Article Contents

Engineering Insight: Vulcanising Rubber

Technical Importance of Vulcanising Rubber in Dredging Hoses for TSHD and CSD Applications

Vulcanisation is a critical chemical process in the manufacturing of high-performance rubber components used in demanding marine environments, particularly in the construction of suction and discharge hoses for Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we apply advanced vulcanisation techniques to ensure our dredging hoses deliver unmatched durability, flexibility, and resistance to abrasion, pressure, and environmental degradation.

The vulcanisation process involves cross-linking polymer chains in raw rubber using sulfur or other curatives under controlled heat and pressure. This transformation enhances the rubber’s mechanical properties, converting a soft, sticky material into a robust, elastic compound capable of withstanding the extreme conditions encountered in dredging operations. For TSHDs and CSDs, where hoses are continuously exposed to abrasive slurries, fluctuating pressures, and dynamic bending, the integrity of the rubber lining is paramount. Improperly vulcanised rubber can lead to premature cracking, delamination, or structural failure—risks that East Marine rigorously mitigates through precision engineering and process control.

Our facility, spanning 0.68 million square meters and staffed by a team of over 150 skilled professionals, integrates state-of-the-art vulcanisation chambers and quality assurance systems to ensure uniform cross-linking throughout every hose layer. This capability allows us to tailor rubber compounds for specific operational demands, whether for deep-sea suction lines on TSHDs or high-pressure discharge hoses on CSDs. The result is a product with superior tensile strength, elongation at break, and resistance to ozone, UV, and seawater—key factors in extending service life and reducing operational downtime.

East Marine’s engineering team leverages finite element analysis (FEA) and real-world performance data to optimise cure times, temperature profiles, and material formulations. This scientific approach ensures that each hose meets or exceeds international standards, including ISO 9001 certification protocols, and performs reliably under cyclic loading and abrasive wear. As a member of WEDA and CEDA, we remain at the forefront of dredging technology, continuously refining our vulcanisation processes to meet evolving industry challenges.

The following table outlines key technical properties achieved through our vulcanisation process in standard dredging hose applications:

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength | ISO 37 | ≥18 MPa |

| Elongation at Break | ISO 37 | ≥450% |

| Hardness (Shore A) | ISO 48-4 | 60–70 |

| Schuurweerstand | ISO 4649 | ≤120 mm³ loss |

| Ozone Resistance | IEC 60068-2-17 | No cracking after 24h @ 50pphm, 40°C |

| Operating Temperature Range | Internal Specification | -20°C to +80°C |

Through rigorous vulcanisation protocols and engineering excellence, East Marine delivers dredging hoses that ensure operational continuity, safety, and cost efficiency for global maritime and dredging clients.

Advanced Manufacturing Process

Precision Vulcanization: Engineering Durability in Dredging Hose Manufacturing

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member since 2007, the vulcanization process represents the critical transformation point where compounded rubber achieves its final, mission-critical properties for dredging suction and discharge hoses. This thermosetting reaction, catalyzed by heat and pressure within precisely controlled autoclaves, crosslinks polymer chains to impart the essential resilience, abrasion resistance, and dimensional stability required to withstand the extreme mechanical stresses, abrasive slurries, and dynamic marine environments inherent in modern dredging operations. Our 0.68M sqm Jiangsu facility leverages 18 dedicated production lines, each integrating advanced vulcanization technology calibrated for specific hose constructions and performance demands.

The process begins with meticulously assembled hose blanks, comprising inner linings, fabric/textile reinforcements, and outer covers, loaded into computer-controlled horizontal or vertical vulcanizing presses. Precise control over time, temperature, and pressure profiles is non-negotiable. Under-vulcanization risks inadequate strength and poor fluid resistance, while over-vulcanization leads to embrittlement and premature failure. East Marine employs real-time monitoring systems tracking core temperature via thermocouples embedded within the hose structure, ensuring the rubber compound reaches and maintains the exact optimal cure state throughout its cross-section. This precision is paramount for hoses operating under high vacuum during suction or承受 significant internal pressure during discharge, where any inconsistency could compromise structural integrity.

Vulcanization parameters are rigorously defined by compound formulation and hose specification, validated through extensive R&D and field performance data. The table below outlines typical critical control ranges for our standard dredging hose vulcanization cycles:

| Parameter | Standard Range | Critical Tolerance | Testing Method |

|---|---|---|---|

| Temperature | 145°C – 165°C | ±2°C | Embedded Thermocouples, Data Loggers |

| Pressure | 1.2 – 1.8 MPa | ±0.1 MPa | Hydraulic/Pneumatic System Sensors |

| Cure Time | 30 – 90 minutes | ±3% of set time | Programmable Logic Controller (PLC) |

| Post-Cure Cooling Rate | ≤ 1.5°C/min | Strictly Controlled | Temperature Ramp Monitoring |

Quality Assurance Framework

This stringent process control is embedded within our ISO 9001 certified quality management system. Every vulcanization cycle undergoes comprehensive documentation and traceability, linking raw material batches, machine parameters, operator logs, and final product test results. Post-vulcanization, hoses undergo rigorous non-destructive testing (NDT) including ultrasonic scanning for internal voids or delamination, followed by hydrostatic pressure testing significantly exceeding operational requirements. Physical properties like tensile strength, elongation at break, and abrasion resistance are verified against ASTM/ISO standards in our in-house laboratory before release. The scale of our 0.68M sqm factory enables not only high-volume throughput across 18 lines but also facilitates continuous process refinement and statistical process control (SPC), ensuring batch-to-batch consistency that dredging contractors rely upon for project continuity and reduced operational downtime. East Marine’s mastery of vulcanization is fundamental to delivering hoses that consistently exceed the demanding lifecycle expectations of the global dredging industry.

Critical Applications

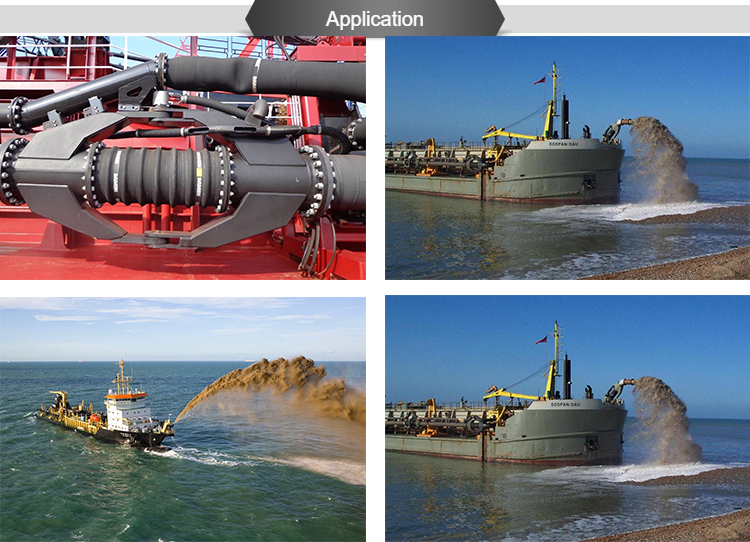

Global Applications of Vulcanised Rubber in Dredging and Marine Infrastructure Projects

Vulcanised rubber plays a pivotal role in the performance and longevity of dredging suction and discharge hoses used in large-scale marine and offshore operations. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, advanced vulcanisation techniques are integral to the production of high-performance rubber hoses designed for extreme operational conditions. This cross-linking process enhances the rubber’s mechanical strength, abrasion resistance, and resilience against temperature fluctuations, making it ideal for deployment in demanding environments such as offshore dredging, oil field operations, and land reclamation projects worldwide.

In dredging operations, particularly in deep-sea and cutter suction dredging, hoses are subjected to constant flexing, high internal pressures, and abrasive slurries containing sand, silt, and gravel. Vulcanised rubber linings and covers ensure structural integrity and extended service life under these harsh conditions. The vulcanisation process creates a durable, seamless bond between rubber layers and reinforcing textiles or steel wire helices, preventing delamination and leakage—critical factors in maintaining operational efficiency and safety.

East Marine’s vulcanised rubber hoses have been deployed in major dredging projects across Asia, the Middle East, and Africa. In land reclamation initiatives such as those in Singapore and the UAE, our hoses facilitate the efficient transfer of millions of cubic meters of sand from seabed to target sites. The resistance of vulcanised rubber to seawater, UV exposure, and microbial degradation ensures reliable performance over extended project timelines. Similarly, in offshore oil and gas fields, these hoses are used for fluid transfer, pipeline cleaning, and subsea intervention tasks, where failure is not an option.

Our membership in CEDA (Central Dredging Association) and WEDA (Western Dredging Association) underscores our commitment to industry standards and innovation in dredging technology. These affiliations enable East Marine to collaborate with leading engineering firms and contractors, ensuring our products meet the evolving technical and environmental requirements of global marine projects.

The integration of precision vulcanisation in our manufacturing process—conducted in a 0.68 million square meter state-of-the-art facility—ensures consistency, quality, and compliance with ISO 9001 standards. Each hose undergoes rigorous testing post-vulcanisation to validate pressure ratings, elongation limits, and adhesion strength.

Below is a summary of key technical specifications for our standard dredging hose series:

| Parameter | Value/Range |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar |

| Temperatuurbereik | -20°C to +85°C |

| Abrasion Resistance (DIN) | ≤ 100 mm³ (ISO 4649) |

| Elongation at Break | ≥ 350% |

| Adhesion Strength (Rubber-Textile) | ≥ 12 kN/m |

| Standards Compliance | ISO 1431, ISO 1817, ISO 8033 |

East Marine continues to support global infrastructure development through engineered rubber solutions where performance, durability, and reliability are non-negotiable. Vulcanised rubber remains at the core of this mission, enabling efficient and sustainable marine operations across continents.

Technical Data & Specs

Technical Excellence in Dredging Hose Performance Through Precision Vulcanization

Vulcanization remains the cornerstone of high-performance dredging rubber hose manufacturing, directly influencing critical operational parameters like pressure integrity, flexibility, and service life in abrasive marine environments. At East Marine, leveraging our 0.68 million square meter ISO 9001-certified facility and 17 years of specialized expertise since 2007, we implement a rigorously controlled multi-stage vulcanization process. This advanced methodology optimizes cross-link density within the rubber compound, ensuring superior molecular bonding that translates directly into enhanced mechanical properties. Unlike standard industry practices, our process incorporates real-time pressure and temperature profiling during curing, minimizing internal stresses and voids. This precision engineering is essential for dredging hoses subjected to continuous high-pressure slurry flow, dynamic bending, and abrasive wear, where material failure can lead to costly downtime and environmental risks. The resulting product exhibits exceptional resistance to internal friction, fatigue cracking, and permeation, forming the foundation for our industry-leading technical specifications.

Our commitment to material science innovation delivers measurable advantages in core performance metrics compared to conventional dredging hoses. The following table details comparative specifications for standard Suction/Discharge hoses used in cutter suction dredgers and trailing suction hopper dredgers. Data reflects typical offerings for a nominal 400mm (16″) inner diameter hose, constructed with high-abrasion-resistant synthetic rubber and high-tensile textile reinforcement, adhering to WEDA/CEDA best practices.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Minimum Bending Radius (m) |

|---|---|---|---|

| East Marine Standard | 14.0 | 56.0 | 3.2 |

| Industry Standard | 10.0 | 40.0 | 4.8 |

| Premium Competitor | 12.0 | 48.0 | 4.0 |

The significance of these specifications is paramount in demanding dredging operations. East Marine’s hoses achieve a 40% higher working pressure rating and a 40% tighter bending radius compared to the industry standard, without compromising the critical 4:1 safety factor between working and burst pressure. This combination is not coincidental; it is a direct result of our optimized vulcanization process enhancing the rubber-to-cord adhesion and the cohesive strength of the cover and tube compounds. The reduced bending radius (8x ID vs. 12x ID for standard hoses) provides substantial operational flexibility, allowing for tighter turns in congested dredge field layouts and reducing pipeline drag forces. Simultaneously, the elevated working pressure enables higher slurry velocities and throughput rates, directly increasing dredging efficiency. Crucially, our vulcanization control minimizes permanent set after bending, ensuring the hose reliably returns to its original profile, preventing kinking and flow restriction during dynamic operations.

These technical differentiators stem from East Marine’s vertical integration and process mastery within our Jiangsu Huashen facility. As active WEDA/CEDA members, we understand that dredging contractors require hoses that maximize uptime and minimize lifecycle costs in harsh conditions. Our vulcanization protocols ensure consistent performance across the entire hose structure, from the abrasion-resistant inner tube to the oil- and weather-resistant cover. The result is a dredging hose that delivers superior pressure handling, exceptional flexibility for maneuverability, and extended service life against the relentless wear of sand, gravel, and high-velocity slurries. This technical superiority translates directly into reduced operational risk and enhanced project profitability for our global dredging partners.

Partner with East Marine

Conclusion: Precision Vulcanisation for Unmatched Dredging Performance

In the demanding world of hydraulic dredging, the integrity and longevity of suction and discharge hoses are directly tied to the quality of the vulcanisation process. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we apply advanced vulcanising rubber technology to ensure every dredging hose we manufacture delivers optimal mechanical strength, abrasion resistance, and structural stability under extreme operational conditions. Our in-house expertise in rubber compounding and thermal curing allows us to tailor hose performance to specific dredging environments—whether operating in high-pressure offshore applications or navigating abrasive sediment in inland waterways.

Vulcanisation is not merely a production step; it is a science that determines the cross-link density of rubber polymers, directly influencing elasticity, durability, and resistance to environmental degradation. Our ISO9001-certified manufacturing facility, spanning 0.68 million square meters, employs computer-controlled autoclaves and real-time monitoring systems to achieve uniform cure profiles across every hose layer. This precision engineering ensures consistent product quality, minimising field failures and maximising uptime for dredging contractors worldwide.

As active members of WEDA and CEDA, we stay at the forefront of industry standards and technological advancements, enabling us to provide hoses that meet the evolving needs of modern dredging operations. Our commitment to innovation is matched by our dedication to customer support, with technical teams available to assist in product selection, installation guidance, and lifecycle optimisation.

Technical Specifications of Vulcanised Dredging Hoses

| Parameter | Specificatie |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 40 bar) |

| Temperatuurbereik | -20°C to +85°C (special compounds up to +120°C) |

| Cover Resistance | Abrasion, UV, Ozone, Seawater |

| Liner Material | SBR/NR/CR Blends (wear-resistant compounds) |

| Reinforcement Layers | High-Tensile Textile + Spiral Steel Wire |

| Standards Compliance | ISO 1431, ISO 1817, EN 12116 |

| Minimum Bend Radius | 8–12 x Nominal Diameter |

| Service Life (typical) | 5–8 years (site-dependent) |

With a global footprint that includes a strategic branch in Singapore, East Marine provides responsive logistics, technical service, and inventory support across Asia, Africa, the Middle East, and beyond. Our Singapore operations serve as a regional hub for project coordination, quality assurance, and rapid deployment of custom hose systems.

For engineering inquiries, project quotations, or technical collaboration, contact our team directly. We are ready to support your next dredging project with vulcanised rubber solutions built to last.

WhatsApp: +86-13806109365

Email: hsdredging@eastmarine.tech

Partner with East Marine—where industrial precision meets marine resilience.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.