective but less durable than rubber options. Custom specifications or additional features such as UV resistance or abrasion-proof coatings will also influence material costs.

-

Lavoro: Labor costs encompass the wages of workers involved in the manufacturing process. Skilled labor for specialized production techniques or assembly can drive up costs, particularly in regions with higher labor rates.

-

Spese generali di produzione: This includes expenses related to production facilities, equipment maintenance, and administrative costs. A well-optimized manufacturing process can reduce these overheads, but any inefficiencies will be reflected in pricing.

-

Utensili: The initial investment in molds and machinery for producing different sizes or custom designs can be substantial. This upfront cost is often amortized over larger production runs, affecting the per-unit cost of lower volume orders.

-

Controllo qualità (CQ): Ensuring compliance with safety standards and certifications (e.g., NFPA 1961) incurs additional costs. Suppliers that prioritize rigorous QC processes may charge a premium, which is justified by the assurance of product reliability.

-

Logistica: Shipping costs can vary widely based on the distance, mode of transportation, and regional tariffs. For international buyers, understanding the logistics component is crucial as it can significantly impact the total landed cost.

-

Margine: Lastly, suppliers will build in a profit margin, which can vary based on market conditions and competitive positioning. Understanding the typical margin in your target market can aid in negotiating better deals.

How Do Price Influencers Impact Hard Suction Hose Costs?

Several factors influence the pricing of hard suction hoses, which international buyers should consider:

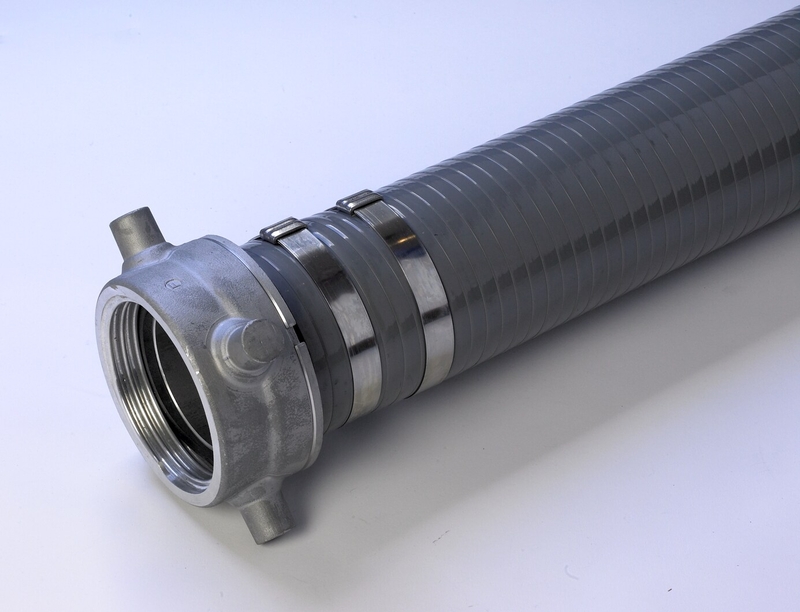

Illustrative image related to hard suction hose fire

-

Volume/MOQ: Suppliers often provide discounts for larger orders due to economies of scale. Minimum order quantities (MOQ) can also affect pricing; smaller orders may incur higher per-unit costs.

-

Specifiche e personalizzazione: Custom lengths, diameters, or specialized fittings can lead to increased costs. Buyers should evaluate whether standard options meet their needs or if customization is necessary.

-

Qualità dei materiali e certificazioni: Higher quality materials and certifications can raise the price, but they often result in longer-lasting products. Investing in certified hoses can reduce long-term costs related to maintenance and replacement.

-

Fattori di fornitura: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The agreed-upon terms of shipment and delivery (Incoterms) can influence costs. Buyers should clarify who bears responsibility for shipping, insurance, and tariffs to avoid unexpected expenses.

What Tips Can Buyers Use to Optimize Costs When Sourcing Hard Suction Hoses?

To navigate the complexities of sourcing hard suction hoses effectively, consider these buyer tips:

-

Negotiate Wisely: Leverage your purchasing volume to negotiate better pricing. Establish long-term relationships with suppliers to enhance your bargaining power over time.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the upfront price. Consider factors such as durability, maintenance, and replacement frequency when assessing value.

-

Comprendere le sfumature dei prezzi per i mercati internazionali: Be aware of regional pricing variations. For example, buyers in Africa or South America may face different tariffs or shipping costs compared to European buyers.

-

Stay Informed on Market Trends: Keeping abreast of market trends can provide insights into pricing fluctuations and help you make informed purchasing decisions.

-

Request Samples: Before committing to larger orders, request samples to evaluate quality and ensure they meet your operational requirements.

Disclaimer on Pricing

The prices mentioned for hard suction hoses are indicative and subject to change based on market conditions, supplier pricing strategies, and specific buyer agreements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing hard suction hose fire With Other Solutions

When evaluating fire suppression solutions, it’s crucial to consider various alternatives to hard suction hoses. Each option has unique characteristics that may align differently with the operational needs and budget constraints of organizations, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis compares hard suction hoses with two viable alternatives: PVC suction hoses and fire pumps.

Tabella di confronto

| Aspetto di confronto | Hard Suction Hose Fire | Tubo di aspirazione in PVC | Fire Pump |

|---|---|---|---|

| Prestazioni | High flow rates; durable under pressure | Lighter but less durable; suitable for smaller volumes | Very high flow rates; versatile applications |

| Costo | Moderate to high ($141.91 to $1,410.60) | Low to moderate ($120 to $910) | High initial investment; ongoing maintenance costs |

| Facilità di implementazione | Requires specific fittings and setup | Easy to handle and deploy | Complex installation; may require training |

| Manutenzione | Generally low; regular inspections needed | Low; check for wear and tear regularly | Moderate; requires periodic servicing |

| Il miglior caso d'uso | Sucking water from static sources like ponds | Suitable for lightweight applications; ideal for emergencies | Ideal for high-demand fire suppression scenarios |

What Are the Pros and Cons of PVC Suction Hoses as an Alternative?

PVC suction hoses are lightweight and less expensive than hard suction hoses, making them an attractive option for organizations with budget constraints. They are particularly beneficial in situations where weight is a significant factor, such as in portable firefighting equipment. However, PVC hoses are less durable and may not withstand the same level of pressure as hard suction hoses, which can be a drawback in high-stress environments. Their suitability for smaller volumes also limits their effectiveness in large-scale firefighting operations.

How Do Fire Pumps Compare to Hard Suction Hoses?

Fire pumps are a robust solution for fire suppression, capable of delivering high flow rates and powering multiple hoses simultaneously. They are versatile and can be used for various applications beyond firefighting, such as irrigation or industrial processes. However, the initial investment and ongoing maintenance costs can be substantial. Additionally, fire pumps often require specialized training for effective operation, which can complicate implementation in regions with limited resources. Their complexity may deter some organizations from adopting them, despite their effectiveness.

Conclusion: How to Choose the Right Solution for Your Fire Suppression Needs?

Selecting the right fire suppression solution hinges on understanding your specific operational requirements, budget, and resource availability. Hard suction hoses offer high durability and performance for static water sources, making them suitable for many fire departments. In contrast, PVC hoses provide a cost-effective, lightweight alternative for less demanding situations. Fire pumps present a versatile but costly option for organizations needing high flow rates and multiple operational capabilities. By assessing these factors, B2B buyers can make informed decisions that align with their unique fire suppression needs and operational contexts.

Essential Technical Properties and Trade Terminology for hard suction hose fire

What Are the Key Technical Properties of Hard Suction Hose Fire?

Understanding the essential technical properties of hard suction hoses is vital for B2B buyers involved in fire safety equipment procurement. Here are several critical specifications that should be considered:

-

Grado del materiale

Hard suction hoses are typically made from materials like PVC, rubber, or reinforced synthetic fabrics. The material grade affects durability, flexibility, and resistance to environmental factors such as UV rays and abrasion. For example, hoses made from high-grade PVC are lighter and more flexible, making them easier to handle while still providing adequate strength for suction operations. Choosing the right material can significantly impact operational efficiency and longevity. -

Diameter

Common diameters for hard suction hoses range from 2 inches to 6 inches. The diameter directly influences the flow rate of water, which is critical in firefighting scenarios. A larger diameter allows for a greater volume of water to be moved quickly, which can be crucial during emergencies. Buyers should assess their specific needs and the types of water sources they will be drawing from to select the appropriate diameter. -

Length

Hard suction hoses are available in various lengths, typically ranging from 10 to 20 feet. The length of the hose should be considered based on the distance to the water source and the setup of the firefighting equipment. Longer hoses may provide flexibility in positioning but can also add weight and complexity to deployment. Understanding the operational environment can guide buyers in selecting the optimal length. -

Pressione nominale di esercizio

The working pressure rating indicates the maximum pressure the hose can withstand during operation. This specification is crucial for ensuring safety and reliability during use. A hose with a higher pressure rating may be necessary for specific applications, particularly in high-demand firefighting scenarios. Buyers should evaluate their equipment and the anticipated pressure requirements before making a purchase. -

Temperature Tolerance

Temperature tolerance refers to the range of temperatures that the hose can safely operate under. This property is particularly important in regions with extreme weather conditions. Hoses that can withstand a wider temperature range offer greater versatility and reliability, ensuring they perform well regardless of environmental challenges. -

Coupling Type

Couplings are the fittings that connect hoses to pumps or other hoses. Common coupling types include camlock and threaded options. The choice of coupling affects ease of use, maintenance, and compatibility with existing equipment. Buyers should ensure that the couplings are suitable for their specific needs to avoid operational issues.

What Are Common Trade Terms Related to Hard Suction Hose Fire?

In the procurement process, understanding industry jargon is essential for effective communication and negotiation. Here are several common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, sourcing from OEMs can ensure quality and compatibility with existing systems. -

MOQ (quantità minima d'ordine)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for buyers looking to maintain a steady supply of hard suction hoses. -

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process allows buyers to compare offers and negotiate better deals, making it an essential step in the procurement cycle. -

Incoterms (Termini commerciali internazionali)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping responsibilities, risks, and costs, ensuring smoother logistics. -

Tempi di consegna

This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is critical for planning and ensuring that necessary equipment is available when needed. -

Certification Standards

Many hoses must meet specific industry standards (e.g., NFPA for fire safety) to ensure safety and reliability. Buyers should verify that products meet relevant certifications to comply with regulations and industry best practices.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting hard suction hoses for firefighting applications, ultimately enhancing operational effectiveness and safety.

Navigating Market Dynamics and Sourcing Trends in the hard suction hose fire Sector

What Are the Current Market Dynamics for Hard Suction Hose Fire Products?

The global hard suction hose market is experiencing robust growth, driven by rising demand for efficient firefighting solutions across various regions. Key factors propelling this market include increasing urbanization, heightened awareness of fire safety, and the expansion of emergency response services in developing regions such as Africa and South America. Furthermore, the integration of advanced materials and technologies is enhancing product performance and durability, making them attractive to international buyers.

Emerging trends in B2B sourcing reveal a shift towards lightweight and flexible hoses, such as PVC and hybrid materials, which offer enhanced maneuverability and ease of use. Additionally, the advent of digital platforms for procurement is streamlining the purchasing process, allowing buyers to compare options and make informed decisions quickly. Buyers from Europe, particularly Germany and the UK, are increasingly interested in products that meet stringent safety standards, while those in emerging markets are often looking for cost-effective solutions without compromising quality.

Moreover, sustainability is becoming a crucial consideration in sourcing decisions. As buyers become more environmentally conscious, they are seeking suppliers that prioritize eco-friendly practices and materials in their manufacturing processes. This trend is particularly pronounced in markets where regulations are tightening around environmental impact, pushing manufacturers to innovate and adapt to meet these expectations.

How Is Sustainability and Ethical Sourcing Impacting the Hard Suction Hose Market?

Sustainability in the hard suction hose sector is no longer a mere trend but a necessity. The environmental impact of manufacturing processes, including resource extraction and waste generation, is under increasing scrutiny. For B2B buyers, understanding the sustainability practices of suppliers can significantly influence purchasing decisions. Buyers are now looking for hoses made from recyclable materials or those that have certifications indicating a lower carbon footprint.

Ethical sourcing is equally important, as it ensures that suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management or the Global Recycled Standard are becoming critical in the procurement process. Buyers who prioritize these certifications not only contribute to a sustainable environment but also enhance their corporate social responsibility (CSR) profiles, which is increasingly becoming a factor for end consumers.

The use of advanced materials that provide durability while being environmentally friendly is gaining traction. Hoses that incorporate UV-resistant properties and are designed for longevity reduce the need for frequent replacements, thereby minimizing waste. As such, suppliers who innovate in these areas are likely to gain a competitive edge in the market.

What Historical Developments Have Shaped the Hard Suction Hose Industry?

The evolution of hard suction hoses can be traced back to the early days of firefighting when rudimentary materials were used to transport water from natural sources. The introduction of rubber and synthetic materials in the mid-20th century marked a significant turning point, enhancing the durability and flexibility of hoses. Over the decades, advancements in material science have led to the development of lightweight and more efficient hoses, such as PVC and composite materials, which have revolutionized firefighting techniques.

Today, the hard suction hose market continues to innovate, driven by the dual demands of performance and sustainability. As global regulations evolve and the focus on environmental stewardship intensifies, the industry is poised for further advancements that will cater to both operational efficiency and ecological responsibility. This historical context is crucial for B2B buyers, as it highlights the ongoing transformation in the sector and the importance of aligning sourcing strategies with current and future market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of hard suction hose fire

-

How do I determine the right size of hard suction hose for my fire department?

Choosing the correct size of hard suction hose primarily depends on the specifications of your fire pumps and the water source. Common sizes include 2″, 4″, and 6″ hoses, with larger diameters facilitating higher flow rates. For optimal performance, consult your fire pump’s manual and consider the distance from the water source to the pump. Additionally, consider the maximum lift and suction capabilities of your equipment. Always verify compatibility with fittings and couplings used in your existing systems to ensure seamless operations. -

What is the best material for hard suction hoses used in firefighting applications?

The best material for hard suction hoses is typically reinforced PVC or rubber, which offer excellent durability and flexibility. PVC hoses are lightweight and resistant to abrasion, making them ideal for situations where weight is a concern. Rubber hoses, on the other hand, are known for their strength and long service life, especially under extreme conditions. Evaluate your specific operational needs, including temperature and environmental factors, to select the material that will perform best in your region. -

What are the key features to look for in a hard suction hose?

When selecting a hard suction hose, consider features such as flexibility, bend radius, and coupling quality. A hose with a tighter bend radius allows for better maneuverability in tight spaces. Look for hoses with clear PVC construction for visual monitoring of water flow, as well as durable couplings made from materials like aircraft aluminum for enhanced abrasion resistance. Additionally, UV protection is crucial if the hose will be exposed to sunlight, as it prolongs the lifespan and maintains performance. -

What is the minimum order quantity (MOQ) for hard suction hoses when sourcing internationally?

The minimum order quantity (MOQ) for hard suction hoses can vary significantly by supplier and region. Typically, MOQs range from 10 to 50 units, depending on the manufacturer’s production capabilities and inventory policies. When negotiating with suppliers, inquire about bulk order discounts and shipping options to optimize your procurement process. It’s advisable to establish a relationship with suppliers who can accommodate your needs, especially if you anticipate fluctuating demand. -

How can I verify the quality of hard suction hoses from potential suppliers?

To verify the quality of hard suction hoses, request certifications that indicate compliance with industry standards such as NFPA 1961. Conducting supplier audits or site visits can also provide insights into their manufacturing processes. Additionally, seek samples for testing to assess performance under your specific conditions. Customer reviews and case studies can provide valuable feedback on the durability and reliability of the hoses in real-world applications. -

What payment terms should I expect when sourcing hard suction hoses internationally?

Payment terms for international sourcing of hard suction hoses can vary widely. Common practices include upfront payments, letters of credit, or net 30/60 days after delivery. Discuss terms with suppliers to find a mutually agreeable arrangement. It’s crucial to ensure that payment methods are secure, and consider using escrow services for larger transactions to protect your investment. Always review contracts carefully to avoid any hidden fees or unfavorable conditions. -

What logistics considerations should I keep in mind when importing hard suction hoses?

Logistics for importing hard suction hoses involve several key considerations, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling fire equipment to ensure smooth transport. Be aware of import regulations in your country, including any tariffs or duties that may apply. Proper documentation is essential, so ensure all necessary paperwork is prepared to prevent delays at customs. -

How can I customize hard suction hoses to meet specific operational needs?

Customizing hard suction hoses is often possible through discussions with your supplier. You can specify length, diameter, and coupling types based on your operational requirements. Many manufacturers offer options for color coding or branding, which can aid in quick identification during emergencies. When considering customization, factor in lead times and potential cost implications to ensure that the tailored solution aligns with your budget and timeline.

Top 4 Hard Suction Hose Fire Manufacturers & Suppliers List

1. Cascade Fire – PVC Suction Hose

Dominio: cascadefire.com

Registrato: 1997 (28 anni)

Introduzione: {“PVC Suction Hose”:{“price_range”:”$120.00 – $910.00″,”features”:”Lighter and less expensive than conventional suction hose”},”Hard Suction Hose”:{“price_range”:”$8.00 – $18.00″,”features”:”Used to suck water out of unpressurized sources, such as ponds or rivers, by means of a vacuum”},”Polyester Soft Suction Hose”:{“price_range”:”$6.00 – $18.00″,”features”:”Used to transfer water from hydrant to…

2. First Out Rescue – Hard Suction Hoses

Dominio: firstoutrescue.com

Registrato: 2005 (20 anni)

Introduzione: Hard suction hoses are designed for firefighting and water supply applications. They are typically made of durable materials to withstand high pressures and harsh conditions. These hoses feature a rigid construction that allows for easy handling and efficient water flow. They are available in various lengths and diameters to meet specific needs. The hoses are often equipped with fittings that ensu…

3. Facebook – Hard Suction Hose

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: A hard suction hose is a non-collapsible suction hose attached to a pump, used to draft water from a source when the water source is lower than the pump.

4. FireHoseSupply.com – 5 Hard PVC Suction Hose Black Storz

Dominio: firehosesupply.com

Registrato: 2012 (13 anni)

Introduzione: {“name”: “5\” Hard PVC Suction Hose Black Storz”, “price”: {“regular”: 1601.51, “discounted”: 1397.41, “discount_percentage”: 12}, “availability”: “In Stock”, “shipping”: “Free Shipping”, “product_type”: “Black PVC Suction Hose”, “vendor”: “FireHoseSupply.com”, “sku”: “FHSS104NSTZ-1”, “length_options”: [“5 Feet”, “10 Feet”, “15 Feet”, “20 Feet”, “25 Feet”], “features”: [“24% tighter bend radius”, …

Strategic Sourcing Conclusion and Outlook for hard suction hose fire

In conclusion, the strategic sourcing of hard suction hoses is essential for ensuring reliable fire response capabilities across various regions, including Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of evaluating product specifications, such as flexibility, durability, and material quality, to select hoses that meet specific operational needs. Additionally, understanding pricing structures and availability can aid in making informed purchasing decisions that align with budget constraints and delivery timelines.

Investing in high-quality hard suction hoses not only enhances firefighting efficiency but also contributes to long-term cost savings through reduced maintenance and replacement needs. As the demand for reliable firefighting equipment continues to grow globally, B2B buyers should leverage strategic sourcing to build robust supply chains that can withstand market fluctuations and supply challenges.

Looking ahead, it is crucial for international buyers to forge partnerships with reputable suppliers who can provide innovative solutions tailored to local conditions. By prioritizing quality and strategic sourcing practices, organizations can enhance their firefighting capabilities and ensure readiness for any emergency. Engage with suppliers today to secure the best solutions for your operational needs and stay ahead in an evolving market.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to hard suction hose fire

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.