Inleiding: Navigeren door de wereldwijde markt voor niet-inklapbare zuigslang

Op de wereldmarkt van vandaag vormt het vinden van niet-inklapbare zuigslangen een unieke uitdaging voor B2B-kopers. Met verschillende toepassingen, variërend van agrarisch gebruik tot industrieel waterbeheer, is de behoefte aan betrouwbare en hoogwaardige zuigslangen van cruciaal belang. Het kan echter ontmoedigend zijn om door de complexiteit van specificaties, geloofwaardigheid van leveranciers en kosteneffectiviteit te navigeren, vooral voor internationale inkopers uit diverse regio's zoals Afrika, Zuid-Amerika, het Midden-Oosten en Europa, inclusief belangrijke markten zoals Duitsland en Brazilië.

Deze uitgebreide gids is een waardevolle bron voor B2B-professionals die weloverwogen aankoopbeslissingen willen nemen over niet-inklapbare zuigslangen. Er wordt ingegaan op de verschillende soorten slangen die verkrijgbaar zijn, hun specifieke toepassingen en de essentiële factoren die in overweging moeten worden genomen bij het doorlichten van leveranciers. Daarnaast komen kostenoverwegingen aan bod, zodat inkopers een evenwicht kunnen vinden tussen kwaliteit en budgettaire beperkingen. Door internationale inkopers te voorzien van bruikbare inzichten en best practices, is deze gids bedoeld om het inkoopproces te vereenvoudigen en bedrijven te helpen de juiste zuigslangen te vinden voor hun operationele behoeften.

Of u nu een doorgewinterde inkoper bent of voor het eerst inkoopt, als u de nuances van niet-inklapbare zuigslangen begrijpt, kunt u strategische beslissingen nemen die de efficiëntie en prestaties van uw activiteiten verbeteren.

Inhoudsopgave

- Top 6 Niet-opvouwbare Zuigslang Fabrikanten & Leveranciers Lijst

- Inleiding: Navigeren door de wereldwijde markt voor niet-inklapbare zuigslang

- Inzicht in niet-inklapbare zuigslangtypes en -variaties

- Belangrijkste industriële toepassingen van niet-inklapbare zuigslang

- 3 veelvoorkomende pijnpunten voor 'niet-inklapbare zuigslang' en hun oplossingen

- Strategische materiaalkeuzegids voor niet-inklapbare zuigslang

- Diepgaande blik: Productieprocessen en kwaliteitsborging voor niet-inklapbare zuigslang

- Praktische inkoopgids: Een stap-voor-stap checklist voor 'niet-inklapbare zuigslang

- Uitgebreide kosten- en prijsanalyse voor niet-inklapbare zuigslang Sourcing

- Alternatievenanalyse: Vergelijking van niet-inklapbare zuigslang met andere oplossingen

- Essentiële technische eigenschappen en handelsterminologie voor niet-inklapbare zuigslang

- Navigeren door marktdynamiek en inkooptrends in de sector van niet-inklapbare zuigslangen

- Veelgestelde vragen (FAQ's) voor B2B-kopers van niet-inklapbare zuigslang

- Strategische Sourcing Conclusie en Vooruitzichten voor niet-inklapbare zuigslang

- Belangrijke disclaimer en gebruiksvoorwaarden

Inzicht in niet-inklapbare zuigslangtypes en -variaties

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Duidelijke PVC Zuigslang | Transparant, lichtgewicht en flexibel | Wateroverdracht, chemische behandeling | Voordelen: Eenvoudig te controleren stroom; lichtgewicht. Minpunten: Minder duurzaam in schurende omgevingen. |

| Rubber Zuigslang | Zwaar, slijtvast en flexibel | Industriële toepassingen, bouwplaatsen | Voordelen: Zeer duurzaam; bestand tegen ruw gebruik. Minpunten: Zwaarder en minder flexibel dan PVC. |

| Zuigslang voor koud weer | Ontworpen om flexibiliteit te behouden bij lage temperaturen | Winterbouw, werkzaamheden bij koud weer | Voordelen: Presteert goed in vrieskou. Minpunten: Meestal duurder dan standaard slangen. |

| Groene PVC Zuigslang | UV-bestendig en lichtgewicht | Landbouw, irrigatie | Voordelen: Goed voor buitengebruik; bestand tegen UV-schade. Minpunten: Kan minder duurzaam zijn dan rubberen opties. |

| Zuigslang van zwaar PVC | Versterkt voor hoge druk en zwaar gebruik | Mijnbouw, olie- en gasindustrie | Voordelen: Uitstekend geschikt voor toepassingen met hoge druk. Minpunten: Stugger en minder flexibel dan standaard PVC. |

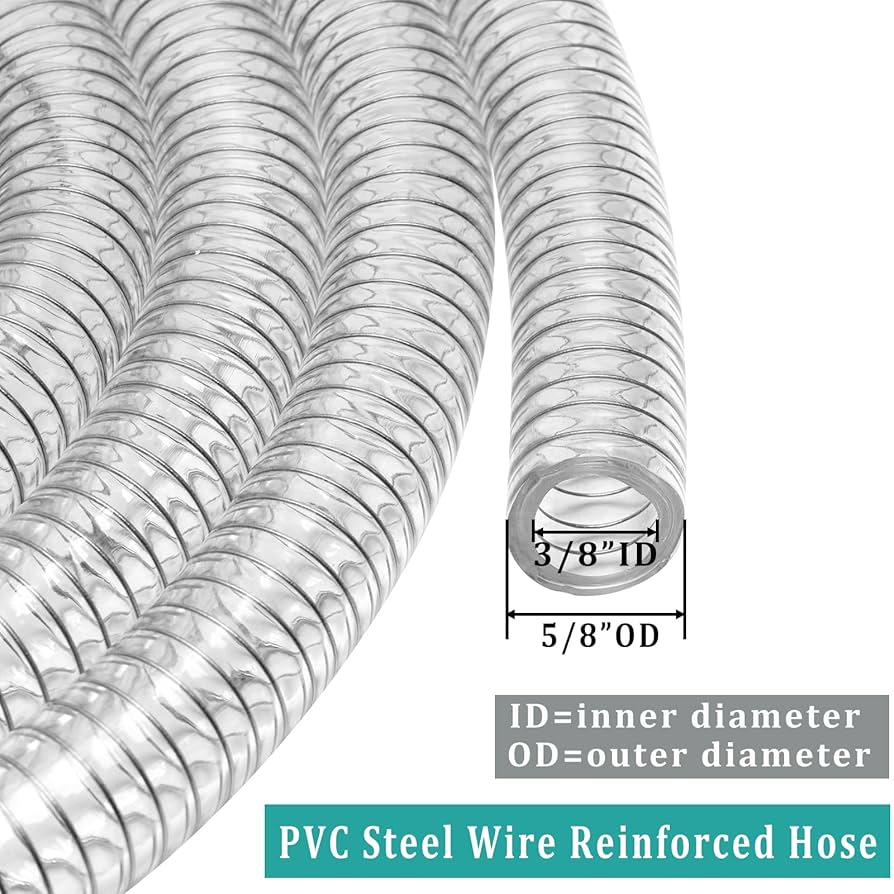

Wat zijn de kenmerken van Clear PVC Suction Hose?

Doorzichtige PVC-zuigslangen staan bekend om hun transparantie, waardoor gebruikers de vloeistofstroom kunnen controleren. Ze zijn licht van gewicht en flexibel, waardoor ze geschikt zijn voor verschillende toepassingen, met name bij het overbrengen van water en het hanteren van chemicaliën. Houd bij de aanschaf rekening met de drukklasse van de slang en de compatibiliteit met de specifieke chemicaliën die worden vervoerd. Helder PVC is ideaal voor situaties waarin zichtbaarheid van de vloeistofstroom essentieel is, maar is mogelijk minder goed bestand tegen schurende materialen dan rubberen slangen.

Waarom kiezen voor rubberen zuigslangen voor industriële toepassingen?

Rubberen zuigslangen worden gekenmerkt door hun zware constructie en slijtvastheid, waardoor ze ideaal zijn voor ruwe industriële omgevingen. Ze kunnen tegen een stootje en zijn geschikt voor bouwterreinen en andere toepassingen waar duurzaamheid van het grootste belang is. Kopers moeten de diameter en lengte van de slang beoordelen op basis van hun specifieke behoeften, evenals de bestendigheid tegen verschillende chemicaliën. Hoewel rubberen slangen zwaarder en minder flexibel zijn dan PVC, rechtvaardigen hun lange levensduur en prestaties onder stress vaak de investering.

Hoe presteert de afzuigslang voor koud weer bij lage temperaturen?

Zuigslangen voor koud weer zijn speciaal ontworpen om flexibiliteit en prestaties te behouden in omgevingen met lage temperaturen. Dit maakt ze bijzonder waardevol voor winterconstructies en werkzaamheden in koude klimaten. Bij het kiezen van een koudwaterslang moeten kopers rekening houden met de laagste temperatuur waarbij de slang effectief kan werken. Hoewel deze slangen duur zijn, kan hun betrouwbaarheid bij vrieskou kostbare stilstand voorkomen en ononderbroken werkzaamheden garanderen.

Welke voordelen biedt de groene pvc-zuigslang voor de landbouw?

Groene PVC-zuigslangen zijn UV-bestendig en licht van gewicht, waardoor ze een uitstekende keuze zijn voor landbouwtoepassingen en irrigatiesystemen. Hun ontwerp helpt degradatie door blootstelling aan de zon te voorkomen, wat cruciaal is voor gebruik buitenshuis. Bij aankoop moeten kopers evalueren of de slang bestand is tegen de specifieke chemicaliën of meststoffen die bij hun werkzaamheden worden gebruikt. Hoewel groene PVC-slangen veelzijdig zijn, zijn ze misschien niet zo duurzaam als rubberen slangen.

Wat maakt PVC Zuigslang voor zwaar gebruik geschikt voor toepassingen met hoge druk?

PVC-zuigslangen voor zwaar gebruik zijn versterkt om hoge druk en zwaar gebruik te weerstaan, waardoor ze ideaal zijn voor veeleisende toepassingen in industrieën zoals mijnbouw en olie en gas. Kopers moeten letten op de drukklasse van de slang en ervoor zorgen dat deze voldoet aan hun operationele eisen. Hoewel deze slangen uitstekende prestaties onder druk leveren, zijn ze over het algemeen minder flexibel dan standaard PVC-slangen, wat het gebruik in krappe ruimtes kan beperken. Inzicht in de afwegingen tussen flexibiliteit en drukcapaciteit is cruciaal voor een weloverwogen aankoop.

Belangrijkste industriële toepassingen van niet-inklapbare zuigslang

| Industrie/sector | Specifieke toepassing van niet-inklapbare zuigslang | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Landbouw | Irrigatie- en drainagesystemen | Zorgt voor efficiënte wateroverdracht, waardoor minder afval ontstaat | Bestand tegen UV-blootstelling en weersomstandigheden |

| Bouw | Ontwatering en drainage | Voorkomt overstromingen en waarborgt de tijdlijnen van projecten | Flexibiliteit en drukwaarden voor verschillende terreinen |

| Afvalbeheer | Verwijdering van vloeibaar afval en slib | Verbetert de operationele efficiëntie en veiligheid | Chemische weerstand en compatibiliteit met afvalsoorten |

| Mijnbouw | Drijfmesttransport en waterwinning | Verhoogt de productiviteit en minimaliseert stilstand | Hoge slijtvastheid en compatibiliteit met zware materialen |

| Eten en drinken | Overbrengen van vloeibare ingrediënten en reinigingsprocessen | Zorgt voor hygiëne en naleving van de veiligheidsnormen | FDA-conformiteit en materiaalcertificeringen |

Hoe wordt niet-opvouwbare zuigslang gebruikt in de landbouw?

In de landbouwsector zijn niet-inklapbare zuigslangen essentieel voor irrigatie- en drainagesystemen. Deze slangen zorgen voor een efficiënte overdracht van water van bronnen zoals rivieren of reservoirs rechtstreeks naar de velden, zodat de gewassen voldoende gehydrateerd worden. Ze spelen ook een cruciale rol bij het afvoeren van overtollig water van velden, waardoor waterverzadiging wordt voorkomen die de gewassen kan beschadigen. Kopers in deze sector moeten de voorkeur geven aan slangen die UV-bestendig en duurzaam zijn, zodat ze bestand zijn tegen verschillende weersomstandigheden, vooral in regio's met een extreem klimaat.

Welke rol speelt de niet-inklapbare zuigslang in de bouw?

In de bouw zijn niet-inklapbare zuigslangen essentieel voor effectieve ontwatering en drainage. Ze worden gebruikt om overtollig water uit uitgravingen en funderingen te verwijderen, overstromingen te voorkomen en ervoor te zorgen dat projecten op schema blijven. Een betrouwbare zuigslang kan stilstand door waterophoping aanzienlijk verminderen. Inkopers in de bouw moeten slangen overwegen die flexibel en toch robuust genoeg zijn om de druk op verschillende terreinen aan te kunnen, zodat ze zich kunnen aanpassen aan verschillende omstandigheden op de bouwplaats.

Hoe wordt niet-inklapbare zuigslang gebruikt in afvalbeheer?

Binnen de afvalverwerkingsindustrie zijn niet-opvouwbare zuigslangen cruciaal voor de veilige verwijdering van vloeibaar afval en slib. Deze slangen verbeteren de operationele efficiëntie doordat ze een snelle en effectieve afvalverplaatsing mogelijk maken en het risico op morsen en milieuvervuiling minimaliseren. Kopers moeten zich richten op slangen die bestand zijn tegen chemicaliën, omdat ze verschillende soorten afval veilig moeten kunnen verwerken. Bovendien kan de compatibiliteit met bestaande apparatuur de werkzaamheden stroomlijnen en de kosten verlagen.

Wat zijn de toepassingen van niet-opvouwbare zuigslangen in de mijnbouw?

In de mijnbouw worden niet-opvouwbare zuigslangen gebruikt voor het transporteren van slurry en het afzuigen van water uit mijnterreinen. Deze slangen zijn ontworpen voor abrasieve materialen en omgevingen met hoge druk, die vaak voorkomen in de mijnbouw. De efficiëntie van slurrytransport is van vitaal belang om de productiviteit op peil te houden en stilstand tot een minimum te beperken. Kopers in deze sector moeten slangen zoeken met een hoge slijtvastheid en het vermogen om zware lasten te weerstaan, die cruciaal zijn om een continue workflow te garanderen.

Hoe wordt niet-opvouwbare zuigslang toegepast in de voedingsmiddelen- en drankenindustrie?

In de voedingsmiddelen- en drankenindustrie worden niet-opvouwbare zuigslangen gebruikt voor het overbrengen van vloeibare ingrediënten en reinigingsprocessen. Deze slangen moeten voldoen aan strenge hygiënenormen om de voedselveiligheid en naleving van gezondheidsvoorschriften te garanderen. Kopers moeten er zeker van zijn dat de slangen gemaakt zijn van FDA-conforme materialen en de nodige certificeringen hebben om besmetting te voorkomen. De juiste zuigslang kan de operationele efficiëntie verbeteren terwijl de kwaliteit en veiligheid van voedingsmiddelen behouden blijft.

Afbeelding ter illustratie van niet-inklapbare zuigslang

3 veelvoorkomende pijnpunten voor 'niet-inklapbare zuigslang' en hun oplossingen

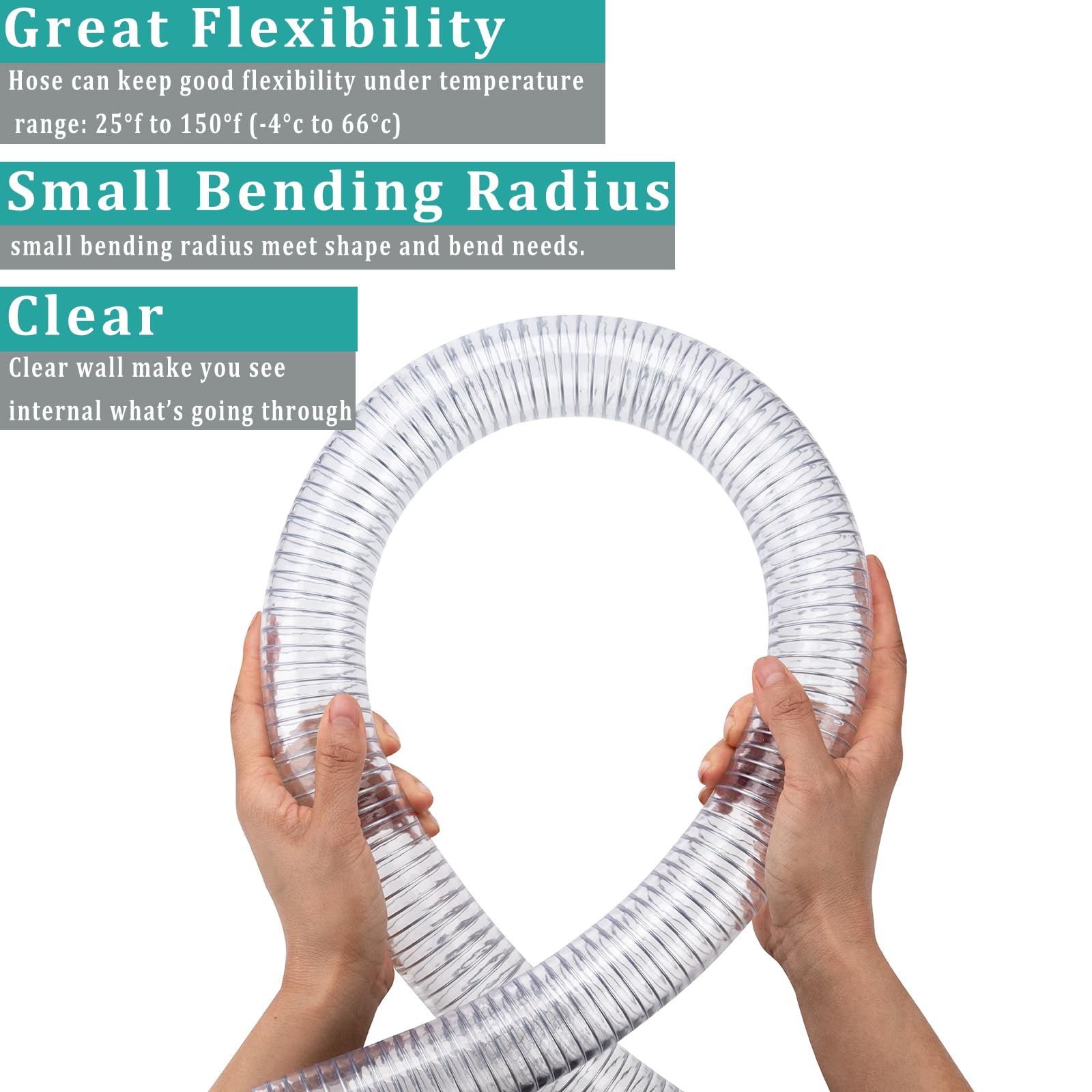

Scenario 1: Moeilijkheden met flexibele slangen in krappe ruimtes

Het probleem: B2B-inkopers worden vaak geconfronteerd met uitdagingen bij het gebruik van niet-inklapbare zuigslangen in omgevingen waar de ruimte beperkt is. Op bouwterreinen of in industriële installaties moeten de slangen bijvoorbeeld rond apparatuur, hoeken of krappe ruimtes worden gemanoeuvreerd. De stijfheid van niet-inklapbare slangen kan het moeilijk maken om door deze ruimtes te navigeren, wat leidt tot inefficiëntie, mogelijke schade aan de slang en hogere arbeidskosten omdat werknemers moeite hebben om de slang op de juiste manier te positioneren.

De oplossing: Om dit probleem aan te pakken, moeten kopers rekening houden met de specifieke toepassingen van hun zuigslangen en slangen kiezen met kenmerken die de flexibiliteit vergroten. Het kan bijvoorbeeld helpen om slangen te kiezen met een specificatie voor de buigradius. Daarnaast kan investeren in draaibare koppelingen ervoor zorgen dat de slang vrij kan draaien, waardoor de druk op de slang wordt verminderd terwijl een optimale doorstroming wordt behouden. Bij het plaatsen van bestellingen moeten inkopers ook hun ruimtelijke beperkingen met leveranciers bespreken om er zeker van te zijn dat ze de juiste lengte en koppelingen ontvangen die eenvoudige installatie en manoeuvreerbaarheid mogelijk maken.

Scenario 2: Risico op instorten van slangen onder hoge vacuümomstandigheden

Het probleem: Niet-opvouwbare zuigslangen zijn ontworpen voor specifieke vacuümtoepassingen, maar ze kunnen toch bezwijken onder extreme zuigomstandigheden. Dit is vooral zorgwekkend voor bedrijven in sectoren zoals afvalwaterbeheer of de bouw waar hoge vacuümprestaties nodig zijn. Een ingezakte slang kan leiden tot stilstand van apparatuur, projectvertragingen en hogere operationele kosten, wat vooral in concurrerende markten nadelig kan zijn.

Afbeelding ter illustratie van niet-inklapbare zuigslang

De oplossing: Om het risico op het bezwijken van de slang te beperken, is het cruciaal dat kopers de vacuümwaarde van hun zuigslangen beoordelen voordat ze deze kopen. Ze moeten de voorkeur geven aan slangen die gemaakt zijn van materialen die speciaal ontworpen zijn voor toepassingen met hoog vacuüm, zoals versterkt PVC of rubber. Daarnaast moeten kopers ervoor zorgen dat de slangdiameter geschikt is voor hun zuigbehoeften; slangen met een grotere diameter presteren over het algemeen beter onder hoogvacuümomstandigheden. Regelmatig onderhoud en controle op slijtage kunnen ook onverwachte storingen voorkomen.

Scenario 3: Beperkte compatibiliteit met bestaande apparatuur

Het probleem: Een ander veel voorkomend probleem doet zich voor wanneer B2B-kopers zich realiseren dat hun niet-inklapbare zuigslangen niet compatibel zijn met bestaande apparatuur of koppelingen. Dit kan leiden tot onverwachte kosten voor extra adapters of zelfs de noodzaak om apparatuur helemaal te vervangen. Dergelijke compatibiliteitsproblemen kunnen de workflow verstoren en de tijdlijnen van projecten verlengen, met negatieve gevolgen voor de algehele productiviteit.

De oplossing: Om compatibiliteitsproblemen te voorkomen, moeten kopers grondig onderzoek doen naar de specificaties van hun bestaande systemen voordat ze nieuwe slangen kopen. Dit omvat het opmeten van fittingmaten en het begrijpen van de verbindingstypes die in hun machines worden gebruikt. Bij het kiezen van slangen moeten kopers kiezen voor slangen met verschillende pasmogelijkheden of aanpasbare assemblages, zodat ze gemakkelijk aan verschillende apparatuur kunnen worden aangepast. In zee gaan met leveranciers die technische ondersteuning bieden, kan kopers ook helpen bij compatibiliteitsproblemen en ervoor zorgen dat ze weloverwogen keuzes maken over hun investeringen in zuigslangen.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Door deze veelvoorkomende pijnpunten proactief aan te pakken, kunnen B2B inkopers de efficiëntie en betrouwbaarheid van hun activiteiten verbeteren, wat uiteindelijk leidt tot een hogere winstgevendheid en klanttevredenheid.

Strategische materiaalkeuzegids voor niet-inklapbare zuigslang

Bij het kiezen van materialen voor niet-opvouwbare zuigslangen is het essentieel om rekening te houden met verschillende factoren zoals prestatie-eigenschappen, duurzaamheid, kosten en toepassingscompatibiliteit. De volgende analyse richt zich op vier veelgebruikte materialen voor de productie van niet-opvouwbare zuigslangen: PVC, rubber, polyurethaan en polyethyleen.

Wat zijn de belangrijkste eigenschappen van PVC voor niet-opvouwbare zuigslangen?

Polyvinylchloride (PVC) wordt veel gebruikt in zuigslangen vanwege de uitstekende chemische bestendigheid en betaalbaarheid. PVC-slangen zijn bestand tegen temperaturen van -10°C tot 60°C en drukken tot 150 psi, waardoor ze geschikt zijn voor verschillende toepassingen, waaronder water en landbouwchemicaliën.

Voordelen: PVC is licht van gewicht, flexibel en bestand tegen veel chemicaliën, waardoor het een uitstekende keuze is voor niet-opvouwbare slangen. De kosteneffectiviteit is vooral aantrekkelijk voor bulkaankopen.

Minpunten: PVC kan echter broos worden bij extreme kou en presteert mogelijk niet goed onder hoge druk. Bovendien is het mogelijk niet geschikt voor bepaalde agressieve chemicaliën, waardoor het toepassingsgebied beperkt is.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Internationale overwegingen: Kopers in regio's zoals Europa en Zuid-Amerika moeten ervoor zorgen dat PVC slangen voldoen aan de lokale regelgeving, zoals ASTM- of DIN-normen, vooral wanneer ze worden gebruikt voor drinkwatertoepassingen.

Hoe is rubber te vergelijken met niet-opvouwbare zuigslangen?

Rubberen slangen, vooral die van synthetisch rubber, staan bekend om hun duurzaamheid en flexibiliteit. Ze kunnen een groter temperatuurbereik aan, meestal van -40°C tot 100°C, en zijn bestand tegen hogere drukken, vaak meer dan 200 psi.

Voordelen: De robuustheid van rubberen slangen maakt ze ideaal voor zware toepassingen, zoals in de bouw en de industrie. Ze zijn ook zeer slijtvast, wat hun levensduur verlengt.

Minpunten: De complexere productie en de hogere kosten van rubberen slangen kunnen een nadeel zijn voor prijsbewuste kopers. Bovendien kunnen ze zwaarder zijn dan PVC-alternatieven, wat gevolgen kan hebben voor hantering en installatie.

Internationale overwegingen: Naleving van internationale normen is cruciaal, vooral in regio's als Afrika en het Midden-Oosten, waar extreme weersomstandigheden de prestaties van het materiaal kunnen beïnvloeden.

Wat zijn de voordelen van polyurethaan in niet-opvouwbare afzuigslangen?

Polyurethaan wint aan populariteit vanwege de superieure slijtvastheid en flexibiliteit. Het kan effectief werken bij temperaturen van -30 °C tot 80 °C en kan een druk aan die vergelijkbaar is met rubberen slangen.

Voordelen: Omdat polyurethaanslangen licht van gewicht zijn, zijn ze gemakkelijk te hanteren en te installeren. Door hun weerstand tegen perforaties en scheuren zijn ze geschikt voor ruwe omgevingen.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Minpunten: Polyurethaanslangen kunnen echter duurder zijn dan PVC- en rubberen slangen. Ze kunnen ook een beperkte chemische compatibiliteit hebben, wat het gebruik in specifieke toepassingen kan beperken.

Internationale overwegingen: Kopers moeten controleren of polyurethaanslangen voldoen aan relevante internationale normen, met name in toepassingen voor chemische verwerking, om veiligheid en naleving te garanderen.

Waarom is polyethyleen een bruikbare optie voor niet-opvouwbare zuigslangen?

Polyethyleen is een ander veelgebruikt materiaal voor zuigslangen, vooral in landbouwtoepassingen. Het is bestand tegen temperaturen van -50°C tot 60°C en is over het algemeen bestand tegen een groot aantal chemicaliën.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Voordelen: Polyethyleen slangen zijn licht van gewicht, flexibel en bestand tegen UV-straling, waardoor ze geschikt zijn voor buitentoepassingen. De kosten zijn doorgaans lager dan die van rubber en polyurethaan.

Minpunten: Polyethyleen is echter minder goed bestand tegen hoge druk dan rubber of polyurethaan, waardoor het minder geschikt is voor industriële toepassingen. Het kan ook minder duurzaam zijn bij extreme temperaturen.

Internationale overwegingen: Kopers in Europa en Zuid-Amerika moeten ervoor zorgen dat polyethyleen slangen voldoen aan de plaatselijke normen voor agrarisch gebruik, vooral met betrekking tot chemische veiligheid.

Samenvattende tabel voor materiaalselectie voor niet-opvouwbare zuigslang

| Materiaal | Typische toepassing voor niet-inklapbare zuigslang | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| PVC | Water en chemische toepassingen in de landbouw | Kosteneffectief en lichtgewicht | Broos bij extreme kou | Laag |

| Rubber | Zware industriële en bouwtoepassingen | Hoge duurzaamheid en drukklasse | Hogere kosten en gewicht | Hoog |

| Polyurethaan | Robuuste omgevingen en flexibele toepassingen | Uitstekende slijtvastheid | Hogere kosten en beperkte chemische compatibiliteit | Med |

| Polyethyleen | Agrarische toepassingen en algemeen gebruik | UV-bestendig en lichtgewicht | Beperkt drukverwerkingsvermogen | Laag |

Deze gids biedt een uitgebreid overzicht van materiaalopties voor niet-opvouwbare zuigslangen, zodat B2B-kopers weloverwogen beslissingen kunnen nemen op basis van hun specifieke toepassingsbehoeften en regionale nalevingsvereisten.

Diepgaande blik: Productieprocessen en kwaliteitsborging voor niet-inklapbare zuigslang

Wat zijn de belangrijkste stappen in het productieproces van niet-opvouwbare zuigslangen?

Het fabricageproces voor niet-opvouwbare zuigslangen omvat meestal verschillende belangrijke stappen, die allemaal cruciaal zijn om ervoor te zorgen dat het eindproduct voldoet aan de vereiste specificaties en prestatienormen.

Materiaalvoorbereiding: Welke materialen worden gebruikt?

De eerste productiefase omvat de selectie en voorbereiding van grondstoffen. Veelgebruikte materialen voor niet-opvouwbare zuigslangen zijn PVC (polyvinylchloride), rubber en polyurethaan. Elk materiaal heeft verschillende eigenschappen die geschikt zijn voor specifieke toepassingen, zoals flexibiliteit, duurzaamheid en bestendigheid tegen chemicaliën.

- Materiaal inkoop: Leveranciers moeten ervoor zorgen dat materialen voldoen aan internationale kwaliteitsnormen. Dit kan betekenen dat ze moeten inkopen bij gecertificeerde fabrikanten of leveranciers die documentatie van materiaaleigenschappen kunnen overleggen.

- Batch testen: Voordat de productie begint, worden de grondstoffen getest om hun fysische en chemische eigenschappen te controleren, zodat ze voldoen aan de vereiste specificaties voor sterkte en flexibiliteit.

Vormgeven: hoe worden slangen gevormd?

Zodra de materialen zijn voorbereid, is de volgende fase het vormen, waarbij de slang wordt gevormd en geconstrueerd.

- Extrusie: Dit is de meest gebruikte methode voor de productie van PVC-slangen. Tijdens de extrusie wordt ruw PVC verwarmd en door een matrijs geperst om een doorlopende slang te maken met de gewenste diameter en dikte. Het extrusieproces zorgt voor een nauwkeurige controle over de binnen- en buitendiameter van de slang, waardoor consistentie gegarandeerd is.

- Versterking: Voor niet-opvouwbare zuigslangen kan extra versterking worden toegevoegd, zoals een spiraalvormige draad of lagen stof, om de structurele integriteit te verbeteren en inzakken onder vacuümomstandigheden te voorkomen. Dit wordt vaak bereikt door co-extrusie of gelaagde technieken.

Montage: Welke onderdelen zijn inbegrepen?

De assemblagefase omvat de integratie van verschillende onderdelen die nodig zijn voor het eindproduct.

- Accessoires: Afhankelijk van de beoogde toepassing kunnen slangen specifieke koppelingen vereisen, zoals camlock- of schroefdraadverbindingen. Deze fittingen zijn vaak voorgemonteerd en aan de slang bevestigd, zodat eindgebruikers ze gemakkelijk kunnen gebruiken.

- Kwaliteitscontrolepunten: Tijdens de assemblage implementeren fabrikanten kwaliteitscontrolepunten om ervoor te zorgen dat alle onderdelen correct passen en functioneren zoals bedoeld. Dit omvat visuele inspecties en functionele tests om de integriteit van verbindingen en fittingen te controleren.

Afwerking: Hoe wordt de slang voorbereid voor distributie?

De laatste fase is de afwerking, die ervoor zorgt dat de slang klaar is voor verzending en voldoet aan alle esthetische en functionele eisen.

Afbeelding ter illustratie van niet-inklapbare zuigslang

- Reiniging en inspectie: Na de assemblage worden de slangen grondig gereinigd om alle overgebleven productieresten te verwijderen. Ze ondergaan een laatste inspectie om te controleren op defecten in het materiaal of de assemblage.

- Verpakking: Vervolgens worden de slangen verpakt op een manier die schade tijdens het transport voorkomt. Dit kan betekenen dat de slangen worden opgerold en vastgezet met riemen of dat ze in beschermende hoezen worden geplaatst.

Welke maatregelen voor kwaliteitsborging zijn cruciaal voor niet-opvouwbare afzuigslangen?

Kwaliteitsborging (QA) is van het grootste belang bij de productie van niet-opvouwbare zuigslangen, omdat het een directe invloed heeft op de prestaties en de veiligheid van het product.

Van welke internationale standaarden moeten kopers zich bewust zijn?

B2B-kopers moeten zich vertrouwd maken met relevante internationale en industriespecifieke kwaliteitsnormen:

- ISO 9001: Deze internationale norm beschrijft de criteria voor een kwaliteitsmanagementsysteem (QMS). Fabrikanten die gecertificeerd zijn volgens ISO 9001 laten zien dat ze in staat zijn om consistent producten te leveren die voldoen aan de eisen van klanten en regelgevende instanties.

- CE-markering: Voor producten die in Europa worden verkocht, geeft de CE-markering aan dat ze voldoen aan de normen voor gezondheid, veiligheid en milieubescherming. Dit is vooral belangrijk voor kopers in de EU, omdat het garandeert dat het product voldoet aan de richtlijnen van de Europese Unie.

- API-normen: Voor slangen die in de olie- en gasindustrie worden gebruikt, is het van cruciaal belang dat ze voldoen aan de normen van het American Petroleum Institute (API). Deze normen zorgen ervoor dat producten bestand zijn tegen de veeleisende omstandigheden van oliewinning en -transport.

Wat zijn de belangrijkste controlepunten voor kwaliteitscontrole?

Controlepunten voor kwaliteitscontrole (QC) zijn essentieel tijdens het hele productieproces om de integriteit van het product te garanderen:

- Inkomende kwaliteitscontrole (IQC): Dit houdt in dat grondstoffen bij ontvangst worden getest om er zeker van te zijn dat ze aan bepaalde normen voldoen voordat ze het productieproces ingaan.

- Kwaliteitscontrole tijdens het proces (IPQC): Tijdens de productie worden regelmatige controles uitgevoerd om het productieproces te bewaken en ervoor te zorgen dat het binnen de gespecificeerde toleranties blijft. Dit omvat het controleren van het extrusieproces en het inspecteren van fittingen tijdens de assemblage.

- Finale kwaliteitscontrole (FQC): Als de slangen klaar zijn, worden ze streng getest om te garanderen dat ze voldoen aan de prestatiespecificaties. Dit kunnen druktests, vacuümtests en fysieke inspecties zijn.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

Voor B2B-kopers, vooral in regio's als Afrika, Zuid-Amerika, het Midden-Oosten en Europa, is het verifiëren van de kwaliteitscontrole van leveranciers essentieel om de betrouwbaarheid van producten te garanderen.

Welke controle- en rapportagepraktijken moeten worden gevolgd?

- Leveranciersaudits: Regelmatige audits van leveranciers kunnen helpen om te controleren of ze voldoen aan de kwaliteitsnormen. Hierbij kan het gaan om inspecties ter plaatse en het beoordelen van documentatie met betrekking tot hun kwaliteitsbeheerpraktijken.

- Kwaliteitsrapporten: Het opvragen van kwaliteitsrapporten bij leveranciers kan inzicht geven in hun productiepraktijken en eventuele problemen tijdens de productie. Deze rapporten moeten de resultaten van IQC-, IPQC- en FQC-processen gedetailleerd weergeven.

Welke rol spelen inspecties door derden?

Het inschakelen van inspectiediensten van derden kan een extra laag van zekerheid toevoegen. Deze diensten kunnen onbevooroordeelde evaluaties van het productieproces leveren en ervoor zorgen dat de producten voldoen aan de gespecificeerde normen voordat ze worden verzonden.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Wat zijn de nuances van kwaliteitscontrole voor internationale kopers?

Voor internationale inkopers is het essentieel om de nuances van kwaliteitscontrole te begrijpen om mogelijke uitdagingen het hoofd te bieden:

- Naleving van regelgeving: Verschillende regio's kunnen unieke wettelijke vereisten hebben, dus het is cruciaal dat kopers hiervan op de hoogte zijn wanneer ze producten inkopen. Producten die bijvoorbeeld in Europa worden verkocht, moeten mogelijk een CE-markering hebben, terwijl producten in de VS mogelijk aan specifieke ANSI-normen moeten voldoen.

- Culturele overwegingen: Communicatiebarrières en culturele verschillen kunnen van invloed zijn op het begrip van de kwaliteitsverwachtingen. Het opstellen van duidelijke richtlijnen en het onderhouden van open communicatielijnen met leveranciers kan helpen om deze kloven te overbruggen.

Kortom, een goed begrip van de productieprocessen en kwaliteitsborgingsmaatregelen voor niet-opvouwbare zuigslangen stelt B2B inkopers in staat om weloverwogen aankoopbeslissingen te nemen. Door zich te richten op kwaliteitsnormen, strenge QC-controlepunten en effectieve verificatiemethoden voor leveranciers, kunnen inkopers risico's beperken en ervoor zorgen dat ze producten van hoge kwaliteit ontvangen die voldoen aan hun behoeften.

Praktische inkoopgids: Een stap-voor-stap checklist voor 'niet-inklapbare zuigslang

Inleiding

Deze inkoopgids is bedoeld om B2B inkopers te helpen bij het inkopen van niet-opvouwbare zuigslangen, die essentieel zijn voor verschillende industriële toepassingen, waaronder water- en chemicaliëntransport. Door deze checklist te volgen, kunt u ervoor zorgen dat uw inkoopproces efficiënt en kosteneffectief verloopt en is afgestemd op uw specifieke operationele behoeften.

Stap 1: Je technische specificaties definiëren

Voordat u begint met zoeken, is het belangrijk om de technische specificaties te bepalen van de niet-opvouwbare zuigslang die u nodig hebt. Dit omvat het bepalen van de slangdiameter, de lengte, het materiaal (bijv. PVC, rubber) en de beoogde toepassingen, zoals agrarisch of industrieel gebruik. Duidelijk omschreven specificaties helpen om leveranciers te vinden die precies aan uw behoeften kunnen voldoen.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Stap 2: Onderzoek potentiële leveranciers

Doe grondig onderzoek naar potentiële leveranciers om gerenommeerde fabrikanten of distributeurs te vinden. Zoek naar bedrijven met een bewezen staat van dienst in de branche en bedrijven die gespecialiseerd zijn in zuigslangen. Maak gebruik van online gidsen, beurzen en industriële forums om informatie en inzichten te verzamelen.

Stap 3: Leverancierscertificeringen evalueren

Het is van cruciaal belang om te controleren of je geselecteerde leveranciers over de nodige certificeringen en kwaliteitsnormen beschikken. Certificeringen zoals ISO 9001 of industriespecifieke goedkeuringen geven aan dat ze zich houden aan kwaliteitsmanagementsystemen. Zorg ervoor dat de leveranciers documentatie kunnen overleggen die bevestigt dat ze voldoen aan de relevante regelgeving, vooral als je actief bent in sterk gereguleerde markten.

Stap 4: Monsters aanvragen voor testen

Voordat je je bestelling afrondt, vraag je de geselecteerde leveranciers om monsters van de zuigslangen. Door deze monsters te testen kun je hun duurzaamheid, flexibiliteit en compatibiliteit met je systemen beoordelen. Het is ook een kans om de reactiesnelheid en servicekwaliteit van de leverancier te beoordelen.

Stap 5: Prijzen en verkoopvoorwaarden bekijken

Zodra je de monsters hebt geëvalueerd, vergelijk je de prijzen tussen de leveranciers. Kijk verder dan de basisprijs; houd rekening met verzendkosten, betalingsvoorwaarden en eventuele kwantumkortingen. Zorg ervoor dat de totale kosten overeenkomen met je budget, terwijl je ook rekening houdt met de kwaliteit van het product dat wordt aangeboden.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Stap 6: Controleer referenties en beoordelingen van klanten

Neem voordat je een definitieve beslissing neemt contact op met eerdere klanten van de leverancier om inzicht te krijgen in hun ervaringen. Vraag naar de betrouwbaarheid, productkwaliteit en klantenservice van de leverancier. Online beoordelingen en getuigenissen kunnen ook extra context en zekerheid bieden met betrekking tot je keuze.

Stap 7: Een duidelijk communicatieplan opstellen

Als je eenmaal een leverancier hebt geselecteerd, stel dan een communicatieplan op om ervoor te zorgen dat alle partijen op één lijn zitten wat betreft verwachtingen, tijdlijnen en leveringsschema's. Maak duidelijk wie de contactpersonen zijn, welke communicatiekanalen de voorkeur hebben en hoe vaak er updates moeten worden gegeven. Effectieve communicatie helpt misverstanden voorkomen en zorgt voor een soepel inkoopproces.

Door deze stappen te volgen, kunnen B2B inkopers effectief niet-opvouwbare zuigslangen kopen die voldoen aan hun operationele eisen, zodat ze met succes kunnen inkopen.

Uitgebreide kosten- en prijsanalyse voor niet-inklapbare zuigslang Sourcing

Wat zijn de belangrijkste kostencomponenten bij de inkoop van niet-opvouwbare zuigslangen?

Bij het inkopen van niet-opvouwbare zuigslangen is inzicht in de kostenstructuur cruciaal voor effectieve budgettering en onderhandelingen. De primaire kostencomponenten omvatten:

-

Materialen: De materiaalkeuze heeft een grote invloed op de prijs. Gangbare materialen zijn onder meer PVC, rubber en speciale compounds die bestand zijn tegen koud weer. De kosten variëren afhankelijk van de kwaliteit en het type van het gebruikte materiaal.

-

Arbeid: Arbeidskosten omvatten de arbeidskrachten die betrokken zijn bij het productieproces. Dit omvat geschoolde arbeid voor assemblage en kwaliteitscontrole. Afhankelijk van de regio kunnen de arbeidskosten aanzienlijk schommelen.

-

Productie Overhead: Dit omvat indirecte kosten zoals nutsvoorzieningen, huur en administratieve kosten in verband met de productiefaciliteit. Efficiënte productieprocessen kunnen helpen de overhead te verlagen.

-

Gereedschap: De initiële investering in mallen en gereedschap is essentieel voor de productie van zuigslangen. Aangepaste ontwerpen of specifieke maten kunnen uniek gereedschap vereisen, wat de totale kosten kan verhogen.

-

Kwaliteitscontrole (QC): Het implementeren van rigoureuze QC-processen garandeert de betrouwbaarheid van producten en naleving van internationale normen. Dit kan het testen van materialen en eindproducten inhouden, wat extra kosten met zich meebrengt maar essentieel is voor het handhaven van de kwaliteit.

-

Logistiek: Transport- en opslagkosten kunnen variëren op basis van de locatie van de leverancier en de bestemming van de koper. Verzendmethoden en afstanden beïnvloeden de totale logistieke kosten.

-

Marge: Leveranciers houden rekening met hun winstmarges, die sterk kunnen variëren afhankelijk van de marktomstandigheden en de concurrentie.

Hoe beïnvloeden prijsbeïnvloeders de kosten van niet-opvouwbare zuigslangen?

Verschillende factoren beïnvloeden de prijs van niet-opvouwbare zuigslangen, vooral op de internationale B2B-markt:

-

Volume en minimale bestelhoeveelheid (MOQ): Grotere bestellingen leiden vaak tot kortingen vanwege schaalvoordelen. Inzicht in de MOQ kan kopers helpen om betere prijzen te bedingen.

-

Specificaties en aanpassingen: Aangepaste slangen die aan specifieke eisen voldoen (lengte, diameter, materiaal) hebben meestal een meerprijs. Kopers moeten hun behoeften duidelijk communiceren om onverwachte kosten te voorkomen.

-

Materialen en kwaliteitscertificaten: De prijs kan aanzienlijk variëren op basis van de kwaliteit van de materialen en eventuele vereiste certificeringen (bijv. ISO, FDA). Materialen van hogere kwaliteit kunnen hogere initiële kosten met zich meebrengen, maar leiden tot een betere duurzaamheid en een lagere Total Cost of Ownership (TCO).

-

Factoren van leveranciers: De reputatie en betrouwbaarheid van de leverancier kunnen de prijs beïnvloeden. Gevestigde leveranciers kunnen hogere prijzen bieden, maar garanderen kwaliteit en service.

-

Incoterms: Inzicht in de verzendingsvoorwaarden (bijv. FOB, CIF) is cruciaal omdat deze bepalen wie de verantwoordelijkheid draagt voor de verzendkosten en risico's. Dit kan de uiteindelijke prijs aanzienlijk beïnvloeden. Dit kan de uiteindelijke prijs aanzienlijk beïnvloeden.

Welke tips kunnen kopers helpen om de kosten van de inkoop van niet-opvouwbare zuigslangen te optimaliseren?

Voor internationale B2B-kopers, met name uit Afrika, Zuid-Amerika, het Midden-Oosten en Europa, zijn er verschillende strategische benaderingen nodig om de kosten voor de inkoop van niet-opvouwbare zuigslangen te optimaliseren:

-

Onderhandeling: Open onderhandelingen met leveranciers kunnen gunstige voorwaarden opleveren. Het benadrukken van het potentieel voor herhalingsaankopen kan leveranciers aanmoedigen om betere prijzen of voorwaarden aan te bieden.

-

Focus op totale eigendomskosten (TCO): Kijk niet alleen naar de aankoopprijs, maar ook naar de TCO, die onderhoud, duurzaamheid en efficiëntie omvat. Investeren in slangen van hogere kwaliteit kan de kosten op lange termijn verlagen.

-

Prijsnuances voor internationale markten begrijpen: Valutaschommelingen en lokale marktomstandigheden kunnen de prijzen beïnvloeden. Kopers moeten op de hoogte blijven van economische factoren die de kosten kunnen beïnvloeden.

-

Relaties opbouwen met leveranciers: Het opbouwen van sterke relaties met leveranciers kan leiden tot betere prijzen, prioriteit in productieschema's en verbeterde service.

-

Onderzoek en benchmarking: Grondig marktonderzoek en het vergelijken van prijzen van meerdere leveranciers kunnen kopers helpen om eerlijke prijzen te begrijpen en weloverwogen beslissingen te nemen.

Kortom, een goed begrip van de kostencomponenten, prijsbeïnvloeders en strategische inkooptips stelt B2B inkopers in staat om weloverwogen beslissingen te nemen bij het inkopen van niet-opvouwbare zuigslangen. Onthoud dat prijzen sterk kunnen variëren op basis van talloze factoren, dus houd altijd rekening met deze inzichten in uw inkoopstrategie.

Alternatievenanalyse: Vergelijking van niet-inklapbare zuigslang met andere oplossingen

Alternatieve oplossingen voor zuigbehoeften onderzoeken

Bij het evalueren van opties voor vloeistoftransport en zuigtoepassingen is het essentieel om verschillende oplossingen te overwegen die verder gaan dan de traditionele niet-inklapbare zuigslang. Afhankelijk van specifieke vereisten zoals prestaties, kosten en onderhoud, kunnen alternatieve technologieën beter geschikt zijn voor uw activiteiten. In deze analyse wordt de niet-inklapbare zuigslang vergeleken met twee haalbare alternatieven: starre leidingsystemen en flexibele blaastanks.

Vergelijkende tabel

| Vergelijkingsaspect | Niet-opvouwbare zuigslang | Star leidingsysteem | Flexibele blaastank |

|---|---|---|---|

| Prestaties | Hoge stroomsnelheid, flexibel gebruik | Vaste stroomsnelheid, beperkte flexibiliteit | Variabel debiet, aanpasbare vormen |

| Kosten | Matige initiële kosten | Hogere installatiekosten | Lagere initiële kosten, variabele bedrijfskosten |

| Gemak van implementatie | Gemakkelijk te installeren en vervoeren | Vereist professionele installatie | Eenvoudige installatie, draagbaar |

| Onderhoud | Minimaal onderhoud | Regelmatige inspecties nodig | Matig, afhankelijk van gebruik |

| Beste gebruikscasus | Tijdelijke of mobiele toepassingen | Permanente installaties | Tijdelijke opslag en transport |

Gedetailleerd overzicht van alternatieven

Star leidingsysteem

Starre leidingsystemen worden vaak gebruikt voor permanente installaties in industriële omgevingen waar vloeistoftransport nodig is. Ze bieden een hoge duurzaamheid en betrouwbaarheid, waardoor ze geschikt zijn voor langdurige toepassingen. De installatiekosten kunnen echter aanzienlijk hoger zijn dan die van niet-inklapbare zuigslangen, omdat ze professionele arbeid en vaak uitgebreid grondwerk vereisen. Onderhoud kan ook een probleem zijn, omdat er regelmatig inspecties nodig zijn om lekken of verstoppingen te voorkomen. Ze zijn het meest geschikt voor vaste installaties waar vloeistoftransport over lange afstanden nodig is of voor systemen met grote volumes.

Afbeelding ter illustratie van niet-inklapbare zuigslang

Flexibele blaastank

Flexibele bladdertanks zijn een steeds populairder alternatief voor vloeistofopslag en -transport, vooral in tijdelijke of noodsituaties. Ze zijn licht en draagbaar, waardoor ze gemakkelijk kunnen worden opgezet en verplaatst. De initiële kosten zijn over het algemeen lager dan die van starre leidingsystemen en kunnen voordeliger zijn wat betreft ruimte en installatietijd. Het debiet kan echter variëren afhankelijk van het ontwerp en de toegepaste druk, wat de operationele efficiëntie kan beïnvloeden. Hoewel het onderhoud minder intensief is dan bij starre leidingen, moeten gebruikers nog steeds controleren op lekken of slijtage, vooral in ruige omgevingen. Flexibele blaastanks zijn ideaal voor tijdelijke opslag, landbouwtoepassingen of rampenbestrijding.

Conclusie: De juiste oplossing voor uw behoeften kiezen

Bij het kiezen van de juiste oplossing voor vloeistofoverdracht moeten B2B-kopers hun specifieke operationele eisen beoordelen, waaronder prestaties, kosten en onderhoudsoverwegingen. Niet-inklapbare zuigslangen bieden een flexibele en kosteneffectieve optie voor tijdelijke toepassingen, terwijl starre leidingsystemen duurzaamheid bieden voor permanente installaties. Flexibele blaastanks vormen een aanpasbaar alternatief dat kosten en flexibiliteit in balans brengt voor uiteenlopende toepassingen. Door de sterke en zwakke punten van elke optie te begrijpen, kunnen kopers weloverwogen beslissingen nemen die het beste passen bij hun operationele behoeften en budgetbeperkingen.

Essentiële technische eigenschappen en handelsterminologie voor niet-inklapbare zuigslang

Wat zijn de belangrijkste technische eigenschappen van niet-opvouwbare zuigslangen?

Bij het kiezen van een niet-opvouwbare zuigslang is het cruciaal om de specifieke technische eigenschappen te kennen die de prestaties en de geschiktheid voor verschillende toepassingen beïnvloeden. Hier zijn enkele belangrijke specificaties:

1. Materiaalklasse

De materialen die worden gebruikt in niet-opvouwbare zuigslangen, zoals PVC, rubber of polyurethaan, hebben een grote invloed op de duurzaamheid en flexibiliteit. PVC-slangen zijn licht en bestand tegen chemicaliën, terwijl rubberen slangen superieur sterk en slijtvast zijn. Door de juiste materiaalsoort te kiezen, bent u er zeker van dat de slang bestand is tegen de specifieke omstandigheden van uw toepassing, of het nu gaat om landbouw, bouw of industrie.

Afbeelding ter illustratie van niet-inklapbare zuigslang

2. Diameter en lengte

Slangen zijn verkrijgbaar in verschillende diameters, meestal variërend van 1 inch tot 12 inch, en lengtes kunnen variëren van 25 voet tot 100 voet of meer. De diameter is van invloed op het debiet en de druk van de getransporteerde vloeistof, terwijl de lengte rekening moet houden met de afstand tussen de aanzuigbron en het afvoerpunt. De juiste dimensionering is essentieel om efficiëntie te garanderen en operationele problemen te voorkomen.

3. Werkdrukclassificatie

Deze specificatie geeft de maximale druk aan die de slang tijdens gebruik aankan. Een hogere werkdruk wordt meestal gemeten in psi (pounds per square inch) en is essentieel voor toepassingen met hogedruksystemen, zoals het verpompen van water of chemicaliën. Als u ervoor zorgt dat de slang aan de vereiste drukniveaus voldoet of deze overschrijdt, voorkomt u storingen en lekken.

4. Temperatuurbestendigheid

Niet-opvouwbare zuigslangen moeten bestand zijn tegen verschillende temperaturen, afhankelijk van de toepassing. Sommige slangen zijn ontworpen voor gebruik bij koud weer, terwijl andere bestand zijn tegen hoge temperaturen. Weten welk temperatuurbereik een slang aankan, is essentieel om ervoor te zorgen dat de slang onder verschillende omgevingsomstandigheden functioneel en veilig blijft.

5. Flexibiliteit en buigradius

Flexibiliteit is vooral belangrijk bij toepassingen waarbij de slang door krappe ruimtes of bochten moet. De buigradius is de minimale radius die de slang kan buigen zonder te knikken. Een slang die te stijf is, presteert mogelijk niet goed in dynamische toepassingen, wat leidt tot verhoogde slijtage en mogelijk defecten.

Afbeelding ter illustratie van niet-inklapbare zuigslang

6. Schuurweerstand

In industriële en bouwtoepassingen komen slangen vaak in aanraking met ruwe oppervlakken en materialen. Slijtvastheid verwijst naar het vermogen van de slang om slijtage door deze omstandigheden te weerstaan. Door een slang met een hoge slijtvastheid te kiezen, verlengt u de levensduur en verlaagt u de onderhoudskosten.

Welke handelsvoorwaarden moeten B2B-inkopers kennen bij de aankoop van niet-opvouwbare zuigslangen?

Een goed begrip van de vakterminologie kan het inkoopproces stroomlijnen en de communicatie met leveranciers verbeteren. Hier volgen enkele veelgebruikte termen die relevant zijn voor niet-opvouwbare zuigslangen:

1. OEM (Original Equipment Manufacturer)

OEM verwijst naar bedrijven die onderdelen of apparatuur produceren die door een andere fabrikant op de markt worden gebracht. In de context van zuigslangen geeft dit aan dat een product gemaakt is volgens de specificaties van een bepaald merk, waardoor compatibiliteit en kwaliteit gegarandeerd zijn.

2. MOQ (minimale bestelhoeveelheid)

Deze term definieert de kleinste hoeveelheid van een product die een leverancier bereid is te verkopen. Voor inkopers helpt inzicht in MOQ bij het budgetteren en plannen van voorraden, zodat ze aan de eisen van leveranciers kunnen voldoen zonder zich financieel te veel vast te leggen.

3. RFQ (Offerteaanvraag)

Een RFQ is een standaard bedrijfsproces waarbij een koper prijsoffertes vraagt van leveranciers voor specifieke producten. In dit document worden de behoeften van de koper geschetst, zodat leveranciers gedetailleerde antwoorden kunnen geven die betere prijsvergelijkingen en onderhandelingen mogelijk maken.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms zijn een reeks vooraf gedefinieerde commerciële termen die zijn gepubliceerd door de Internationale Kamer van Koophandel. Ze verduidelijken de verantwoordelijkheden van kopers en verkopers bij internationale transacties, waaronder wie verantwoordelijk is voor verzending, verzekering en tarieven. Bekendheid met deze voorwaarden kan kopers helpen onverwachte kosten en vertragingen te voorkomen.

5. Doorlooptijd

Doorlooptijd verwijst naar de tijd die verstrijkt tussen het plaatsen van een bestelling en de ontvangst van het product. Inzicht in doorlooptijden is cruciaal voor voorraadbeheer en om ervoor te zorgen dat de activiteiten soepel verlopen, vooral in tijdgevoelige sectoren.

Door deze technische eigenschappen en handelstermen te begrijpen, kunnen B2B inkopers weloverwogen beslissingen nemen bij de aanschaf van niet-opvouwbare zuigslangen, wat uiteindelijk leidt tot een betere operationele efficiëntie en kostenbesparingen.

Navigeren door marktdynamiek en inkooptrends in de sector van niet-inklapbare zuigslangen

Wat zijn de belangrijkste trends en dynamieken die de markt voor niet-inklapbare zuigslangen vormgeven?

De wereldwijde markt voor niet-opvouwbare zuigslangen maakt een aanzienlijke groei door onder invloed van verschillende factoren, waaronder industriële expansie, toegenomen landbouwactiviteiten en de stijgende vraag naar vloeistoftransport in de bouw en industrie. In regio's als Afrika en Zuid-Amerika is vooral de toename van infrastructuurprojecten en landbouwontwikkeling opvallend. Daarnaast investeren landen in het Midden-Oosten veel in de olie- en gassector, waardoor de behoefte aan robuuste zuigslangen die met verschillende vloeistoffen overweg kunnen, toeneemt. In Europa, met name in Duitsland, wordt sterk de nadruk gelegd op technologische innovatie, wat leidt tot de ontwikkeling van geavanceerde materialen die de duurzaamheid en efficiëntie van zuigslangen verbeteren.

Opkomende B2B-technologietrends transformeren inkoopstrategieën. Met digitale inkooptools en -platforms kunnen inkopers hun inkoopprocessen stroomlijnen, waardoor leveranciers beter kunnen worden beheerd en de kosten beter in de hand kunnen worden gehouden. De integratie van IoT-apparaten in industriële toepassingen maakt het ook mogelijk om de prestaties van slangen in realtime te controleren, waardoor de operationele efficiëntie toeneemt. Bovendien vergemakkelijkt het toenemende gebruik van e-commerce platforms de toegang voor internationale inkopers tot hoogwaardige zuigslangen, met opties om per voet of in bulk te kopen.

Hoe beïnvloedt duurzaamheid de inkoop van niet-opvouwbare zuigslangen?

Duurzaamheid is een belangrijk aandachtspunt geworden voor bedrijven in alle sectoren, inclusief de markt voor niet-opvouwbare zuigslangen. De milieu-impact van productieprocessen en de materialen die in zuigslangen worden gebruikt, worden kritisch bekeken. Kopers zijn in toenemende mate op zoek naar producten die gemaakt zijn van gerecyclede of duurzame materialen en naar producten die een kleinere ecologische voetafdruk hebben.

Ethisch verantwoord inkopen is van het grootste belang; van bedrijven wordt verwacht dat ze hun toeleveringsketens transparant houden en ervoor zorgen dat materialen op verantwoorde wijze worden ingekocht. Certificeringen zoals ISO 14001 (milieubeheer) en Green Seal worden essentieel voor leveranciers die geloofwaardig willen overkomen en milieubewuste kopers willen aanspreken. Daarnaast kan het gebruik van milieuvriendelijke materialen de merkreputatie en klantenloyaliteit verbeteren, omdat bedrijven hun activiteiten afstemmen op bredere duurzaamheidsdoelen.

Wat is de historische context achter de ontwikkeling van niet-opvouwbare zuigslangen?

De niet-opvouwbare zuigslang is in de loop der jaren sterk geëvolueerd, te beginnen in het midden van de 20e eeuw toen industriële toepassingen betrouwbaardere en efficiëntere oplossingen voor vloeistofoverdracht begonnen te vereisen. Vroege versies waren voornamelijk gemaakt van rubber en misten de flexibiliteit en duurzaamheid die nodig waren voor verschillende toepassingen.

Naarmate de technologie voortschreed, begonnen fabrikanten te experimenteren met verschillende materialen, wat leidde tot de ontwikkeling van PVC en andere synthetische opties die verbeterde prestatiekenmerken boden, zoals slijtvastheid en bestendigheid tegen chemicaliën. De evolutie van productietechnieken heeft ook bijgedragen aan een betere kwaliteitscontrole en aanpassingsopties, waardoor bedrijven aan specifieke industriële eisen kunnen voldoen. Deze historische context onderstreept het belang van innovatie om tegemoet te komen aan de veranderende behoeften van internationale B2B-kopers in diverse sectoren.

Conclusie

De markt voor niet-opvouwbare zuigslangen is klaar voor groei, aangedreven door een combinatie van industriële expansie, technologische vooruitgang en een focus op duurzaamheid. Voor internationale B2B inkopers, vooral in opkomende markten, is het begrijpen van deze dynamiek cruciaal om weloverwogen inkoopbeslissingen te kunnen nemen. Door prioriteit te geven aan ethische inkoop en duurzaamheid kunnen bedrijven niet alleen voldoen aan de wettelijke vereisten, maar ook hun marktpositie verbeteren in een steeds concurrerender landschap.

Veelgestelde vragen (FAQ's) voor B2B-kopers van niet-inklapbare zuigslang

-

Hoe bepaal ik de juiste maat niet-opvouwbare zuigslang voor mijn toepassing?

Het kiezen van de juiste maat niet-opvouwbare zuigslang is cruciaal voor efficiëntie en prestaties. Begin met het beoordelen van het vloeistoftype dat u gaat vervoeren, aangezien verschillende materialen specifieke slangkenmerken vereisen. Houd rekening met de stroomsnelheid en de diameter van de koppelingen op uw apparatuur. Een te kleine slang kan het debiet beperken, terwijl een te grote slang tot inefficiëntie kan leiden. Het is raadzaam om leveranciers of technische specificaties te raadplegen om de juiste maat te kiezen op basis van uw operationele behoeften. -

Van welke materialen zijn niet-opvouwbare zuigslangen gemaakt en welke is het beste voor mijn behoeften?

Niet-opvouwbare zuigslangen zijn meestal gemaakt van materialen zoals PVC, rubber en polyurethaan. PVC-slangen zijn licht van gewicht en geschikt voor water en milde chemicaliën, waardoor ze een populaire keuze zijn voor landbouwtoepassingen. Rubberen slangen zijn duurzamer en bestand tegen zwaardere omstandigheden, waardoor ze ideaal zijn voor de bouw en industrie. Houd rekening met de specifieke eigenschappen van elk materiaal, zoals flexibiliteit, temperatuurbestendigheid en chemische compatibiliteit, om de beste optie voor uw toepassing te bepalen. -

Wat zijn de minimale bestelhoeveelheden (MOQ's) voor niet-opvouwbare zuigslangen?

MOQ's voor niet-opvouwbare zuigslangen kunnen aanzienlijk verschillen per leverancier en regio. Sommige fabrikanten bieden flexibele MOQ's voor proefbestellingen, terwijl andere fabrikanten bulkaankopen vereisen om kosteneffectiviteit te garanderen. Informeer bij internationale leveranciers vooraf naar hun MOQ-beleid om verrassingen te voorkomen. Houd daarnaast rekening met uw opslagmogelijkheden en de vraag naar de slangen op uw markt om een afgewogen aankoopbeslissing te nemen. -

Hoe kan ik leveranciers van niet-opvouwbare afzuigslangen doorlichten om de kwaliteit te garanderen?

Het doorlichten van leveranciers is essentieel om ervoor te zorgen dat je niet-opvouwbare zuigslangen van hoge kwaliteit ontvangt. Begin met het bekijken van hun certificeringen, zoals ISO of industriespecifieke normen, die aangeven dat ze voldoen aan de productiekwaliteit. Vraag monsters aan om de duurzaamheid en prestaties van de slang te beoordelen. Vraag ook naar referenties van andere klanten, met name in uw branche, om inzicht te krijgen in hun betrouwbaarheid en service. Tot slot kunt u overwegen om de fabriek van de leverancier te bezoeken als dat mogelijk is, omdat u dan een goed beeld krijgt van hun activiteiten. -

Welke betalingsvoorwaarden worden doorgaans geboden voor internationale bestellingen van afzuigslangen?

De betalingsvoorwaarden voor internationale bestellingen kunnen per leverancier sterk verschillen. Veel voorkomende opties zijn vooruitbetaling, kredietbrieven of betaling bij levering. Sommige leveranciers bieden nettobetalingstermijnen aan, waarbij je een bepaald aantal dagen na ontvangst van de goederen kunt betalen. Informeer altijd naar de betalingsvoorwaarden voordat je een bestelling afrondt en overweeg het gebruik van veilige betalingsmethoden om je investering te beschermen. Onderhandelen over gunstige betalingsvoorwaarden kan ook helpen om de cashflow effectief te beheren. -

Op welke kwaliteitsmaatregelen moet ik letten bij het kopen van afzuigslangen?

Kwaliteitsmaatregelen kunnen de prestaties en levensduur van zuigslangen aanzienlijk beïnvloeden. Ga op zoek naar leveranciers die strenge tests uitvoeren, zoals druktests, flexibiliteitsbeoordelingen en evaluaties van chemische compatibiliteit. Certificeringen van erkende kwaliteitsnormen, zoals ISO 9001, kunnen ook duiden op een streven naar kwaliteit. Vraag ook om documentatie over kwaliteitscontroleprocessen en garantie-informatie om er zeker van te zijn dat u een betrouwbare investering doet. -

Met welke logistieke overwegingen moet ik rekening houden bij het importeren van afzuigslangen?

Houd bij het importeren van niet-opvouwbare zuigslangen rekening met de transportlogistiek, inclusief verzendmethoden en kosten. Beoordeel de doorlooptijden voor productie en levering, aangezien deze van invloed kunnen zijn op de tijdlijnen van uw project. Zorg ervoor dat u op de hoogte bent van de importregels en -tarieven in uw land, die van invloed kunnen zijn op de totale kosten. Samenwerken met een logistieke partner met ervaring in internationale handel kan helpen om het proces te stroomlijnen en mogelijke vertragingen te beperken. -

Kan ik niet-opvouwbare zuigslangen aanpassen voor specifieke toepassingen?

Ja, veel leveranciers bieden aanpassingsopties voor niet-opvouwbare zuigslangen om te voldoen aan specifieke toepassingsvereisten. Aanpassingen kunnen variaties in lengte, diameter, materiaal en fittingen omvatten. Als u uw behoeften met leveranciers bespreekt, moet u duidelijk zijn over de beoogde toepassing, de omgevingsomstandigheden en eventuele specifieke industrienormen. Slangen op maat kunnen de prestaties en efficiëntie verbeteren, dus het is de moeite waard om deze opties te onderzoeken om er zeker van te zijn dat u de beste pasvorm krijgt voor uw operationele behoeften.

Top 6 Niet-opvouwbare Zuigslang Fabrikanten & Leveranciers Lijst

1. Fabrieksslang - Duurzame zuigslangen

Domein: fabrieksdirecthose.com

Geregistreerd: 2004 (21 jaar)

Inleiding: Factory Direct Hose biedt een assortiment duurzame zuigslangen van 1″ tot 12″. Klanten kunnen de slangen per voet, per rol of voorgemonteerd kopen. De slangen zijn geschikt voor water-, chemische en ag-spraytoepassingen. De beschikbare types zijn helder PVC, groen PVC, slangen voor koud weer en rubberen zuigslangen. Opties zijn onder andere assemblages met nokvergrendelingsfittingen of pijpfittingen. Alle producten...

2. FarmChem - Zuigslang voor alle weersomstandigheden

Domein: boerderijchemie.nl

Geregistreerd: 1997 (28 jaar)

Inleiding: {"Productnaam": "1" All Weather afzuigslang", "onderdeelnummer": "ESH1", "Beschikbare lengtes": ["12.5 ft", "25 ft", "50 ft", "100 ft"], "Drukclassificatie": "65 PSI", "Materiaal": "Gegolfd polyethyleen", "Eigenschappen": ["Lichtgewicht", "Flexibel", "Robuust", "Goede chemische bestendigheid", "Uitstekend voor het overbrengen van meststofoplossingen, septische oplossingen, pesticiden", "Lasso® bestendig", "Duurzaam en...

3. McGill slang - Water aanzuig- en afvoerslang

Domein: mcgillhose.com

Geregistreerd: 2000 (25 jaar)

Inleiding: Waterzuig- en afvoerslangen zijn ontworpen voor het overbrengen van water in de bouw, mijnbouw, olie-exploratie, landbouw en materiaalverhuur. Ze zijn meestal gemaakt van een rubberen of PVC-buis versterkt met meerdere lagen stof of draad voor sterkte en duurzaamheid. Zuigslangen zijn stijver om te weerstaan aan bezwijken onder vacuüm, terwijl afvoerslangen flexibeler zijn om...

4. Wastecorp - EPDM Pompslang 2 x 20 ft

Domein: afvalverwerker.nl

Geregistreerd: 1998 (27 jaar)

Inleiding: Niet-oprolbare EPDM (groen/zwart) pompslang voor water en afvalwater, 2″ x 20 ft, compleet met aluminium Deel C & KC camlockfittingen. Professionele zuig- en afvoerslang voor afvalwater, slurry, rioolwater, vuil water met vaste deeltjes en meer toepassingen. Prijs: $212,98 USD. Beschikbaarheid: 2-3 Dagen.

5. Brandslang Direct - Rode 1 x 100′ niet-opvouwbare lichtgewicht slang

Domein: firehosedirect.com

Geregistreerd: 2011 (14 jaar)

Inleiding: Rode 1″ x 100′ niet-opvouwbare lichtgewicht slang (alu 1″ NH-koppelingen)

6. ePumps - Duurzame 2 x 25′ niet-opvouwbare zuigslang

Domein: epumps.nl

Geregistreerd: 2014 (11 jaar)

Inleiding: {"Productnaam": "Durable 2″ x 25′ Non-Collapsible Suction Hose", "SKU": "2x25NC", "Prijs": "$75,00", "Originele prijs": "$105.00", "Materiaal": "Heavy duty non-collapsible PVC", "Specificaties": {"Afmeting": "2" x 25′", "Aansluiting": "2" male NPT by 2″ female NPT"},"Shipping": {"Same Day Shipping": "Ja, voor bestellingen geplaatst voor 15:30 EST op weekdagen", "Gratis verzending": "Op bestellingen van meer dan $250, exclusief...

Strategische Sourcing Conclusie en Vooruitzichten voor niet-inklapbare zuigslang

Aangezien de vraag naar niet-opvouwbare zuigslangen in verschillende industrieën blijft toenemen, is strategische inkoop van cruciaal belang voor succes op de huidige concurrerende wereldmarkt. Door prioriteit te geven aan kwaliteit, veelzijdigheid en betrouwbaarheid, kunnen B2B inkopers ervoor zorgen dat ze investeren in producten die niet alleen voldoen aan onmiddellijke operationele behoeften, maar ook waarde bieden op de lange termijn. Dankzij de diverse beschikbare maten en materialen, waaronder PVC- en rubberopties, kunnen bedrijven hun inkoopstrategieën afstemmen op specifieke toepassingen, of het nu gaat om waterbeheer, chemicaliëntransport of agrarisch gebruik.

Bovendien kan het onderhouden van relaties met gerenommeerde leveranciers de efficiëntie van de toeleveringsketen verbeteren en de doorlooptijden minimaliseren, een belangrijke overweging voor bedrijven die actief zijn in regio's als Afrika, Zuid-Amerika, het Midden-Oosten en Europa. Het is essentieel voor inkopers om marktinzichten en leverancierscapaciteiten te benutten om weloverwogen beslissingen te nemen die aansluiten bij hun operationele doelen.

Vooruitkijkend biedt het wereldwijde landschap voor niet-opvouwbare zuigslangen talloze mogelijkheden voor innovatie en groei. Door strategische inkooppraktijken te omarmen, kunnen internationale inkopers zich positioneren om te profiteren van opkomende trends en eisen, zodat hun activiteiten zijn uitgerust voor de toekomst. Nu is het tijd om in zee te gaan met betrouwbare leveranciers en het enorme potentieel te verkennen dat strategische inkoop voor uw bedrijf kan ontsluiten.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.