Article Contents

Engineering Insight: Hose Water Jet

Technical Imperatives of Water Jet Hoses in Modern Dredging Operations

Water jet hoses represent a critical yet often underappreciated component within the hydraulic systems of Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs). These specialized hoses deliver high-pressure water streams essential for sediment fluidization at the dredge head or draghead. In TSHDs, the water jet system mobilizes seabed material ahead of the suction inlet, significantly enhancing intake efficiency and reducing clogging risks during hopper loading. For CSDs, water jets are integral to the cutter head assembly, loosening compacted soils and improving the cutter’s effectiveness while minimizing mechanical strain. The operational demands placed on these hoses are extreme: they must withstand continuous exposure to abrasive slurries, cyclic pressure surges exceeding 30 bar, and the corrosive marine environment, all while maintaining flexible articulation under vessel motion. Failure due to abrasion, delamination, or coupling fatigue directly impacts dredging productivity, leading to costly downtime and compromised project timelines. Material science and structural integrity are therefore non-negotiable; the hose construction must feature abrasion-resistant synthetic rubber compounds, high-tensile textile or wire reinforcement layers, and precision-engineered couplings resistant to torque and vibration.

East Marine, leveraging its 150+ strong engineering and technical workforce, addresses these challenges through rigorous R&D and manufacturing protocols. Our dedicated dredging division, operating within a 0.68 million square meter ISO 9001 certified facility and supported by WEDA/CEDA industry insights, focuses on optimizing hose architecture for maximum service life. We prioritize multi-layer reinforcement designs that absorb pressure spikes without compromising flexibility, alongside proprietary rubber formulations tested against ISO 1431-1 for ozone resistance and ISO 188 for heat aging. This ensures sustained performance in temperatures ranging from -30°C to +80°C, critical for global dredging operations across diverse climates. The engineering team conducts finite element analysis (FEA) on every design iteration, simulating real-world stress points induced by vessel movement and high-velocity slurry flow to preempt failure modes.

The following table outlines key technical specifications for East Marine’s dredging water jet hose series, engineered specifically for TSHD and CSD applications:

| Parameter | Specification Range | Compliance Standard |

|---|---|---|

| Internal Diameter (ID) | 50 mm to 300 mm | ISO 1307 |

| Working Pressure | 25 bar to 40 bar | ISO 1307 / EN 853 |

| Test Pressure | 1.5x Working Pressure | ISO 1402 |

| Promień gięcia | 10x ID (min) | ISO 10619-1 |

| Cover Material | NBR/EPDM Blends | ISO 1817 |

| Wzmocnienie | High-Tensile Polyester / Steel Wire | ISO 13949-1 |

| Zakres temperatur | -30°C to +80°C | ISO 188 |

East Marine’s engineering capability extends beyond standard manufacturing; our team collaborates directly with dredging contractors to analyze site-specific wear patterns and pressure dynamics, enabling customized solutions that extend operational cycles. With 17 years of focused expertise since 2007, we deliver water jet hoses that are not merely components, but engineered productivity assets ensuring reliable sediment mobilization under the most demanding hydraulic conditions. This technical commitment underpins our position as a trusted partner in global dredging infrastructure.

Advanced Manufacturing Process

Manufacturing Excellence in Dredging Hose Production at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance dredging rubber hoses is rooted in precision engineering, advanced material science, and rigorous process control. With a state-of-the-art 0.68M sqm manufacturing facility and 18 dedicated production lines, our operations are designed to deliver consistent quality and scalability for global marine and dredging projects. Central to this process is the vulcanization phase, a critical step that transforms raw rubber compounds into durable, resilient hose structures capable of withstanding extreme hydraulic pressures, abrasive slurries, and harsh marine environments.

The manufacturing process begins with the selection of premium synthetic and natural rubber compounds, reinforced with high-tensile textile or steel cords depending on the application. These materials are precisely layered using automated extrusion and calendaring systems to form the inner tube, reinforcement layers, and outer cover. Each layer is inspected in-line to ensure dimensional accuracy and material integrity before the uncured hose assembly moves to the vulcanization stage.

Vulcanization is the chemical process in which sulfur or other curatives are used to cross-link rubber polymer chains under controlled heat and pressure. At East Marine, this is performed in high-pressure autoclaves and continuous vulcanization tunnels, calibrated to exact time-temperature profiles specific to each hose type. This ensures optimal physical properties such as tensile strength, abrasion resistance, and flexibility across a wide temperature range. Our 18 production lines are equipped with real-time monitoring systems that track pressure, temperature, and cycle duration, ensuring repeatability and compliance with international standards.

Quality control is embedded throughout the manufacturing cycle. As an ISO 9001-certified facility and active member of WEDA and CEDA, East Marine adheres to stringent quality protocols. Every hose undergoes hydrostatic pressure testing, dimensional verification, and visual inspection post-vulcanization. Additionally, periodic batch testing is conducted in our on-site laboratory to validate elongation, hardness, and adhesion strength between layers.

Our investment in automation, process standardization, and workforce training enables us to maintain tight tolerances and rapid throughput without compromising durability. The integration of digital quality management systems allows full traceability from raw material to finished product, providing clients with confidence in every meter of hose supplied.

The following table outlines the standard technical specifications for our dredging suction and discharge hoses:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 40 bar) |

| Zakres temperatur | -20°C to +85°C |

| Reinforcement Type | High-Tensile Synthetic Fabric or Steel Wire |

| Cover Resistance | Abrasion, UV, Ozone, Seawater |

| Standards Compliance | ISO 1436, DIN 28220, BS 5842 |

| Production Capacity (Annual) | 300,000 meters |

| Vulcanization Method | Autoclave & Continuous Tunnel |

Critical Applications

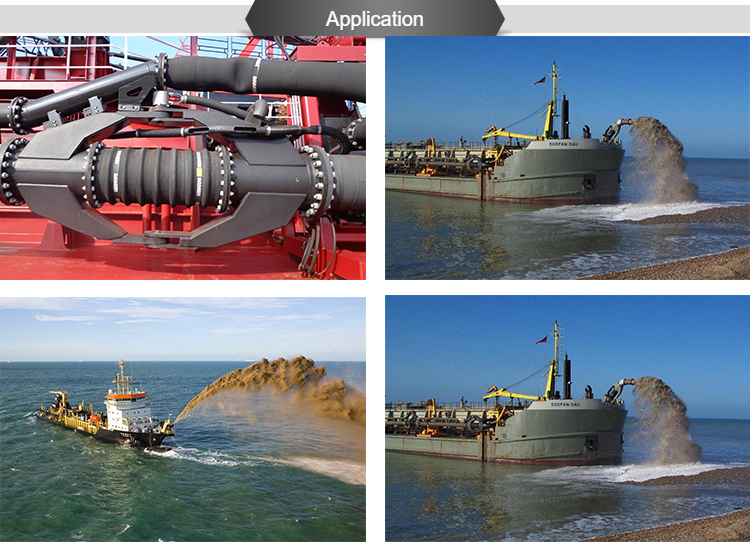

Global Project Applications for High-Pressure Dredging Hoses in Water Jet-Assisted Operations

The term “hose water jet” requires precise technical clarification within the dredging and marine construction sector. East Marine, as a specialized manufacturer of dredging rubber hoses, confirms that water jets themselves are integral components of cutter suction dredgers (CSDs) or jet pumps designed to fluidize seabed material. The critical rubber hoses—our core product—transport the resulting high-velocity slurry mixture of water, sand, silt, and debris under extreme pressure and abrasion. These reinforced suction and discharge hoses are indispensable across demanding global projects where water jet technology enhances excavation efficiency.

In major capital dredging projects, such as deepening shipping channels or port expansions, CSDs utilize submerged water jets to break down compacted sediments. East Marine’s dredging hoses, engineered with multi-spiral wire reinforcement and specialized abrasion-resistant rubber compounds, reliably convey this abrasive slurry over distances exceeding several kilometers. Their flexibility and pressure integrity are paramount during pipeline laying operations in challenging marine environments, directly supporting the effectiveness of the water jet excavation process. Similarly, in offshore oil and gas fields, these hoses are deployed for pipeline cleaning (pigging operations), wellhead maintenance, and subsea excavation near platforms. The ability to withstand cyclic pressure surges and resist degradation from hydrocarbons or seawater is non-negotiable for operational safety and continuity in these critical energy infrastructure settings.

Land reclamation projects, particularly large-scale coastal developments and island creation, represent another vital application domain. Here, dredged material—fluidized initially by water jets—is pumped via extensive floating and submerged hose systems to designated reclamation areas. East Marine hoses must endure constant wave action, UV exposure, and the relentless abrasion of dense sand-laden flows. Their robust construction ensures minimal downtime during continuous 24/7 operations, which is essential for meeting aggressive project timelines on megaprojects common in Southeast Asia and the Middle East. As active members of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), East Marine adheres to the highest international standards for equipment performance and environmental stewardship embedded within these projects. Our ISO 9001-certified manufacturing processes, operating across a 0.68 million square meter facility since 2007, guarantee the consistency and reliability demanded by global contractors executing complex water jet-assisted operations.

Technical specifications for hoses deployed in these water jet-integrated applications must address extreme operational demands. Key performance parameters include:

| Application Type | Pressure Range (bar) | Key Material Property | Typical Project Scale |

|---|---|---|---|

| Capital Dredging (CSDs) | 16-25 | Ultra-High Abrasion Resistance (ISO 4649 < 80 mm³) | Port Expansions, Deepwater Channels (10M+ m³) |

| Offshore Oil & Gas Support | 10-20 | Hydrocarbon & Seawater Resistance | Pipeline Maintenance, Subsea Excavation |

| Land Reclamation | 12-18 | Flex Fatigue Endurance & UV Stability | Coastal Development, Island Creation (5M+ m³) |

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: Performance Metrics for Suction and Discharge Applications

In the demanding environment of hydraulic dredging operations, the performance of suction and discharge hoses directly impacts project efficiency, safety, and operational uptime. As a leading manufacturer within the dredging industry, East Marine—operating under Jiangsu Huashen Special Rubber Products—delivers high-performance rubber hoses engineered for extreme abrasion resistance, pressure integrity, and flexibility. With over 15 years of specialized production experience and a 0.68 million square meter manufacturing facility, our hoses are developed in alignment with international standards and tested rigorously to ensure reliability under harsh marine and riverbed conditions.

When comparing dredging hoses, four key technical parameters determine suitability for specific applications: inner diameter (ID), working pressure, burst pressure, and minimum bending radius. These factors influence flow capacity, structural durability, and ease of deployment across floating, submerged, and articulated pipeline systems. East Marine’s hoses are reinforced with high-tensile textile and steel wire braiding, providing superior pressure resistance while maintaining a compact bending radius for improved maneuverability in confined or dynamic environments.

Competitor hoses, while available across global markets, often prioritize cost reduction over long-term performance, leading to thicker wall construction, reduced flexibility, and lower burst-to-working pressure ratios. In contrast, East Marine’s optimized rubber compound formulation and precision layering techniques result in lighter, more flexible hoses without compromising safety margins. Our products consistently achieve a minimum 4:1 burst-to-working pressure ratio, exceeding ISO 1436 and API 16C standards.

The following table presents a representative comparison across standard dredging hose configurations commonly used in medium- to large-scale dredging projects. All values reflect typical industry sizes and are based on 8-layer wire-reinforced rubber hoses with textile interlayers and anti-abrasion outer covers.

| Inner Diameter (mm) | Working Pressure (bar) | Burst Pressure (bar) | Bending Radius (mm) |

|---|---|---|---|

| East Marine | |||

| 400 | 16 | ≥64 | 1,200 |

| 500 | 14 | ≥56 | 1,500 |

| 600 | 12 | ≥48 | 1,800 |

| Competitor Average | |||

| 400 | 12 | ≥48 | 1,400 |

| 500 | 10 | ≥40 | 1,700 |

| 600 | 10 | ≥40 | 2,000 |

East Marine’s technical edge is evident in both higher working pressures and tighter bending radii across equivalent diameters. This combination allows for increased slurry throughput and easier installation on floating pontoons or articulated joints, reducing stress at coupling points and minimizing downtime due to hose fatigue or failure. Additionally, our hoses are manufactured under ISO 9001-certified quality systems and supported by WEDA and CEDA technical collaborations, ensuring continuous innovation and field-proven reliability.

For dredging contractors seeking optimal balance between performance, longevity, and operational flexibility, East Marine’s rubber hoses represent a benchmark in modern dredging fluid transfer technology.

Partner with East Marine

Conclusion: Engineering Precision for Demanding Dredging Water Jet Applications

Selecting the optimal hose for high-pressure water jet systems in dredging operations is not merely a procurement decision; it is a critical engineering imperative that directly impacts project efficiency, operational safety, and total cost of ownership. The relentless abrasion from sediment-laden water, extreme pressure cycling, and exposure to harsh marine environments demand a solution engineered beyond standard specifications. East Marine, leveraging 17 years of specialized expertise as a WEDA and CEDA member, delivers dredging hoses that transcend conventional performance through advanced material science and rigorous ISO9001-certified manufacturing processes. Our hoses are not assembled—they are engineered systems, integrating multi-layer reinforcement architectures and proprietary rubber compounds to ensure structural integrity under sustained 30+ bar working pressures while resisting catastrophic failure modes like cover delamination or braid rupture. This precision engineering translates directly into extended service life, reduced downtime for replacements, and lower lifecycle costs for your capital-intensive dredging assets.

The technical superiority of our solutions is validated daily across global projects, from riverine sediment management to offshore reclamation. We understand that a single hose failure can halt multi-million-dollar operations, which is why every meter of hose undergoes 100% hydrostatic testing and dimensional validation against project-specific parameters. Our commitment extends beyond the product: East Marine’s engineering team collaborates proactively with clients during the design phase to address unique challenges such as dynamic vessel motion, subsea depth compensation, or abrasive slurry composition. This consultative approach ensures seamless integration into your hydraulic system, optimizing flow dynamics and energy efficiency.

Technical Performance Benchmarks for Dredging Water Jet Hoses

| Parameter | Standard Specification | East Marine Enhanced Specification | Test Standard |

|---|---|---|---|

| Working Pressure | 20 bar | 30 bar | ISO 1436 |

| Burst Pressure | 60 bar | ≥ 120 bar | ISO 1402 |

| Zakres temperatur | -20°C to +70°C | -30°C to +85°C | ASTM D2240 |

| Odporność na ścieranie | 120 mm³ loss | ≤ 85 mm³ loss | DIN 53516 |

| Reinforcement Layers | 2-Wire Braid | 3-Wire Braid + Spiral Breaker | ISO 1307 |

| Bend Radius (DN200) | 12 x ID | 9 x ID | ISO 1307 |

Partnering with East Marine means aligning with a manufacturer whose 680,000 sqm facility in Jiangsu operates at the forefront of industrial rubber technology. Our Singapore branch provides dedicated regional support for APAC projects, ensuring rapid technical consultation, logistics coordination, and compliance with local maritime regulations. For projects demanding uncompromising reliability in water jet dredging systems, initiate a technical dialogue with our engineering team. Contact us via WhatsApp at +86-13806109365 for immediate operational support or email hsdredging@eastmarine.tech to schedule a system audit. Specify your project’s pressure profile, media composition, and environmental conditions to receive a validated performance proposal within 24 hours. East Marine does not supply hoses—we deliver engineered certainty for the world’s most challenging hydraulic conveyance tasks. Let our data-driven solutions become the foundation of your next dredging success.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.