Article Contents

Engineering Insight: Fuel Hose Manufacturers

Technical Imperatives for Dredging Hose Manufacturers in Modern Dredger Operations

The operational integrity of Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs) hinges critically on the performance of specialized marine hoses, specifically suction and discharge hoses designed for abrasive slurry transport. While the term “fuel hose” is occasionally misapplied in casual discourse, the critical components within dredging systems are engineered for vastly different challenges: conveying dense, highly abrasive sand-water mixtures under significant pressure and dynamic stress, not petroleum products. Confusing these distinct hose categories poses severe operational risks. Genuine dredging hose manufacturers must possess deep expertise in material science and hydrodynamic engineering to address the unique demands of slurry handling, where failure equates to costly downtime and environmental hazards. The hose must withstand extreme abrasion, maintain structural integrity during vessel motion and wave action, resist internal vacuum during suction, and endure prolonged exposure to seawater and UV radiation. Precision in reinforcement layer design, rubber compound formulation, and joint integrity is non-negotiable for continuous, efficient dredging operations in challenging marine environments.

East Marine, operating as a core subsidiary of Jiangsu Huashen Special Rubber Products since 2007, exemplifies the engineering rigor required in this niche. With over 150 dedicated technical personnel, including specialized rubber compounders, mechanical engineers, and marine systems designers, we translate complex operational demands into robust hose solutions. Our engineering team leverages advanced finite element analysis (FEA) and extensive field data to optimize layer construction, ensuring hoses dynamically adapt to bending stresses during vessel maneuvering while resisting internal wear from 60%+ solids content slurries. This deep in-house capability, honed over 15+ years and validated through WEDA/CEDA collaboration, directly addresses the core failure modes plaguing dredging operations: cover abrasion, reinforcement fatigue, and coupling separation. Our commitment to ISO 9001 certified processes ensures every hose, from initial compound mixing to final pressure testing, meets the stringent reliability standards demanded by global dredging contractors operating multi-million dollar assets.

Key performance parameters defining high-integrity dredging hoses are non-negotiable for TSHD and CSD applications. The table below outlines critical specifications where engineering excellence is paramount.

| Technical Parameter | Typical Requirement for Heavy-Duty Dredging Hoses | Engineering Significance |

|---|---|---|

| Working Pressure (Bar) | 16 – 25+ | Must handle high discharge pressures of CSDs and dynamic surges during TSHD pumping cycles |

| Vacuum Resistance (Bar) | ≤ -0.8 | Critical for maintaining hose integrity during suction lift on TSHDs |

| Abrasion Resistance (mm³) | ≤ 80 (DIN 53516) | Directly correlates with service life in high-slurry-velocity applications |

| Bend Radius (Static) | ≤ 10x Nominal ID | Enables safe routing on vessel decks and spud carriers under operational constraints |

| Cover Hardness (Shore A) | 60 – 70 | Balances cut/chip resistance with flexibility for handling and storage |

| Temperature Range (°C) | -30 to +80 | Ensures performance stability across global operating environments |

East Marine’s engineering cohort, embedded within our 0.68 million sqm manufacturing complex, focuses relentlessly on exceeding these baseline specifications. We understand that the hose is not merely a conduit but a dynamic structural component integral to the dredger’s pumping system. Our solutions are engineered to minimize total cost of ownership through extended service life and reduced unscheduled maintenance, directly supporting the productivity and profitability of our dredging partners. Technical mastery in dredging hose manufacturing is not optional; it is the foundation of reliable, efficient, and safe capital-intensive marine operations.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization in Dredging Hose Production at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the manufacturing of high-performance dredging suction and discharge hoses is grounded in precision engineering, advanced rubber technology, and rigorous quality assurance. With a 0.68M sqm state-of-the-art production facility located in Jiangsu, China, the company leverages 18 dedicated production lines to deliver durable, abrasion-resistant hoses designed for the demanding conditions of marine and inland dredging operations. Central to this process is the critical phase of vulcanization—a scientifically controlled thermal treatment that transforms raw rubber compounds into resilient, high-tensile materials capable of withstanding extreme pressures, abrasive slurries, and prolonged exposure to seawater and hydrocarbons.

The production process begins with the formulation of specialized rubber compounds tailored to the operational requirements of fuel and slurry transfer. These formulations, incorporating natural rubber, synthetic elastomers (such as SBR and NBR), and reinforcing fillers, are carefully mixed to ensure homogeneity and optimal physical properties. The compounded rubber is then extruded onto high-strength textile or steel wire reinforcement layers, which provide the hose with structural integrity and flexibility. Multiple layers—including inner linings, carcass reinforcement, and outer protective covers—are built up in precise configurations to meet international performance standards.

Vulcanization is the cornerstone of East Marine’s manufacturing excellence. The assembled hose blanks are subjected to high-pressure steam or nitrogen environments in autoclaves, where temperatures typically range between 145°C and 160°C. This cross-linking process enhances the rubber’s elasticity, tensile strength, and resistance to swelling, ensuring long-term durability in aggressive operating environments. Each vulcanization cycle is meticulously monitored using real-time data logging systems to maintain consistency across batches. Deviations in time, temperature, or pressure are automatically flagged, ensuring adherence to ISO 9001-certified quality control protocols.

Quality assurance is embedded throughout production. Every hose undergoes hydrostatic pressure testing, dimensional inspection, and adhesion testing between rubber and reinforcement layers. Non-destructive testing methods, including ultrasonic scanning, are employed to detect internal defects. Only hoses that meet or exceed CEDA and WEDA industry benchmarks are released for shipment.

East Marine’s integration of large-scale manufacturing capacity with advanced vulcanization technology and systematic quality control ensures that every dredging hose delivers reliable performance in the field. The combination of a 0.68M sqm factory footprint, 18 specialized production lines, and a certified quality management system positions the company as a leading supplier of engineered rubber solutions for global marine and dredging markets.

| Technical Parameter | Specification |

|---|---|

| Factory Size | 0.68 Million sqm |

| Production Lines | 18 Dedicated Lines |

| Vulcanization Method | High-Pressure Autoclave (Steam/N₂) |

| Zakres temperatur | 145°C – 160°C |

| Typical Cure Time | 60–120 minutes (based on diameter & length) |

| Quality Standard | ISO 9001:2015 |

| Testing Procedures | Hydrostatic Test, Adhesion Test, NDT (Ultrasonic) |

| Compliance | CEDA, WEDA, MARPOL (for fuel transfer models) |

Critical Applications

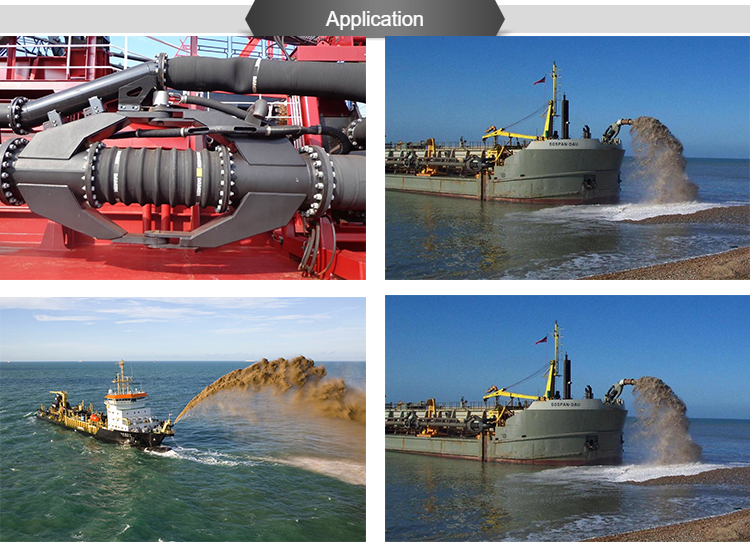

Global Applications of Specialized Dredging Hose Systems in Critical Marine Infrastructure Projects

East Marine, operating as the dedicated marine solutions subsidiary of Jiangsu Huashen Special Rubber Products Co. Ltd., delivers engineered rubber hose systems specifically designed for the demanding environments of dredging and marine construction. While the broader term “fuel hose manufacturers” exists within the industrial supply chain, our core expertise and global project footprint lie firmly within the realm of high-performance dredging suction and discharge hoses. These critical components are indispensable across major international infrastructure initiatives, far removed from petroleum transfer applications. Our hoses are rigorously engineered to handle abrasive sand-water slurries, continuous submersion, and severe mechanical stresses inherent in large-scale maritime operations. As active members of both WEDA (Western Dredging Association) and CEDA (Central Dredging Association), East Marine adheres to the highest international standards for dredging equipment performance and safety, ensuring our solutions meet the stringent requirements of global contractors and project owners.

The primary application domain for East Marine’s hose systems is large-scale dredging projects. This encompasses capital dredging for port expansions like the deepening of the Suez Canal or Rotterdam Maasvlakte 2, where our high-volume discharge hoses transport millions of cubic meters of material over significant distances. Maintenance dredging in vital shipping lanes such as the Mississippi River or Singapore Strait relies on our robust suction hoses to maintain navigable depths efficiently. Furthermore, our specialized floating hose systems are fundamental to land reclamation mega-projects, including the creation of artificial islands in the Persian Gulf and coastal protection initiatives across Southeast Asia. These hoses form the dynamic link between the dredger and the reclamation site, enduring wave action, tidal changes, and constant slurry flow. While not designed for fuel transfer, our hoses frequently support offshore oil and gas field development indirectly. They are deployed for pre-construction seabed preparation, trenching for pipeline burial, and creating stable platforms or access channels in shallow waters, directly contributing to the infrastructure enabling energy extraction.

The operational demands of these global projects necessitate hoses exceeding standard industrial specifications. East Marine leverages its 17-year heritage since 2007 and its 0.68 million square meter manufacturing facility in Jiangsu to produce hoses with proven resilience. Our commitment to quality, certified under ISO 9001, ensures consistent performance in corrosive seawater, extreme temperatures, and high-abrasion scenarios. The following table outlines the critical technical parameters defining our standard dredging hose series, engineered for these exacting applications:

| Parameter | Standard Dredging Hose Series | Test Pressure | Zakres temperatur | Key Construction Features |

|---|---|---|---|---|

| ID Range | 200 mm – 1200 mm | 2.0 x MWP | -20°C to +80°C | High-tensile synthetic fabric plies |

| Working Pressure (MWP) | 10 bar – 25 bar | 30 bar max | Specialized abrasion-resistant rubber compound | |

| Burst Pressure | Min. 4.0 x MWP | Integrated helical steel wire reinforcement | ||

| Odporność na ścieranie | ASTM D5963: ≤ 80 mm³ | Optimized tube compound for sand/water slurry | ||

| Flexibility | Bend Radius: 12 x ID | Multi-spiral construction for kink resistance |

East Marine’s global project experience, underpinned by WEDA/CEDA best practices and our substantial manufacturing capability, positions us as a strategic partner for contractors executing the world’s most challenging dredging and marine infrastructure developments. We provide the reliable, high-capacity fluid transfer solutions essential for moving the earth beneath the waves.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: Performance Specifications

In the demanding environment of dredging operations, the performance of suction and discharge hoses directly impacts efficiency, safety, and project timelines. East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, delivers high-performance dredging hoses engineered for superior durability, pressure resistance, and flexibility. Designed for continuous operation in abrasive and high-pressure conditions, our hoses meet ISO 9001 quality standards and are validated through rigorous in-house testing protocols. This technical comparison evaluates key performance parameters of East Marine dredging hoses against typical industry competitors, focusing on inner diameter, working pressure, burst pressure, and minimum bending radius—critical factors in system design and operational reliability.

East Marine’s advanced rubber compound formulation, combined with high-tensile textile and steel wire reinforcement, enables optimized pressure handling and structural integrity. Our manufacturing process, supported by a 0.68 million square meter production facility and adherence to WEDA and CEDA guidelines, ensures dimensional accuracy and long service life even under cyclic loading and submersion. In contrast, many competitor hoses rely on standard reinforcement architectures that may compromise performance under peak loads or tight spatial configurations.

The following table presents a representative comparison across common dredging hose sizes, highlighting East Marine’s technical advantages:

| Inner Diameter (mm) | Working Pressure (bar) – East Marine | Working Pressure (bar) – Competitors | Burst Pressure (bar) – East Marine | Burst Pressure (bar) – Competitors | Bending Radius (mm) – East Marine | Bending Radius (mm) – Competitors |

|---|---|---|---|---|---|---|

| 200 | 16 | 12 | 64 | 48 | 600 | 700 |

| 300 | 14 | 10 | 56 | 40 | 850 | 1000 |

| 400 | 12 | 9 | 48 | 36 | 1100 | 1300 |

| 500 | 10 | 8 | 40 | 32 | 1400 | 1600 |

| 600 | 9 | 7 | 36 | 28 | 1700 | 1900 |

East Marine hoses consistently demonstrate a 25–40% higher working pressure and a 20–33% improvement in bending radius compared to average competitor products. The elevated burst pressure ratios (4:1 safety factor) exceed international safety benchmarks, minimizing rupture risks during pressure surges. Additionally, the reduced bending radius allows for tighter routing in confined dredge fields or vessel setups, enhancing operational flexibility and reducing installation costs.

All East Marine dredging hoses undergo 100% hydrostatic testing and are designed for compatibility with sand, slurry, and high-velocity particulate media. With over 15 years of specialized manufacturing experience since 2007, our engineering team supports custom configurations to meet project-specific requirements, ensuring optimal performance across diverse marine and inland dredging applications.

Partner with East Marine

Conclusion: Engineering Reliability for Demanding Dredging Operations

East Marine, operating as a specialized subsidiary of Jiangsu Huashen Special Rubber Products since 2007, stands at the forefront of engineered dredging hose solutions. Our 0.68 million square meter manufacturing facility, certified to ISO 9001 standards and supported by active WEDA and CEDA membership, delivers suction and discharge hoses engineered to withstand the most aggressive sediment transport environments. Unlike generic fuel hose manufacturers, our focus remains singularly on the unique mechanical, chemical, and operational demands of dredging applications—from high-abrasion cutter suction dredgers to long-distance trailing suction hopper pipelines. This specialization ensures every hose assembly we produce integrates advanced rubber compounding, reinforced carcass structures, and rigorous validation protocols to maximize uptime and minimize lifecycle costs.

The technical superiority of our dredging hoses is quantifiable through performance-critical parameters. Below is a representative specification for our flagship dredging hose series, designed for severe-duty offshore and inland operations:

| Technical Parameter | Value | Industry Relevance |

|---|---|---|

| Working Pressure | 16-25 bar (232-363 psi) | Supports high-head pumping systems |

| Vacuum Resistance | Full vacuum at 100°C (212°F) | Prevents collapse during priming/suction phases |

| Zakres temperatur | -40°C to +100°C (-40°F to +212°F) | Tolerates thermal stress from slurries |

| Cover Material | NR/BR/SBR blend with ozone protection | Resists abrasion, UV, and seawater degradation |

| Wzmocnienie | High-tenacity polyester/cord layers | Ensures kink resistance and dimensional stability |

This level of engineering precision stems from our 17 years of dedicated R&D in marine rubber technology. Our hoses are not merely manufactured; they are validated against real-world dredging challenges, including dynamic flexing in wave action, prolonged exposure to saline environments, and sustained contact with abrasive sand-clay mixtures. The Singapore branch further enhances our global responsiveness, providing localized technical support, inventory management, and rapid deployment coordination for Asia-Pacific projects—ensuring minimal downtime during critical operations.

For fuel hose manufacturers exploring diversification into dredging or seeking a specialized partner for high-wear applications, East Marine offers more than components: we deliver engineered risk mitigation. Our engineering team collaborates directly with clients to validate hose compatibility with specific dredge pumps, slurry densities, and project geographies. This consultative approach prevents costly mismatches in pressure ratings, bend radii, or chemical resistance that generic solutions often overlook.

Initiate Your Technical Partnership Today

Do not compromise on the integrity of your dredging pipeline system. Contact East Marine’s engineering division to discuss your project’s operational parameters and receive a customized hose specification dossier. Our technical advisors are available for immediate consultation via WhatsApp at +86-13806109365 or through dedicated project email hsdredging@eastmarine.tech. Mention this article to request our latest dredging hose performance validation report, including third-party abrasion test data and ISO-compliant certification packages. With manufacturing capacity spanning 0.68 million square meters and strategic support from our Singapore hub, we ensure scalable delivery without sacrificing engineering rigor. Partner with a supplier whose hoses have moved over 500 million cubic meters of sediment globally—where every meter counts, trust East Marine.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.