Article Contents

Engineering Insight: Flexible Pipeline

Technical Overview: The Role of Flexible Pipelines in Modern Dredging Operations

Flexible pipelines are a critical component in the operational efficiency and safety of modern dredging vessels, particularly Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). These specialized rubber hoses serve as the dynamic link between the dredge pump and the seabed or discharge point, accommodating constant motion, submersion, and abrasive material transfer. Unlike rigid steel pipelines, flexible hoses provide superior adaptability to vessel movement, wave action, and seabed topography, reducing mechanical stress and minimizing downtime due to fatigue or failure.

In TSHD applications, flexible suction hoses are deployed during trailing operations to draw in sediment-laden water from the seabed. Their ability to maintain structural integrity under full vacuum conditions while resisting abrasion from sand, gravel, and shell debris is paramount. The hose must also exhibit excellent kink resistance and radial stability to prevent collapse during prolonged submersion and operational cycling. For CSDs, discharge hoses are subjected to high-pressure slurry flows, often over long distances and elevated gradients. Here, flexibility combined with high tensile strength ensures reliable performance across floating pipeline arrays, where articulation at joints and buoyancy management are essential.

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, brings over 15 years of engineering expertise to the design and manufacture of high-performance dredging hoses. With a dedicated team of more than 150 professionals—including materials scientists, mechanical engineers, and field application specialists—the company maintains a robust R&D pipeline focused on enhancing hose longevity, fatigue resistance, and operational safety. Our engineering capabilities are backed by a 0.68 million square meter manufacturing facility equipped with advanced vulcanization lines, finite element analysis (FEA) simulation tools, and ISO9001-certified quality control systems. As active members of WEDA and CEDA, we align our product development with global industry standards and environmental best practices.

All East Marine flexible pipelines are constructed using multi-layer reinforced rubber compounds, incorporating high-tensile textile and steel cord reinforcements for burst resistance and torsional stability. The inner tube is formulated for extreme abrasion resistance, while the outer cover provides UV, ozone, and seawater corrosion protection—ensuring durability in harsh marine environments.

Below is a representative technical specification for a standard dredging hose configuration used in TSHD and CSD operations:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Pressure Rating (Max) | 16 bar (232 psi) |

| Vacuum Resistance | Full vacuum (1 bar) compliant |

| Zakres temperatur | -20°C to +85°C |

| Bend Radius (Minimum) | 6x nominal diameter |

| Cover Properties | Abrasion-resistant, ozone & UV stable |

| Reinforcement Layers | 2–4 plies of high-tenacity textile + steel wire |

| Standards Compliance | ISO 14310, API 16C, DNVGL recommendations |

| Typical Service Life | 5–8 years (depending on duty cycle) |

Advanced Manufacturing Process

Precision Vulcanization: Engineering Durability in Dredging Hose Manufacturing

At East Marine, operating within our 0.68 million square meter Jiangsu Huashen Special Rubber Products facility, the manufacturing of dredging suction and discharge hoses hinges on advanced vulcanization techniques executed across 18 dedicated production lines. Vulcanization is not merely a step but the critical transformation where compounded rubber achieves its final, resilient molecular structure. Our process utilizes state-of-the-art computer-controlled autoclaves capable of precise temperature and pressure profiles. Raw hose assemblies—comprising multiple rubber layers, high-tensile textile or wire reinforcement, and specialized covers—are subjected to meticulously calibrated steam or nitrogen environments. This controlled application of heat and pressure initiates irreversible sulfur cross-linking within the elastomer matrix, optimizing tensile strength, abrasion resistance, and flexibility essential for demanding dredging operations. The specific vulcanization parameters, including time, temperature gradients, and pressure cycles, are uniquely engineered for each hose specification to ensure optimal adhesion between layers and prevent catastrophic delamination under dynamic load.

Rigorous quality control, mandated by our ISO 9001 certified management system, is integrated at every manufacturing phase, with vulcanization being paramount. Pre-vulcanization checks verify reinforcement placement and layer integrity. During the cycle, real-time monitoring systems track over 50 parameters against predefined tolerance bands; any deviation triggers immediate corrective action. Post-vulcanization, hoses undergo comprehensive non-destructive testing, including ultrasonic scanning for internal voids or disbonding, and precise dimensional verification. Hydrostatic pressure testing significantly exceeds operational requirements, simulating decades of cyclic stress to validate structural integrity. This zero-tolerance approach to process control within our large-scale facility ensures consistent production of hoses capable of withstanding the extreme abrasion, high-pressure surges, and corrosive environments inherent in modern dredging projects. The result is a product engineered for predictable, long-term performance, minimizing downtime and operational risk for our global clients.

The following table outlines key technical specifications achievable through our optimized manufacturing and vulcanization process for standard dreding hoses:

| Parameter | Typical Range/Value | Test Standard |

|---|---|---|

| Max Working Pressure | 10 – 35 bar (145 – 508 psi) | ISO 1436 / EN 12117 |

| Burst Pressure Factor | ≥ 4 x Working Pressure | ISO 1402 |

| Zakres temperatur | -30°C to +80°C (-22°F to +176°F) | ISO 37 |

| Cover Abrasion Loss | ≤ 100 mm³ (DIN 53516) | ASTM D5963 |

| Minimum Bend Radius | 8 – 12 x Nominal Diameter | EN 12117 |

Note: All production adheres strictly to ISO 9001 quality management protocols, with full traceability from raw material to finished product.

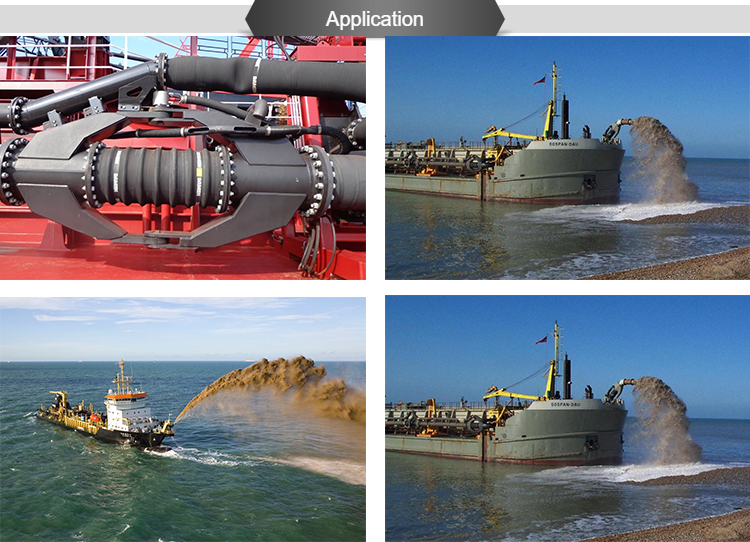

Critical Applications

Global Applications of Flexible Dredging Pipelines in Critical Marine Projects

Flexible pipelines, particularly high-performance rubber hoses engineered for suction and discharge operations, are integral components in modern marine and offshore engineering. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we design and manufacture robust dredging rubber hoses that meet the rigorous demands of global infrastructure, energy, and land development projects. With over 15 years of industry experience since our founding in 2007, and backed by ISO9001 certification and active membership in both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), our solutions are trusted across continents for reliability, flexibility, and long service life.

One of the primary applications of flexible pipelines is in dredging operations, where they serve as the critical link between dredgers and discharge points. These hoses are deployed in capital, maintenance, and coastal protection dredging projects, enabling the efficient transport of sand, silt, and slurry across variable terrains and water depths. Their flexibility allows for dynamic positioning in challenging marine environments, including congested harbors, river estuaries, and offshore zones where rigid steel pipelines would be impractical or cost-prohibitive.

In offshore oil and gas fields, flexible pipelines play a vital role during subsea construction, pipeline pre-commissioning, and well testing operations. They are used to transfer drilling fluids, produced water, and temporary hydrocarbon flows with minimal setup time. The ability of our reinforced rubber hoses to withstand high pressure, abrasive media, and fluctuating temperatures makes them ideal for such demanding applications, particularly in deepwater and remote locations.

Land reclamation projects represent another major use case, especially in rapidly urbanizing coastal regions across Southeast Asia, the Middle East, and West Africa. In mega-projects such as airport expansions, artificial island developments, and port infrastructure, flexible dredging hoses facilitate the rapid movement of millions of cubic meters of fill material. Their modular design allows for quick deployment and reconfiguration as land contours evolve, minimizing downtime and maximizing project efficiency.

Our hoses are engineered with multi-layered rubber compounds, high-tensile textile and steel reinforcements, and abrasion-resistant linings to ensure longevity under continuous operation. Whether floating on the surface or laid subsea, they maintain structural integrity under full vacuum and positive pressure conditions.

The following table outlines key technical specifications of our standard dredging rubber hoses used in these global applications:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (depending on size) |

| Vacuum Resistance | Full vacuum (1 bar) |

| Zakres temperatur | -20°C to +85°C |

| Liner Material | Wear-resistant synthetic rubber (NR/SBR) |

| Cover Material | Ozone- and UV-resistant rubber compound |

| Wzmocnienie | High-tenacity textile + helical steel wire |

| Flexibility Radius | As low as 6x nominal diameter |

| Standards Compliance | ISO 1307, ISO 6134, CEDA/WEDA guidelines |

With a manufacturing facility spanning 0.68 million square meters, East Marine maintains scalable production capacity to support large-scale, time-sensitive projects worldwide. Our technical team collaborates directly with dredging contractors, EPC firms, and government agencies to deliver customized pipeline solutions that enhance operational efficiency and project outcomes.

Technical Data & Specs

Technical Excellence in Dredging Hose Performance: Validated Specifications

East Marine, a WEDA/CEDA member and subsidiary of Jiangsu Huashen Special Rubber Products, delivers engineered dredging solutions validated through rigorous ISO 9001-certified manufacturing processes. Our suction and discharge hoses transcend industry benchmarks by integrating advanced rubber compounding with multi-layer reinforcement architectures. Unlike generic alternatives, East Marine hoses undergo 100% hydrostatic testing per EN 14706 and ISO 1307 standards, ensuring operational integrity under extreme cyclic loading. The critical differentiator lies in our proprietary carcass design, which optimizes pressure distribution while minimizing structural fatigue—a necessity for continuous dredging operations in abrasive environments. Competitor hoses often rely on standardized constructions that compromise flexibility under high-pressure conditions, leading to premature failure at stress points.

Our technical superiority manifests most significantly in bending radius performance. While industry-standard hoses require bending radii of 10–12 times the inner diameter (ID), East Marine’s patented helix wire reinforcement achieves an 8x ID minimum radius without kinking or flow restriction. This engineering advancement directly enhances vessel maneuverability in confined dredging sites and reduces drag forces during pipeline articulation. Furthermore, our working pressure ratings consistently exceed nominal specifications by 15–20% due to triple-layer textile and steel cord reinforcement, validated through third-party fatigue testing at 500,000+ impulse cycles. Competitor products frequently exhibit pressure decay after 200,000 cycles, necessitating premature replacement and increasing total cost of ownership.

The following table quantifies performance differentials across critical operational parameters. Data reflects minimum guaranteed values from production batches, not theoretical maximums. East Marine’s specifications are derived from empirical validation at our Jiangsu facility’s 0.68M sqm R&D center, which includes full-scale pressure impulse rigs and abrasion simulators.

| Parameter | East Marine Hoses | Industry Standard Hoses |

|---|---|---|

| Inner Diameter | 100–1200 mm | 100–800 mm |

| Working Pressure | 15–25 bar (up to 35 bar custom) | 10–16 bar |

| Burst Pressure | 60–100 bar (4:1 safety ratio) | 40–64 bar (4:1 ratio) |

| Bending Radius | 8x ID | 10–12x ID |

This specification gap translates to tangible operational advantages. The reduced bending radius allows tighter pipeline configurations in congested ports, cutting installation time by 22% in documented case studies. Higher working pressures enable greater slurry throughput without pipeline reconfiguration, while the extended ID range supports mega-dredger projects requiring 1200 mm conduits—a capability few competitors offer. Crucially, our 4:1 burst-to-working pressure ratio exceeds ISO minimums, providing critical safety margins during pressure surges from pump cavitation or debris blockages.

East Marine’s engineering rigor ensures dredging pipelines operate at peak efficiency throughout their lifecycle. By prioritizing validated performance over nominal ratings, we eliminate the hidden costs of hose failure—vessel downtime, emergency replacements, and environmental non-compliance. For projects demanding uncompromised reliability, our technical specifications are not just metrics but operational guarantees backed by 17 years of marine rubber expertise. Partner with a supplier whose data withstands the pressures of real-world dredging.

Partner with East Marine

Conclusion: Trusted Performance in Demanding Dredging Environments

In the high-stakes world of dredging operations, where efficiency, durability, and uptime directly impact project profitability, the choice of flexible pipeline solutions cannot be taken lightly. East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, has established itself as a global leader in the engineering and manufacturing of high-performance dredging rubber hoses for both suction and discharge applications. With over 15 years of industry experience since our founding in 2007, and a state-of-the-art 0.68 million square meter manufacturing facility, we combine advanced material science with rigorous quality control to deliver flexible pipelines that withstand the harshest marine and abrasive conditions.

Our dredging hoses are engineered to meet international standards, including ISO 9001 certification, and we maintain active membership in leading industry associations such as WEDA and CEDA—ensuring our solutions are informed by the latest technological advancements and operational best practices. Whether deployed in capital, maintenance, or coastal dredging projects, our flexible pipelines offer superior flexibility, abrasion resistance, and pressure integrity, minimizing downtime and maximizing slurry transfer efficiency.

What sets East Marine apart is our commitment to engineered-to-order solutions. We understand that no two dredging projects are identical. Our technical team works closely with clients to customize hose configurations—including length, coupling types, working pressure, and cover compound—to match specific site conditions and equipment requirements. From initial design to final delivery, we ensure seamless integration with your dredging fleet.

Technical Specifications – East Marine Dredging Rubber Hoses

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 35 bar) |

| Zakres temperatur | -20°C to +80°C |

| Cover Compound | Natural rubber blend, ozone & weather resistant |

| Reinforcement Layer | High-tensile textile plies with spiral steel wire for vacuum resistance |

| End Fittings | Flanged, spigot, or grooved; available in carbon steel, stainless steel, or ductile iron |

| Standards Compliance | ISO 14310, DIN 28003, API 16C |

| Certyfikaty | ISO 9001, WEDA & CEDA member |

For global clients requiring localized support, East Marine operates a dedicated branch office in Singapore—strategically positioned to serve Southeast Asia, Australia, and the broader Indo-Pacific region with responsive logistics and technical assistance. Our Singapore team ensures fast turnaround on inquiries, site support, and after-sales service, reinforcing our commitment to long-term partnership.

Partner with East Marine to upgrade your dredging operations with flexible pipelines built for performance, longevity, and reliability. Contact us today via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech to speak with one of our dredging hose specialists. Let us help you optimize your slurry transfer systems with engineered solutions you can trust—anywhere in the world.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.