Introduction: Navigating the Global Market for vulcanized rubber

In the ever-evolving landscape of global commerce, sourcing high-quality vulcanized rubber poses a significant challenge for B2B buyers. With its superior strength, elasticity, and resistance to abrasion, vulcanized rubber is essential for a wide range of applications, from automotive components to industrial machinery. However, navigating the complexities of the market can be daunting, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil.

This comprehensive guide delves into the multifaceted world of vulcanized rubber, offering insights into various types, production processes, and applications. It also provides a robust framework for evaluating potential suppliers, ensuring that buyers can make informed decisions that align with their operational needs and budget constraints. By addressing critical factors such as sourcing strategies, cost considerations, and quality assurance, this guide empowers businesses to confidently engage with suppliers and optimize their procurement processes.

Whether you are looking to enhance your product offerings or streamline your supply chain, understanding the nuances of vulcanized rubber will equip you with the knowledge to make strategic purchasing decisions. Dive into this guide to unlock the potential of vulcanized rubber in your business operations and stay ahead in the competitive global market.

Inhoudsopgave

- Top 5 Vulcanized Rubber Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vulcanized rubber

- Understanding vulcanized rubber Types and Variations

- Key Industrial Applications of vulcanized rubber

- 3 Common User Pain Points for ‘vulcanized rubber’ & Their Solutions

- Strategic Material Selection Guide for vulcanized rubber

- In-depth Look: Manufacturing Processes and Quality Assurance for vulcanized rubber

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vulcanized rubber’

- Comprehensive Cost and Pricing Analysis for vulcanized rubber Sourcing

- Alternatives Analysis: Comparing vulcanized rubber With Other Solutions

- Essential Technical Properties and Trade Terminology for vulcanized rubber

- Navigating Market Dynamics and Sourcing Trends in the vulcanized rubber Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vulcanized rubber

- Strategic Sourcing Conclusion and Outlook for vulcanized rubber

- Belangrijke disclaimer en gebruiksvoorwaarden

Understanding vulcanized rubber Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Natural Rubber Vulcanizate | Derived from rubber tree sap; excellent elasticity and resilience | Automotive tires, footwear, industrial products | Voordelen: High elasticity, good wear resistance. Minpunten: Susceptible to ozone and UV degradation. |

| Synthetic Rubber (SBR) | Combination of styrene and butadiene; improved heat resistance | Tire manufacturing, conveyor belts, seals | Voordelen: Cost-effective, good abrasion resistance. Minpunten: Less elastic than natural rubber. |

| EPDM Rubber | Ethylene propylene diene monomer; excellent weather resistance | Roofing, automotive weather seals, gaskets | Voordelen: Superior UV and ozone resistance. Minpunten: Limited high-temperature performance. |

| Neoprene Rubber | Synthetic rubber; good chemical stability and flexibility | Electrical insulation, automotive parts, wetsuits | Voordelen: Resistant to oils and chemicals. Minpunten: Higher cost compared to other types. |

| Silicone Rubber | High-temperature stability and flexibility; non-toxic | Medical devices, automotive applications, seals | Voordelen: Exceptional thermal resistance, biocompatible. Minpunten: Generally more expensive. |

What are the Key Characteristics of Natural Rubber Vulcanizate?

Natural rubber vulcanizate is known for its remarkable elasticity and resilience, making it a preferred choice for applications requiring flexibility and durability. It is commonly utilized in automotive tires and footwear, where performance under stress is crucial. Buyers should consider its susceptibility to ozone and UV degradation, which may necessitate additional protective measures in certain environments.

How Does Synthetic Rubber (SBR) Stand Out in B2B Applications?

Styrene-butadiene rubber (SBR) combines affordability with good abrasion resistance, making it ideal for tire manufacturing and conveyor belts. This synthetic variant offers improved heat resistance over natural rubber, catering to various industrial applications. However, its elasticity is slightly lower, which may impact performance in highly flexible applications.

Why is EPDM Rubber Preferred for Weather Resistance?

EPDM (ethylene propylene diene monomer) rubber excels in applications exposed to harsh weather conditions, such as roofing and automotive weather seals. Its superior resistance to UV light and ozone makes it highly durable in outdoor settings. Buyers should note that while EPDM performs well in cold and moderate temperatures, it may struggle in high-temperature scenarios.

What Makes Neoprene Rubber a Versatile Choice for B2B Buyers?

Neoprene rubber is renowned for its chemical stability and flexibility, making it suitable for diverse applications, including electrical insulation and automotive parts. Its resistance to oils and chemicals is a significant advantage for industrial environments. However, buyers should be aware that neoprene can be more expensive compared to other rubber types, which may affect budget considerations.

How Does Silicone Rubber Offer Unique Benefits in Specialized Applications?

Silicone rubber stands out for its exceptional thermal stability and flexibility, making it ideal for high-temperature applications and medical devices. Its non-toxic nature and biocompatibility are crucial in sectors such as healthcare. While silicone’s benefits are substantial, potential buyers should consider the higher costs associated with this material, which may influence purchasing decisions.

Key Industrial Applications of vulcanized rubber

| Industrie/sector | Specific Application of vulcanized rubber | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Automotive | Tires and Seals | Enhanced durability and performance in varying conditions | Quality certifications and compliance with local regulations |

| Bouw | Gaskets and Seals | Prevents leaks and enhances energy efficiency | Availability of custom sizes and resistance to environmental factors |

| Aerospace | O-rings and Seals | Reliable performance in extreme conditions | Material certifications and high-temperature resistance |

| Consumer Goods | Footwear and Sporting Goods | Increased comfort and longevity | Sourcing from sustainable manufacturers and design flexibility |

| Industrial Machinery | Vibration Dampers and Hoses | Reduces wear and tear, enhancing machinery lifespan | Customization options and resistance to chemicals and abrasives |

How is Vulcanized Rubber Used in the Automotive Sector?

In the automotive industry, vulcanized rubber is primarily utilized in the production of tires and seals. The enhanced strength and elasticity provided by the vulcanization process ensure that tires can withstand various environmental conditions and stresses, improving safety and performance. For international buyers, especially in regions like Africa and South America, sourcing tires that meet local road conditions and regulatory standards is crucial. Additionally, seals made from vulcanized rubber are essential for preventing leaks in engines and fuel systems, directly impacting efficiency and operational costs.

What Role Does Vulcanized Rubber Play in Construction?

Vulcanized rubber is widely used in construction for gaskets and seals that prevent leaks in plumbing and HVAC systems. These components are vital for maintaining energy efficiency and ensuring the integrity of buildings. Buyers should focus on sourcing gaskets that can withstand varying temperatures and pressures, particularly in regions with extreme weather conditions. Customization is often necessary to fit specific applications, and suppliers should be able to provide options that meet local building codes and standards.

Why is Vulcanized Rubber Important in Aerospace Applications?

In the aerospace sector, vulcanized rubber is essential for manufacturing O-rings and seals that ensure the integrity of fuel systems and hydraulic components. The ability of vulcanized rubber to perform reliably under extreme temperatures and pressures makes it indispensable in this industry. International buyers must prioritize suppliers who provide material certifications and can demonstrate compliance with stringent aerospace standards. Additionally, the ability to source high-quality materials that resist degradation over time is crucial for maintaining aircraft safety.

How is Vulcanized Rubber Beneficial for Consumer Goods?

Vulcanized rubber is commonly found in footwear and sporting goods, where its durability and comfort-enhancing properties are highly valued. The vulcanization process allows for the creation of flexible yet robust materials that can withstand daily wear and tear. For B2B buyers in Europe and the Middle East, sourcing from sustainable manufacturers who can provide innovative designs and customization options is essential. This not only meets consumer demand for quality products but also aligns with growing sustainability trends in the market.

What Advantages Does Vulcanized Rubber Offer in Industrial Machinery?

In industrial machinery, vulcanized rubber is used in applications such as vibration dampers and hoses, where its resilience minimizes wear and extends machinery lifespan. The ability to withstand harsh chemicals and abrasives is a significant advantage, especially in manufacturing environments. For international buyers, ensuring that sourced materials meet specific industry standards and offer customization options can enhance operational efficiency. Suppliers must also be able to provide technical support and guidance on the best applications for their products.

3 Common User Pain Points for ‘vulcanized rubber’ & Their Solutions

Scenario 1: Quality Inconsistencies in Vulcanized Rubber Products

Het probleem: B2B buyers often face challenges with quality inconsistencies in vulcanized rubber products. This can manifest in variations in strength, elasticity, and resistance to abrasion, leading to product failures in critical applications. For example, a manufacturer sourcing rubber gaskets for machinery may find that some batches do not meet the required specifications, resulting in leaks, downtime, and financial losses. Such issues can erode trust in suppliers and complicate production schedules.

Illustrative image related to vulcanized rubber

De oplossing: To mitigate these risks, buyers should establish a thorough supplier vetting process that includes quality control certifications and testing protocols. Request samples from multiple suppliers and conduct independent quality tests to assess properties such as tensile strength, elongation, and hardness before committing to large orders. Additionally, consider suppliers that offer traceability of materials and adhere to international standards, such as ISO 9001. Regular audits of supplier facilities can also ensure compliance with quality expectations, minimizing the risk of inconsistencies in vulcanized rubber products.

Scenario 2: Difficulty in Specifying the Right Type of Vulcanized Rubber

Het probleem: When sourcing vulcanized rubber, buyers often encounter difficulties in specifying the right type for their applications. Different formulations of vulcanized rubber offer varying properties, and choosing the wrong type can lead to performance failures. For instance, a company in the automotive sector might need rubber that can withstand extreme temperatures and chemical exposure, but may inadvertently select a formulation not suited for such conditions, leading to premature wear and potential safety hazards.

De oplossing: To address this challenge, buyers should invest time in understanding the specific performance requirements of their applications. Collaborating with engineers or material specialists can help clarify the necessary properties, such as thermal stability, chemical resistance, and flexibility. Develop a detailed specification sheet that outlines these requirements and use it to communicate effectively with suppliers. Engaging in discussions with suppliers about their product offerings and potential custom formulations can lead to better-suited solutions for unique applications, ensuring that the selected vulcanized rubber meets all necessary performance criteria.

Scenario 3: Managing Lead Times and Supply Chain Disruptions

Het probleem: B2B buyers often struggle with managing lead times and potential supply chain disruptions when sourcing vulcanized rubber. Given the global nature of the rubber market, factors like geopolitical issues, natural disasters, or logistics challenges can significantly impact delivery schedules. For example, a company in South America may face unexpected delays in receiving critical rubber components for manufacturing, jeopardizing their production timelines and customer commitments.

Illustrative image related to vulcanized rubber

De oplossing: To combat lead time issues, buyers should adopt a proactive supply chain strategy that includes diversifying their supplier base. Relying on multiple suppliers across different regions can reduce dependency on a single source and mitigate risks associated with local disruptions. Implementing just-in-time inventory practices can also help maintain production flow while minimizing excess stock. Additionally, establishing clear communication channels with suppliers regarding inventory levels and anticipated delivery times can enhance responsiveness to changes in demand or supply conditions. Utilizing technology for supply chain visibility can further aid in anticipating potential delays, allowing buyers to make informed decisions and maintain operational continuity.

Strategic Material Selection Guide for vulcanized rubber

When selecting vulcanized rubber materials for various applications, international B2B buyers must consider the unique properties and suitability of different types of rubber. Below, we analyze several common materials used in the production of vulcanized rubber, focusing on their properties, advantages, disadvantages, and implications for specific markets.

What are the Key Properties of Natural Rubber in Vulcanization?

Natural rubber, derived from the latex of rubber trees, boasts excellent elasticity and tensile strength. It performs well under a range of temperatures, typically from -50°C to 80°C, making it suitable for various applications like tires and seals. However, natural rubber has limited resistance to heat and aging compared to synthetic alternatives, which can affect its longevity in demanding environments.

Voordelen: Natural rubber is highly elastic, offers superior tensile strength, and is biodegradable, making it an eco-friendly choice.

Illustrative image related to vulcanized rubber

Minpunten: Its susceptibility to ozone degradation and limited temperature range can restrict its use in harsh conditions.

Invloed op de toepassing: Natural rubber is ideal for applications requiring flexibility and resilience but may not be suitable for high-heat or chemically aggressive environments.

Overwegingen voor internationale kopers: Compliance with local regulations regarding natural materials is essential, especially in Europe, where environmental standards are stringent. Buyers should also consider the availability of natural rubber in their region, as supply chains can vary significantly.

How Does Synthetic Rubber Compare in Terms of Performance?

Synthetic rubber, such as Styrene-Butadiene Rubber (SBR) and Ethylene Propylene Diene Monomer (EPDM), is engineered to enhance specific properties. SBR is known for its excellent abrasion resistance and aging stability, while EPDM excels in weather resistance and temperature tolerance, often ranging from -40°C to 120°C.

Voordelen: Synthetic rubber typically offers better heat resistance, chemical stability, and lower cost compared to natural rubber, making it suitable for a wider range of applications.

Minpunten: It is less elastic than natural rubber and may not perform as well in low-temperature applications.

Invloed op de toepassing: Synthetic rubber is well-suited for automotive parts, industrial applications, and products exposed to harsh weather conditions.

Overwegingen voor internationale kopers: Buyers should ensure that synthetic rubber products meet relevant international standards, such as ASTM and DIN, particularly in markets like Germany and Brazil, where compliance is critical.

What Role Do Specialty Rubbers Play in Vulcanization?

Specialty rubbers, including Fluoroelastomers (FKM) and Silicone rubber, are designed for specific applications requiring high-performance characteristics. FKM is known for its exceptional chemical resistance and thermal stability, while silicone rubber offers excellent flexibility and temperature resistance, ranging from -60°C to 230°C.

Illustrative image related to vulcanized rubber

Voordelen: These materials provide superior performance in extreme conditions, making them ideal for applications in the chemical and aerospace industries.

Minpunten: The high cost of specialty rubbers can be a barrier for some applications, and they may require more complex manufacturing processes.

Invloed op de toepassing: Specialty rubbers are essential in applications where standard rubber cannot withstand the operational demands, such as in fuel systems or high-temperature seals.

Overwegingen voor internationale kopers: Buyers must consider the certification of specialty rubbers for specific applications, especially in regulated industries. Understanding the local market demand for high-performance materials is crucial in regions like the Middle East, where industrial applications are expanding.

How Do Recycled Rubber Products Fit into the Market?

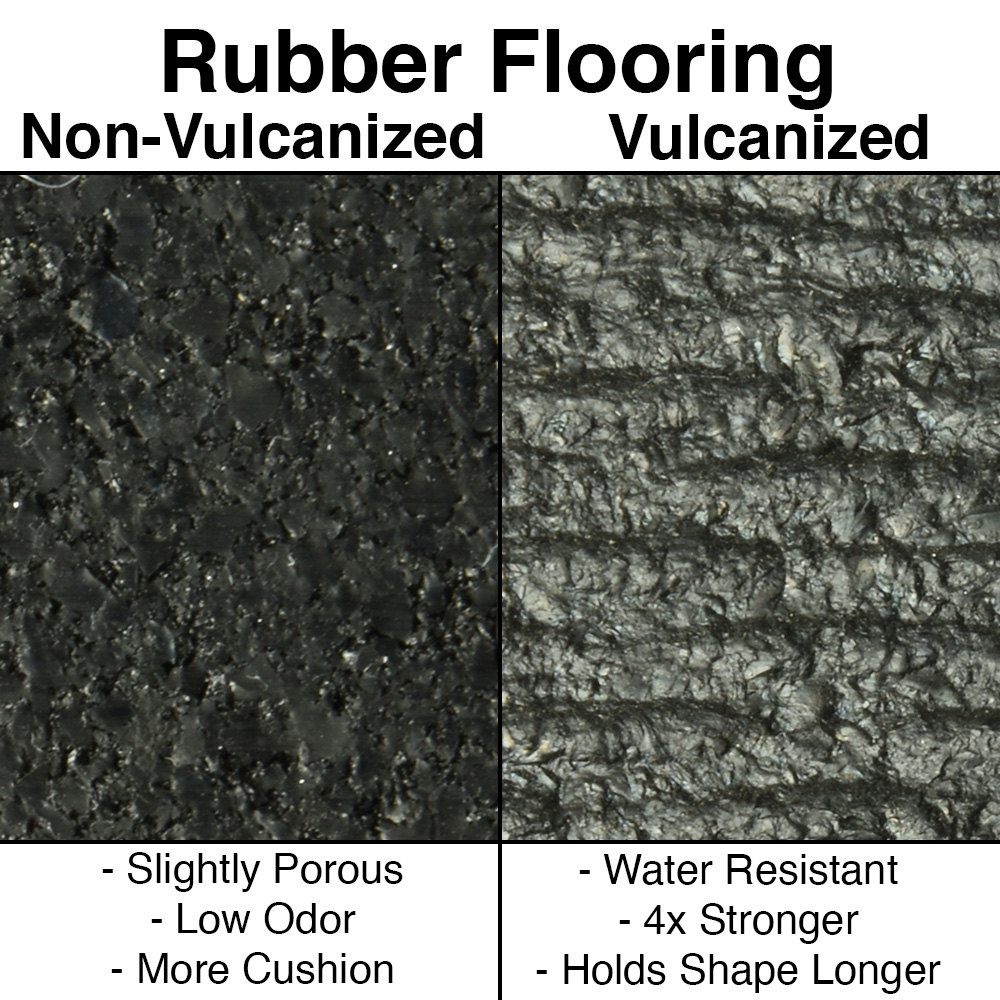

Recycled rubber is made from reclaimed rubber products and can be used in various applications, such as flooring, mats, and automotive parts. It provides a sustainable option that can reduce waste and lower costs.

Voordelen: Cost-effective and environmentally friendly, recycled rubber can meet specific performance requirements while promoting sustainability.

Minpunten: The quality of recycled rubber can vary significantly, impacting performance and durability.

Invloed op de toepassing: Recycled rubber is suitable for non-critical applications where cost savings are prioritized over performance.

Overwegingen voor internationale kopers: Buyers should assess the quality of recycled rubber and ensure it meets local standards. In regions like South America, where sustainability is gaining traction, recycled materials may be increasingly favored.

Summary Table of Material Selection for Vulcanized Rubber

| Materiaal | Typical Use Case for vulcanized rubber | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Natural Rubber | Tires, seals | High elasticity and tensile strength | Limited heat and ozone resistance | Medium |

| Synthetic Rubber | Automotive parts, industrial products | Better heat and chemical resistance | Less elastic than natural rubber | Laag |

| Specialty Rubbers | Aerospace, chemical seals | Exceptional chemical and thermal stability | Hogere kosten en complexere productie | Hoog |

| Recycled Rubber | Flooring, mats | Cost-effective and eco-friendly | Variable quality affecting performance | Laag |

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions based on performance requirements, cost considerations, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vulcanized rubber

What Are the Main Stages of Manufacturing Vulcanized Rubber?

The manufacturing process of vulcanized rubber involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

How Is Material Prepared for Vulcanization?

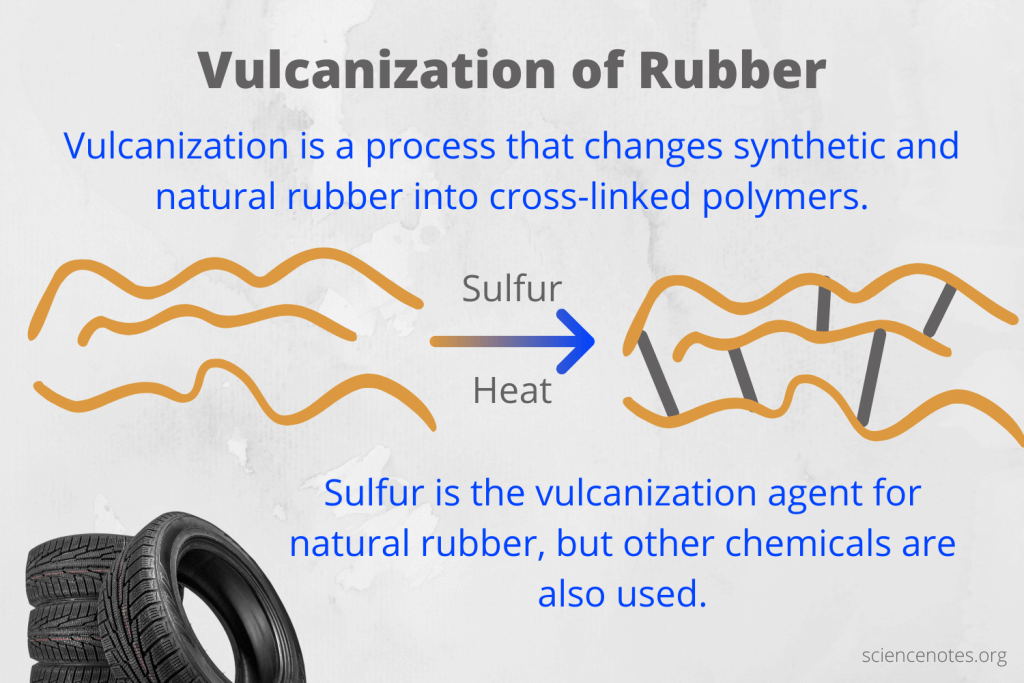

The initial stage involves preparing the raw materials, which primarily include natural or synthetic rubber, sulfur, and various additives. The rubber is typically mixed with sulfur in a controlled environment to ensure consistent quality. Additives such as accelerators, fillers, and plasticizers are incorporated to enhance the rubber’s properties. This mixing process is crucial as it sets the foundation for the subsequent vulcanization.

Illustrative image related to vulcanized rubber

What Techniques Are Used in Forming Vulcanized Rubber?

Once the materials are prepared, they are subjected to forming processes, which can vary based on the desired end product. Common techniques include:

-

Molding: The prepared rubber compound is placed into molds to achieve specific shapes. There are various molding methods, including compression, transfer, and injection molding. Each method has its advantages depending on the complexity and volume of production.

-

Extrusie: In this method, the rubber is forced through a die to create continuous shapes such as hoses or seals. This technique is efficient for producing long sections of rubber with uniform cross-sections.

-

Calendering: This involves passing the rubber through a series of rollers to create thin sheets. Calendering is often used when the product requires a specific thickness or finish.

How Is Vulcanized Rubber Assembled and Finished?

After forming, the rubber undergoes assembly, where various components may be joined together. This could include attaching rubber parts to metal components or integrating additional materials. Finishing processes like trimming, surface treatment, and coating may also be applied to enhance durability and aesthetics.

The final product is then subjected to a curing process, where it is heated to initiate the vulcanization reaction. This step is critical as it cross-links the rubber molecules, resulting in enhanced strength and elasticity.

What Are the Key Quality Control Measures for Vulcanized Rubber?

Quality assurance is vital in the manufacturing of vulcanized rubber, ensuring that products meet international and industry-specific standards. Here are the key quality control measures that B2B buyers should be aware of.

Which International Standards Should B2B Buyers Consider?

For vulcanized rubber products, adherence to international standards is essential. Key standards include:

-

ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality across all processes.

-

CE-markering: This certification indicates that products meet EU safety, health, and environmental protection requirements. For buyers in Europe, ensuring that suppliers have CE certification is critical.

-

API-normen: For products used in the oil and gas industry, API standards ensure that rubber materials can withstand harsh environments.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. Common checkpoints include:

-

Inkomende kwaliteitscontrole (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before processing begins.

-

Kwaliteitscontrole tijdens het proces (IPQC): During manufacturing, random samples may be tested to ensure that production processes are yielding products that meet quality standards.

-

Finale kwaliteitscontrole (FQC): Once production is complete, a thorough inspection of the finished products is conducted. This may include visual inspections, dimensional checks, and functional testing.

Which Testing Methods Are Commonly Used for Vulcanized Rubber?

Testing methods play a crucial role in verifying the quality and performance of vulcanized rubber. Common tests include:

-

Tensile Testing: This measures the material’s strength and elasticity by applying tension until the material breaks.

-

Hardness Testing: Often conducted using a durometer, this test assesses the rubber’s hardness, which can impact its performance in various applications.

-

Abrasion Resistance Testing: This evaluates how well the rubber can withstand wear and tear, particularly important for products like tires and seals.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

For international buyers, verifying a supplier’s quality control measures is crucial in ensuring product reliability. Here are some actionable steps:

Illustrative image related to vulcanized rubber

What Should B2B Buyers Look for in Supplier Audits and Reports?

-

Leveranciersaudits: Conducting regular audits of potential suppliers helps assess their compliance with quality standards. Buyers should request audit reports and review them for adherence to ISO and other relevant certifications.

-

Quality Control Reports: Suppliers should provide detailed QC reports that outline their testing methods, results, and any corrective actions taken for non-conforming products.

How Can Third-party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspections can cover various aspects, including manufacturing practices, safety compliance, and final product evaluations. This step is particularly important for buyers in regions with strict import regulations, such as the EU.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the following nuances:

-

Cultural and Regulatory Differences: Understanding local regulations and cultural expectations can help buyers navigate the complexities of international trade. For example, certain regions may have stricter environmental regulations that affect production processes.

-

Logistics and Supply Chain Considerations: Ensure that suppliers have robust logistics in place to handle international shipping, as delays can impact product quality. Buyers should inquire about the supplier’s experience in exporting to their specific region.

In summary, the manufacturing processes and quality assurance for vulcanized rubber are intricate and demand careful consideration by B2B buyers. By understanding the stages of manufacturing, quality control measures, and how to verify supplier compliance, buyers can make informed decisions that enhance their supply chain resilience and product reliability.

Illustrative image related to vulcanized rubber

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vulcanized rubber’

In the competitive landscape of manufacturing, sourcing high-quality vulcanized rubber is essential for businesses looking to enhance product durability and performance. This step-by-step checklist will guide you through the process of procuring vulcanized rubber, ensuring that you make informed decisions that align with your operational needs.

Stap 1: Je technische specificaties definiëren

Before starting your sourcing journey, clearly outline your technical requirements for vulcanized rubber. This includes the desired hardness, elasticity, and resistance to abrasion or chemicals. Having precise specifications helps in communicating effectively with suppliers and ensures you receive materials that meet your performance standards.

- Consider Applications: Identify the end-use of the rubber, such as automotive parts, industrial seals, or consumer goods.

- Material Standards: Specify if you need natural or synthetic rubber and any relevant industry standards that must be met.

Stap 2: Research and Identify Suppliers

Conduct thorough research to compile a list of potential suppliers who specialize in vulcanized rubber. Utilize online platforms, industry directories, and trade shows to gather information.

- Check Industry Reputation: Look for suppliers with a strong track record and positive reviews from other businesses in your sector.

- Geographic Considerations: Take into account the suppliers’ locations, especially if shipping costs and delivery times are critical for your operations.

Stap 3: Leverancierscertificeringen evalueren

Before finalizing your choices, verify that potential suppliers have the necessary certifications and quality control processes in place. Certifications such as ISO 9001 or specific industry-related certifications indicate a commitment to quality.

- Quality Assurance Processes: Inquire about the supplier’s quality control measures and testing protocols for vulcanized rubber.

- Sustainability Certifications: If sustainability is important to your business, look for suppliers with eco-friendly certifications.

Stap 4: Monsters aanvragen voor testen

Once you have shortlisted suppliers, request samples of their vulcanized rubber products. Testing samples is crucial to ensure that the materials meet your specifications and performance expectations.

Illustrative image related to vulcanized rubber

- Conduct Performance Testing: Evaluate the samples under conditions that mirror your operational environment.

- Assess Consistency: Ensure that the samples demonstrate uniformity in quality and characteristics.

Stap 5: Negotiate Pricing and Terms

Engage in negotiations with the selected suppliers to establish pricing and terms of purchase. This step is vital for aligning your budget with your sourcing strategy.

- Consider Total Cost of Ownership: Factor in shipping, customs, and potential tariffs when assessing overall costs.

- Payment Terms: Discuss payment options, lead times, and minimum order quantities to ensure they align with your financial planning.

Stap 6: Finalize Contracts and Agreements

Once negotiations are complete, draft and finalize contracts that clearly outline terms of service, delivery schedules, and penalties for non-compliance. A well-defined agreement protects both parties and establishes clear expectations.

- Legal Review: Consider having legal counsel review contracts to ensure compliance with international trade laws and regulations.

- Performance Metrics: Include performance metrics and quality benchmarks to hold suppliers accountable.

Stap 7: Een communicatieplan opstellen

After establishing a partnership, create a communication plan to maintain ongoing dialogue with your suppliers. Clear communication is essential for addressing any issues that may arise during the production and delivery phases.

- Regular Updates: Schedule regular check-ins to discuss order status, quality concerns, and any changes in requirements.

- Feedback Loop: Implement a system for providing feedback on product performance to help suppliers improve their offerings.

By following this checklist, B2B buyers can effectively source high-quality vulcanized rubber that meets their specific needs, ensuring a strong foundation for their manufacturing processes.

Comprehensive Cost and Pricing Analysis for vulcanized rubber Sourcing

What Are the Key Cost Components for Sourcing Vulcanized Rubber?

Sourcing vulcanized rubber involves a complex cost structure that includes several critical components. Understanding these can aid buyers in making informed decisions.

Illustrative image related to vulcanized rubber

-

Materialen: The primary cost driver in vulcanized rubber is the raw materials, which include natural or synthetic rubber and sulfur. The type of rubber chosen can significantly affect the overall cost. For instance, synthetic rubber, while more resistant to environmental factors, may incur higher costs than natural rubber.

-

Arbeid: Labor costs encompass the expenses associated with skilled workers who oversee the vulcanization process. This includes machine operators, quality control personnel, and technicians. Regions with higher labor costs can lead to increased overall pricing for vulcanized rubber products.

-

Productie Overhead: This includes costs related to facilities, utilities, and maintenance of manufacturing equipment. For international buyers, understanding the manufacturing environment in the supplier’s region can offer insights into potential variations in overhead costs.

-

Gereedschap: Custom molds and tooling necessary for producing specific shapes and designs add to the initial setup costs. The complexity of the product design can lead to higher tooling costs, impacting the overall pricing structure.

-

Kwaliteitscontrole (QC): Implementing stringent QC measures is vital to ensure that the vulcanized rubber meets the required specifications. The costs associated with testing and quality assurance can vary based on the product’s intended application and required certifications.

-

Logistiek: Shipping costs, including freight, customs duties, and insurance, can significantly affect the final price. Buyers should consider the distance from the manufacturing location to their destination, as well as the Incoterms agreed upon, which dictate the responsibilities of buyers and sellers in the shipping process.

-

Marge: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions, competition, and the supplier’s operational costs.

What Influences Pricing for Vulcanized Rubber?

Several factors can influence the pricing of vulcanized rubber, particularly for international buyers:

-

Volume/MOQ: Larger orders often qualify for discounts, so understanding the minimum order quantity (MOQ) can lead to significant cost savings.

-

Specificaties en aanpassingen: Custom specifications, such as specific grades of rubber or unique formulations, can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: Higher quality materials and additional certifications (e.g., ISO, ASTM) can lead to elevated pricing. Buyers should assess the long-term benefits of investing in certified products against immediate costs.

-

Factoren van leveranciers: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge a premium, but their consistency and service levels can provide greater value over time.

-

Incoterms: Different Incoterms (like FOB, CIF, DDP) dictate shipping responsibilities and costs. Understanding these terms can help buyers negotiate better pricing and manage total costs effectively.

How Can Buyers Optimize Costs When Sourcing Vulcanized Rubber?

To ensure cost-efficiency, international buyers should consider the following strategies:

-

Onderhandeling: Engage in negotiations with multiple suppliers to gain insights into pricing structures and leverage competitive offers. Building a long-term relationship with suppliers can also yield better terms.

-

Totale eigendomskosten (TCO): Evaluate the TCO, which includes purchase price, shipping, handling, and potential disposal costs. This holistic view helps in assessing the true cost of the product over its lifecycle.

-

Pricing Nuances for Different Regions: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions that can affect pricing. For example, tariffs, trade agreements, and regional demand can vary greatly and impact overall costs.

Conclusie

Sourcing vulcanized rubber necessitates a comprehensive understanding of the cost structure, pricing influencers, and strategies for optimizing procurement. By taking these factors into account, international buyers can navigate the complexities of the market and make informed purchasing decisions. Always consult multiple suppliers and consider the broader implications of each sourcing decision to achieve the best results.

Alternatives Analysis: Comparing vulcanized rubber With Other Solutions

Exploring Alternatives to Vulcanized Rubber for Industrial Applications

In the quest for materials that enhance product performance while meeting industry-specific requirements, vulcanized rubber stands out due to its unique properties. However, there are alternative solutions available that may cater to specific needs or applications, each with its own advantages and drawbacks. This analysis will compare vulcanized rubber against two viable alternatives: thermoplastic elastomers (TPEs) and silicone rubber.

Illustrative image related to vulcanized rubber

| Vergelijkingsaspect | Vulcanized Rubber | Thermoplastic Elastomers (TPEs) | Silicone Rubber |

|---|---|---|---|

| Prestaties | High strength, excellent elasticity, abrasion-resistant | Moderate strength, good flexibility and impact resistance | High-temperature resistance, good elasticity but less durable than vulcanized rubber |

| Kosten | Generally higher due to processing costs | Typically lower, easy to process | Moderate to high, depending on the grade |

| Gemak van implementatie | Requires specific curing processes; less flexible in manufacturing | Easy to mold and process; can be recycled | Requires careful handling and curing; limited recycling options |

| Onderhoud | Low maintenance, durable under various conditions | Moderate maintenance, can degrade under certain conditions | Low maintenance, resistant to environmental factors |

| Beste gebruikscasus | Automotive tires, seals, gaskets | Consumer goods, automotive parts, medical devices | High-temperature applications, electronics, medical devices |

What Are the Benefits and Drawbacks of Thermoplastic Elastomers (TPEs)?

Thermoplastic elastomers (TPEs) are a blend of rubber and plastic that can be processed like plastic while retaining the elastic properties of rubber. They offer good flexibility and impact resistance, making them suitable for a wide range of applications, including consumer products and automotive components. The primary advantage of TPEs is their ease of processing, allowing for quicker production times and lower costs. However, they may not match the high-performance capabilities of vulcanized rubber, particularly in demanding applications requiring superior strength and abrasion resistance.

How Does Silicone Rubber Compare to Vulcanized Rubber?

Silicone rubber is another alternative that excels in high-temperature applications due to its thermal stability and resistance to extreme environmental conditions. It maintains flexibility over a broad temperature range and is often used in industries like aerospace and electronics. The advantages of silicone rubber include its low toxicity and biocompatibility, making it ideal for medical applications. However, it tends to be less durable than vulcanized rubber, particularly in applications where abrasion resistance is critical, and its cost can vary widely based on the specific formulation.

Hoe kunnen B2B kopers de juiste oplossing kiezen?

When considering the best material for your industrial applications, B2B buyers should evaluate the specific performance requirements of their products. Vulcanized rubber is often the preferred choice for applications demanding high strength and durability. However, TPEs may offer cost-effective solutions for products requiring flexibility and ease of manufacturing. Meanwhile, silicone rubber shines in high-temperature environments and applications where biocompatibility is essential. By analyzing these factors—performance, cost, implementation ease, maintenance needs, and use cases—buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for vulcanized rubber

What are the Key Technical Properties of Vulcanized Rubber?

Understanding the critical specifications of vulcanized rubber is essential for B2B buyers to ensure they select the right materials for their applications. Here are some key properties:

1. Materiaalklasse

Material grade indicates the specific formulation of rubber, including its composition and intended use. Common grades include SBR (Styrene-Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer). Selecting the appropriate grade is vital, as it impacts durability, weather resistance, and overall performance in specific applications, such as automotive or industrial settings.

2. Tensile Strength

Tensile strength measures the maximum stress that a rubber sample can withstand while being stretched before breaking. This property is crucial for products that experience significant loads or mechanical stress, such as tires or seals. A higher tensile strength indicates a more durable product, which is essential for reducing downtime and maintenance costs in industrial applications.

3. Elongation at Break

Elongation at break refers to the percentage increase in length that a rubber sample can endure before it fails. This property is significant in applications requiring flexibility and adaptability. A high elongation percentage allows for greater deformation without permanent damage, making it suitable for dynamic applications like hoses and gaskets.

4. Hardness (Shore A)

Hardness is measured using the Shore A durometer scale, which indicates how soft or hard the rubber is. Different hardness levels are essential for various applications; softer rubbers are often used for seals and gaskets, while harder rubbers are typically employed in tire manufacturing. Understanding hardness helps buyers select the right material for specific operational environments.

5. Schuurweerstand

Abrasion resistance assesses a material’s ability to withstand wear and tear from friction. In industries like construction or automotive, where rubber components may be exposed to harsh conditions, high abrasion resistance minimizes the risk of damage and extends product lifespan. This property is critical for manufacturers focused on durability and cost-efficiency.

6. Thermal Stability

Thermal stability indicates how well vulcanized rubber can maintain its properties under varying temperature conditions. This is particularly important for applications exposed to extreme heat or cold, such as automotive or aerospace components. Selecting rubber with good thermal stability ensures consistent performance and safety in fluctuating environments.

What are Common Trade Terms Related to Vulcanized Rubber?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers, as they often dictate quality standards and compatibility in component sourcing.

Illustrative image related to vulcanized rubber

2. MOQ (minimale bestelhoeveelheid)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan inventory and manage budgets effectively. It can also affect pricing, as larger orders often lead to cost savings.

3. RFQ (Offerteaanvraag)

An RFQ is a document sent to suppliers asking for a price quotation on specified products or services. This process is crucial for buyers seeking competitive pricing and quality assurance. A well-defined RFQ helps streamline procurement processes and ensures clarity in requirements.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and delivery responsibilities, which is critical for international transactions.

5. Doorlooptijd

Lead time is the period from the initiation of an order to its completion. Understanding lead times helps buyers plan their production schedules and manage supply chain dynamics effectively. Shorter lead times can improve responsiveness and customer satisfaction.

Illustrative image related to vulcanized rubber

6. Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety benchmarks. Buyers should prioritize suppliers who comply with relevant certifications to ensure product reliability and performance, especially in regulated industries.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing vulcanized rubber products, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the vulcanized rubber Sector

What Are the Current Market Dynamics and Key Trends in the Vulcanized Rubber Sector?

The global vulcanized rubber market is experiencing significant growth, driven by increasing demand across various industries, including automotive, aerospace, and consumer goods. Emerging economies in Africa and South America are witnessing a surge in automotive production, which is propelling the need for high-quality vulcanized rubber components, particularly tires and seals. In Europe, particularly in Germany, the shift towards electric vehicles is creating new opportunities for innovative rubber applications, including lightweight materials that enhance energy efficiency.

Technological advancements are reshaping sourcing strategies in this sector. The rise of Industry 4.0 technologies, including IoT and AI, is facilitating more efficient production and supply chain management. This enables manufacturers to predict demand better and optimize inventory levels. Moreover, digital platforms are becoming essential for international B2B buyers, providing real-time data and analytics for informed decision-making. Blockchain technology is also gaining traction, enhancing transparency in supply chains, which is critical for buyers seeking reliable sourcing options.

As sustainability becomes a focal point for businesses globally, vulcanized rubber suppliers are increasingly adopting eco-friendly practices. This trend is particularly prominent among European buyers, who prioritize sustainable sourcing in their procurement strategies. The integration of recycled materials into vulcanized rubber products is emerging as a key trend, appealing to environmentally conscious consumers and businesses alike.

How Is Sustainability and Ethical Sourcing Shaping the Vulcanized Rubber Industry?

The environmental impact of vulcanized rubber production is a pressing concern for international buyers. Traditional rubber sourcing can lead to deforestation and habitat destruction, particularly in regions where natural rubber is harvested. Consequently, B2B buyers are increasingly prioritizing ethical sourcing practices that minimize environmental degradation.

To navigate this landscape, many suppliers are obtaining certifications such as Forest Stewardship Council (FSC) and Global Organic Textile Standard (GOTS), which ensure sustainable sourcing practices. These certifications not only enhance the credibility of suppliers but also resonate with buyers looking to align their procurement processes with corporate social responsibility (CSR) goals.

Furthermore, the use of “green” materials, such as bio-based or recycled rubber, is gaining traction. These alternatives not only reduce the carbon footprint of products but also appeal to a growing segment of environmentally conscious consumers. Buyers from the Middle East and Africa, in particular, are starting to consider sustainability as a critical factor in their procurement decisions, reflecting a broader global shift towards responsible sourcing.

What Is the Historical Context of Vulcanized Rubber in B2B Markets?

The vulcanization process, developed in the 19th century, revolutionized the rubber industry by enhancing the strength and elasticity of rubber products. Before its invention, rubber was limited in its applications due to its susceptibility to temperature changes. The introduction of sulfur and heat in the vulcanization process enabled manufacturers to create durable and versatile rubber products suitable for a wide range of applications, from tires to industrial seals.

Illustrative image related to vulcanized rubber

Historically, the vulcanized rubber industry has evolved from reliance on natural rubber sourced from tropical regions to a more balanced mix of natural and synthetic rubber, driven by advances in polymer science. This evolution has allowed manufacturers to meet the diverse demands of international markets, particularly in regions like Europe and South America, where industrial growth and technological innovation are propelling the need for high-performance rubber products.

Understanding this historical context is crucial for B2B buyers, as it highlights the importance of quality and innovation in sourcing decisions. Today, the legacy of vulcanization continues to shape the industry, influencing not only the types of products available but also the sourcing strategies employed by businesses worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of vulcanized rubber

1. How do I determine the right specifications for vulcanized rubber products?

To select the appropriate specifications for vulcanized rubber products, assess the intended application and environmental conditions. Consider factors such as temperature resistance, elasticity, tensile strength, and abrasion resistance. Consulting with manufacturers or suppliers can provide insights based on their expertise and experience with similar applications. Additionally, reviewing industry standards and conducting material testing can help ensure that the chosen rubber meets your requirements effectively.

2. What is the best type of vulcanized rubber for automotive applications?

For automotive applications, styrene-butadiene rubber (SBR) is often considered the best choice due to its excellent abrasion resistance, strength, and durability under various conditions. Natural rubber can also be utilized, especially for components that require superior elasticity. However, the choice may vary based on specific requirements, such as exposure to oils or chemicals. Collaborating with a supplier who understands automotive standards can help you make the best decision.

3. What are the common customization options available for vulcanized rubber products?

Customization options for vulcanized rubber products include varying hardness levels, colors, sizes, and shapes to meet specific requirements. Suppliers often provide the ability to add specialized additives for enhanced properties such as UV resistance or flame retardancy. Discussing your unique needs with potential suppliers can lead to tailored solutions that better serve your application while ensuring compliance with industry standards.

4. How do I evaluate and vet suppliers of vulcanized rubber?

To evaluate suppliers of vulcanized rubber, start by checking their certifications, production capabilities, and experience in your industry. Request samples to assess quality and performance. It’s also beneficial to read client testimonials and reviews. Engaging in direct communication to discuss their manufacturing processes, lead times, and after-sales support can provide additional confidence in their reliability as a partner.

5. What is the minimum order quantity (MOQ) for vulcanized rubber products?

Minimum order quantities (MOQ) for vulcanized rubber products can vary significantly based on the supplier and the complexity of the product. Typically, MOQs can range from a few hundred to several thousand units. Discussing your needs directly with suppliers can sometimes lead to flexibility in MOQ, especially if you are willing to pay a premium for smaller orders or if you are a first-time buyer looking to establish a long-term relationship.

6. What payment terms are commonly offered by suppliers of vulcanized rubber?

Payment terms for vulcanized rubber products vary by supplier, but common arrangements include net 30, net 60, or upfront payment for first orders. Some suppliers may offer letter of credit or payment via escrow for larger transactions. Always clarify terms before placing an order, and consider negotiating better terms if you establish a long-term partnership, as suppliers may be more flexible with reliable buyers.

7. How is quality assurance managed for vulcanized rubber products?

Quality assurance for vulcanized rubber products typically involves rigorous testing at various stages of production, including raw material inspection, in-process checks, and final product evaluations. Suppliers often adhere to industry standards such as ISO certifications to ensure consistency and reliability. Requesting documentation of quality control processes and test results can provide reassurance about the product’s performance and durability.

8. What logistics considerations should I keep in mind when sourcing vulcanized rubber internationally?

When sourcing vulcanized rubber internationally, consider shipping methods, lead times, and customs regulations in both the exporting and importing countries. Partnering with a logistics provider experienced in handling industrial materials can streamline the process. Additionally, ensure that all necessary documentation, such as certificates of origin and compliance, is in order to avoid delays and facilitate smooth customs clearance.

Top 5 Vulcanized Rubber Manufacturers & Suppliers List

1. ElastoStar – Silicone & Rubber Solutions

Domein: elastostar.com

Registered: 2013 (12 years)

Inleiding: Closed Cell Silicone Sponge Rubber, Metal & X-Ray Detectable Rubber, Silicone Rubber O-Rings, Die Cutting Gaskets, Platinum Cured Rubber Tubing, Rubber U-Channel, Rubber P-Channel, Extruded Rubber Bulb Seal

2. Walker Rubber – Custom Rubber Extrusions

Domein: walker-rubber.co.uk

Geregistreerd: 1999 (26 jaar)

Inleiding: Rubber Extrusions, Custom Rubber Extrusions, Angle Extrusion, Rubber Boat Window Seals, Brick Grabs, Cab Tyres, Rubber Cable Protection, Coloured Extrusions, Container Door Seal Extrusion, Conveyor Side Skirting, Rubber Door Seals, EPDM Extrusions, Rubber Expansion Seals, Rubber Façade Seal Extrusions, Flame Retardant Extrusions, Food Grade Extrusions, Rubber Gate Seals, Rubber Glazing Seals, H Pr…

3. WARE – Industrial & Commercial Boiler Solutions

Domein: wareinc.com

Geregistreerd: 2000 (25 jaar)

Inleiding: WARE is an industrial & commercial boiler rental and service company specializing in sales, service, valve repair, rentals, parts, turn key solutions, and boiler training. Key offerings include:

– Boiler Rentals: A wide range of rental boilers for various applications and industries.

– Boiler Sales: New, used, and remanufactured boiler equipment with over 70 years of experience.

– Aux Equipment: I…

4. EBSCO – Vulcanized Rubber Solutions

Domein: ebsco.com

Registered: 1990 (35 years)

Inleiding: Vulcanized rubber is a durable material created through a chemical process known as vulcanization, which enhances rubber’s elasticity, tensile strength, and resistance to temperature variations. The process involves mixing natural rubber from the Hevea brasiliensis tree with sulfur and applying heat, resulting in chemical cross-links between polymer molecules. Patented by Charles Goodyear in the m…

5. ScienceDirect – Vulcanization Process

Domein: sciencedirect.com

Geregistreerd: 1997 (28 jaar)

Inleiding: Vulcanization is a chemical process that enhances the elasticity and retractile force of rubbery or elastomeric materials by forming a crosslinked molecular network, reducing permanent deformation after the removal of applied forces. It typically involves the insertion of crosslinks between polymer chains using sulfur or other vulcanizing agents. The process improves mechanical properties, enhance…

Strategic Sourcing Conclusion and Outlook for vulcanized rubber

In the rapidly evolving landscape of industrial materials, vulcanized rubber stands out for its superior strength, elasticity, and durability. These properties make it an essential component across various sectors, including automotive, construction, and consumer goods. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of vulcanized rubber is crucial for making informed sourcing decisions. The strategic sourcing of vulcanized rubber not only enhances product quality but also ensures compliance with regional standards and sustainability initiatives.

Investing in robust supplier relationships and leveraging the latest advancements in vulcanization processes can lead to significant cost savings and improved product performance. As global demand for high-performance materials continues to rise, businesses that prioritize strategic sourcing will gain a competitive edge.

Looking ahead, it is essential for buyers to engage with trusted suppliers and stay updated on industry trends to harness the full potential of vulcanized rubber. By doing so, you will not only meet current market demands but also prepare for future innovations. Embrace the opportunity to elevate your sourcing strategy today, ensuring sustainable growth and success in your operations.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.