Article Contents

Engineering Insight: Suction Hoses

Technical Imperatives of Suction Hoses in Modern Dredging Operations

Suction hoses represent a critical engineered component within the hydraulic circuit of Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs), directly impacting system efficiency, operational uptime, and project economics. Unlike discharge lines operating under positive pressure, suction hoses must reliably withstand significant negative pressure (vacuum) while simultaneously resisting the abrasive action of high-concentration sand, silt, and gravel slurries. Failure to maintain structural integrity under these combined stresses leads to catastrophic collapse, air ingress disrupting pump prime, or rapid cover degradation causing premature hose failure. The inherent flexibility required for vessel motion and ladder articulation further compounds the engineering challenge, demanding precise elastomer compound formulation and carcass reinforcement design to prevent kinking or fatigue cracking without compromising vacuum resistance. Operational reliability hinges on the hose’s ability to maintain consistent internal diameter under vacuum, ensuring optimal slurry velocity and preventing settling or blockages within the suction line – a direct contributor to maximizing production rates and minimizing costly downtime for replacement.

East Marine, leveraging its 15+ years of specialized marine rubber expertise and a dedicated engineering team exceeding 150 professionals, addresses these complex demands through rigorous material science and structural design. Our ISO 9001-certified manufacturing processes, conducted within our 680,000 sqm facility, integrate advanced finite element analysis (FEA) with empirical testing to optimize carcass construction. This includes multi-ply high-tensile textile or wire braiding configurations specifically calibrated for vacuum stability, coupled with proprietary ultra-abrasion-resistant rubber compounds for both the inner tube and outer cover. As active WEDA and CEDA members, we maintain continuous alignment with evolving industry standards and operational feedback from global dredging contractors, ensuring our solutions meet the exacting requirements of deep-sea TSHD operations and high-head CSD applications. Our engineering capability extends beyond standard configurations to bespoke solutions addressing specific project challenges such as ultra-fine sediment handling, high-temperature discharges, or enhanced anti-static properties for volatile environments.

The following table outlines the core technical specifications characterizing East Marine’s premium dredging suction hose range, engineered for maximum service life in demanding conditions.

| Parameter | Standard Range | High-Performance Option | Test Standard |

|---|---|---|---|

| Internal Diameter (ID) | 200 mm – 1200 mm | Up to 1500 mm | ISO 1436 |

| Vacuum Resistance | ≥ 0.09 MPa (750 mmHg) | ≥ 0.10 MPa (760 mmHg) | ISO 10360 |

| Working Pressure | -0.09 MPa to +1.0 MPa | -0.10 MPa to +1.6 MPa | ISO 1436 |

| Temperatuurbereik | -20°C to +80°C | -30°C to +100°C | ISO 188 |

| Cover Type | Abrasion-Resistant (Standard) | Heavy-Duty / Anti-Static | ISO 4671 |

| Bend Radius (Min) | 10x ID (at working pressure) | 8x ID (at working pressure) | ISO 9514 |

| Key Reinforcement | Multi-Ply High-Tensile Textile | Hybrid Textile/Wire Braid | Internal Validation |

The operational success of any dredging asset is intrinsically linked to the performance fidelity of its suction hose system. East Marine’s engineering commitment, backed by substantial R&D investment and deep domain expertise, delivers hoses that are not merely components but integral enablers of sustained, high-productivity dredging operations, directly contributing to reduced lifecycle costs and enhanced project deliverability for our global partners.

Advanced Manufacturing Process

Advanced Manufacturing and Precision Vulcanization of Dredging Suction Hoses at East Marine

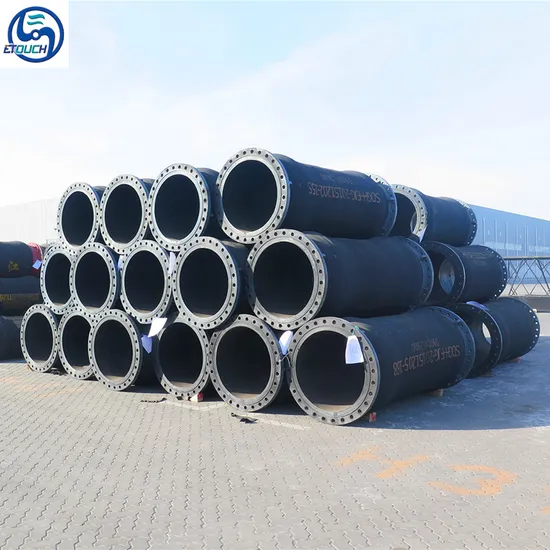

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance dredging suction hoses is grounded in industrial precision, advanced material science, and rigorous quality assurance. Operating from a state-of-the-art 0.68M sqm manufacturing facility, the company leverages 18 dedicated production lines to deliver robust, durable rubber hoses engineered for the most demanding marine and dredging applications. Central to this process is the critical phase of vulcanization—a transformative step that ensures structural integrity, abrasion resistance, and long-term operational reliability.

The manufacturing process begins with the careful selection of premium synthetic and natural rubber compounds, specifically formulated to withstand abrasive slurries, fluctuating temperatures, and continuous hydraulic pressure. These compounds are precisely mixed using automated batching systems to ensure consistency across batches. The rubber is then calendered onto high-tensile textile or steel reinforcement layers, which provide the necessary burst strength and flexibility required in dredging operations.

Once the hose carcass is assembled, it enters the vulcanization stage—an exacting thermal curing process that cross-links rubber molecules to enhance elasticity, durability, and resistance to environmental degradation. East Marine employs steam autoclave and pressurized sulfur vulcanization techniques, maintaining strict control over time, temperature, and pressure parameters. This ensures uniform curing throughout the hose wall, eliminating weak points and optimizing performance under dynamic subsea and high-pressure conditions.

Each of the 18 production lines is equipped with real-time monitoring systems that track critical variables during extrusion, layering, and vulcanization. This integration of process control technology enables traceability and consistency, supporting compliance with ISO 9001 quality management standards. Every hose undergoes post-vulcanization inspection, including dimensional verification, visual surface examination, and hydrostatic pressure testing at 1.5 times the working pressure to validate structural soundness.

East Marine’s membership in industry-leading organizations such as WEDA and CEDA further underscores its commitment to technical excellence and adherence to global dredging standards. The combination of large-scale manufacturing capacity, advanced vulcanization technology, and a disciplined quality control framework ensures that every suction hose leaving the facility meets the highest benchmarks for safety, efficiency, and longevity.

The following table outlines key technical specifications of standard dredging suction hoses produced at the East Marine facility:

| Parameter | Specificatie |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (varies by size) |

| Temperatuurbereik | -20°C to +85°C |

| Reinforcement Layer | High-tensile synthetic fabric or steel wire |

| Cover Rubber | Abrasion-resistant, ozone & UV stabilized |

| Standards Compliance | ISO 1431, ISO 1817, DIN 28019 |

| Test Pressure | 1.5 x Working Pressure (min. 5 min hold) |

| Bend Radius (at max. working) | 10 x Nominal Diameter |

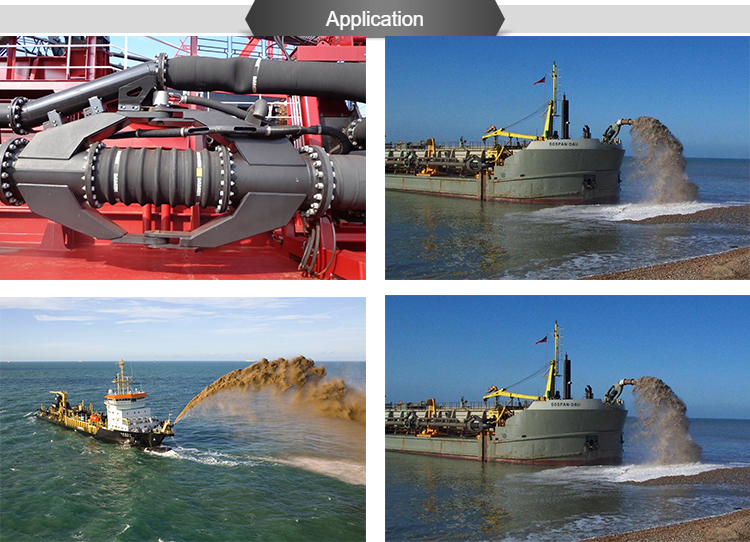

Critical Applications

Global Project Applications for Industrial Suction Hoses in Dredging and Resource Management

Suction hoses represent the critical first interface in fluid transfer systems for large-scale marine and industrial operations, demanding exceptional engineering to withstand abrasive slurries, dynamic environmental forces, and continuous operational stress. At East Marine, leveraging our foundational expertise as a subsidiary of Jiangsu Huashen Special Rubber Products and our active membership in both WEDA (Western Dredging Association) and CEDA (Central Dredging Association), we design and manufacture suction hoses specifically engineered for the most demanding global project environments. Our solutions are integral to the success of capital dredging, maintenance dredging, coastal protection initiatives, offshore resource extraction, and major land reclamation programs worldwide.

Within capital and maintenance dredging projects, suction hoses form the essential connection between the dredge pump and the cutter head or suction pipe. These hoses must maintain structural integrity while handling high concentrations of sand, gravel, and clay under significant vacuum pressure, often in deep water or challenging seabed conditions. East Marine hoses, incorporating multi-ply high-tensile textile and wire reinforcement, ensure consistent hydraulic efficiency and resistance to kinking or collapse, directly impacting project productivity and reducing costly downtime. Coastal protection schemes, such as beach nourishment along vulnerable shorelines in Europe and the Americas, rely on our hoses to reliably transport vast sediment volumes from borrow areas to eroded zones, even in exposed locations with significant wave action.

The oil and gas sector utilizes robust suction hoses for critical applications including offshore platform sand cleaning, pipeline pigging operations, and handling produced water or drilling muds in both marine and onshore fields. These environments demand hoses resistant to hydrocarbons, extreme temperature fluctuations, and continuous flexing. East Marine hoses, formulated with specialized oil-resistant and abrasion-resistant synthetic rubber compounds meeting stringent international standards, provide the necessary durability and safety margin for operations in regions spanning the North Sea to the Gulf of Mexico.

Land reclamation projects, particularly significant in Southeast Asia and the Middle East (e.g., Singapore, UAE), represent another major application domain. Creating new landmass requires moving colossal quantities of seabed material. Our large-diameter suction hoses, capable of handling high-flow slurries over extended lay lengths, are fundamental components in these endeavors. Their ability to resist abrasion from sharp coral fragments or silica-rich sands, coupled with flexibility for dynamic positioning during reclamation, ensures project continuity and cost-effectiveness. Compliance with WEDA and CEDA best practices, reflected in our ISO 9001-certified manufacturing processes at our 680,000 sqm Jiangsu facility, guarantees hoses meet the rigorous safety and performance expectations of global engineering contractors.

The performance of suction hoses directly influences project timelines, operational safety, and total cost of ownership. Catastrophic failure is not an option in these high-stakes environments. East Marine’s technical specifications reflect this imperative, balancing pressure capability, flexibility, and longevity.

Technical Performance Parameters for East Marine Dredging Suction Hoses

| Parameter | Typical Value Range | Units | Standard Reference |

|---|---|---|---|

| Nominal Bore Diameter | 200 – 1200 | mm | ISO 1436 / API 16C |

| Max. Working Pressure | 10 – 25 | bar | EN 12117 |

| Vacuum Resistance | Full Vacuum (760 mmHg) | – | ISO 1307 |

| Temperatuurbereik | -30°C to +80°C | °C | Material Specific |

| Cover Material | Abrasion-Resistant Synthetic Rubber | – | Custom Formulation |

| Versterking | Multi-Ply Textile + Helical Wire | – | Proprietary Design |

East Marine’s commitment to advancing dredging and marine construction technology, underpinned by nearly two decades of specialized manufacturing since 2007 and adherence to global industry consortium standards, positions us as a trusted partner for executing complex fluid transfer challenges across the world’s most ambitious infrastructure and resource projects. Our suction hoses are engineered not just to meet specifications, but to exceed the operational realities of the field.

Technical Data & Specs

Technical Comparison of Dredging Suction and Discharge Hoses: East Marine vs. Industry Competitors

In the demanding environment of dredging operations, the performance and reliability of suction and discharge hoses are critical to operational efficiency, safety, and project timelines. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted member of WEDA and CEDA, delivers high-performance dredging hoses engineered for extreme abrasion resistance, structural integrity, and long service life. With over 15 years of specialized manufacturing experience since 2007 and a 0.68 million sqm production facility, East Marine applies stringent ISO9001-certified quality controls to ensure every hose exceeds international standards.

When evaluating dredging hoses, four key technical parameters define performance: inner diameter, working pressure, burst pressure, and minimum bending radius. These factors directly influence flow capacity, safety margin, flexibility during deployment, and compatibility with various dredging systems. East Marine’s hoses are designed with a balance of robust reinforcement layers, high-tensile textile cords, and premium-grade rubber compounds to optimize all four parameters.

Compared to standard offerings from general industrial hose manufacturers, East Marine’s dredging hoses demonstrate superior pressure handling and flexibility. While many competitors prioritize cost reduction through thinner wall construction or fewer reinforcement plies, East Marine integrates multi-spiral wire reinforcement and abrasion-resistant inner linings to extend service life in high-slurry environments. This engineering approach results in a lower minimum bending radius without sacrificing burst strength—a critical advantage in dynamic offshore and river dredging applications.

The following table presents a representative comparison of technical specifications for dreding suction and discharge hoses across common inner diameters. Data reflects standard configurations for 16-bar working pressure hoses used in cutter suction dredgers and aggregate transfer systems.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) – East Marine | Bending Radius (mm) – Typical Competitor |

|---|---|---|---|---|

| 200 | 16 | ≥ 64 | 900 | 1,100 |

| 250 | 16 | ≥ 64 | 1,100 | 1,350 |

| 300 | 16 | ≥ 64 | 1,300 | 1,600 |

| 400 | 16 | ≥ 64 | 1,700 | 2,100 |

| 500 | 16 | ≥ 64 | 2,200 | 2,600 |

East Marine’s optimized bending radii enhance maneuverability in confined spaces and reduce stress at coupling points, minimizing failure risks during articulation. Additionally, the consistent 4:1 safety factor (burst to working pressure) exceeds DIN 28220 and ISO 1307 standards, ensuring compliance with global marine engineering requirements.

By combining advanced material science with rigorous hydrostatic and impulse testing protocols, East Marine provides dredging contractors with a technically superior alternative to generic hose solutions. This performance edge translates into reduced downtime, lower total cost of ownership, and enhanced operational safety across diverse dredging environments—from coastal reclamation to inland river maintenance.

Partner with East Marine

Conclusion: Engineering Reliability for Demanding Dredging Operations

In the high-stakes environment of hydraulic dredging, the integrity of suction hoses directly dictates project efficiency, operational safety, and long-term cost viability. East Marine, leveraging 17 years of specialized expertise and our 0.68 million square meter ISO 9001-certified manufacturing facility, delivers suction hoses engineered to exceed the rigorous demands of modern dredging. Our solutions integrate advanced rubber compounding, precision reinforcement architectures, and stringent adherence to WEDA/CEDA best practices—ensuring optimal hydrodynamic efficiency, abrasion resistance, and vacuum stability even under extreme pressure differentials and abrasive sediment loads. As a trusted partner to global dredging contractors since 2007, we prioritize not just product performance but lifecycle value, minimizing downtime through hoses designed for extended service in saline, silty, and high-wear conditions.

Selecting the right suction hose transcends technical specifications; it requires a strategic partnership with a supplier who understands the operational nuances of capital dredging, coastal protection, and land reclamation. East Marine’s engineering team collaborates directly with clients to tailor solutions—whether for cutter suction dredgers, trailing suction hopper dredgers, or specialized subsea applications—ensuring seamless integration with pump systems and environmental compliance. Our commitment extends beyond delivery: through proactive technical support, real-time wear analysis, and rapid-response logistics, we mitigate project risks before they impact your critical path.

The table below summarizes the core technical capabilities defining our premium suction hose range, validated through third-party testing per ISO 14313 and ASTM D2682 standards:

| Technical Parameter | Performance Range | Testing Standard | Application Relevance |

|---|---|---|---|

| Working Pressure | 10–25 bar | ISO 1307 | High-head discharge stability |

| Full Vacuum Resistance | ≤ 0.08 bar residual | EN 12138 | Prevents collapse during priming |

| Temperatuurbereik | -30°C to +85°C | ISO 188 | Arctic to tropical operability |

| Abrasion Resistance (DIN) | ≤ 85 mm³ | ISO 4649 | 2–3x industry average lifespan |

| Cover Material | SBR/NR/EPDM blends | ASTM D2000 | Oil/saltwater/silt resistance |

Initiate Your Project with Precision Engineering Support

For dredging contractors navigating complex marine environments, the margin for hose failure is zero. East Marine provides the technical authority and manufacturing scale to secure your operations—from initial system design consultation to on-site troubleshooting. Contact our global engineering desk to request customized specifications, hydraulic modeling data, or project-specific validation reports. Our Singapore branch serves as a dedicated regional hub for Southeast Asian and Oceania projects, offering localized technical coordination, inventory staging, and 24/7 emergency response.

Reach our dredging solutions team directly via WhatsApp at +86-13806109365 for urgent technical queries or real-time project support. For detailed engineering documentation, quotation requests, or partnership discussions, email hsdredging@eastmarine.tech with project parameters including flow rate, sediment density, and operational depth. As a WEDA member and subsidiary of Jiangsu Huashen Special Rubber, we operate with zero minimum order constraints—delivering the same rigorous quality for single-vessel retrofits or multi-year fleet contracts. Do not compromise on the critical interface between your dredge pump and the seabed; partner with East Marine to transform suction hose performance from a vulnerability into your operational advantage. Act now to secure engineered reliability for your next project cycle.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.