Introduction: Navigating the Global Market for discharge hoses

In today’s fast-paced global economy, sourcing high-quality discharge hoses can be a daunting task for international B2B buyers. With diverse applications spanning agriculture, construction, and industrial sectors, the demand for reliable discharge hoses has surged, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Buyers face the challenge of navigating a complex landscape of suppliers, materials, and specifications, which can significantly impact operational efficiency and cost-effectiveness.

This comprehensive guide serves as an essential resource for businesses looking to make informed purchasing decisions regarding discharge hoses. We delve into various types of hoses, including PVC, rubber, and specialized options for drinking water, to help you understand their unique properties and applications. Additionally, we provide insights into supplier vetting processes, enabling you to identify reputable manufacturers and distributors in your region. Cost considerations, including bulk purchasing options and potential savings through roll purchases, are also covered to ensure you maximize your budget.

By equipping you with actionable insights and best practices, this guide empowers B2B buyers to confidently select the right discharge hoses tailored to their specific needs. Whether you’re operating in Vietnam, Nigeria, or elsewhere, our expert recommendations will help you streamline your procurement process and enhance your operational capabilities.

Inhoudsopgave

- Top 7 Discharge Hoses Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for discharge hoses

- Understanding discharge hoses Types and Variations

- Key Industrial Applications of discharge hoses

- 3 Common User Pain Points for ‘discharge hoses’ & Their Solutions

- Strategic Material Selection Guide for discharge hoses

- In-depth Look: Manufacturing Processes and Quality Assurance for discharge hoses

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘discharge hoses’

- Comprehensive Cost and Pricing Analysis for discharge hoses Sourcing

- Alternatives Analysis: Comparing discharge hoses With Other Solutions

- Essential Technical Properties and Trade Terminology for discharge hoses

- Navigating Market Dynamics and Sourcing Trends in the discharge hoses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of discharge hoses

- Strategic Sourcing Conclusion and Outlook for discharge hoses

- Belangrijke disclaimer en gebruiksvoorwaarden

Understanding discharge hoses Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| PVC Discharge Hose | Lightweight, flexible, and cost-effective. | Agriculture, construction, and irrigation. | Voordelen: Affordable, easy to handle. Minpunten: Limited durability under extreme conditions. |

| Rubber Discharge Hose | High durability, resistant to abrasion and heat. | Mining, industrial, and heavy-duty applications. | Voordelen: Long-lasting, handles high pressures. Minpunten: Zwaarder en minder flexibel dan PVC. |

| Urethane Discharge Hose | Excellent chemical resistance and flexibility. | Chemical transfer, food processing, and water. | Voordelen: Versatile, withstands various environments. Minpunten: Higher cost compared to PVC. |

| Lay Flat Discharge Hose | Easily transportable and compact when stored. | Firefighting, agriculture, and emergency services. | Voordelen: Space-saving, lightweight. Minpunten: Can be prone to punctures. |

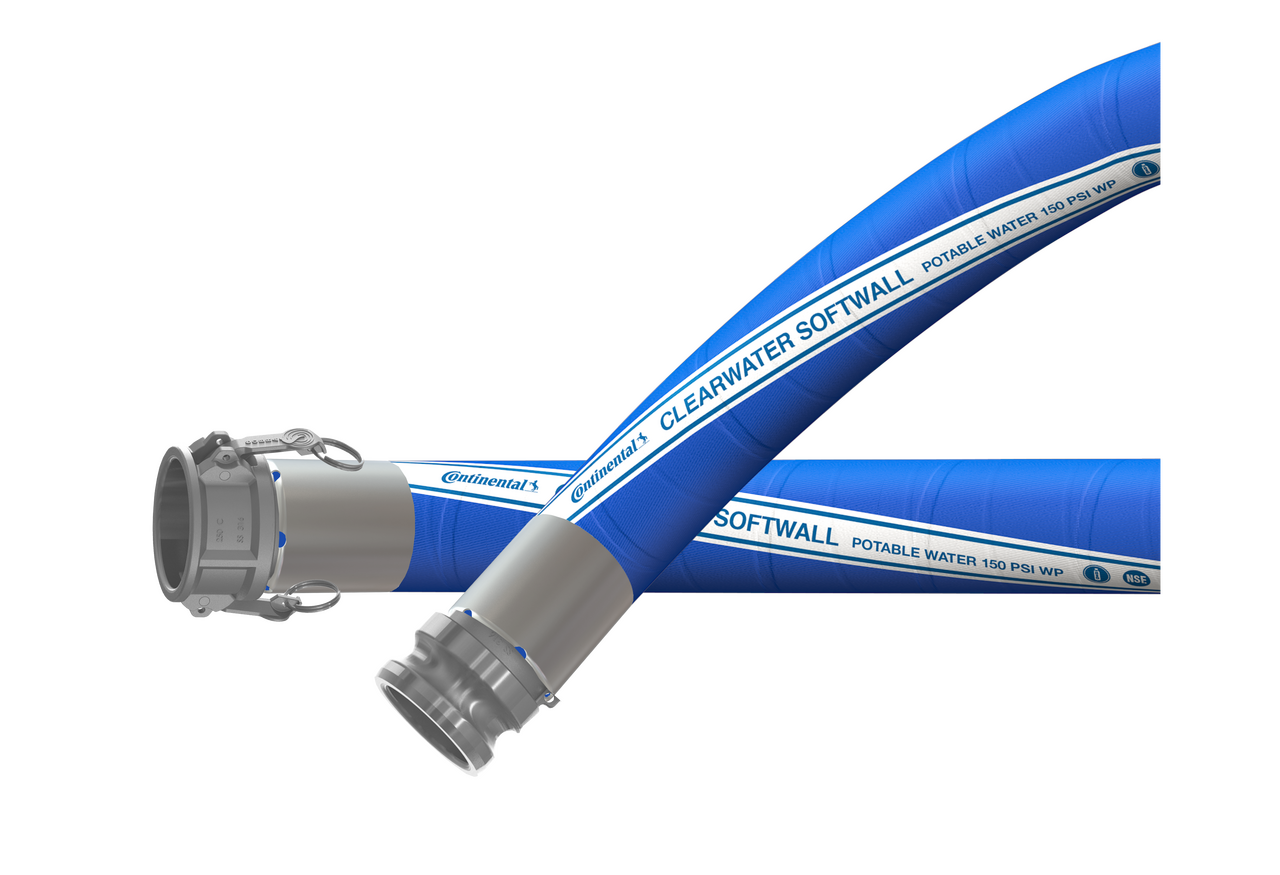

| Drinking Water Discharge Hose | NSF approved for potable water applications. | Municipal water supply, irrigation of food crops. | Voordelen: Safe for drinking water, durable. Minpunten: Higher price point due to certification. |

What Are the Key Characteristics of PVC Discharge Hoses?

PVC discharge hoses are popular in various industries due to their lightweight and flexible nature. They are typically used in agriculture, construction, and irrigation, where ease of handling and cost-effectiveness are paramount. However, buyers should consider their limitations in extreme weather conditions, which may affect their longevity and performance.

Why Choose Rubber Discharge Hoses for Heavy-Duty Applications?

Rubber discharge hoses are designed for high durability and can withstand harsh conditions, making them ideal for mining and industrial applications. They are known for their resistance to abrasion and heat, which allows them to handle higher pressure levels. While they are heavier and less flexible than PVC options, their longevity and performance in demanding environments make them a preferred choice for B2B buyers focused on durability.

Illustrative image related to discharge hoses

What Advantages Do Urethane Discharge Hoses Offer?

Urethane discharge hoses provide excellent chemical resistance and flexibility, making them suitable for a variety of applications, including chemical transfer and food processing. Their versatility allows them to withstand different environments, but buyers should be prepared for a higher initial investment compared to PVC hoses. This type of hose is ideal for businesses that prioritize performance and safety.

How Do Lay Flat Discharge Hoses Enhance Portability?

Lay flat discharge hoses are designed for ease of transport and storage, as they can be rolled up compactly when not in use. Commonly utilized in firefighting and agriculture, these hoses are lightweight and easy to handle. However, potential buyers must be cautious of their susceptibility to punctures, which can impact their reliability in critical situations.

What Makes Drinking Water Discharge Hoses Essential for Safety?

Drinking water discharge hoses are NSF approved, ensuring they are safe for potable water applications. They are essential for municipal water supply systems and irrigation of food crops, where safety is a primary concern. While these hoses come at a higher price due to their certification, the assurance of safety and durability makes them a worthwhile investment for businesses focused on compliance and quality.

Key Industrial Applications of discharge hoses

| Industrie/sector | Specific Application of discharge hoses | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Landbouw | Irrigation and water distribution | Efficient water transfer improves crop yields | Durability, pressure ratings, and length options |

| Bouw | Ontwatering en drainage | Reduces site flooding, improving safety and productivity | Material type, temperature resistance, and flexibility |

| Mijnbouw | Slurry and wastewater management | Effective handling of abrasive materials enhances efficiency | Hose strength, abrasion resistance, and compatibility |

| Oil and Gas | Fuel and chemical transfer | Safe and reliable transportation of hazardous materials | Chemical resistance, pressure ratings, and certifications |

| Municipal Services | Stormwater management and flood control | Mitigates flood risks and environmental impact | Compliance with local regulations and material standards |

How Are Discharge Hoses Used in Agriculture for Irrigation and Water Distribution?

In the agricultural sector, discharge hoses are vital for irrigation and efficient water distribution. They facilitate the transfer of water from sources like wells or reservoirs directly to fields, enhancing crop yields and reducing water wastage. Buyers in this sector must consider factors such as hose durability to withstand UV exposure, pressure ratings to handle varying water pressures, and flexibility for easy maneuvering around fields. Sourcing options may include purchasing hoses by the roll or foot to meet specific farm sizes and needs.

What Role Do Discharge Hoses Play in Construction Dewatering and Site Drainage?

In construction, discharge hoses are crucial for dewatering and managing site drainage. They help remove excess water from excavations and construction sites, preventing flooding and ensuring safety for workers. Effective drainage improves project timelines and reduces the risk of structural issues. Buyers should focus on the hose’s material strength, temperature resistance, and flexibility to adapt to different site conditions. Sourcing high-quality hoses that can handle heavy-duty applications is essential to minimize downtime and maintain project efficiency.

How Are Discharge Hoses Utilized in Mining for Slurry and Wastewater Management?

Mining operations rely on discharge hoses for managing slurry and wastewater effectively. These hoses transport abrasive materials and liquids, ensuring efficient processing and minimizing environmental impact. The ability to withstand harsh conditions and resist abrasion is critical for mining applications. Buyers must consider the hose’s construction materials, pressure ratings, and compatibility with the specific types of slurries being handled. Sourcing hoses with certifications for durability and safety can significantly enhance operational reliability in this challenging environment.

What Are the Key Benefits of Discharge Hoses in Oil and Gas Fuel and Chemical Transfer?

In the oil and gas industry, discharge hoses are essential for the safe and efficient transfer of fuels and hazardous chemicals. These hoses are designed to handle high pressures and resist chemical degradation, ensuring safe operations. Buyers need to prioritize sourcing hoses that meet industry standards for chemical resistance and pressure ratings. Additionally, certifications for safety and environmental compliance are critical, especially when operating in regions with strict regulations. Effective sourcing can prevent costly spills and enhance overall safety.

Illustrative image related to discharge hoses

How Do Discharge Hoses Contribute to Municipal Stormwater Management and Flood Control?

Municipal services utilize discharge hoses for stormwater management and flood control, especially in urban areas prone to flooding. These hoses help redirect excess water away from populated areas, minimizing environmental impact and damage to infrastructure. Buyers in this sector must consider compliance with local regulations regarding materials and environmental standards. Sourcing hoses that can handle varying flow rates and are constructed from durable materials can significantly enhance the effectiveness of municipal flood control efforts.

3 Common User Pain Points for ‘discharge hoses’ & Their Solutions

Scenario 1: Sizing Issues Leading to Inefficiency

Het probleem: One of the most common challenges faced by B2B buyers is selecting the appropriate size of discharge hoses for their operations. Inaccurate sizing can lead to reduced efficiency, increased operational costs, and potential damage to equipment. For instance, using a hose that is too small can create excessive back pressure, which may lead to pump failure or inefficient fluid transfer. Conversely, oversized hoses may lead to wasted resources, as larger hoses require more fluid to fill before effective discharge can occur.

De oplossing: To address sizing issues, buyers should conduct a thorough assessment of their operational needs, including flow rate requirements and the specific application of the discharge hose. Utilizing manufacturers’ flow rate charts can be highly beneficial. Buyers should also consider consulting with hose specialists who can provide expert recommendations based on the specific conditions of use, such as temperature, pressure, and the type of fluid being transferred. Additionally, investing in adjustable fittings can offer flexibility and adaptability for various applications, allowing for quick changes without the need for additional hoses.

Scenario 2: Material Compatibility Concerns

Het probleem: Different environments and applications require specific materials for discharge hoses. For example, using a hose made from a material that is not compatible with the fluid being transported can lead to hose degradation, leaks, or catastrophic failures. This is particularly critical in industries such as agriculture or chemical processing, where exposure to harsh substances can compromise hose integrity. Buyers often struggle to identify the right material that balances durability and chemical compatibility.

De oplossing: To prevent material incompatibility, buyers should begin by conducting a compatibility analysis of the fluids they intend to transfer. This involves reviewing chemical data sheets and consulting with hose manufacturers to determine the best material options, such as PVC, rubber, or polyurethane, which can withstand specific chemical exposures. Additionally, buyers should consider sourcing hoses designed for multi-purpose use, which can handle a variety of fluids while maintaining performance. Regular maintenance checks can also help identify early signs of wear or damage, allowing for timely replacement before a failure occurs.

Illustrative image related to discharge hoses

Scenario 3: Difficulty in Assembly and Disassembly

Het probleem: B2B buyers often encounter challenges during the assembly and disassembly of discharge hoses, particularly when connecting them to pumps or other equipment. Complications can arise due to the lack of proper fittings, leading to leaks and inefficient operation. Moreover, incorrect assembly can lead to downtime, which is costly for businesses that depend on continuous operation for their processes.

De oplossing: To streamline assembly and disassembly, buyers should prioritize purchasing hoses with standardized fittings, such as cam lock or threaded connections, which are easier to handle and ensure secure attachments. It is advisable to create a standardized assembly protocol that includes detailed instructions or visual aids for employees. Training staff on the proper techniques for assembling and disassembling hoses can further reduce the risk of leaks and equipment damage. Furthermore, investing in quick-connect fittings can enhance efficiency by allowing for faster setup and tear-down times, ultimately minimizing operational disruptions.

By addressing these common pain points, B2B buyers can enhance their operational efficiency, reduce costs, and ensure safety in their discharge hose applications.

Illustrative image related to discharge hoses

Strategic Material Selection Guide for discharge hoses

When selecting materials for discharge hoses, it’s crucial for B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge will help ensure that the chosen hose meets the specific requirements of their applications, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of PVC Discharge Hoses?

Polyvinyl Chloride (PVC) is one of the most commonly used materials for discharge hoses. It offers a good balance of flexibility, durability, and cost-effectiveness. PVC hoses typically have a temperature rating of up to 150°F (65°C) and can handle pressures ranging from 80 to 110 PSI, making them suitable for a variety of applications including irrigation and construction.

Voordelen: PVC hoses are lightweight, resistant to corrosion, and relatively inexpensive. They are also easy to handle and install, which makes them a preferred choice for many users.

Illustrative image related to discharge hoses

Minpunten: However, PVC hoses can become brittle over time, especially when exposed to UV light or extreme temperatures. They may not be suitable for applications involving high temperatures or aggressive chemicals.

Invloed op de toepassing: PVC is compatible with water and many non-corrosive fluids, making it ideal for agricultural and general-purpose use. However, buyers should verify compatibility with specific media to avoid degradation.

Overwegingen voor internationale kopers: Compliance with standards such as ASTM or DIN is essential. Buyers in regions like Africa and South America should also consider local regulations regarding material safety and environmental impact.

Illustrative image related to discharge hoses

How Do Rubber Discharge Hoses Compare?

Rubber discharge hoses are known for their superior durability and flexibility. They can withstand higher temperatures (up to 200°F or 93°C) and pressures (often exceeding 150 PSI), making them suitable for industrial applications, including mining and construction.

Voordelen: Rubber hoses are highly resistant to abrasion, UV light, and extreme temperatures. They maintain their flexibility even in cold conditions, which is beneficial for outdoor applications.

Minpunten: The primary drawback is their higher cost compared to PVC hoses. Additionally, rubber hoses can be heavier and may require more complex manufacturing processes.

Illustrative image related to discharge hoses

Invloed op de toepassing: Rubber hoses are ideal for transporting abrasive materials or high-temperature fluids. They are often used in heavy-duty applications where durability is paramount.

Overwegingen voor internationale kopers: Buyers must ensure that rubber hoses comply with local and international standards, such as JIS or ISO. In regions with extreme climates, such as the Middle East, the ability to withstand high temperatures is particularly important.

What About Urethane Discharge Hoses?

Urethane hoses offer excellent resistance to abrasion and chemicals, making them suitable for a wide range of applications, including slurry and wastewater discharge.

Voordelen: Urethane hoses are lightweight yet extremely durable, with a temperature range of -40°F to 200°F (-40°C to 93°C) and pressure ratings that can reach 250 PSI. They are also more flexible than rubber, which facilitates easier handling.

Minpunten: The main limitation is the higher cost associated with urethane hoses. They may also require specialized fittings, which can add to overall expenses.

Invloed op de toepassing: Urethane is compatible with a wide variety of media, including chemicals and abrasive materials, making it versatile for industrial applications.

Overwegingen voor internationale kopers: Compliance with NSF standards for potable water applications is crucial. Buyers should also be aware of local chemical compatibility standards to ensure safe usage.

Illustrative image related to discharge hoses

How Do Composite Hoses Fit In?

Composite hoses, made from a combination of materials, offer unique advantages in specific applications. They typically feature a thermoplastic inner layer, reinforced with various materials for strength.

Voordelen: These hoses are lightweight, flexible, and resistant to a wide range of chemicals. They can handle pressures up to 150 PSI and temperatures from -40°F to 180°F (-40°C to 82°C).

Minpunten: Composite hoses can be more expensive than traditional materials and may require specific storage and handling procedures to maintain their integrity.

Invloed op de toepassing: Ideal for transferring chemicals, fuels, and other hazardous materials, composite hoses provide safety and reliability in demanding environments.

Overwegingen voor internationale kopers: Buyers should ensure compliance with international standards such as ISO and local regulations regarding hazardous material handling.

Summary Table of Material Selection for Discharge Hoses

| Materiaal | Typical Use Case for Discharge Hoses | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| PVC | Irrigation, general-purpose | Lightweight and cost-effective | Brittle over time | Laag |

| Rubber | Mining, construction | High durability and flexibility | Higher cost | Hoog |

| Urethane | Slurry, wastewater discharge | Excellent abrasion and chemical resistance | Hogere kosten en gespecialiseerde fittingen | Med |

| Samengesteld | Chemical and fuel transfer | Lightweight and flexible | More expensive and requires specific handling | Hoog |

This strategic material selection guide equips B2B buyers with essential insights into discharge hoses, enabling informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for discharge hoses

What Are the Main Stages of Manufacturing Discharge Hoses?

The manufacturing process for discharge hoses involves several critical stages that ensure the final product meets industry standards and customer specifications.

Materiaalvoorbereiding

The first step in the manufacturing of discharge hoses is material preparation. This typically involves sourcing high-quality raw materials, such as PVC, rubber, or polyurethane, depending on the intended application of the hose. Suppliers must ensure that these materials are compliant with relevant international standards, as the quality of the raw materials significantly impacts the durability and performance of the finished product. This stage also includes cutting and treating the materials to prepare them for forming.

Illustrative image related to discharge hoses

How Are Discharge Hoses Formed?

Once the materials are prepared, the next stage is forming. This process involves shaping the hose through various methods such as extrusion, where the prepared material is heated and forced through a die to create a continuous length of hose. During this process, manufacturers may also incorporate reinforcements, such as textile or wire, to enhance the hose’s strength and flexibility. The hose is then cooled and cut to the required lengths, ensuring that each piece meets specified dimensional tolerances.

What Does the Assembly Process Involve?

After forming, hoses undergo an assembly process where fittings, such as cam lock or threaded connections, are attached. This step may involve welding, crimping, or other techniques to ensure a secure connection that can withstand the operational pressures of the hose’s intended use. Quality control checks are often integrated into this stage to confirm that all assemblies meet design specifications.

Which Finishing Techniques Are Commonly Used?

The final stage of the manufacturing process is finishing, which may include additional treatments to enhance the hose’s resistance to environmental factors such as UV light, chemicals, and abrasion. Hoses may also undergo a surface treatment to improve their appearance and functionality. After finishing, the hoses are packaged for shipment, often with detailed labeling that indicates the specifications and any relevant certifications.

What Quality Assurance Processes Are Essential for Discharge Hoses?

Quality assurance is critical in the manufacturing of discharge hoses, as it ensures that products meet both regulatory standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a vital role in the quality management systems of manufacturers. This standard focuses on maintaining a consistent quality of products through systematic processes. Additionally, industry-specific certifications like CE marking for safety in the European market or API standards for oil and gas applications may also apply. Buyers should inquire about these certifications to ensure compliance with regional regulations.

Wat zijn de belangrijkste controlepunten voor kwaliteitscontrole?

Quality control (QC) in hose manufacturing typically includes several checkpoints:

-

Inkomende kwaliteitscontrole (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specifications. Any non-conforming materials are rejected at this point.

-

Kwaliteitscontrole tijdens het proces (IPQC): During manufacturing, ongoing inspections are conducted at various stages to monitor production processes and ensure adherence to quality standards. This includes checking dimensions, pressure ratings, and material properties.

-

Final Quality Control (FQC): Before shipment, a final inspection is conducted to verify that the finished hoses meet all specifications and quality standards. This may involve testing for pressure resistance, flexibility, and other performance metrics.

What Common Testing Methods Are Used?

Several testing methods are employed during the QC process, including:

-

Hydrostatic Testing: This involves filling the hose with water and pressurizing it to ensure it can withstand operational pressures without leaking or bursting.

-

Testen op slijtvastheid: This evaluates the hose’s ability to withstand wear and tear, which is crucial for hoses used in industrial applications.

-

Temperature Resistance Testing: Hoses are subjected to extreme temperatures to ensure they can perform reliably in various environments.

Hoe kunnen B2B-inkopers de kwaliteitscontrolepraktijken van leveranciers controleren?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers to ensure they receive high-quality discharge hoses.

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is a fundamental step in verifying quality control practices. Buyers should request to visit manufacturing facilities to observe processes firsthand and assess compliance with quality standards. During these audits, buyers should evaluate the supplier’s commitment to quality, including their adherence to international standards and their quality management systems.

How Can Buyers Access Quality Control Reports?

Buyers should request detailed quality control reports from suppliers, which should outline their QC processes, inspection results, and any corrective actions taken for non-conforming products. These reports provide transparency and can help buyers assess the reliability of the supplier.

Welke rol spelen inspecties door derden?

Engaging third-party inspection services can further enhance the verification process. Independent inspectors can conduct thorough assessments of the manufacturing processes and quality control measures in place, offering an unbiased perspective on the supplier’s capabilities. This is particularly beneficial for international buyers, as it adds an additional layer of assurance regarding product quality.

What Are the Specific QC and Certification Nuances for International Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, must navigate unique challenges related to quality assurance and certification.

How Do Regional Standards Impact Quality Assurance?

Different regions may have specific standards and regulations governing the use of discharge hoses. For instance, products exported to the European market must meet CE marking requirements, while those sold in the Middle East may need to comply with local standards. Buyers should familiarize themselves with these regulations to ensure that the hoses they purchase are compliant.

Illustrative image related to discharge hoses

What Are the Challenges of Certification in Emerging Markets?

In emerging markets, buyers may face challenges related to the availability of accredited testing facilities and certification bodies. This can complicate the process of verifying that products meet international standards. Buyers should seek suppliers with established relationships with recognized certification bodies to facilitate compliance.

How Can Buyers Ensure Consistent Quality Across Borders?

To maintain consistent quality across borders, buyers should work closely with suppliers to establish clear quality expectations and communication channels. Regular updates on production processes, quality checks, and any changes in regulations can help ensure that both parties remain aligned throughout the manufacturing process.

By understanding the manufacturing processes and quality assurance measures associated with discharge hoses, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘discharge hoses’

Inleiding

This practical sourcing guide is designed to assist B2B buyers in procuring discharge hoses effectively. By following this step-by-step checklist, you can ensure that your sourcing process is thorough and aligned with your operational needs, ultimately leading to better purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is essential to clearly outline the technical specifications required for your discharge hoses. This includes factors such as diameter, material (e.g., PVC, rubber), pressure ratings, and temperature tolerances.

– Why it matters: Accurate specifications help in identifying suitable products and minimizing the risk of purchasing incompatible hoses.

Step 2: Identify Your Application Needs

Different industries utilize discharge hoses for varying applications, such as agriculture, construction, or industrial processes. Determine the specific use cases for your hoses, whether for water discharge, slurry transport, or potable water applications.

– Why it matters: Understanding your application ensures that you select hoses that meet the necessary standards and performance criteria for your specific tasks.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other buyers in similar industries or geographical regions.

– Why it matters: Supplier reliability and quality directly impact your operational efficiency. A well-reviewed supplier is more likely to provide high-quality products and support.

Step 4: Request Samples and Test Products

Once you have shortlisted suppliers, request samples of the discharge hoses you are considering. Testing these samples in real-world conditions can provide invaluable insights into their performance and durability.

– Why it matters: Hands-on evaluation allows you to verify that the hoses will meet your operational requirements before making a larger financial commitment.

Step 5: Compare Pricing and Terms

After gathering samples and evaluating their performance, compare the pricing structures and terms offered by different suppliers. Look for bulk purchase discounts, payment terms, and shipping costs.

– Why it matters: Understanding the total cost of ownership, including potential maintenance and replacement costs, will help you make a more informed decision.

Illustrative image related to discharge hoses

Step 6: Verify Compliance and Certifications

Ensure that the discharge hoses you are considering meet relevant industry standards and certifications, such as NSF for potable water applications. Request documentation from suppliers to confirm compliance.

– Why it matters: Compliance with regulations ensures that the hoses are safe for their intended use and can prevent legal issues or operational disruptions.

Step 7: Establish a Relationship with Your Supplier

Once you have made a purchase, consider establishing a long-term relationship with your supplier. Regular communication about your needs and any changes in specifications can lead to better service and potential cost savings in future orders.

– Why it matters: A strong supplier relationship can facilitate smoother transactions and provide you with better access to innovations and product updates in the future.

By following this checklist, you can navigate the complexities of sourcing discharge hoses and make informed decisions that benefit your business operations.

Comprehensive Cost and Pricing Analysis for discharge hoses Sourcing

What Are the Key Cost Components in Discharge Hose Manufacturing?

Understanding the cost structure of discharge hoses is crucial for B2B buyers looking to make informed sourcing decisions. The primary components of the cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materialen: The choice of materials significantly affects pricing. Common materials include PVC, rubber, and polyurethane, each with varying costs based on quality and performance specifications. For instance, high-grade rubber hoses may command a premium due to their durability and resistance to environmental factors.

-

Arbeid: Labor costs depend on the region where the hoses are manufactured. Countries with lower labor costs may offer more competitive pricing, but it’s essential to ensure that quality standards are not compromised.

-

Productie Overhead: This includes expenses related to factory operation, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, benefiting both manufacturers and buyers.

-

Gereedschap: Initial tooling costs can be significant, especially for custom orders. Manufacturers often pass these costs onto buyers, particularly for lower volume orders.

-

Quality Control: Implementing rigorous QC measures ensures that the hoses meet industry standards, which can influence pricing. Certifications such as NSF or ISO can further elevate costs but are crucial for specific applications, especially in potable water transfer.

-

Logistiek: Shipping and handling costs can vary based on the distance from the manufacturing facility to the buyer’s location. Additionally, the choice of Incoterms can affect who bears the responsibility for these costs.

-

Marge: The manufacturer’s profit margin will also play a role in the final price. Buyers should be aware that margins can vary widely based on the supplier’s market position and perceived value.

How Do Price Influencers Affect Discharge Hose Sourcing?

Several factors influence the pricing of discharge hoses, particularly for international buyers:

-

Volume en minimale bestelhoeveelheid (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing and reduce costs per unit.

-

Specificaties en aanpassingen: Customized hoses tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Kwaliteit en certificeringen: Hoses that meet higher quality standards or come with certifications typically cost more. However, investing in certified products can reduce long-term risks and ensure compliance with local regulations.

-

Factoren van leveranciers: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge higher prices but offer greater assurance in performance and service.

-

Incoterms: Understanding the chosen Incoterms can help buyers anticipate additional costs related to shipping, insurance, and tariffs. This is especially important for international transactions.

What Are the Best Practices for Negotiating Prices on Discharge Hoses?

Negotiating prices effectively can lead to significant cost savings for B2B buyers. Here are some tips:

-

Onderzoek en benchmarking: Compare prices from multiple suppliers to understand the market rate. This data can strengthen your negotiating position.

-

Build Relationships: Developing a strong relationship with suppliers can lead to better pricing and favorable terms over time. Regular communication can also facilitate smoother negotiations.

-

Discuss Total Cost of Ownership (TCO): Emphasize TCO over initial purchase price. Hoses that may seem cheaper upfront can lead to higher maintenance or replacement costs if they are of lower quality.

-

Be Open to Alternatives: Consider different materials or specifications that may provide similar performance at a lower cost. Flexibility can often lead to better pricing.

-

Leverage Volume: If your business can commit to larger orders, use this as leverage in negotiations. Suppliers are often willing to offer better terms for guaranteed business.

Conclusion: Understanding Pricing Nuances for International Buyers

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of discharge hose pricing requires a comprehensive understanding of the cost structure and price influencers. Keep in mind that indicative prices may vary based on market conditions, and engaging directly with suppliers can yield the most accurate and competitive quotes. Always consider the long-term implications of your purchases to ensure sustainable sourcing decisions.

Alternatives Analysis: Comparing discharge hoses With Other Solutions

Introduction: Exploring Alternatives to Discharge Hoses

In the realm of fluid management and transportation, discharge hoses are a popular choice for their versatility and efficiency. However, various alternative solutions also exist, each with unique advantages and potential drawbacks. This analysis will compare discharge hoses against two viable alternatives: pompen en pipeline systems. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their specific operational needs.

Illustrative image related to discharge hoses

Vergelijkende tabel

| Vergelijkingsaspect | Discharge Hoses | Pompen | Pipeline Systems |

|---|---|---|---|

| Prestaties | High flexibility; suitable for various applications | Effective for continuous flow; can handle high pressures | Excellent for large-scale, continuous transport |

| Kosten | Generally lower upfront costs; variable based on material and size | Higher initial investment; ongoing operational costs | High initial installation cost; lower long-term operational costs |

| Gemak van implementatie | Easy to set up and transport; minimal training required | Requires installation and setup; may need professional help | Complex installation; requires engineering expertise |

| Onderhoud | Low maintenance; periodic inspections needed | Regular maintenance required; potential for downtime | Low maintenance once installed; rare inspections required |

| Beste gebruikscasus | Ideal for temporary setups, construction sites, and agriculture | Best for consistent fluid delivery in industrial applications | Best for permanent installations in large facilities or municipalities |

Gedetailleerd overzicht van alternatieven

Pompen

Pumps are mechanical devices designed to move fluids by mechanical action. They are particularly effective in applications requiring a continuous flow of liquid, such as in manufacturing or irrigation systems. One of the primary advantages of pumps is their ability to handle high pressures and maintain a steady flow rate. However, they come with a higher initial investment and ongoing operational costs due to electricity and maintenance requirements. Additionally, the installation process can be complex, often necessitating professional assistance.

Pipeline Systems

Pipeline systems provide a permanent solution for transporting fluids over long distances. They are designed for large-scale operations, such as municipal water supply or oil transport, offering excellent efficiency for continuous flow. The main advantages include lower long-term operational costs and reduced labor for fluid management. However, pipeline systems require significant upfront investment and complex installation, which may involve engineering design and environmental assessments. Once installed, they typically require minimal maintenance, making them an attractive option for businesses with stable, high-volume fluid transport needs.

Conclusie: De juiste oplossing voor uw behoeften kiezen

When selecting the appropriate fluid transportation solution, B2B buyers must consider their specific operational requirements, budget constraints, and long-term goals. Discharge hoses offer flexibility and lower initial costs, making them ideal for temporary or varied applications. Conversely, pumps provide consistent flow for industrial use but come with higher costs and maintenance needs. For organizations requiring a permanent and efficient transport solution, pipeline systems may be the best choice, despite their significant upfront investment. Ultimately, understanding the unique benefits and limitations of each option will empower buyers to make informed decisions that align with their operational strategies.

Essential Technical Properties and Trade Terminology for discharge hoses

What Are the Essential Technical Properties of Discharge Hoses?

Discharge hoses are critical components in various industries, including agriculture, construction, and mining. Understanding their technical properties can significantly influence purchasing decisions, ensuring that the right hose is selected for specific applications. Here are some key specifications to consider:

-

Material Composition

Discharge hoses are typically made from materials such as PVC, rubber, or polyurethane. Each material has unique properties: PVC is lightweight and cost-effective, while rubber offers superior durability and resistance to abrasion. Knowing the material helps buyers assess the hose’s suitability for their operational environment and fluid types. -

Working Pressure

This specification indicates the maximum pressure the hose can withstand during operation, usually measured in psi (pounds per square inch). For instance, a hose rated at 110 psi is suitable for moderate applications, while a hose with a rating of 250 psi is ideal for high-pressure tasks. Understanding working pressure helps buyers ensure safety and efficiency in fluid transfer operations. -

Inner and Outer Diameter

The inner diameter (ID) determines the flow capacity, while the outer diameter (OD) affects compatibility with fittings and connections. A hose with a larger ID can transport more fluid, making it crucial for high-volume applications. Accurate measurements are essential for ensuring a proper fit with existing systems and achieving optimal flow rates. -

Temperatuurbereik

Each discharge hose has a specified temperature range, indicating the extremes it can handle without degrading. For example, a hose with a max temperature of 150°F is suitable for warm water applications, whereas others may handle more extreme conditions. Knowledge of temperature limits ensures that the hose will not fail under operational stresses. -

Length Options

Discharge hoses come in various lengths, often sold by the foot or in rolls. Shorter hoses may be ideal for small tasks, while longer hoses are necessary for larger projects requiring extended reach. Buyers should evaluate their needs to optimize costs and minimize waste. -

Gewicht

The weight of the hose affects its portability and ease of installation. Lighter hoses are easier to handle, especially in remote or challenging environments. Buyers should consider the balance between weight and durability, particularly in applications where hoses are frequently moved or repositioned.

What Are the Common Trade Terms Used in the Discharge Hose Industry?

Familiarity with industry terminology is vital for effective communication and decision-making in B2B transactions. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing equipment. -

MOQ (minimale bestelhoeveelheid)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, particularly for smaller businesses that may not need large quantities. -

RFQ (Offerteaanvraag)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers. This process helps in comparing costs and terms from different manufacturers, facilitating informed purchasing decisions. -

Incoterms (internationale handelsvoorwaarden)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for clarifying shipping costs, risk allocation, and delivery obligations, especially for international buyers. -

Fittings

This term refers to the connectors used to join hoses to pipes or other hoses. The type of fittings (e.g., camlock, threaded) can significantly impact the hose’s usability and the overall efficiency of fluid transfer. -

Layflat Hose

A type of discharge hose that can be laid flat when not in use, making it easy to transport and store. This feature is particularly beneficial for applications requiring flexible deployment in varying environments.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, enhancing operational efficiency and cost-effectiveness in their fluid handling processes.

Navigating Market Dynamics and Sourcing Trends in the discharge hoses Sector

What Are the Current Market Dynamics and Key Trends in the Discharge Hoses Sector?

The discharge hoses market is experiencing significant growth driven by various global factors. Increasing industrial activity, particularly in agriculture, construction, and mining, is propelling demand for reliable discharge solutions. Emerging economies in Africa and South America are investing heavily in infrastructure development, leading to heightened demand for efficient water management systems and discharge hoses. Additionally, the rising emphasis on sustainable practices is pushing manufacturers to innovate in terms of materials and production methods.

Technological advancements are also shaping the sourcing landscape. The integration of IoT (Internet of Things) in industrial applications is enhancing the monitoring and management of hose performance, which benefits international B2B buyers by ensuring optimal efficiency. Moreover, e-commerce platforms have simplified the sourcing process, allowing buyers from regions like Nigeria and Vietnam to access a broader range of products and suppliers, increasing competition and driving down costs.

Furthermore, customization is becoming a key trend, with buyers seeking hoses tailored to specific applications, such as those resistant to chemicals or extreme temperatures. This demand for tailored solutions is leading suppliers to diversify their offerings, catering to niche markets and specific industry needs.

How Can Sustainability and Ethical Sourcing Impact Your Discharge Hoses Procurement?

Sustainability is becoming a cornerstone of supply chain management in the discharge hoses sector. Environmental impacts associated with traditional materials, such as PVC, have prompted buyers to seek alternatives that are less harmful to the ecosystem. This shift is not just beneficial for the environment but also enhances brand reputation, making sustainability a crucial consideration for B2B buyers.

Ethical sourcing practices are equally important. Ensuring that the supply chain adheres to ethical labor standards and environmental regulations can significantly influence purchasing decisions. Buyers are increasingly looking for suppliers who can demonstrate compliance with international standards, such as ISO certifications, which validate their commitment to ethical practices.

Moreover, the availability of ‘green’ certifications for materials used in the production of discharge hoses, such as those made from recycled plastics or biodegradable materials, is on the rise. These options not only help companies meet regulatory requirements but also appeal to environmentally conscious consumers and stakeholders, making them an attractive choice for businesses aiming to enhance their sustainability credentials.

What Is the Brief Evolution of Discharge Hoses in the B2B Sector?

The discharge hoses sector has evolved significantly over the decades. Initially, discharge hoses were primarily made from rubber, offering flexibility but lacking in durability and resistance to chemicals. As industries expanded and diversified, the demand for more robust and versatile materials led to the introduction of PVC and polyurethane hoses. These materials offered improved resistance to wear and tear, temperature fluctuations, and chemical exposure, making them suitable for a broader range of applications.

With the advent of technology, manufacturing processes have also advanced. Modern techniques allow for the production of hoses with enhanced performance characteristics, such as higher pressure ratings and better flexibility. The evolution of discharge hoses is not just a response to changing industry needs; it reflects a growing understanding of environmental impacts and the necessity for sustainable practices in manufacturing, ensuring that today’s discharge hoses meet the demands of various sectors while promoting responsible sourcing.

In summary, navigating the discharge hoses market requires an understanding of current trends, sustainability considerations, and the historical context that has shaped the sector. For B2B buyers, these insights are crucial for making informed procurement decisions that align with both operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of discharge hoses

-

How do I choose the right discharge hose for my application?

When selecting a discharge hose, consider factors such as the hose diameter, material, length, and pressure rating. Determine the type of fluid being discharged, as different materials (PVC, rubber, or polyurethane) offer varying levels of chemical resistance and temperature tolerance. Additionally, assess the environment where the hose will be used to ensure durability and flexibility. Finally, consult with suppliers about specific requirements for agricultural, industrial, or construction applications to ensure optimal performance. -

What specifications should I look for in a discharge hose?

Key specifications to evaluate include the hose diameter (ranging from 1 inch to 16 inches), working pressure (typically between 80 to 250 PSI), and maximum temperature limits (commonly up to 150°F). It’s essential to review the hose’s material properties, such as resistance to abrasion, UV exposure, and chemical compatibility. Lastly, consider the assembly options available, such as camlock fittings or threaded ends, which can affect installation and usage in your specific setup. -

What are the common applications for discharge hoses?

Discharge hoses are versatile and used in numerous applications, including irrigation, construction, mining, and industrial processes. They are ideal for transporting water, slurry, and other liquids across various terrains. Specific applications may include dewatering sites, supplying water to agricultural fields, or handling materials in quarries. Understanding the intended use will guide your selection of material and construction type for optimal performance. -

What is the minimum order quantity (MOQ) for discharge hoses?

The MOQ for discharge hoses varies by supplier and can depend on factors such as the type of hose, customization options, and shipping logistics. Generally, manufacturers may have a lower MOQ for standard products, while custom hoses or specialized configurations might require larger orders. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies and negotiate terms that fit your purchasing needs. -

How do I vet suppliers for discharge hoses?

To effectively vet suppliers, begin by researching their reputation in the industry through customer reviews, testimonials, and case studies. Verify their certifications and compliance with international quality standards, which can indicate reliability and product quality. Additionally, assess their production capabilities, lead times, and customer service responsiveness. Engaging in direct communication and requesting samples can also help gauge the supplier’s reliability and product quality before making a larger commitment. -

What payment terms should I expect when purchasing discharge hoses internationally?

Payment terms can vary widely among suppliers but typically include options such as advance payment, letters of credit, or payment upon delivery. For international transactions, it is common to negotiate terms that protect both parties, such as partial upfront payments and the balance upon delivery. Ensure that you discuss the payment methods accepted, currency considerations, and any associated transaction fees to avoid misunderstandings. -

How can I ensure quality assurance for my discharge hoses?

To guarantee quality assurance, request detailed information about the supplier’s manufacturing processes, including quality control measures and testing protocols. Look for suppliers that provide certifications, such as ISO standards, which indicate adherence to quality management practices. Additionally, consider ordering a sample batch for testing before placing a larger order. Establishing clear communication about your quality expectations and performance criteria is crucial to achieving satisfactory results. -

What logistics considerations should I keep in mind when importing discharge hoses?

When importing discharge hoses, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Collaborate with suppliers who have experience in international shipping to ensure proper packaging and documentation. Understand the lead times for production and shipping, and factor in potential delays at customs. It’s also wise to work with a reliable freight forwarder who can help navigate the complexities of international logistics and ensure timely delivery.

Top 7 Discharge Hoses Manufacturers & Suppliers List

1. Factory Direct Hose – Discharge Hoses

Domein: fabrieksdirecthose.com

Geregistreerd: 2004 (21 jaar)

Inleiding: Discharge Hose (1 inch – 16 inch) | Factory Direct Hose offers a variety of discharge hoses ranging from 1 inch to 16 inch. Hoses can be purchased by the foot or by the roll. Available lengths include 25 ft, 50 ft, 100 ft, and 300 ft. Hoses are offered in various sizes including 1/2″, 1″, 1 1/2″, 2″, 2.5″, 3″, 4″, 5″, 6″, 8″, 10″, 12″, 14″, and 16″. Types include discharge hoses and suction hoses….

2. Absolute Water Pumps – Discharge Hoses

Domein: absolutewaterpumps.com

Geregistreerd: 2012 (13 jaar)

Inleiding: Discharge Hoses for Water Pumps | Absolute Water Pumps

– Manufacturer: AMT by Gorman-Rupp, Apache, JGB

– Hose Length Options: 10′, 20′, 25′, 50′, 100′, 200′

– Discharge Hose Diameters: 1.5″, 2″, 2.5″, 3″, 4″, 6″, 8″

– Coupling Material: Aluminum

– Coupling Connection Types: MxF Cam & Groove, MxF Threaded Coupling

– Agency Compliance: CARB, EPA

– Potable Water Use: No (clients using non-potable wa…

3. Hosecraft USA – PVC Layflat Discharge Hoses

Domein: hosecraftusa.com

Geregistreerd: 2005 (20 jaar)

Inleiding: Hosecraft USA offers a variety of discharge hoses including:

1. PD1 PVC Layflat Discharge Hose – Blue, standard duty, 1-1/2″ to 6″ diameters, 5F to 130F, rolls up flat for easy storage.

2. PD2 PVC Heavy Duty Layflat Discharge Hose – Red, heavy duty, 1-1/2″ to 8″ diameters, 5F to 130F, rolls up flat for easy storage.

3. RL1 Mill Discharge Hose – General purpose, rubber SBR age resistant tube, 1-1/…

4. Firehose Direct – 2 Discharge Hoses

5. Kuriyama – Discharge Hose Solutions

Domein: producten.kuriyama.com

Geregistreerd: 1997 (28 jaar)

Inleiding: Discharge Hose products from Kuriyama of America, Inc. include various types of hoses and accessories such as Mill Discharge Hose Assemblies, Nitrile/PVC Oil & Weather Resistant Rubber Discharge Hose, Polyurethane Discharge Hoses, PVC Layflat Discharge Hoses, and Water Discharge Industrial Rubber Hoses. The product line also features EZ-Seal™ Leak Resistant Couplings and Aluminum Pin Lug Couplings…

6. Fire Hose Supply – Durable Discharge Hose

Domein: firehosesupply.com

Geregistreerd: 2012 (13 jaar)

Inleiding: Discharge Hose: Durable woven hoses suitable for various applications including trash pumps, sump pumps, water tanks, fire hydrants, and heavy-duty construction. Equipped with pipe fittings, fire hose fittings, or quick connect camlock fittings. Available sizes and prices: 1″ Inch Single Jacket Discharge Hose – $147.55, 1″ Inch Single Jacket Quick Camlock Hose – $146.30, 1 1/2″ Inch Single Jacket …

7. Amazon Hose – Water Suction and Discharge Solutions

Domein: winkelen.amazonhose.com

Geregistreerd: 1998 (27 jaar)

Inleiding: This company, Amazon Hose – Water Suction and Discharge Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for discharge hoses

In today’s global market, the strategic sourcing of discharge hoses is essential for businesses across various industries, including agriculture, construction, and industrial applications. Sourcing high-quality hoses that meet specific operational needs can significantly impact efficiency, cost-effectiveness, and overall project success. By focusing on factors such as material quality, durability, and supplier reliability, buyers can ensure that they invest in hoses that offer longevity and performance in demanding environments.

Illustrative image related to discharge hoses

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that provide customization options and a robust inventory. This flexibility allows businesses to tailor solutions that align with their unique operational requirements. Additionally, leveraging local suppliers can reduce lead times and shipping costs, enhancing overall supply chain efficiency.

As industries evolve and face new challenges, the demand for versatile and high-performance discharge hoses will only increase. By adopting a proactive approach to sourcing, businesses can position themselves to capitalize on emerging opportunities and drive sustainable growth. Now is the time to evaluate your sourcing strategy—connect with trusted suppliers and explore innovative solutions that can elevate your operations to the next level.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.