Article Contents

Engineering Insight: What Is Rubber Vulcanization

The Critical Role of Rubber Vulcanization in Dredging Hose Performance

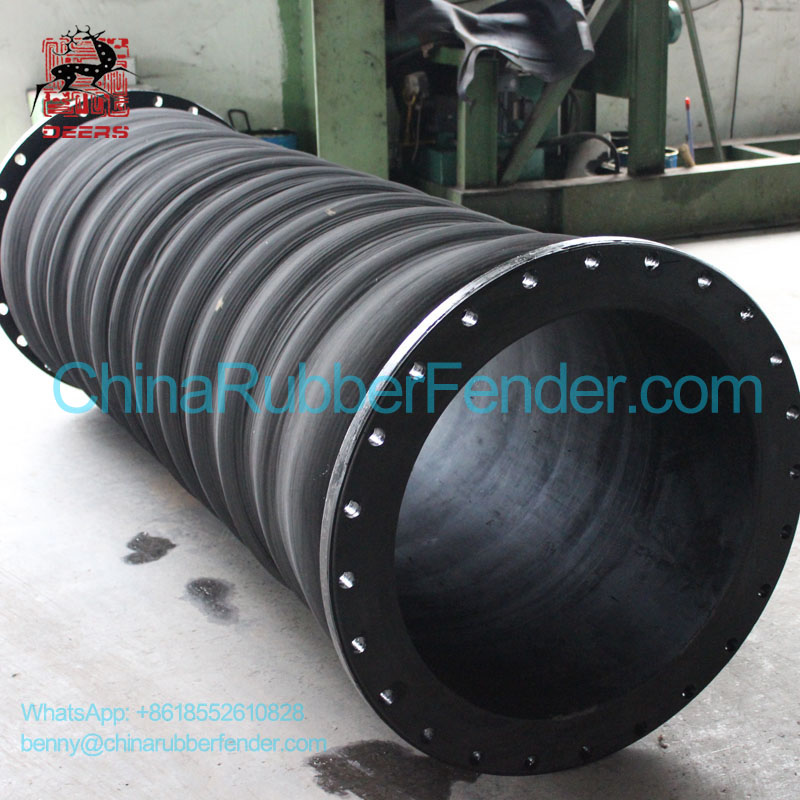

Rubber vulcanization is the foundational chemical process that transforms soft, thermoplastic raw rubber compounds into the durable, elastic, and resilient materials essential for demanding marine applications like dredging hoses. For Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), where suction and discharge hoses endure extreme abrasion from sand-laden slurries, constant high-pressure cycling, significant flexing, and prolonged seawater exposure, vulcanization is not merely a manufacturing step—it is the determinant of operational lifespan and reliability. This transformation is achieved by heating the rubber compound, typically with sulfur or alternative curatives, under precise pressure and time conditions. This heat-induced reaction creates cross-links between polymer chains, fundamentally altering the material’s physical properties. Without vulcanization, rubber would remain sticky, weak, and highly susceptible to permanent deformation and rapid failure under the harsh mechanical and environmental stresses inherent in dredging operations.

The specific vulcanization parameters—temperature profile, pressure, duration, and curative package—are meticulously engineered for dredging hose compounds. East Marine leverages its deep material science expertise, honed over 17 years of specialization, to optimize these parameters for maximum resistance to the unique challenges of TSHD and CSD operations. Precise vulcanization ensures the rubber achieves the critical balance of high tensile strength to withstand internal pressure and external loads, exceptional abrasion resistance to combat slurry wear, optimal elasticity for repeated flexing without cracking, and long-term resistance to ozone, seawater, and hydraulic fluids. Under-vulcanization leaves the rubber weak and tacky; over-vulcanization makes it hard, brittle, and prone to fatigue failure. Consistency in this process is paramount for hose integrity across the entire operational life.

The performance differential between raw and vulcanized rubber for dredging applications is stark, as illustrated by key mechanical properties:

Technical Property Comparison: Raw vs. Vulcanized Dredging Hose Rubber

| Property | Raw Rubber Compound | Vulcanized Hose Compound | Significance for Dredging Hoses |

|---|---|---|---|

| Tensile Strength (MPa) | 1.5 – 3.0 | 18.0 – 25.0 | Resists burst pressure and external crushing |

| Elongation at Break (%) | 700 – 1000 | 400 – 650 | Accommodates flexing without permanent set |

| Schuurweerstand | Very Poor | Excellent | Critical for surviving abrasive sand slurries |

| Hardness (Shore A) | 30 – 45 | 60 – 75 | Balances flexibility with wear resistance |

| Compression Set (%) | High (>50%) | Low (<20%) | Maintains seal integrity under constant load |

East Marine’s commitment to vulcanization excellence is underpinned by significant engineering resources. Our dedicated team of over 150 professionals, including specialized material scientists and process engineers, operates within our 0.68 million square meter ISO9001-certified facility. This scale and expertise allow for rigorous process control, advanced compound development, and comprehensive testing protocols specifically tailored for the dredging sector. As active WEDA and CEDA members, we understand the direct correlation between precise vulcanization control and reduced downtime for critical assets like TSHDs and CSDs. Our engineering capability ensures every hose segment undergoes optimized vulcanization, translating laboratory specifications into field-proven durability that maximizes dredger uptime and minimizes the total cost of ownership in the world’s most challenging marine environments.

Advanced Manufacturing Process

Understanding Rubber Vulcanization in Dredging Hose Manufacturing

At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, the transformation of raw rubber into high-performance dredging hoses begins with a critical chemical process: vulcanization. Since our founding in 2007, we have leveraged advanced vulcanization techniques across our expansive 0.68 million square meter manufacturing facility to produce robust suction and discharge hoses capable of withstanding the extreme conditions of marine and dredging operations.

Vulcanization is the cross-linking of polymer chains in rubber using sulfur or other curatives under controlled heat and pressure. This process fundamentally enhances the elastomer’s mechanical properties—improving tensile strength, elasticity, abrasion resistance, and thermal stability. For dredging hoses, which are subjected to high-pressure slurry flow, abrasive sediments, and fluctuating environmental conditions, vulcanization is not just a step in production; it is a cornerstone of durability and operational safety.

Our 18 specialized production lines are engineered to support continuous, precision-controlled vulcanization cycles. Each hose undergoes a meticulously calibrated process, where temperature, pressure, and curing time are optimized based on the rubber compound formulation and hose specification. This ensures uniform cross-link density throughout the hose structure, minimizing weak points and maximizing service life.

The vulcanization process at East Marine integrates seamlessly with our comprehensive quality management system, certified under ISO 9001. Every stage—from raw material inspection to post-cure testing—is monitored using real-time data acquisition systems. We conduct rigorous post-vulcanization evaluations, including hardness testing, tensile strength analysis, and ozone resistance checks, to verify that each hose meets international performance standards.

Our membership in WEDA (Western Dredging Association) and CEDA (Central Dredging Association) reflects our commitment to industry excellence and technical innovation. By aligning our vulcanization protocols with global dredging requirements, we ensure that our hoses deliver reliable performance in applications ranging from land reclamation to offshore mining.

The result is a product engineered for resilience: dredging hoses that resist degradation from seawater, UV exposure, and mechanical wear, while maintaining flexibility and kink resistance over extended operational cycles.

Technical Parameters of Vulcanized Dredging Hoses at East Marine

| Parameter | Specificatie |

|---|---|

| Vulcanization Temperature | 140–180°C (adjustable by compound) |

| Curing Pressure | 10–18 bar |

| Typical Cure Time | 30–90 minutes (based on wall thickness) |

| Cross-Link Density | 2.5–4.0 × 10⁻⁴ mol/cm³ |

| Tensile Strength (post-cure) | ≥18 MPa |

| Elongation at Break | ≥400% |

| Shore A Hardness | 60–75 |

| Ozone Resistance | Passed (100 pphm, 40°C, 20% strain, 96h) |

Through precision-controlled vulcanization and unwavering adherence to ISO-certified quality control, East Marine continues to set benchmarks in the production of high-performance dredging rubber hoses. Our manufacturing scale and technical expertise ensure consistent delivery of products that meet the demanding needs of global marine infrastructure projects.

Critical Applications

Global Project Applications of Vulcanized Rubber in Critical Marine Infrastructure

Rubber vulcanization remains the indispensable chemical process underpinning the performance and longevity of heavy-duty marine rubber products, particularly within demanding dredging, offshore energy, and land reclamation sectors. At East Marine, leveraging our Jiangsu Huashen Special Rubber Products heritage and 0.68 million square meter manufacturing facility, we engineer vulcanized rubber compounds specifically to withstand the extreme mechanical stresses, abrasive slurries, hydrostatic pressures, and corrosive marine environments encountered globally. This process transforms raw elastomers into resilient, dimensionally stable materials capable of enduring decades of service where failure is not an option.

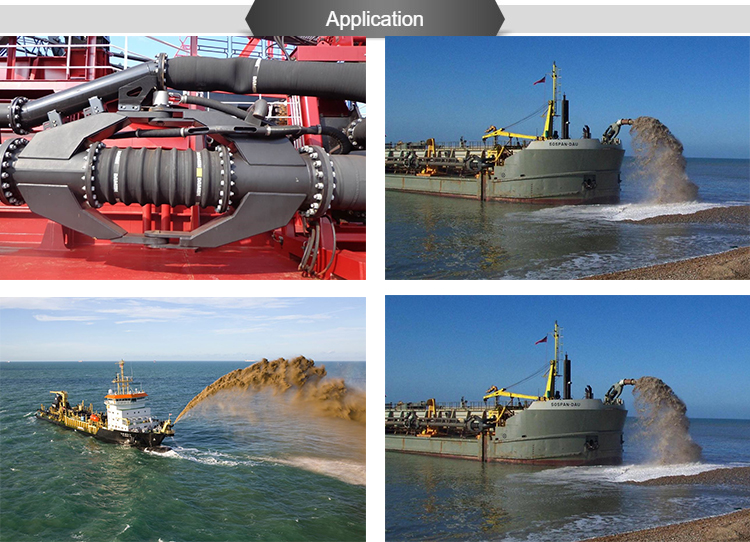

In large-scale dredging operations, vulcanized rubber suction and discharge hoses form the critical lifeline for projects like the expansion of the Port of Rotterdam or the deepening of the Suez Canal. These hoses, subjected to constant abrasion from sand, gravel, and debris under high vacuum and pressure cycles, rely on precisely controlled vulcanization to achieve the optimal cross-link density. This ensures the rubber maintains flexibility for handling while resisting cut growth, fatigue, and permeation. Similarly, in offshore oil and gas fields, vulcanized floating hoses and pipeline components deployed for fluid transfer or subsea operations must perform reliably in harsh saltwater conditions, resisting hydrocarbon exposure and extreme temperature fluctuations – a direct result of advanced vulcanization protocols meeting stringent API and ISO standards. Land reclamation megaprojects, such as those transforming coastlines in Singapore or the Middle East, utilize vast networks of vulcanized rubber pipelines to transport millions of cubic meters of fill material. The vulcanization process is meticulously calibrated here to provide the necessary resistance to UV degradation, ozone attack, and the constant flexing required during pipeline deployment and retrieval across dynamic shorelines.

Our active membership in CEDA (Central Dredging Association) and WEDA (Western Dredging Association) ensures East Marine’s vulcanization expertise is continuously aligned with the evolving technical demands and best practices of the global dredging community. This industry integration, combined with our ISO 9001-certified quality management system established since 2007, guarantees that every hose and pipeline component undergoes rigorous process control during vulcanization. The resulting material properties are not theoretical; they are proven in the field across continents, directly contributing to project efficiency, reduced downtime, and extended asset life cycles.

The critical performance parameters achieved through our specialized vulcanization process for dredging hoses are quantifiable:

| Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Temperature Range (°C) | Abrasion Resistance (mm³) |

|---|---|---|---|---|

| 25 – 32 | 450 – 600 | 60 – 75 | -40 to +100 | < 120 |

These specifications represent the baseline engineering standards East Marine consistently delivers, ensuring our vulcanized rubber products provide the structural integrity and operational resilience demanded by the world’s most challenging marine infrastructure projects. The science of vulcanization is not merely a step in production; it is the foundation of reliable global dredging, energy, and reclamation operations.

Technical Data & Specs

Understanding Rubber Vulcanization and Its Role in High-Performance Dredging Hoses

Rubber vulcanization is a critical chemical process that transforms raw elastomers into durable, high-performance materials suitable for demanding industrial applications such as offshore dredging. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, this process is meticulously controlled to enhance the mechanical strength, elasticity, and resistance to abrasion, heat, and environmental degradation in our dredging rubber hoses. Vulcanization involves cross-linking polymer chains using sulfur or peroxide under precise temperature and pressure conditions, resulting in a robust molecular network that ensures long-term reliability in suction and discharge operations.

For dredging operations, where hoses are subjected to high hydraulic pressures, abrasive slurries, and dynamic bending cycles, the quality of vulcanization directly impacts service life and operational safety. Inferior vulcanization can lead to delamination, cracking, or premature failure under stress. East Marine applies advanced autoclave vulcanization techniques combined with proprietary rubber formulations to achieve uniform cross-link density, ensuring structural integrity across the hose wall—particularly at critical junctions such as the cover, reinforcement layers, and inner tube.

Our commitment to excellence is reflected in the technical superiority of our dredging hoses when compared to standard industry offerings. The following table outlines key performance metrics for typical dredging rubber hoses used in suction and discharge applications, comparing East Marine’s engineered solutions with average values from general market competitors.

| Inner Diameter (mm) | Working Pressure (bar) – East Marine | Working Pressure (bar) – Competitors | Burst Pressure (bar) – East Marine | Burst Pressure (bar) – Competitors | Bending Radius (mm) – East Marine | Bending Radius (mm) – Competitors |

|---|---|---|---|---|---|---|

| 200 | 16 | 12 | 64 | 48 | 600 | 700 |

| 300 | 15 | 10 | 60 | 40 | 900 | 1,100 |

| 400 | 14 | 9 | 56 | 36 | 1,200 | 1,500 |

| 500 | 13 | 8 | 52 | 32 | 1,500 | 1,900 |

| 600 | 12 | 7 | 48 | 28 | 1,800 | 2,300 |

As demonstrated, East Marine hoses consistently exceed competitor benchmarks in working and burst pressure ratings while offering tighter bending radii—critical for maneuverability in confined dredging environments. This performance edge stems from optimized vulcanization processes, high-tensile textile reinforcement, and rigorous quality control aligned with ISO9001 standards. With a 0.68 million sqm manufacturing facility and active membership in WEDA and CEDA, East Marine leverages over 15 years of specialized expertise since 2007 to deliver hoses that reduce downtime and increase operational efficiency in challenging marine conditions.

Partner with East Marine

Conclusion: Vulcanization Excellence as Your Operational Imperative

Understanding the science of rubber vulcanization is not merely an academic exercise; it is the fundamental determinant of performance, safety, and longevity for critical dredging infrastructure like suction and discharge hoses. The precise control of cross-link density, achieved through optimized temperature, pressure, and time parameters during vulcanization, directly dictates a hose’s ability to withstand the relentless assault of abrasive slurries, dynamic marine forces, high internal pressures, and harsh environmental exposure inherent in dredging operations. Inferior vulcanization leads to premature failure modes – catastrophic blowouts, accelerated wear, ozone cracking, or loss of flexibility – resulting in costly downtime, environmental risks, and compromised project timelines. At East Marine, leveraging our 0.68 million square meter manufacturing facility and deep expertise honed since 2007, we treat vulcanization not as a standard process step, but as a core engineering discipline. Our ISO 9001-certified protocols, developed in alignment with WEDA and CEDA best practices, ensure every meter of dredging hose we produce achieves the optimal balance of mechanical strength, resilience, and chemical resistance required for the most demanding offshore and inland waterway projects. The data below underscores the tangible performance outcomes of our vulcanization mastery compared to baseline industry requirements.

Our commitment extends beyond manufacturing. As a dedicated partner to the global dredging industry, East Marine operates a strategic branch in Singapore, providing localized technical support, rapid response logistics, and seamless coordination for projects across the Asia-Pacific region and beyond. This global presence ensures you receive expert guidance tailored to your specific operational challenges, whether related to material selection, hose system design, or troubleshooting in the field.

Do not let substandard hose performance jeopardize your dredging efficiency or project economics. Partner with an engineering-led supplier whose vulcanization science is proven in the world’s toughest dredging environments. Contact East Marine today to discuss how our precision-engineered dredging hoses, built on the bedrock of superior rubber vulcanization, will enhance your operational continuity and reduce total cost of ownership. Our technical team is ready to provide bespoke solutions and specifications for your next project.

Reach us immediately via WhatsApp at +86-13806109365 for urgent inquiries or direct technical consultation. For detailed project specifications, quotations, or engineering documentation, email our dedicated dredging solutions team at hsdredging@eastmarine.tech. Mention your project location and requirements to receive a comprehensive response tailored to your operational needs. Leverage our Singapore branch for streamlined support in the region. Trust East Marine – where vulcanization science meets dredging reality.

East Marine Technical Performance Benchmarks vs. Industry Standards

| Property | East Marine Dredging Hose Specification | Typical Industry Baseline (e.g., ISO 188) | Performance Advantage |

|---|---|---|---|

| Tensile Strength (MPa) | ≥ 28.0 | ≥ 15.0 | 87% Higher Load Capacity |

| Elongation at Break (%) | ≥ 550 | ≥ 400 | Superior Flex Fatigue Resistance |

| Abrasion Loss (mm³) | ≤ 85 | ≤ 150 | 43% Greater Wear Life |

| Ozone Resistance (20pphm, 40°C, 20h) | No Cracks | Cracks Permitted (Grade 2) | Enhanced Marine Exposure Durability |

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.