Introduction: Navigating the Global Market for slijtvaste slangen

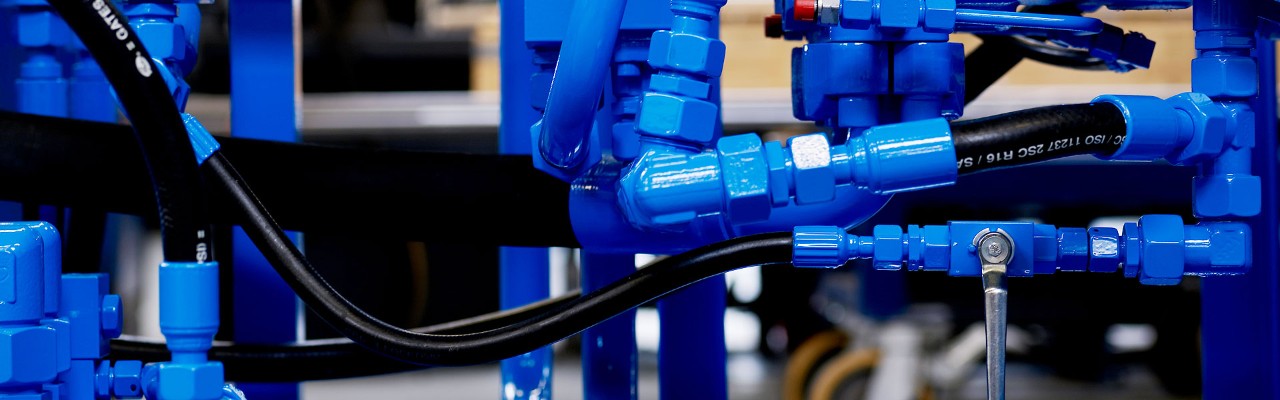

In today’s competitive landscape, sourcing high-quality slijtvaste slangen (abrasion-resistant hoses) poses a significant challenge for B2B buyers, especially those in industries handling abrasive materials. With applications ranging from construction to agricultural transport, understanding the nuances of different hose types—such as bulkslangen, gierslangen, and granulaatslangen—becomes crucial. This comprehensive guide delves into the diverse applications, material specifications, and performance characteristics of slijtvaste slangen, enabling buyers to make informed decisions tailored to their operational needs.

As international markets expand, particularly across Africa, South America, the Middle East, and Europe, the demand for reliable suppliers and cost-effective solutions has surged. This guide not only outlines the various types of abrasion-resistant hoses available but also provides actionable insights on supplier vetting processes, pricing structures, and the latest industry trends. By equipping buyers with the necessary knowledge and tools, this resource empowers businesses to navigate the complexities of the global market confidently.

Whether you are involved in transporting dry cement, sand, or other abrasive materials, understanding the performance metrics and application suitability of slijtvaste slangen will enhance your procurement strategy. Ultimately, this guide serves as a vital resource for B2B buyers seeking to optimize their supply chains and ensure operational efficiency in their respective industries.

Spis treści

- Top 9 Slijtvaste Slangen Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for slijtvaste slangen

- Understanding slijtvaste slangen Types and Variations

- Key Industrial Applications of slijtvaste slangen

- 3 Common User Pain Points for ‘slijtvaste slangen’ & Their Solutions

- Strategic Material Selection Guide for slijtvaste slangen

- In-depth Look: Manufacturing Processes and Quality Assurance for slijtvaste slangen

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘slijtvaste slangen’

- Comprehensive Cost and Pricing Analysis for slijtvaste slangen Sourcing

- Alternatives Analysis: Comparing slijtvaste slangen With Other Solutions

- Essential Technical Properties and Trade Terminology for slijtvaste slangen

- Navigating Market Dynamics and Sourcing Trends in the slijtvaste slangen Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of slijtvaste slangen

- Strategic Sourcing Conclusion and Outlook for slijtvaste slangen

- Ważne zastrzeżenia i warunki użytkowania

Understanding slijtvaste slangen Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Slijtvaste Bulkslangen | Designed for high-volume transport of abrasive bulk materials | Transporting animal feed, dry powders, and granules | Plusy: Versatile applications; Wady: Requires specific fittings for optimal performance. |

| Slijtvaste Gierslangen | Made from durable PVC or rubber; suitable for liquid and slurry | Manure injection, slurry transport | Plusy: Highly flexible; Wady: Material choice impacts longevity. |

| Slijtvaste Granulaatslangen | Specialized for transporting granular materials | Conveying sand, gravel, and other abrasive particles | Plusy: Excellent wear resistance; Wady: May not be suitable for liquids. |

| Slijtvaste Cement Slangen | High-pressure capability; resistant to abrasion from cement | Construction, plastering applications | Plusy: Long service life under pressure; Wady: Heavier than standard hoses. |

| Slijtvaste Sandblast Slangen | Designed for high-speed sandblasting; anti-static properties | Industrial sandblasting and surface preparation | Plusy: Efficient material transfer; Wady: Requires regular maintenance to prevent wear. |

What Are the Key Characteristics of Slijtvaste Bulkslangen?

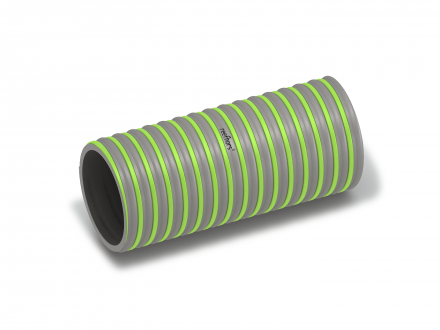

Slijtvaste bulkslangen are engineered to manage the transport of a variety of abrasive bulk materials, including animal feed and dry powders. Their robust construction allows for the efficient movement of materials under pressure, making them suitable for pneumatic conveying systems. When considering a purchase, buyers should evaluate the hose’s compatibility with specific materials and the required fittings to ensure optimal performance.

How Do Slijtvaste Gierslangen Perform in Various Applications?

Slijtvaste gierslangen are primarily crafted from durable PVC or rubber, offering flexibility for handling both liquid and slurry applications. These hoses are commonly used in agricultural settings for manure injection and other slurry transport needs. When purchasing, it is vital for buyers to consider the specific material requirements for their application, as the choice of PVC or rubber can significantly impact the hose’s lifespan and performance.

Why Are Slijtvaste Granulaatslangen Essential for Construction?

Slijtvaste granulaatslangen are specifically designed for the transportation of granular materials, such as sand and gravel. Their construction includes abrasion-resistant materials that can withstand the wear and tear associated with transporting these harsh substances. Buyers should assess the hose’s diameter and pressure rating to ensure it meets the demands of their operational environment, particularly in construction sites where durability is paramount.

What Advantages Do Slijtvaste Cement Slangen Offer?

These hoses are built to handle high-pressure applications and are particularly resistant to abrasion from cement and similar materials. Slijtvaste cement slangen are crucial in construction and plastering tasks, where efficient material transfer is necessary. Buyers should consider the hose’s pressure rating and flexibility, as heavier hoses may be more durable but can also complicate handling and installation.

How Do Slijtvaste Sandblast Slangen Enhance Industrial Efficiency?

Slijtvaste sandblast slangen are engineered for high-speed applications, particularly in sandblasting and surface preparation tasks. Their anti-static properties help prevent the buildup of static electricity, enhancing safety during operations. When procuring these hoses, buyers should evaluate the required maintenance and wear characteristics, as regular checks can help maintain efficiency and extend the hose’s service life.

Key Industrial Applications of slijtvaste slangen

| Przemysł/sektor | Specific Application of slijtvaste slangen | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Budowa | Transporting concrete and plaster mixtures | Ensures efficient material delivery, reducing downtime | Durability, pressure ratings, and flexibility are critical. |

| Rolnictwo | Conveying bulk animal feed and fertilizers | Supports high-volume transport, enhancing productivity | Material compatibility and resistance to abrasion are essential. |

| Mining and Quarrying | Handling abrasive materials like sand and gravel | Minimizes wear and tear, lowering maintenance costs | Sourcing hoses that can withstand harsh environments is crucial. |

| Przetwarzanie chemiczne | Transporting corrosive or abrasive chemicals | Ensures safety and integrity of the materials handled | Chemical compatibility and resistance to extreme temperatures are vital. |

| Zarządzanie odpadami | Suction and discharge of sludge and waste materials | Improves operational efficiency and reduces spill risks | Sourcing hoses with high tensile strength and abrasion resistance is important. |

How Are Slijtvaste Slangen Used in Construction Applications?

In the construction industry, slijtvaste slangen are vital for transporting concrete and plaster mixtures. These hoses facilitate the efficient delivery of materials to various points on a job site, significantly reducing downtime and labor costs. Buyers must consider the hose’s durability and pressure ratings, as they must withstand the rigors of construction environments while maintaining flexibility for easy maneuverability.

What Role Do Slijtvaste Slangen Play in Agriculture?

Agriculture relies on slijtvaste slangen for the effective conveyance of bulk animal feed and fertilizers. These hoses enable high-volume transport, which is essential for maintaining productivity during planting and harvesting seasons. When sourcing these hoses, buyers should prioritize material compatibility and abrasion resistance to ensure longevity and reliability in various agricultural settings.

How Are Slijtvaste Slangen Essential for Mining and Quarrying?

In mining and quarrying, slijtvaste slangen are utilized to handle abrasive materials such as sand and gravel. Their resistance to wear minimizes maintenance costs and downtime, leading to increased efficiency in material handling operations. Buyers should focus on sourcing hoses that can endure harsh conditions and provide consistent performance over time, ensuring they meet the specific demands of the mining industry.

Why Are Slijtvaste Slangen Critical in Chemical Processing?

In the chemical processing sector, slijtvaste slangen are crucial for transporting corrosive or abrasive chemicals safely. These hoses ensure the integrity of the materials being handled while preventing leaks and spills that could pose safety risks. Buyers must ensure that the hoses they source are chemically compatible and capable of withstanding extreme temperatures to maintain operational safety and efficiency.

How Do Slijtvaste Slangen Enhance Waste Management Efforts?

Slijtvaste slangen are instrumental in waste management for suction and discharge applications involving sludge and other waste materials. Their robust construction improves operational efficiency and minimizes the risk of spills, which can be hazardous. When sourcing these hoses, businesses should prioritize high tensile strength and abrasion resistance to ensure they can effectively handle the demanding tasks associated with waste management.

3 Common User Pain Points for ‘slijtvaste slangen’ & Their Solutions

Scenario 1: High Wear Rates Leading to Downtime

Problem:

B2B buyers often face significant challenges with high wear rates of ‘slijtvaste slangen’ (abrasion-resistant hoses) used in industries such as construction and bulk material transport. The abrasive materials these hoses handle—like cement, sand, and granulates—can quickly degrade the hose, leading to frequent replacements and unexpected downtime. This not only disrupts operations but also inflates maintenance costs and affects overall productivity, creating frustration for procurement managers who need to balance quality with cost-effectiveness.

Rozwiązanie:

To mitigate wear and prolong the life of abrasion-resistant hoses, buyers should focus on selecting the right materials and specifications for their specific applications. It’s essential to analyze the type of abrasive materials being transported and the operating conditions, including pressure and temperature. For example, hoses made from synthetic rubber compounds designed for high abrasion resistance can significantly reduce wear rates.

Additionally, implementing a proactive maintenance schedule that includes regular inspections for signs of wear and tear can prevent sudden failures. Buyers should also consider suppliers that offer hoses with advanced reinforcement features, such as high-tensile textile cords, which enhance durability. Finally, investing in training for operational staff on proper hose handling and installation techniques can further minimize wear and extend the lifespan of the hoses.

Illustrative image related to slijtvaste slangen

Scenario 2: Incompatibility with Existing Systems

Problem:

Another common pain point for B2B buyers is the incompatibility of ‘slijtvaste slangen’ with existing systems or machinery. This issue often arises when companies expand their operations or switch to different types of abrasive materials. For instance, a construction firm might discover that their current hoses cannot handle the increased pressure or abrasive nature of new materials, leading to inefficiencies and increased operational risks.

Rozwiązanie:

To address compatibility issues, it is critical for buyers to perform a comprehensive assessment of their current systems before procuring new hoses. This includes reviewing pressure ratings, temperature ranges, and the chemical properties of both the hose material and the abrasive substances being transported. Engaging with suppliers who provide detailed specifications and consultation can help in selecting the right hoses that meet the operational demands.

Furthermore, buyers should consider modular hose systems that allow for easy integration with existing equipment. These systems can be customized to adapt to various applications and materials, reducing the risk of future incompatibility. Regular communication with suppliers to stay updated on new hose technologies and materials can also facilitate smoother transitions and upgrades.

Scenario 3: Limited Supplier Options and Quality Assurance

Problem:

B2B buyers frequently encounter a limited selection of suppliers offering ‘slijtvaste slangen’ that meet their quality and compliance standards. This can lead to challenges in ensuring consistent product quality, which is crucial in sectors where safety and reliability are paramount. When suppliers fail to provide high-quality hoses, it can lead to increased downtime, safety hazards, and financial losses.

Rozwiązanie:

To overcome the limitations of supplier options, buyers should prioritize building relationships with multiple trusted suppliers who specialize in abrasion-resistant hoses. This not only increases the chances of finding high-quality products but also allows for competitive pricing. Buyers should conduct thorough due diligence by evaluating supplier certifications, product testing results, and customer reviews.

Establishing a quality assurance protocol that includes testing hoses under real operating conditions can further ensure that the selected products meet the required standards. Additionally, participating in industry forums and trade shows can help buyers discover innovative suppliers and new technologies, expanding their options and ensuring access to the best products available. Regularly reviewing supplier performance and maintaining open lines of communication will also foster long-term partnerships that enhance product reliability and service quality.

Strategic Material Selection Guide for slijtvaste slangen

When selecting materials for slijtvaste slangen (abrasion-resistant hoses), understanding the properties, advantages, and limitations of different materials is crucial for B2B buyers. This section explores four common materials used in the manufacturing of these hoses: natural rubber, synthetic rubber, PVC, and polyurethane. Each material has distinct characteristics that influence its performance in various applications.

What Are the Key Properties of Natural Rubber for Slijtvaste Slangen?

Natural rubber is renowned for its exceptional elasticity and abrasion resistance. It typically offers a temperature range of -40°C to +70°C and can withstand pressures up to 10.5 bar. Its natural composition provides excellent flexibility, making it suitable for applications requiring tight bends or curves.

Pros and Cons: Natural rubber hoses are durable and provide a long service life, particularly in environments with abrasive materials like sand or cement. However, they have limited resistance to chemicals and UV exposure, which can lead to degradation over time. Additionally, sourcing natural rubber can be more expensive compared to synthetic alternatives.

Illustrative image related to slijtvaste slangen

Wpływ na aplikację: Natural rubber is ideal for transporting abrasive materials in construction and mining industries, where flexibility and durability are paramount. Buyers should consider the local climate and potential exposure to chemicals when selecting this material.

How Does Synthetic Rubber Compare in Performance?

Synthetic rubber, such as SBR (Styrene-Butadiene Rubber) and NR (Natural Rubber), is often engineered to enhance specific properties. It typically offers similar temperature and pressure ratings as natural rubber but with improved chemical resistance and UV stability.

Pros and Cons: The versatility of synthetic rubber allows for customization based on specific application needs, making it a popular choice among manufacturers. However, it may not match the natural elasticity of rubber, which can be a drawback in applications requiring extreme flexibility.

Illustrative image related to slijtvaste slangen

Wpływ na aplikację: Synthetic rubber is well-suited for environments where exposure to chemicals is a concern, such as in the oil and gas industry. B2B buyers should assess the chemical compatibility of synthetic rubber with the materials being transported to ensure optimal performance.

What Role Does PVC Play in Slijtvaste Slangen?

PVC (Polyvinyl Chloride) is a cost-effective option for slijtvaste slangen, particularly in less demanding applications. It is lightweight and can handle a temperature range of -10°C to +60°C, with pressure ratings varying by formulation.

Pros and Cons: PVC hoses are generally more affordable than rubber alternatives and are resistant to certain chemicals. However, they lack the flexibility and abrasion resistance of rubber, which can limit their use in high-stress applications.

Illustrative image related to slijtvaste slangen

Wpływ na aplikację: PVC is commonly used for transporting bulk materials like powders and granules in agricultural and industrial settings. Buyers should evaluate the specific requirements of their applications to determine if PVC meets their needs.

Why Choose Polyurethane for Slijtvaste Slangen?

Polyurethane is gaining popularity due to its superior abrasion resistance and flexibility. It can operate effectively in a temperature range of -40°C to +80°C and can handle high-pressure applications, making it suitable for demanding environments.

Pros and Cons: The primary advantage of polyurethane is its durability, which extends the lifespan of hoses in abrasive applications. However, it can be more expensive than other materials, and its manufacturing process may be more complex.

Wpływ na aplikację: Polyurethane hoses are ideal for applications involving high wear, such as sandblasting or transporting abrasive materials in construction. B2B buyers should consider the long-term cost benefits of investing in durable polyurethane hoses.

Summary Table of Material Selection for Slijtvaste Slangen

| Materiał | Typical Use Case for slijtvaste slangen | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Natural Rubber | Transporting abrasive materials in construction | High elasticity and abrasion resistance | Limited chemical and UV resistance | Wysoki |

| Synthetic Rubber | Oil and gas applications | Enhanced chemical resistance | Less elasticity compared to natural rubber | Średni |

| PVC | Bulk material transport in agriculture | Ekonomiczny i lekki | Lower flexibility and abrasion resistance | Niski |

| Poliuretan | Sandblasting and high-wear applications | Superior durability and flexibility | Higher cost and complex manufacturing | Wysoki |

This guide provides B2B buyers with essential insights into material selection for slijtvaste slangen, enabling informed decisions that align with their operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for slijtvaste slangen

What Are the Key Stages in the Manufacturing Process of Slijtvaste Slangen?

The manufacturing of slijtvaste slangen, or abrasion-resistant hoses, involves a series of well-defined stages that ensure the final product meets the rigorous demands of various industries. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Manufacturing Slijtvaste Slangen?

The process begins with the selection of high-quality raw materials. Typically, synthetic rubbers and thermoplastics are chosen for their durability and resistance to abrasion. These materials are often compounded with additives to enhance properties such as flexibility, heat resistance, and anti-static characteristics. During this phase, the raw materials undergo thorough testing to verify their specifications, ensuring they meet predefined standards.

What Techniques Are Used in Forming Slijtvaste Slangen?

Forming is a critical stage in the manufacturing process where the prepared materials are shaped into hoses. Techniques such as extrusion and molding are commonly employed.

-

Extrusion: In this method, the rubber compound is forced through a die to create a continuous hose profile. This allows for precise control over the inner diameter and wall thickness, which are vital for the hose’s performance in transporting abrasive materials.

-

Molding: For specialized shapes or fittings, molding techniques are utilized. This may include the use of heat and pressure to form the hose into specific configurations that are required for particular applications.

How Is Assembly Performed for Slijtvaste Slangen?

Once the hoses are formed, the assembly process involves incorporating reinforcements. High-tensile textile cords or steel wire are often integrated into the hose to enhance strength and pressure resistance. This reinforcement is crucial for applications that involve high-pressure conditions or require flexibility during use.

Quality checks are conducted at this stage to ensure that the assembly aligns with technical specifications.

What Finishing Techniques Are Applied to Slijtvaste Slangen?

Finishing treatments are applied to enhance the durability and functionality of the hoses. This may include:

-

Surface Treatments: The outer surface of the hose can be treated to improve its resistance to environmental factors such as ozone and UV exposure, which is particularly important for outdoor applications.

-

Marking and Branding: Appropriate labeling is crucial for identification and compliance with international standards. Marking the hoses with relevant specifications aids in compliance checks and facilitates traceability.

What Quality Assurance Standards Are Relevant for Slijtvaste Slangen?

Quality assurance (QA) is paramount in the manufacturing of slijtvaste slangen. Adhering to international standards such as ISO 9001 ensures that manufacturing processes are consistently monitored and controlled to maintain quality.

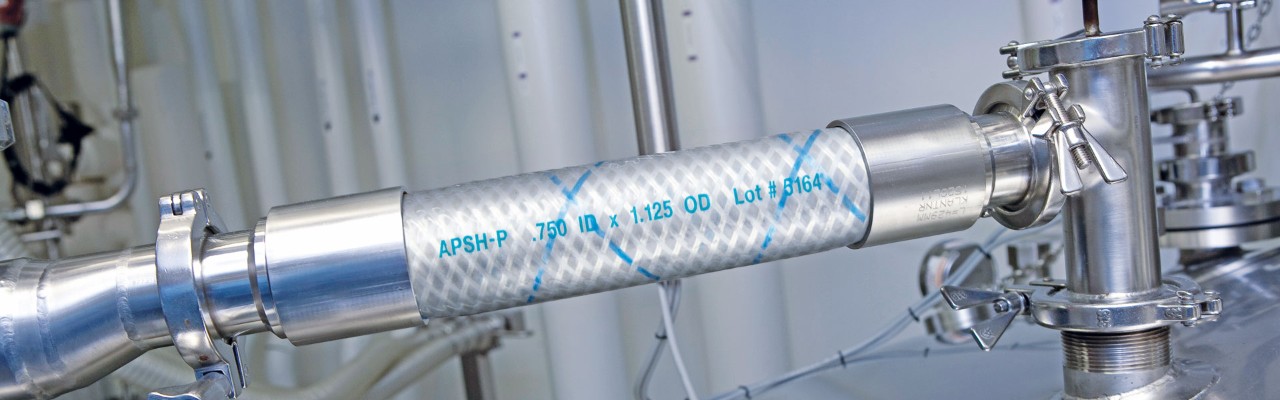

Industry-specific standards like CE marking in Europe, API for petroleum applications, and other local regulations may also apply, depending on the intended use of the hoses. These certifications not only guarantee the quality of the hoses but also enhance the credibility of suppliers in the eyes of international buyers.

What Are the Key QC Checkpoints in the Manufacturing Process of Slijtvaste Slangen?

Quality Control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that defects are identified and rectified promptly.

-

Przychodząca kontrola jakości (IQC): This is the first checkpoint where raw materials are inspected for quality and compliance with specifications before production begins.

-

Kontrola jakości w trakcie procesu (IPQC): During manufacturing, random samples are tested to monitor ongoing production quality. This includes checking for dimensional accuracy and material properties.

-

Końcowa kontrola jakości (FQC): Once the hoses are completed, they undergo rigorous testing for pressure tolerance, abrasion resistance, and flexibility. This stage often includes performance tests simulating actual operating conditions.

What Common Testing Methods Are Employed for Slijtvaste Slangen?

Several testing methods are employed to ensure the hoses can withstand the demands of their intended applications:

-

Abrasion Testing: This measures the hose’s ability to resist wear when exposed to abrasive materials.

-

Pressure Testing: Hoses are subjected to high-pressure conditions to verify their integrity and performance under stress.

-

Temperature Testing: This assesses the hose’s performance at extreme temperatures, ensuring it can operate effectively in various environments.

W jaki sposób nabywcy B2B mogą weryfikować praktyki kontroli jakości dostawców?

B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, must ensure that their suppliers adhere to stringent quality control practices. Here are several strategies for verification:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational integrity of the supplier.

-

Requesting Quality Reports: Buyers should request documentation of quality control processes, including test results, certifications, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers should be aware of regional differences in quality standards and regulations. For instance, European buyers may prioritize CE certification, while those in the Middle East might focus on local compliance standards. Understanding these nuances helps buyers make informed decisions and ensures that the products they source meet their specific regulatory requirements.

In conclusion, the manufacturing processes and quality assurance practices for slijtvaste slangen are complex yet vital for ensuring product reliability and performance. By understanding these processes and leveraging effective verification strategies, B2B buyers can make informed purchasing decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slijtvaste slangen’

Wprowadzenie

Sourcing ‘slijtvaste slangen’ (abrasion-resistant hoses) effectively is vital for industries that require reliable transport of abrasive materials, such as construction and agriculture. This guide provides a structured checklist to assist international B2B buyers in making informed decisions when procuring these essential components. Following these steps ensures that you select the right products and suppliers to meet your operational needs.

Krok 1: Zdefiniuj swoje specyfikacje techniczne

Before initiating the sourcing process, clearly outline the technical specifications required for your application. Consider factors such as the type of materials to be transported, pressure ratings, temperature ranges, and compatibility with your existing systems.

– Materiały: Identify if you need hoses made of rubber, PVC, or a blend, based on the abrasiveness of the materials.

– Wydajność: Specify the required pressure ratings and temperature limits to ensure durability and safety.

Krok 2: Badanie potencjalnych dostawców

Start by conducting comprehensive research to identify potential suppliers. Look for manufacturers and distributors known for their expertise in ‘slijtvaste slangen’.

– Market Reputation: Check online reviews, industry forums, and trade publications to gauge supplier reliability.

– Geographical Considerations: Prioritize suppliers within your region to minimize shipping costs and lead times, especially if sourcing from Africa, South America, or the Middle East.

Krok 3: Ocena certyfikatów dostawców

Verify the certifications and compliance standards of potential suppliers. This is crucial as it ensures the products meet international quality and safety standards.

– ISO Certification: Look for suppliers with ISO certifications, which indicate adherence to quality management systems.

– Product Standards: Ensure that their products comply with relevant industry standards, such as ASTM or EN, depending on your region.

Krok 4: Zamów próbki i przeprowadź testy

Before finalizing your order, request samples of the hoses you are interested in. Testing these samples in your operational environment is essential to evaluate performance.

– Durability Testing: Assess how well the hose withstands the abrasiveness of the materials it will handle.

– Compatibility Testing: Ensure the hose integrates smoothly with your existing equipment without leaks or malfunctions.

Krok 5: Review Pricing and Payment Terms

Once you have identified suitable suppliers, review their pricing structures and payment terms. It’s important to balance cost with quality to ensure long-term value.

– Bulk Discounts: Inquire about volume discounts or long-term contracts that could reduce costs.

– Payment Flexibility: Look for suppliers that offer favorable payment terms, such as deferred payment options or financing solutions.

Krok 6: Negotiate Delivery and Lead Times

Discuss delivery schedules and lead times with your chosen supplier. Understanding these factors upfront helps in planning your operations and avoiding disruptions.

– Delivery Methods: Confirm the shipping options available and choose one that aligns with your urgency and budget.

– Lead Time Guarantees: Ensure the supplier provides clear lead time commitments to avoid unexpected delays.

Krok 7: Establish a Long-Term Relationship

Once you have successfully sourced your ‘slijtvaste slangen’, aim to establish a long-term relationship with your supplier. This can lead to better pricing, improved service, and priority support.

– Communication: Maintain open lines of communication for feedback and assistance.

– Continuous Assessment: Regularly evaluate the supplier’s performance to ensure they continue to meet your needs as your operations evolve.

Following this checklist will empower you to make informed decisions and optimize your procurement process for abrasion-resistant hoses, ultimately contributing to the efficiency and success of your operations.

Comprehensive Cost and Pricing Analysis for slijtvaste slangen Sourcing

What Are the Key Cost Components in Sourcing Slijtvaste Slangen?

When sourcing slijtvaste slangen (abrasion-resistant hoses), understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materiały: The choice of materials significantly impacts pricing. High-quality synthetic rubbers and textiles are commonly used for durability, which may increase initial costs but reduce long-term expenses due to lower replacement rates.

-

Praca: Labor costs vary depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can affect the quality and consistency of the products.

-

Koszty ogólne produkcji: This includes costs related to facility maintenance, utilities, and indirect labor. Efficient production processes can help mitigate these costs, resulting in more competitive pricing for buyers.

-

Oprzyrządowanie: Customization of hoses often requires specialized tooling, which can add to the upfront costs. Buyers should consider whether the investment in tooling will lead to cost savings in bulk orders.

-

Kontrola jakości (QC): Implementing robust QC processes ensures that products meet specified standards, which can incur additional costs. However, this investment can prevent costly returns and enhance customer satisfaction.

-

Logistyka: Shipping and handling costs can vary significantly based on the supplier’s location and the destination. Buyers should be aware of potential tariffs, duties, and transport fees that could affect overall costs.

-

Margines: Suppliers typically include a margin to cover their expenses and profit. Understanding the margin expectations can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Slijtvaste Slangen?

Several factors influence the pricing of slijtvaste slangen, making it essential for buyers to consider the following:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for larger orders. Buyers should assess their needs and negotiate terms that allow for bulk purchasing without overcommitting.

-

Specyfikacje i personalizacja: Customized solutions may lead to higher costs due to the need for specialized materials or manufacturing processes. Buyers should clearly define their requirements to avoid unnecessary expenditures.

-

Materiały: The type of materials selected, such as various grades of rubber or textile reinforcements, will impact the price. Premium materials may offer better performance and longevity, justifying the higher initial costs.

-

Jakość i certyfikaty: Products that meet specific industry standards or certifications may come at a premium. However, these certifications can enhance reliability and safety, reducing the likelihood of costly failures.

-

Czynniki dostawcy: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may charge more, but they often provide better quality assurance and service.

-

Incoterms: The choice of Incoterms can significantly affect the total landed cost. Understanding the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) is crucial for accurate budgeting.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing Slijtvaste Slangen?

To maximize value when sourcing slijtvaste slangen, B2B buyers should consider the following strategies:

-

Negocjacje: Always engage in negotiations with suppliers. Leverage volume commitments or long-term contracts to secure better pricing and terms.

-

Całkowity koszt posiadania (TCO): Evaluate the TCO rather than just the initial purchase price. Consider factors like durability, maintenance, and potential downtime costs to determine the most economical option over time.

-

Niuanse cenowe dla międzynarodowych nabywców: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, regional tariffs, and trade agreements that can affect pricing.

-

Research and Comparison: Conduct thorough market research and compare multiple suppliers. Look beyond the price to assess the quality, service, and reliability of each option.

-

Budowanie relacji z dostawcami: Establishing strong relationships can lead to better terms, priority service, and insights into market trends that can benefit future sourcing decisions.

Wnioski

Understanding the cost structure and pricing influencers for slijtvaste slangen is vital for international B2B buyers seeking to make informed purchasing decisions. By considering the various cost components, engaging in strategic negotiations, and focusing on total cost efficiency, businesses can optimize their sourcing strategies and achieve better outcomes. Always remember that indicative prices may fluctuate based on market conditions, so staying informed is key to successful procurement.

Alternatives Analysis: Comparing slijtvaste slangen With Other Solutions

In today’s competitive industrial landscape, selecting the right material handling solution is crucial for maximizing efficiency and minimizing operational costs. Slijtvaste slangen, or abrasion-resistant hoses, are a popular choice for transporting abrasive materials, but it’s essential to consider alternatives that may better suit specific applications. This section provides a comparative analysis of slijtvaste slangen against two viable alternatives: metal piping systems and reinforced PVC hoses.

Illustrative image related to slijtvaste slangen

| Aspekt porównawczy | Slijtvaste Slangen | Metal Piping Systems | Reinforced PVC Hoses |

|---|---|---|---|

| Wydajność | Highly durable, suitable for abrasives | Excellent for high-pressure applications | Moderate durability, suitable for light to moderate abrasives |

| Koszt | Moderate initial investment | High initial costs and installation | Low initial costs, but frequent replacements may increase total cost |

| Łatwość wdrożenia | Requires proper fittings and installation | Complex installation, may need professional services | Simple installation, often DIY-friendly |

| Konserwacja | Low maintenance, high lifespan | Requires regular inspections and maintenance | Moderate maintenance; susceptible to wear and tear |

| Najlepszy przypadek użycia | Heavy-duty applications in construction and mining | High-pressure systems in industrial settings | Lightweight applications in agriculture and light construction |

What Are the Advantages and Disadvantages of Metal Piping Systems Compared to Slijtvaste Slangen?

Metal piping systems are known for their strength and ability to handle high-pressure applications. They are ideal for industries requiring robust solutions, such as oil and gas or chemical processing. However, the high costs associated with installation and maintenance can be prohibitive for many businesses. Additionally, metal pipes can corrode over time, especially in harsh environments, leading to potential leaks and safety hazards.

How Do Reinforced PVC Hoses Stack Up Against Slijtvaste Slangen?

Reinforced PVC hoses are a cost-effective alternative, especially for lighter applications. They are easier to install and handle, making them suitable for agricultural uses or light construction tasks. However, their durability is lower than that of slijtvaste slangen, especially when handling highly abrasive materials. Businesses may find themselves replacing PVC hoses more frequently, which can offset the initial cost savings.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between slijtvaste slangen and alternatives like metal piping systems or reinforced PVC hoses, B2B buyers should assess several factors, including the specific materials to be transported, the operational environment, and budget constraints. For heavy-duty applications involving abrasive materials, slijtvaste slangen typically offer the best balance of durability and performance. Conversely, for lighter applications with budget limitations, reinforced PVC hoses may be more appropriate. Metal piping systems, while robust, should be considered primarily for high-pressure needs where safety and durability are paramount. Ultimately, understanding the unique requirements of your operations will guide you to the most suitable solution.

Essential Technical Properties and Trade Terminology for slijtvaste slangen

What Are the Key Technical Properties of Slijtvaste Slangen?

When selecting slijtvaste slangen (abrasion-resistant hoses), understanding their technical specifications is crucial for ensuring optimal performance in various industrial applications. Here are some essential properties:

1. Skład materiału

The material of the hose significantly affects its durability and resistance to wear. Common materials include synthetic rubber blends, PVC, and reinforced textiles. Each material has unique properties; for example, synthetic rubber offers superior abrasion resistance and flexibility, making it ideal for transporting highly abrasive materials like sand or cement. Choosing the right material reduces downtime and maintenance costs.

2. Ciśnienie znamionowe

The pressure rating, often expressed in bar or psi, indicates the maximum pressure the hose can withstand during operation. For instance, slijtvaste slangen can typically handle pressures up to 100 bar (1500 psi). Understanding this specification is vital for B2B buyers as it determines the hose’s suitability for various applications, from bulk material transport to sandblasting.

3. Zakres temperatur

The operating temperature range specifies the conditions under which the hose can function effectively, typically ranging from -40°C to +80°C. This property is essential for industries operating in extreme environments, such as construction or mining, as it ensures the hose maintains its integrity and performance under varying thermal conditions.

Illustrative image related to slijtvaste slangen

4. Flexibility and Kink Resistance

Flexibility is crucial for applications requiring maneuverability around equipment and tight spaces. Kink resistance ensures that the hose maintains its shape and functionality under pressure. Hoses designed with high tensile strength and reinforced textiles provide the necessary flexibility without compromising durability, reducing the risk of leaks or breaks during operation.

5. Odporność na ścieranie

Abrasion resistance is the primary characteristic that defines slijtvaste slangen. This property indicates how well the hose can withstand wear from abrasive materials. High-quality hoses are engineered with special compounds to resist abrasion, ensuring a longer service life and minimizing replacement costs, which is particularly important in industries dealing with sand, gravel, or concrete.

What Trade Terminology Should B2B Buyers Understand?

Understanding trade terminology is essential for effective communication and negotiation in the procurement of slijtvaste slangen. Here are some common terms:

1. OEM (producent oryginalnego sprzętu)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of slijtvaste slangen, knowing if the supplier is an OEM can assure buyers of the quality and reliability of the hoses being procured.

Illustrative image related to slijtvaste slangen

2. MOQ (minimalna ilość zamówienia)

MOQ specifies the smallest quantity of products that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management, as it can affect cash flow and storage requirements.

3. RFQ (zapytanie ofertowe)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is vital for B2B buyers to compare prices and terms among different suppliers, enabling informed purchasing decisions.

4. Incoterms (międzynarodowe warunki handlowe)

Incoterms define the responsibilities of buyers and sellers in international trade, including the delivery point and risk transfer. Familiarity with these terms helps B2B buyers navigate logistics and shipping processes, ensuring smooth transactions across borders.

5. Czas realizacji

Lead time refers to the period between placing an order and receiving the products. Understanding lead time is crucial for B2B buyers to plan their inventory and project schedules effectively, minimizing delays in production or service delivery.

Illustrative image related to slijtvaste slangen

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing slijtvaste slangen, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the slijtvaste slangen Sector

What Are the Current Market Dynamics and Key Trends in the Slijtvaste Slangen Sector?

The global market for slijtvaste slangen, or abrasion-resistant hoses, is experiencing significant growth driven by increasing demand across various industries such as construction, mining, and agriculture. Key factors propelling this demand include the rise in infrastructure projects in emerging economies, particularly in Africa and South America, where the need for durable and efficient material handling solutions is paramount. Additionally, the construction sector in Europe and the Middle East is witnessing a revival, further bolstering the need for slijtvaste slangen that can withstand harsh conditions while maintaining operational efficiency.

Technological advancements are shaping the sourcing trends in this sector. The integration of smart technologies, such as IoT-enabled monitoring systems, is enabling real-time tracking of hose conditions, leading to proactive maintenance and reduced downtime. International B2B buyers are increasingly seeking suppliers who not only offer high-quality products but also leverage technology for enhanced performance. Moreover, the shift towards just-in-time (JIT) inventory management is influencing sourcing strategies, with buyers preferring suppliers who can ensure timely deliveries without compromising quality.

Emerging markets are also witnessing a trend towards customization, where buyers demand hoses tailored to specific applications, such as transporting highly abrasive materials in mining or construction settings. This trend underscores the importance of collaboration between manufacturers and buyers to develop solutions that meet unique operational challenges.

How Is Sustainability and Ethical Sourcing Influencing the Slijtvaste Slangen Market?

In an era where environmental sustainability is at the forefront of business practices, the slijtvaste slangen sector is no exception. The production and disposal of industrial hoses can have significant environmental impacts, prompting buyers to prioritize suppliers who adhere to sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and carbon emissions.

Ethical sourcing is becoming increasingly important for international buyers, especially those in regions like Africa and South America, where supply chain transparency can be challenging. Buyers are encouraged to seek suppliers who demonstrate a commitment to ethical labor practices and fair trade principles. Certifications such as ISO 14001 for environmental management and other green certifications can provide assurance of a supplier’s dedication to sustainability.

Moreover, the demand for ‘green’ materials is rising, with buyers looking for hoses made from recycled or bio-based materials. Innovations in material science are paving the way for the development of hoses that not only meet performance standards but also reduce environmental footprints. By prioritizing sustainability, buyers can enhance their brand reputation and meet the increasing regulatory requirements related to environmental responsibility.

What Is the Historical Context Behind the Development of Slijtvaste Slangen?

The evolution of slijtvaste slangen can be traced back to the early industrialization period, when the need for durable hoses became evident as industries began to expand. Initially crafted from natural rubber, the designs evolved with technological advancements, leading to the incorporation of synthetic materials that offer superior abrasion resistance.

As industries diversified and the demand for specialized applications grew, manufacturers began developing various subcategories of slijtvaste slangen, including bulkslangen, gierslangen, and granulaatslangen. This evolution was not only a response to changing industrial needs but also a reflection of the growing awareness of the importance of material performance in enhancing operational efficiency.

Today, the sector continues to innovate, focusing on developing hoses that can withstand extreme conditions while ensuring safety and compliance with international standards. This historical backdrop underscores the importance of understanding the material’s journey and its implications for current sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of slijtvaste slangen

-

How do I choose the right slijtvaste slang for my application?

Selecting the appropriate slijtvaste slang (abrasion-resistant hose) involves understanding the specific materials you will transport, as well as the environmental conditions. Consider factors such as the type of abrasive materials (e.g., sand, cement, granules), required pressure ratings, and temperature ranges. Additionally, assess the hose’s flexibility and compatibility with your machinery. Consulting with suppliers about your operational needs can also help in narrowing down the options to ensure maximum efficiency and durability. -

What are the key features to look for in high-quality slijtvaste slangen?

When sourcing high-quality slijtvaste slangen, prioritize features such as abrasion resistance, flexibility, and pressure rating. A durable inner tube, often made of synthetic rubber, is essential for long service life. Reinforcement materials, such as high-tensile textile cords, can enhance strength and reduce the risk of rupture. Additionally, consider the hose’s resistance to chemicals and weather conditions, which can impact performance in various industrial settings. -

What customization options are available for slijtvaste slangen?

Many suppliers offer customization options for slijtvaste slangen to meet specific operational requirements. Customizations may include variations in length, diameter, and hose fittings. You can also request specific material compositions or additional features such as anti-static properties or enhanced chemical resistance. Discussing your unique needs with suppliers can lead to tailored solutions that improve the efficiency and safety of your operations. -

What are the minimum order quantities (MOQs) for slijtvaste slangen?

Minimum order quantities (MOQs) for slijtvaste slangen can vary significantly between suppliers and depend on factors such as hose type, customization, and production capabilities. Typically, MOQs can range from a few meters for standard hoses to larger quantities for custom orders. It’s advisable to clarify MOQs during initial discussions with suppliers to ensure they align with your procurement needs and budget constraints. -

What payment terms should I expect when sourcing slijtvaste slangen internationally?

Payment terms for international purchases of slijtvaste slangen vary by supplier and region. Common terms include advance payment, letter of credit, or payment upon delivery. It’s important to negotiate terms that provide security for both parties, considering factors such as your order size and supplier trustworthiness. Additionally, be aware of any currency exchange implications and transaction fees that may arise during international payments. -

How can I vet suppliers of slijtvaste slangen effectively?

Vetting suppliers for slijtvaste slangen involves researching their reputation, production capabilities, and compliance with international standards. Look for certifications such as ISO 9001 for quality management and industry-specific certifications relevant to your sector. Request references or case studies from previous clients and assess their responsiveness and customer service. Conducting site visits or audits can further ensure that the supplier meets your quality and operational standards. -

What logistics considerations should I keep in mind when importing slijtvaste slangen?

When importing slijtvaste slangen, consider logistics aspects such as shipping methods, delivery times, and customs regulations. Choose a reliable freight forwarder familiar with your destination country’s import requirements to avoid delays. Be aware of potential tariffs and taxes that could affect your overall costs. Proper documentation, including commercial invoices and packing lists, is essential to ensure smooth customs clearance. -

What quality assurance measures should be in place for slijtvaste slangen?

Quality assurance for slijtvaste slangen should include rigorous testing protocols to ensure performance under specified conditions. Suppliers should conduct tests for abrasion resistance, pressure endurance, and flexibility. Regular quality audits and inspections during production can further safeguard against defects. Requesting documentation of testing results and quality control processes from suppliers can provide peace of mind regarding the reliability of the hoses you purchase.

Top 9 Slijtvaste Slangen Manufacturers & Suppliers List

1. Slangenboer – Slijtvaste Slangen

Domena: slangenboer.nl

Registered: 2013 (12 years)

Wprowadzenie: Slijtvaste slangen zijn ontworpen voor het transport van abrasieve materialen en zijn onderverdeeld in subcategorieën zoals bulkslangen, gierslangen en granulaatslangen. Bulkslangen worden vaak gebruikt voor het transport van veevoeder en andere bulkgoederen zoals weipoeder, melkpoeder, lactosepoeder, kristalsuiker, diermeel, granulaat en pvc poeder. Gierslangen zijn gemaakt van pvc of rubber en z…

2. Peters Rubber – Slijtvaste Slangen

Domena: petersrubber.nl

Zarejestrowany: 1998 (27 lat)

Wprowadzenie: Slijtvaste slangen zijn robuuste slangen die bestand zijn tegen abrasieve stoffen. Ze hebben een binnen- en/of buitenwand met hoge slijtvastheid, vaak volgens DIN ISO 4649. Voorbeelden zijn straalgritslangen, beton- en mortelslangen, bulkslangen, granulaatslangen en PU zuigslangen. Producten van ContiTech, SEL en Optimit bieden hoge slijtvastheid. Assortiment omvat:

– ContiTech SURVIVOR, B3380, S…

3. Wildkamp – Slijtvaste Slangen

Domena: wildkamp.nl

Zarejestrowany: 1997 (28 lat)

Wprowadzenie: Bulkslangen en slijtvaste slangen zijn geschikt voor toepassingen met betonmortel, cement, grind, staalgrit, snoeiafval, lucht en zand. De slangen hebben een spiraal of textielinlage. Spiraal voorkomt vacuüm trekken, textielinlage voorkomt uitrekken onder druk. Materialen: Polyurethaan (PU) – slijtvast, knikbestendig; Natuurrubber (NR) – slijtvast, weersbestendig; Styreen butadiëne rubber (SBR) – …

4. Hydraflex – Slijtvaste Slangen

Domena: hydraflex.nl

Zarejestrowany: 2000 (25 lat)

Wprowadzenie: Slijtvaste slangen voor elke toepassing. Beschikbare kleuren: Bruin (7), Oranje (4), Zwart (20). Max werkdruk: 4 bar (8), 6 bar (1), 8 bar (5), 12 bar (7), 40 bar (6). Max barstdruk: Vacuum 0,9 (5), 12 bar (7), 36 bar (7), 120 bar (6). Materiaal: Kunststof (4), NR (20), NR/SBR (1), SBR (6). Max temperatuur: 60°C (4), 80°C (26), 80°C (1). Producten: Turbocord staalgritslang, Turboflex grit-opzuigsl…

5. ERIKS – Slijtvaste Slangen

Domena: eriks.nl

Zarejestrowany: 1996 (29 lat)

Wprowadzenie: Slijtvaste slangen zijn ontworpen voor het transporteren van modder, vuilwater, zand en grit. De levensduur van de slang is afhankelijk van druk, temperatuur en statische eigenschappen. ERIKS biedt een assortiment slijtvaste slangen en bijbehorende koppelingen, waaronder transportslangen, straalgritslangen en levensmiddelen slangen voor droge stoffen. Een speciaal product is de Powderfood slang, d…

6. Flexibeleslangen – Slijtvaste Slangen

Domena: flexibeleslangen.nl

Registered: 2001 (24 years)

Wprowadzenie: Slijtvaste slangen zijn ontworpen voor intensief gebruik en bieden uitstekende slijtvastheid. Ze zijn geschikt voor verschillende toepassingen, waaronder de industrie en de bouw. De slangen zijn beschikbaar in verschillende diameters en lengtes, en zijn vervaardigd uit hoogwaardige materialen die zorgen voor een lange levensduur. Daarnaast zijn ze bestand tegen hoge druk en hebben ze een goede fle…

7. Reefhors – Slijtvaste Slangen

Domena: reefhors.nl

Zarejestrowany: 2007 (18 lat)

Wprowadzenie: Reefhors biedt een assortiment slijtvaste slangen, onderverdeeld in rubberen slangen, polyurethaan slangen en granulaatslangen. Deze slangen zijn geschikt voor toepassingen zoals cementsilo persslangen, cementsilo zuig-/persslangen, granulaatslangen en veevoeder bulkslangen. Voorbeelden van producten zijn de slijtvaste gegolfde zuigslang voor grondzuigmachines, de slijtvaste kunststof zuig-/perssl…

8. Vigot – Slijtvaste Slangen

Domena: vigot.nl

Registered: 2015 (10 years)

Wprowadzenie: Slijtvaste slangen zijn ontworpen voor intensief gebruik met slijt-veroorzakende materialen, zware bulk materialen en schurende substanties. De slangen zijn gemaakt van Polyurethaan en zijn speciaal voor het afvoeren van stof. Ze bieden een glad stroomkanaal, zijn halogeen- en weekmaker vrij, en zijn bestand tegen olie en benzine, met behoud van flexibiliteit in koude omstandigheden. Slangen kunne…

9. Indi – Bulk- en Slijtvaste Slangen

Domena: indi.nl

Zarejestrowany: 2011 (14 lat)

Wprowadzenie: Bulk- en slijtvaste slangen, beschikbaar in verschillende binnendiameters (mm) zoals 40.0, 45.0, 50.0, 51.0, 60.0, 65.0, 76.0, 80.0, 90.0, 102.0, 110.0, 120.0, 125.0, 140.0, 150.0, 160.0, 180.0, 200.0, 250.0. Buitendiameters (mm) variëren van 48.0 tot 260.0. Werkdruk (bar) opties zijn beschikbaar van 0.21 tot 12.0. Toepassingen omvatten het verplaatsen van lucht, vaste stoffen en vloeistoffen. Mer…

Strategic Sourcing Conclusion and Outlook for slijtvaste slangen

In conclusion, effective strategic sourcing of slijtvaste slangen (abrasion-resistant hoses) is essential for businesses operating across various industries, particularly in the construction, agriculture, and mining sectors. These hoses are indispensable for transporting abrasive materials, ensuring operational efficiency and longevity in demanding environments. Understanding the specific requirements of your applications—whether for bulk transport, granulate handling, or specialized constructions—enables you to select the right type of hose that optimally meets your needs.

Investing in high-quality slijtvaste slangen not only enhances productivity but also minimizes maintenance costs and downtime, ultimately driving profitability. As international buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers, the importance of building strong partnerships with manufacturers who prioritize quality and innovation cannot be overstated.

Looking ahead, the demand for durable and efficient abrasion-resistant hoses will continue to rise. As you evaluate suppliers, consider those who offer comprehensive support and a wide range of solutions tailored to your specific operational challenges. Act now to secure your supply chain and ensure your business remains competitive in this evolving marketplace.

Illustrative image related to slijtvaste slangen

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.