Article Contents

Engineering Insight: What Vulcanized Rubber

Technical Overview: The Role of Vulcanized Rubber in Dredging Hose Performance

Vulcanized rubber is a critical material in the construction of high-performance dredging hoses used in Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). The vulcanization process, a chemical treatment developed by Charles Goodyear, involves cross-linking polymer chains in natural or synthetic rubber using sulfur under heat and pressure. This transformation fundamentally enhances the rubber’s mechanical properties, making it ideal for the extreme conditions encountered in marine dredging operations.

In dredging applications, hoses are subjected to continuous abrasion, high internal pressures, dynamic bending, and exposure to seawater, sand, silt, and varying temperatures. Unvulcanized rubber would quickly degrade under such stress, leading to premature failure and costly downtime. Vulcanization significantly improves tensile strength, elasticity, and resistance to wear, ozone, and chemical degradation. These enhancements ensure that the rubber maintains structural integrity and flexibility over extended operational cycles, even in the harshest offshore environments.

For TSHDs and CSDs, the suction and discharge hoses must endure abrasive slurries containing sand, gravel, and debris at high flow velocities. The vulcanized rubber lining acts as a protective barrier, minimizing internal wear and maintaining consistent internal diameter for optimal hydraulic efficiency. Additionally, the cross-linked structure of vulcanized rubber reduces permeability, preventing fluid leakage and maintaining pressure stability during pumping operations.

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, leverages advanced vulcanization techniques in the manufacturing of its dredging hoses. With over 150 skilled employees, including dedicated materials engineers and R&D specialists, the company applies precise control over curing time, temperature, and sulfur content to tailor rubber compounds for specific dredging conditions. This engineering capability ensures consistent product quality and performance across large-scale production runs.

The company’s adherence to ISO9001 standards, combined with its membership in WEDA and CEDA, underscores its commitment to technical excellence in marine rubber solutions. East Marine’s hoses are designed not only to meet international specifications but also to extend service life and reduce total cost of ownership for dredging contractors.

The following table outlines key mechanical properties of vulcanized rubber used in East Marine’s dreding hoses:

| Property | Typical Value (Vulcanized Rubber) | Test Standard |

|---|---|---|

| Tensile Strength | ≥18 MPa | ASTM D412 |

| Elongation at Break | ≥400% | ASTM D412 |

| Hardness (Shore A) | 60–70 | ASTM D2240 |

| Abrasion Resistance (DIN) | ≤120 mm³ loss | ISO 4649 |

| Tear Strength | ≥35 kN/m | ASTM D624 |

| Operating Temperature Range | -30°C to +85°C | Internal Validation |

This technical precision in vulcanization, backed by East Marine’s engineering expertise and large-scale production capacity, ensures reliable, long-lasting performance in critical dredging operations worldwide.

Advanced Manufacturing Process

Precision Vulcanization: Engineering Durability in Dredging Hose Manufacturing

Vulcanization represents the critical chemical transformation where raw rubber compounds achieve their essential mechanical properties for demanding marine applications. At East Marine, subsidiary of Jiangsu Huashen Special Rubber Products, this process is meticulously controlled within our 0.68M sqm manufacturing facility to produce suction and discharge hoses capable of withstanding extreme abrasion, high pressure, and corrosive dredging environments. Our approach transcends simple curing; it is a scientifically optimized stage defining the hose’s operational lifespan and reliability.

The journey begins with compounded rubber blends, formulated specifically for dredging service, incorporating high-tensile synthetic rubbers, specialized fillers, and additives to resist wear and seawater degradation. These compounds are precisely layered with textile or wire reinforcements onto mandrels. The uncured assembly then enters the vulcanization phase. Utilizing our 18 dedicated production lines, hoses undergo precise thermal treatment within state-of-the-art autoclaves or continuous vulcanization tunnels. Temperature, pressure, and time profiles are rigorously calibrated based on hose diameter, wall thickness, and compound chemistry. This controlled cross-linking of polymer chains transforms the soft, sticky compound into a resilient, elastic network. Key outcomes include significantly enhanced tensile strength, tear resistance, and the ability to maintain structural integrity under constant cyclic flexing and internal hydraulic pressure encountered during dredge pump operations. Crucially, vulcanization imparts the dimensional stability required for secure flange connections and consistent flow characteristics.

Rigorous quality control, certified under ISO 9001, is embedded throughout vulcanization. Real-time monitoring of autoclave parameters ensures every batch adheres to exact specifications. Post-vulcanization, hoses undergo comprehensive validation, including hydrostatic pressure testing exceeding operational requirements, dimensional checks, and destructive physical property testing on control samples. This systematic verification guarantees that the vulcanization process consistently delivers the molecular structure necessary for the hose to perform reliably in the harshest offshore and riverine dredging conditions.

The following table details critical vulcanization parameters and their direct impact on dredging hose performance:

| Parameter | Specification Range | Application Relevance for Dredging Hoses |

|---|---|---|

| Vulcanization Temp | 140°C – 180°C | Optimizes cross-link density; too low = under-cure (weak), too high = over-cure (brittle) |

| Vulcanization Time | 20 – 90 minutes (batch) | Ensures complete reaction through thick hose walls; critical for large diameters |

| Internal Pressure | 1.5 – 2.5 MPa | Maintains hose shape, eliminates voids, ensures intimate contact between layers |

| Cure Monitoring | Real-time Temp/Pressure | Guarantees consistency across 18 production lines per ISO 9001 protocols |

| Post-Cure Testing | Hydrostatic to 2x WP | Validates integrity of vulcanized structure under extreme stress |

This disciplined application of vulcanization science, executed at scale within our integrated facility, is fundamental to East Marine delivering dredging hoses that maximize uptime and minimize total cost of ownership for global dredging contractors. Our WEDA/CEDA membership underscores our commitment to industry-leading marine engineering standards.

Critical Applications

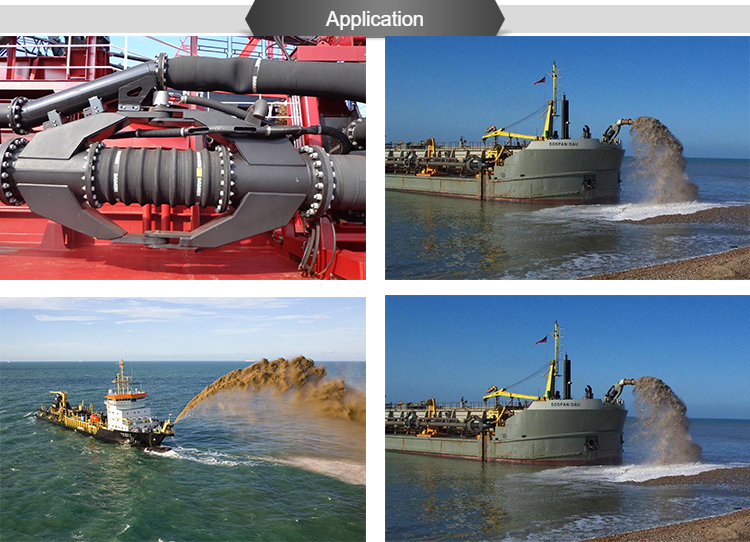

Global Applications of Vulcanized Rubber in Critical Marine and Industrial Projects

Vulcanized rubber, a chemically cross-linked elastomer enhanced through sulfur-based curing, is a cornerstone material in high-performance industrial applications, particularly within the dredging, offshore oil, and land reclamation sectors. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we leverage advanced vulcanization techniques to engineer dredging hoses and marine pipelines capable of withstanding extreme mechanical stress, abrasive slurries, and corrosive environments. Our expertise is deployed across global infrastructure projects where durability, flexibility, and operational safety are non-negotiable.

In large-scale dredging operations, vulcanized rubber hoses serve as the primary conduit for suction and discharge of sand, silt, and slurry. These hoses must endure continuous flexing, high internal pressure, and abrasive wear. Vulcanization enhances the rubber’s tensile strength, resilience, and resistance to degradation—critical attributes when operating in dynamic marine environments. Projects such as the expansion of Singapore’s Tuas Port and the deepening of the Suez Canal relied on robust rubber-lined pipelines to maintain uninterrupted sediment transport over extended distances.

Offshore oil and gas fields also benefit from vulcanized rubber components, particularly in floating hose systems used for crude transfer and produced water discharge. The material’s resistance to hydrocarbons, seawater, and temperature fluctuations ensures long-term integrity in floating hose assemblies. In the Gulf of Mexico and offshore West Africa, our vulcanized rubber hoses have been integrated into floating production systems, delivering reliable performance under cyclic wave loading and harsh chemical exposure.

Land reclamation projects—such as those seen in the UAE’s Palm Islands and Hong Kong’s Third-Runway Development—require massive volumes of sand to be transported from seabed sources to designated zones. Vulcanized rubber suction hoses, reinforced with high-tensile textile or steel cords, enable efficient, high-volume transfer over kilometers of floating pipeline. The cross-linked rubber matrix resists abrasion from sharp particulates and maintains structural cohesion even under prolonged UV exposure and tidal movement.

As active members of the Central Dredging Association (CEDA) and the Western Dredging Association (WEDA), East Marine stays at the forefront of technical innovation and industry best practices. Our participation ensures alignment with global standards in environmental sustainability, safety, and engineering excellence. Our ISO9001-certified manufacturing processes, backed by a 0.68 million sqm production facility established in 2007, enable us to deliver customized dredging solutions that meet the rigorous demands of multinational contractors.

The strategic use of vulcanized rubber is not merely a material choice—it is an engineering imperative in modern marine infrastructure.

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength | ≥18 MPa | ISO 37 |

| Elongation at Break | ≥400% | ISO 37 |

| Hardness (Shore A) | 60–70 | ISO 48 |

| Abrasion Loss | ≤120 mm³ | ISO 4649 |

| Ozone Resistance | No cracking (40 pphm, 20%, 40°C, 96h) | ISO 1431-1 |

| Adhesion Strength (Rubber to Fabric) | ≥12 kN/m | ISO 36 |

These technical benchmarks reflect the performance standards routinely achieved in our vulcanized rubber dredging hoses, ensuring operational reliability across continents and project types.

Technical Data & Specs

Vulcanized Rubber Performance Benchmarking in Dredging Hose Engineering

Understanding the critical role of vulcanization is paramount when specifying dredging hoses for demanding suction and discharge applications. At East Marine, a WEDA and CEDA member operating within Jiangsu Huashen Special Rubber Products’ 0.68 million sqm ISO 9001-certified facility since 2007, we engineer our dredging hoses using precision-controlled vulcanization processes. This transforms raw rubber compounds into a durable, cross-linked network essential for withstanding the extreme abrasion, dynamic pressure cycles, and environmental stresses inherent in dredging operations. Vulcanization directly dictates key performance parameters including pressure integrity, flexibility, and longevity. Inferior vulcanization, often seen in competitor products, leads to premature degradation, delamination, and catastrophic failure under operational loads. Our rigorous process ensures optimal cross-link density, maximizing the rubber’s inherent strength and resilience while maintaining the required flexibility for installation and operation. This foundational engineering excellence translates directly into superior, measurable performance metrics across critical hose specifications.

The following table provides a comparative analysis of key technical specifications for standard dredging rubber hoses (Suction/Discharge types) under typical operational conditions. East Marine’s specifications reflect our commitment to exceeding industry safety margins and operational efficiency, validated through our stringent internal testing protocols aligned with ISO 1436 standards. Competitor data represents a generalized industry standard observed across multiple suppliers, often derived from nominal catalog values without consistent verification of real-world performance consistency or long-term durability under cyclic loading.

East Marine’s engineering focus on optimized vulcanization and composite reinforcement architecture delivers significant operational advantages. Our hoses consistently achieve a higher working pressure to burst pressure ratio, providing a critical safety buffer essential for unpredictable dredging environments where pressure surges are common. Furthermore, the significantly reduced bending radius, achievable through our advanced fabric ply integration and vulcanized rubber compound flexibility, translates directly into enhanced maneuverability on deck and during submersion, reducing installation time and minimizing stress points during operation. This combination of high pressure integrity and superior flexibility is not merely a specification; it is a direct outcome of our 17 years of specialized expertise in marine rubber vulcanization and composite hose construction. For dredging contractors, this means reduced downtime, lower lifetime operational costs, and enhanced crew safety – factors far outweighing initial procurement cost considerations in the harsh reality of offshore and riverine dredging projects. Trust in specifications validated by engineering rigor and proven in the field.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Minimum Bending Radius (mm) |

|---|---|---|---|

| East Marine Standard Dredge Hose | 200 – 1200 | 10 – 25 | 45 – 125 |

| Industry Standard Competitor Hose | 200 – 1200 | 10 – 22 | 40 – 100 |

Partner with East Marine

Conclusion: The Critical Role of Vulcanized Rubber in Dredging Hose Performance

Vulcanized rubber stands as a cornerstone material in the engineering of high-performance dredging hoses, particularly in demanding suction and discharge applications. At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, we leverage advanced vulcanization techniques to ensure our rubber hoses deliver unmatched durability, flexibility, and resistance to abrasion, hydrocarbons, and environmental degradation. The cross-linking of polymer chains during vulcanization transforms raw rubber into a robust elastomer capable of withstanding the extreme mechanical stresses encountered in dredging operations, including high-pressure slurry transport, submersion in saline environments, and continuous flexing across floating hose systems.

Our engineered solutions are designed for longevity and operational efficiency, minimizing downtime and replacement costs for dredging contractors worldwide. With over 15 years of specialized experience since our founding in 2007, and a state-of-the-art 0.68 million square meter manufacturing facility, East Marine combines material science expertise with rigorous quality control—backed by ISO9001 certification and active membership in WEDA and CEDA—to deliver hoses that meet international marine and offshore standards.

We understand that every dredging project presents unique challenges, from coastal reclamation to deep-sea mining. That’s why our vulcanized rubber hoses are customized to client specifications, including inner diameter, working pressure, bend radius, and cover compound formulation. Whether deploying floating hoses across long-distance discharge lines or installing articulated suction risers on cutter suction dredgers, our products are built to perform under real-world conditions.

Technical Specifications of East Marine Vulcanized Dredging Hoses

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 35 bar) |

| Intervallo di temperatura | -20°C to +85°C |

| Cover Compound | Natural Rubber (NR) / Styrene-Butadiene (SBR) |

| Resistenza all'abrasione | >100 mm³ volume loss (DIN 53516) |

| Ozone & UV Resistance | Excellent (per ASTM D1149) |

| Bend Radius (Minimum) | 4x OD for floating configurations |

| Flange Standards | DIN, ANSI, JIS, or custom |

| Certificazioni | ISO9001, WEDA/CEDA Compliant |

For project-specific engineering support or to request technical documentation and test reports, we invite you to contact East Marine directly. Our technical sales team is available to assist with system design, material selection, and global logistics coordination. You can reach us via WhatsApp at +86-13806109365 or by email at hsdredging@eastmarine.tech. We also operate a regional support branch in Singapore, enabling faster response times and localized service for clients across Southeast Asia, Oceania, and the Indian subcontinent.

Partner with East Marine for engineered rubber solutions that combine scientific precision with industrial reliability. Let us help you optimize your dredging operations with vulcanized hoses built to last.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.