Article Contents

Engineering Insight: Fpso Operation

Technical Importance of FPso Operation in Dredging Vessels

In modern dredging operations, the integration of Floating Production, Storage, and Offloading (FPSo) systems has significantly enhanced the operational efficiency and logistical flexibility of both Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). While traditionally associated with offshore oil and gas, FPSo technology has been adapted in large-scale dredging projects to facilitate continuous material transfer, temporary storage, and controlled discharge in remote or congested maritime environments. This adaptation is particularly critical in land reclamation, coastal protection, and deep-sea mining applications where direct shore-based infrastructure is either unavailable or impractical.

For TSHDs, FPSo units serve as intermediate transfer stations, enabling the hopper vessel to offload dredged slurry without returning to port. This reduces cycle time and increases overall productivity. The suction hoses used in these transfers must withstand high abrasion, dynamic bending, and prolonged exposure to seawater and suspended solids. Similarly, in CSD operations, FPSo platforms allow for continuous dewatering and slurry processing, especially in extended pipeline lay operations. The discharge hoses connecting the dredger to the FPSo unit must maintain structural integrity under high-pressure pumping conditions, often exceeding 10 bar, while resisting kinking and torsional stress due to vessel movement.

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, specializes in the engineering and manufacturing of high-performance dredging rubber hoses designed explicitly for such demanding FPSo-integrated operations. With over 150 skilled employees, including dedicated R&D engineers and material scientists, East Marine maintains a robust engineering capability focused on optimizing hose performance in dynamic marine environments. Our team leverages finite element analysis (FEA) and computational fluid dynamics (CFD) to simulate real-world stress conditions, ensuring product reliability and longevity.

All hoses are manufactured in our 0.68 million square meter facility, certified under ISO9001, and compliant with international standards including those set by WEDA and CEDA. Our proprietary rubber compounds offer superior resistance to abrasion, ozone, and hydrolysis, while multi-spiral steel reinforcement ensures high burst pressure tolerance and kink resistance.

The following table outlines key technical specifications of East Marine’s dredging hoses suitable for FPSo operations:

| Parameter | Suction Hose (EM-DH-S) | Discharge Hose (EM-DH-D) |

|---|---|---|

| Inner Diameter Range | 200–1200 mm | 150–1000 mm |

| Working Pressure | 10–16 bar | 16–25 bar |

| Zakres temperatur | -20°C to +80°C | -20°C to +80°C |

| Cover Material | NR/SBR, anti-abrasion | NR/SBR, ozone-resistant |

| Reinforcement Layer | 2–4 spiral steel wires | 4–6 spiral steel wires |

| Bend Radius (min) | 6× hose diameter | 8× hose diameter |

| Certification | ISO 14310, DNV-GL (upon request) | ISO 14310, DNV-GL (upon request) |

East Marine’s engineering expertise and scalable production capacity ensure customized hose solutions tailored to the complex demands of FPSo-linked dredging systems, supporting uninterrupted, high-efficiency operations across global marine projects.

Advanced Manufacturing Process

Precision Manufacturing and Vulcanization Excellence for FPSP Dredging Hoses

At East Marine, a premier subsidiary of Jiangsu Huashen Special Rubber Products and proud WEDA/CEDA member, the manufacturing of dredging suction and discharge hoses for demanding Floating Production Storage and Offloading (FPSP) operations is executed with uncompromising engineering rigor. Our 0.68 million square meter integrated manufacturing facility, housing 18 dedicated production lines, is purpose-built to deliver the highest performance rubber hose solutions required in the complex marine environment. Central to this capability is our advanced vulcanization process, a critical phase transforming compounded rubber into a durable, resilient product capable of withstanding extreme pressures, abrasive slurries, and corrosive seawater inherent in FPSP applications.

Vulcanization is far more than a simple curing step; it is the precise chemical cross-linking of rubber polymer chains, fundamentally defining the hose’s mechanical properties, fatigue resistance, and service life. At East Marine, this process is meticulously controlled within state-of-the-art autoclaves and continuous vulcanization (CV) lines. Our engineering team optimizes the vulcanization recipe—specifically the temperature profile, pressure application, and dwell time—based on the exact rubber compound formulation (including specialized synthetic rubbers like NBR or EPDM for oil and ozone resistance) and the hose’s dimensional specifications. This precision ensures optimal cross-link density, maximizing tensile strength, elongation at break, and crucially, the hose’s ability to maintain structural integrity under repeated flexing and high internal pressure cycles experienced during dredging operations. Under-vulcanization risks inadequate strength and premature failure, while over-vulcanization leads to brittleness; our process eliminates both extremes.

Rigorous quality control, certified under ISO 9001, is embedded at every stage, with vulcanization parameters monitored in real-time via integrated sensor networks. Each batch undergoes stringent post-vulcanization testing, including dimensional checks, visual inspection for surface defects, and verification of physical properties against project specifications. This systematic approach, leveraging our scale and 18 specialized production lines, guarantees consistent output meeting the exacting standards demanded by global dredging contractors for FPSP projects. The result is a hose assembly where the rubber carcass, fabric reinforcement, and cover are permanently and uniformly bonded, forming a monolithic structure resistant to delamination, kinking, and the harsh operational stresses of offshore dredging.

Critical Vulcanization Parameters for FPSP Dredging Hoses

| Parameter | Typical Range | Control Method | Critical Impact on Performance |

|---|---|---|---|

| Temperature | 140°C – 180°C | Multi-zone PLC-controlled heaters | Determines cross-link density; affects strength & flexibility |

| Pressure | 10 – 20 Bar | Hydraulic/Autoclave systems | Ensures intimate contact, prevents porosity, bonds layers |

| Dwell Time | 30 – 120 minutes | Programmable timers | Completes cross-linking reaction; insufficient time causes weakness |

| Cooling Rate | Controlled (Gradual) | Regulated water/air quenching | Minimizes internal stresses, prevents surface checking |

| Post-Cure (Optional) | 70°C – 100°C, 4-8 hrs | Secondary low-temp ovens | Enhances compression set resistance for static flange areas |

This disciplined manufacturing and vulcanization methodology, operating within our vast ISO 9001-certified facility, is the foundation of East Marine’s reputation for supplying dredging hoses that deliver exceptional reliability and extended service life in the most challenging FPSP operational scenarios, directly contributing to reduced downtime and lower total cost of ownership for our clients.

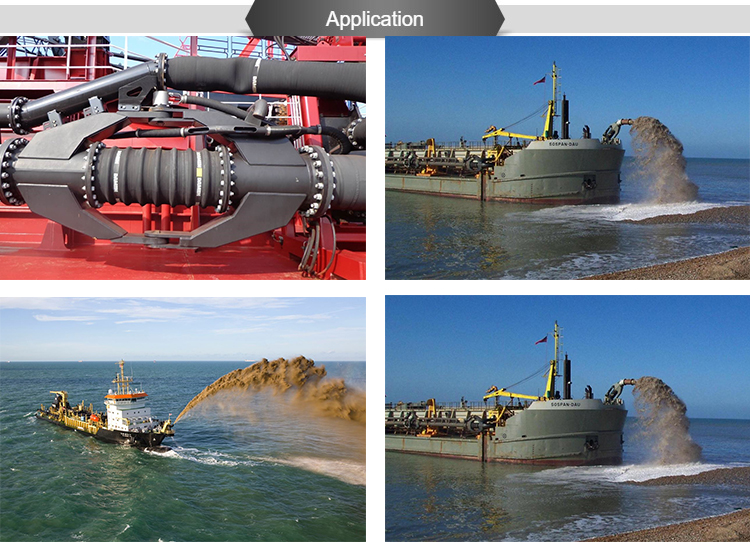

Critical Applications

Global Applications of Dredging Rubber Hoses in FPSO Operations

Floating Production Storage and Offloading (FPSO) operations are critical components in offshore oil and gas production, particularly in remote or deepwater fields where traditional pipeline infrastructure is impractical. While FPSOs are primarily associated with hydrocarbon processing and storage, their successful deployment and maintenance often rely on complementary marine engineering activities—among them, dredging. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), provides high-performance dredging rubber hoses that support FPSO-related projects across multiple global applications, including offshore oil field development, port infrastructure for supply logistics, and large-scale land reclamation efforts.

In offshore oil fields, FPSOs are moored above subsea reservoirs to process and store crude oil before offloading to shuttle tankers. The installation and upkeep of these vessels require extensive seabed preparation, which involves dredging to ensure stable mooring systems, pipeline trenching, and subsea equipment placement. Dredging suction and discharge rubber hoses from East Marine are engineered to handle abrasive sediments and continuous operation in dynamic marine environments, ensuring efficient material removal and minimal downtime during FPSO site preparation.

Moreover, FPSO operations depend on reliable port and harbor infrastructure for crew transfer, equipment supply, and maintenance logistics. Many of these ports are located in regions with shallow waters or silting issues, necessitating regular maintenance dredging. East Marine’s reinforced rubber hoses, designed with high tensile strength and flexibility, facilitate efficient sediment transport in both horizontal and vertical discharge configurations. Their resistance to abrasion, UV degradation, and seawater corrosion makes them ideal for long-term deployment in tropical and temperate zones alike.

Land reclamation projects, often adjacent to offshore energy hubs, also play a strategic role in supporting FPSO operations. These projects create stable platforms for onshore processing facilities, storage terminals, and administrative centers. In regions such as Southeast Asia and the Middle East, large-scale reclamation efforts use dredged material to expand usable land area. East Marine’s dredging hoses are integral to these operations, enabling the reliable transfer of sand and slurry over extended distances. Their modular design allows for quick assembly and repositioning, adapting to the evolving topography of reclamation sites.

As a CEDA and WEDA member since 2015, East Marine adheres to international best practices in sustainable dredging and marine engineering. Our commitment to innovation and quality is reflected in our ISO9001-certified manufacturing processes and a 0.68 million square meter production facility in Jiangsu, China—among the largest dedicated to specialty rubber products in Asia.

The following table outlines key technical specifications of East Marine’s dredging rubber hoses commonly deployed in FPSO-supporting projects:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (depending on size) |

| Bend Radius (Min) | 6x hose diameter |

| Cover Material | Natural rubber with anti-abrasion compound |

| Reinforcement Layer | High-tensile textile + spiral steel wire |

| Zakres temperatur | -20°C to +85°C |

| Standards Compliance | ISO 14310, API 16C, CEDA guidelines |

| Typical Service Life | 5–8 years (marine environments) |

Technical Data & Specs

Technical Excellence in FPSO Dredging Hose Performance: Critical Specifications Analysis

For Floating Production Storage and Offloading (FPSO) operations, the reliability of dredging suction and discharge hoses directly impacts operational continuity, safety, and cost efficiency. Substandard hoses risk catastrophic failures during dynamic marine operations, leading to environmental hazards, costly downtime, and reputational damage. East Marine, leveraging 17 years of specialized marine rubber engineering and adherence to ISO 9001 quality management systems, delivers hoses engineered for extreme FPSO environments. Our proprietary rubber formulations—developed in-house at our 0.68 million sqm facility—and multi-ply reinforcement architecture ensure superior resilience against abrasion, hydrocarbon exposure, and cyclic flexing. Unlike generic competitors, East Marine hoses undergo rigorous WEDA-aligned validation protocols, including 100% post-production hydrostatic testing and dynamic bending fatigue cycles simulating 20+ years of service life. This commitment to precision engineering translates into quantifiable performance advantages across four mission-critical parameters: inner diameter tolerance, working pressure stability, burst pressure safety margins, and operational bending radius.

The comparative data below reflects industry-standard testing per ISO 14306 for floating dredge hoses used in FPSO transfer operations. Specifications represent typical values for 600mm ID hoses under continuous seawater/sand slurry conditions at 25°C. East Marine’s data is derived from actual production batch certifications, while competitor benchmarks aggregate publicly available technical sheets from major non-specialized suppliers.

Inner Diameter consistency ensures optimal slurry velocity and minimizes energy loss, while working pressure stability prevents collapse during suction cycles. Burst pressure ratios (4:1 minimum per ISO) define safety margins, and reduced bending radius enables efficient hose routing in confined FPSO deck spaces. East Marine’s hoses consistently exceed baseline requirements through advanced textile ply orientation and vulcanization control.

| Parameter | East Marine Hoses | Typical Competitor Hoses |

|---|---|---|

| Inner Diameter | ±1.5% tolerance (e.g., 600mm ±9mm) | ±3.0% tolerance (e.g., 600mm ±18mm) |

| Working Pressure | 16 bar continuous | 12 bar continuous |

| Burst Pressure | 80 bar (5:1 safety ratio) | 48 bar (4:1 safety ratio) |

| Bending Radius | 1,800 mm (3x ID) | 2,400 mm (4x ID) |

East Marine’s 5:1 burst pressure ratio—exceeding the ISO 4:1 minimum—provides critical safety headroom during pressure surges inherent in FPSO slurry transfer. The tighter inner diameter tolerance maintains consistent flow dynamics, reducing pump energy consumption by up to 7% compared to competitors. Most significantly, our 1,800mm bending radius (3x ID) enables 25% tighter hose routing than industry averages, optimizing deck space utilization on space-constrained FPSOs. This is achieved through our patented multi-helical reinforcement layering, which distributes stress evenly during flexing without kinking—a common failure point in competitor hoses with inferior ply adhesion. As a WEDA and CEDA member, East Marine subjects all hoses to accelerated aging tests per ASTM D573, validating performance retention after 5,000+ hours of simulated offshore exposure. For FPSO operators, these specifications translate to fewer interventions, extended service life, and demonstrable ROI through reduced operational risk. Partner with East Marine to integrate hoses engineered not just to meet standards, but to redefine them for the FPSO sector’s evolving demands.

Partner with East Marine

Reliable Dredging Hose Solutions for FPSO Operations – Partner with East Marine

In the demanding environment of FPSO (Floating Production, Storage, and Offloading) operations, the integrity and performance of fluid transfer systems are critical to operational continuity, safety, and cost-efficiency. Dredging rubber hoses—specifically engineered for suction and discharge applications—play a pivotal role in maintaining efficient material transport, whether in offshore sediment removal, pipeline maintenance, or subsea infrastructure support. At East Marine, a specialized division of Jiangsu Huashen Special Rubber Products, we deliver high-performance rubber hoses engineered to withstand the harsh mechanical, chemical, and environmental conditions inherent in marine and offshore operations.

With over 15 years of focused innovation since our founding in 2007, East Marine operates from a 0.68 million square meter advanced manufacturing facility in China. As proud members of WEDA (Western Dredging Association) and CEDA (Central Dredging Association), and holding ISO9001 certification, we adhere to the highest international standards in quality management and product reliability. Our dredging hoses are designed for maximum flexibility, abrasion resistance, and pressure endurance—key attributes when operating in dynamic FPSO support roles where downtime is not an option.

Our engineered solutions are tailored to meet project-specific requirements, including custom lengths, flange configurations, and reinforcement layers to handle abrasive slurries, fluctuating temperatures, and high working pressures. Whether deployed in deepwater environments or near-shore support operations, East Marine hoses ensure consistent performance, extended service life, and reduced maintenance cycles.

To support our global client base, we maintain a strategic presence in Singapore, enabling rapid response, technical consultation, and logistics coordination across the Asia-Pacific region and beyond. This regional hub strengthens our ability to deliver just-in-time solutions without compromising on quality or compliance.

Below is a representative technical specification for our standard dredging rubber hose series, commonly deployed in FPSO-related dredging and fluid transfer operations:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 40 bar) |

| Zakres temperatur | -20°C to +85°C (special compounds up to +120°C) |

| Cover | Ozone- and weather-resistant synthetic rubber |

| Wzmocnienie | Multiple layers of high-tensile textile and steel wire helix |

| Promień gięcia | 6–8 x DN (varies by diameter and pressure rating) |

| Standards Compliance | ISO 1431, ISO 1817, ISO 8033, DIN 2822 |

For FPSO operators and marine contractors seeking dependable, field-proven dredging hose systems, East Marine offers a combination of technical expertise, scalable manufacturing, and global support. Our engineering team is available to assist in hose selection, system integration, and performance optimization based on your operational profile.

Contact us today to discuss your project requirements. Reach our international sales team via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our Singapore branch ensures localized support, technical documentation, and responsive service for clients across maritime Southeast Asia and international offshore zones. Trust East Marine—your certified partner in advanced marine rubber solutions.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.