Introduction: Navigating the Global Market for offshore marine hoses

In the competitive landscape of the oil and gas industry, sourcing reliable offshore marine hoses is a critical challenge for international B2B buyers. These specialized hoses are essential for the safe and efficient transfer of fluids in harsh marine environments, where failure can lead to significant operational setbacks and environmental hazards. This comprehensive guide aims to equip buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—with the insights necessary for informed purchasing decisions.

Throughout this guide, we will explore various types of offshore marine hoses, detailing their specific applications, from fluid transfer to emergency response scenarios. Buyers will gain a thorough understanding of crucial factors such as supplier vetting processes, cost considerations, and the latest technological advancements in hose design. By addressing these key areas, this resource empowers businesses to navigate the complexities of sourcing offshore marine hoses with confidence, ensuring compliance with industry standards and maximizing operational efficiency.

Ultimately, this guide serves as an authoritative tool for B2B buyers looking to enhance their procurement strategies, mitigate risks associated with marine operations, and foster partnerships with reputable suppliers in the global market. With the right knowledge, businesses can secure hoses that not only meet their operational needs but also uphold safety and environmental integrity.

Spis treści

- Top 10 Offshore Marine Hoses Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for offshore marine hoses

- Understanding offshore marine hoses Types and Variations

- Key Industrial Applications of offshore marine hoses

- 3 Common User Pain Points for ‘offshore marine hoses’ & Their Solutions

- Strategic Material Selection Guide for offshore marine hoses

- In-depth Look: Manufacturing Processes and Quality Assurance for offshore marine hoses

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore marine hoses’

- Comprehensive Cost and Pricing Analysis for offshore marine hoses Sourcing

- Alternatives Analysis: Comparing offshore marine hoses With Other Solutions

- Essential Technical Properties and Trade Terminology for offshore marine hoses

- Navigating Market Dynamics and Sourcing Trends in the offshore marine hoses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of offshore marine hoses

- Strategic Sourcing Conclusion and Outlook for offshore marine hoses

- Ważne zastrzeżenia i warunki użytkowania

Understanding offshore marine hoses Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Floating Hoses | Designed to float on water, made with buoyant materials | Fluid transfer during offshore loading/unloading | Plusy: High flexibility; reduces risk of damage. Wady: Higher initial cost compared to rigid hoses. |

| Submarine Hoses | Reinforced for deep-water applications; resistant to external pressures | Deep-water drilling and fluid transfer | Plusy: Durable under extreme conditions; reliable performance. Wady: Complex installation; requires specialized handling. |

| Composite Hoses | Lightweight, flexible, and resistant to chemicals | Transfer of various fluids including chemicals | Plusy: Versatile; easier handling and installation. Wady: Less durability in extreme environments. |

| Steel Wire Reinforced Hoses | Enhanced strength with steel reinforcements | High-pressure fluid transfer | Plusy: High pressure tolerance; long lifespan. Wady: Heavier; may require additional support structures. |

| Corrugated Hoses | Flexible design with corrugated structure for better movement | Emergency spill response and fluid transfer | Plusy: Excellent flexibility; compact storage. Wady: Potential for kinking under heavy loads. |

What Are Floating Hoses and Their Applications in Offshore Operations?

Floating hoses are engineered to remain buoyant on the water’s surface, making them essential for offshore loading and unloading operations. They are typically constructed from buoyant materials that prevent contact with sharp underwater objects, minimizing damage risks. Their flexibility allows for adaptation to vessel movements, ensuring safe and efficient fluid transfer. When considering floating hoses, buyers should evaluate their operational environment and the specific buoyancy and flexibility requirements to ensure optimal performance.

How Do Submarine Hoses Function in Deep-Water Environments?

Submarine hoses are specifically designed for deep-water applications, featuring reinforced structures that can withstand high external pressures. These hoses are critical for fluid transfer in offshore drilling operations and are built to endure harsh underwater conditions. B2B buyers should consider the hose’s pressure ratings and material compatibility with the fluids being transferred. The complexity of installation and maintenance also necessitates careful planning and expertise, making supplier reliability a key factor in procurement decisions.

What Advantages Do Composite Hoses Offer for Chemical Transfer?

Composite hoses are lightweight and flexible, making them ideal for transferring a wide range of fluids, including chemicals. Their resistance to various chemicals allows for versatile applications, enhancing their appeal in diverse industries. Buyers should weigh the benefits of easier handling and installation against potential durability issues in extreme environments. Understanding the specific chemical compatibility and operational demands is crucial for ensuring long-term performance and safety in chemical transfer operations.

Why Choose Steel Wire Reinforced Hoses for High-Pressure Applications?

Steel wire reinforced hoses are designed for high-pressure fluid transfer, featuring robust construction that enhances strength and durability. These hoses are commonly used in applications where pressure tolerance is paramount. While their long lifespan and reliability are significant advantages, buyers must also consider the increased weight and potential need for additional support structures during installation. Assessing the specific pressure requirements and environmental conditions is essential for making an informed purchasing decision.

How Can Corrugated Hoses Be Utilized in Emergency Response Scenarios?

Corrugated hoses offer excellent flexibility and compact storage, making them suitable for emergency spill response and fluid transfer tasks. Their unique design allows for easy movement and manipulation, which is crucial in urgent situations. However, buyers should be aware of the potential for kinking under heavy loads, which could compromise their effectiveness. Evaluating the specific emergency scenarios and ensuring the hoses meet necessary performance standards is vital for successful deployment in crisis situations.

Key Industrial Applications of offshore marine hoses

| Przemysł/sektor | Specific Application of offshore marine hoses | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Ropa i gaz | Fluid transfer between offshore platforms and vessels | Ensures safe, efficient transport of crude oil and natural gas | Durability under high pressure; compliance with industry standards |

| Przetwarzanie chemiczne | Transfer of hazardous chemicals between vessels | Minimizes risk of spills and contamination | Material compatibility; safety certifications |

| Emergency Response | Spill containment and diversion during incidents | Protects the environment and reduces cleanup costs | Flexibility and rapid deployment capabilities |

| Offshore Drilling | Movement of drilling fluids between rigs and wells | Zwiększa wydajność operacyjną i bezpieczeństwo | Resistance to abrasion and corrosive materials |

| Marine Transportation | Loading and unloading of cargo at offshore terminals | Streamlines supply chain operations | Customizable configurations for specific vessel types |

How Are Offshore Marine Hoses Used in the Oil and Gas Sector?

In the oil and gas industry, offshore marine hoses are primarily used for the transfer of crude oil and natural gas between offshore platforms and supply vessels. These hoses are designed to withstand high pressures and dynamic movements typical in marine environments, ensuring safe and effective fluid transport. For international buyers, particularly those from regions like Africa and the Middle East, it is crucial to source hoses that comply with local regulations and international safety standards, ensuring reliability in operations.

What Role Do Offshore Marine Hoses Play in Chemical Processing?

Offshore marine hoses are vital for the safe transfer of hazardous chemicals between vessels and offshore platforms. They minimize the risk of spills and contamination, which can lead to significant environmental damage and financial liabilities. Buyers in South America and Europe must consider the material compatibility of hoses with specific chemicals, as well as the certifications that guarantee safety in handling hazardous substances.

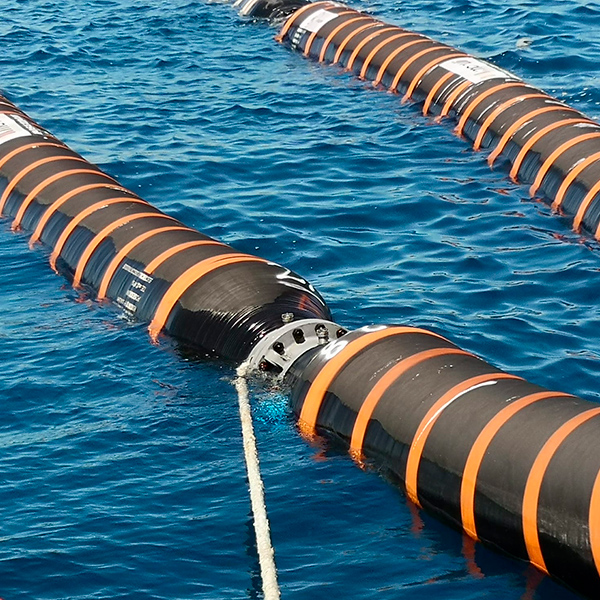

Illustrative image related to offshore marine hoses

How Are Offshore Marine Hoses Utilized in Emergency Response Scenarios?

In emergency situations, offshore marine hoses are essential for spill containment and diversion, helping to minimize environmental impact. These hoses allow for rapid deployment and flexible configurations, which are crucial during incidents where time is of the essence. Businesses must prioritize sourcing hoses that are not only flexible but also robust enough to handle the demands of emergency scenarios, ensuring that they can respond effectively to unforeseen events.

What Is the Importance of Offshore Marine Hoses in Offshore Drilling Operations?

In offshore drilling operations, marine hoses facilitate the movement of drilling fluids between rigs and wells. This application is critical for maintaining operational efficiency and ensuring safety during drilling activities. Buyers should focus on hoses that exhibit high resistance to abrasion and corrosion, as drilling fluids can be particularly harsh. Understanding the specific requirements for drilling operations is essential for selecting the appropriate hose type.

How Do Offshore Marine Hoses Enhance Marine Transportation Efficiency?

Offshore marine hoses streamline loading and unloading processes at offshore terminals, facilitating the transportation of various cargo types. Their ability to adapt to different vessel types and configurations enhances supply chain efficiency. For buyers in Europe and South America, sourcing hoses that offer customization options can significantly improve operational workflows and reduce downtime during cargo handling.

3 Common User Pain Points for ‘offshore marine hoses’ & Their Solutions

Scenario 1: Inconsistent Fluid Transfer Efficiency

Problem: B2B buyers often face significant challenges with the efficiency of fluid transfer operations using offshore marine hoses. Inconsistent performance can lead to delays, operational downtime, and increased costs, particularly in remote locations where timely delivery of crude oil, natural gas, or chemicals is critical. Environmental conditions, such as strong currents or harsh weather, can exacerbate this issue, leading to hose failure or leaks that compromise safety and environmental integrity.

Rozwiązanie: To ensure consistent fluid transfer efficiency, buyers should prioritize sourcing high-quality offshore marine hoses specifically designed for dynamic offshore environments. It is crucial to specify hoses that meet rigorous industry standards for pressure and flexibility. Buyers should consult with manufacturers to understand Minimum Bending Radius (MBR) and Maximum Rated Buoyancy (MRB) metrics relevant to their specific applications. Regular maintenance checks, including inspections for wear and tear, can also prevent unexpected failures. Additionally, investing in advanced monitoring technologies that track hose performance in real-time can help identify issues before they escalate, ensuring smoother operations.

Illustrative image related to offshore marine hoses

Scenario 2: Frequent Hose Damage and Replacement

Problem: Many B2B buyers experience high costs and operational interruptions due to frequent damage and replacement of offshore marine hoses. Factors such as abrasive materials, exposure to harsh chemicals, or physical impacts from submerged structures can lead to premature wear. This not only incurs replacement costs but can also result in environmental hazards and regulatory fines due to leaks or spills.

Rozwiązanie: To mitigate damage, buyers should choose offshore marine hoses constructed from advanced, durable materials designed to withstand the specific environmental and operational challenges they face. For example, hoses with reinforced outer layers or those made from composite materials can provide additional protection against abrasions and chemical exposure. Collaborating with suppliers who offer custom solutions tailored to the unique demands of a specific operation can also be beneficial. Regular training for personnel on proper handling and installation techniques can further reduce the risk of damage during hose deployment and retrieval.

Scenario 3: Compliance with Regulatory Standards

Problem: Navigating the complex web of environmental and safety regulations can be daunting for B2B buyers of offshore marine hoses. Non-compliance can lead to significant financial penalties, reputational damage, and operational shutdowns. This is especially challenging for companies operating across different regions, each with its own regulatory requirements.

Rozwiązanie: Buyers should conduct thorough research into the regulatory landscape relevant to their operations and ensure that all offshore marine hoses sourced comply with the latest standards. Engaging with suppliers who are well-versed in international regulations can provide valuable insights and help ensure that products meet necessary certifications. Additionally, implementing an internal compliance program that regularly reviews and updates operational practices in line with evolving regulations will further safeguard against compliance issues. Establishing a relationship with legal advisors or consultants specializing in maritime law can also provide ongoing support and guidance in navigating these complexities.

Strategic Material Selection Guide for offshore marine hoses

What Are the Key Materials Used in Offshore Marine Hoses?

When selecting materials for offshore marine hoses, buyers must consider various factors, including performance characteristics, environmental conditions, and regulatory compliance. Below is an analysis of four common materials used in the manufacturing of offshore marine hoses, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Illustrative image related to offshore marine hoses

How Do Rubber-Based Materials Perform in Offshore Marine Hoses?

Rubber, particularly synthetic varieties like nitrile and neoprene, is widely used in offshore marine hoses due to its excellent flexibility and resistance to abrasion. These materials typically have a temperature rating of -40°C to 100°C and can withstand pressures up to 20 bar, making them suitable for various fluid transfer applications.

Plusy: Rubber hoses are durable and resistant to wear, making them ideal for dynamic offshore environments. They are also relatively cost-effective, which appeals to budget-conscious buyers.

Wady: However, rubber can be susceptible to degradation from certain chemicals and UV exposure, limiting its use in specific applications. Additionally, manufacturing complexities can arise when designing hoses with specialized rubber compounds.

Wpływ na aplikację: Rubber-based hoses are compatible with a wide range of media, including crude oil and water-based fluids, but may not be suitable for aggressive chemicals.

Illustrative image related to offshore marine hoses

Uwagi dla międzynarodowych nabywców: Buyers in regions like Africa and South America should ensure that rubber hoses meet local compliance standards, such as ASTM or ISO certifications, to guarantee quality and safety.

What Are the Advantages of Using Thermoplastic Materials in Offshore Marine Hoses?

Thermoplastic materials, such as polyvinyl chloride (PVC) and polyurethane (PU), are increasingly popular in offshore marine hoses due to their lightweight nature and excellent chemical resistance. These materials can handle temperatures ranging from -30°C to 80°C and pressures up to 25 bar.

Plusy: The primary advantage of thermoplastics is their resistance to a wide range of chemicals, making them suitable for transporting various fluids, including corrosive chemicals. Their lightweight nature also simplifies installation and reduces shipping costs.

Wady: On the downside, thermoplastic hoses may have lower flexibility than rubber hoses, which can be a disadvantage in dynamic offshore environments. They are also generally more expensive to manufacture.

Wpływ na aplikację: Thermoplastic hoses are ideal for applications requiring high chemical compatibility, such as loading and unloading operations involving hazardous materials.

Illustrative image related to offshore marine hoses

Uwagi dla międzynarodowych nabywców: Buyers must ensure compliance with international standards like DIN or JIS, particularly in European markets, where regulations can be stringent.

How Do Composite Materials Enhance Offshore Marine Hose Performance?

Composite materials, which combine various substances like rubber and thermoplastics, offer enhanced performance characteristics. These hoses typically have temperature ratings of -40°C to 100°C and can withstand pressures exceeding 25 bar.

Plusy: The key advantage of composite hoses is their superior flexibility and strength, making them highly adaptable to varying offshore conditions. They also exhibit excellent resistance to chemicals and UV light.

Wady: However, composite hoses can be more expensive than traditional rubber or thermoplastic hoses, which may deter some buyers. Manufacturing complexities can also increase lead times.

Wpływ na aplikację: Composite hoses are particularly well-suited for applications involving aggressive chemicals or high-pressure scenarios, such as offshore drilling operations.

Illustrative image related to offshore marine hoses

Uwagi dla międzynarodowych nabywców: Buyers should verify that composite hoses comply with relevant international standards, as the complexity of materials can lead to variations in quality.

Why Are Steel Reinforced Hoses Essential for Heavy-Duty Applications?

Steel-reinforced hoses are designed for high-pressure applications, often used in the oil and gas industry for transporting heavy fluids. These hoses can handle temperatures from -40°C to 120°C and pressures exceeding 40 bar.

Plusy: The primary advantage of steel-reinforced hoses is their exceptional strength and durability, making them ideal for heavy-duty applications. They are also resistant to kinking and crushing.

Illustrative image related to offshore marine hoses

Wady: The main disadvantage is their weight and rigidity, which can complicate handling and installation. Additionally, they are generally more expensive than other hose types.

Wpływ na aplikację: Steel-reinforced hoses are essential for applications requiring high-pressure fluid transfer, such as in offshore drilling and emergency response scenarios.

Uwagi dla międzynarodowych nabywców: Buyers should ensure these hoses meet rigorous safety and quality standards, particularly in Europe and the Middle East, where compliance is critical.

Summary Table of Material Selection for Offshore Marine Hoses

| Materiał | Typical Use Case for Offshore Marine Hoses | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Guma | Fluid transfer, general applications | Durable and cost-effective | Susceptible to chemical degradation | Niski |

| Termoplastyczny | Chemical transport, lightweight applications | High chemical resistance | Lower flexibility compared to rubber | Med |

| Composite | High-pressure and chemical applications | Superior flexibility and strength | Higher manufacturing costs | Wysoki |

| Steel Reinforced | Heavy-duty, high-pressure applications | Exceptional strength and durability | Heavy and rigid, complicating installation | Wysoki |

This strategic material selection guide provides a comprehensive overview for B2B buyers in the offshore marine hose market, enabling informed decisions based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for offshore marine hoses

What Are the Main Stages in the Manufacturing Process of Offshore Marine Hoses?

The manufacturing of offshore marine hoses involves several critical stages, each designed to ensure the final product meets the rigorous demands of the oil and gas industry. The main stages include material preparation, forming, assembly, and finishing.

-

Przygotowanie materiału

The first step in the manufacturing process is selecting high-quality raw materials, typically comprising synthetic rubber, textiles, and reinforcing fibers. These materials are evaluated for their resistance to chemicals, temperature extremes, and abrasion. The preparation phase may involve mixing rubber compounds with various additives to enhance performance characteristics. This step is essential to ensure that the hoses can withstand harsh offshore environments. -

Formowanie

During the forming stage, the prepared materials are shaped into the desired hose structure. This typically involves extrusion, where the rubber is heated and forced through a die to create the hose profile. Depending on the design, this may also include layering different materials to provide the necessary structural integrity and flexibility. Techniques such as mandrel winding or braiding may be utilized to enhance the hose’s strength and buoyancy. -

Montaż

In the assembly stage, the formed hose is integrated with additional components, such as end fittings and connectors, which are crucial for ensuring leak-free connections during fluid transfer. This process may involve vulcanization, where heat and pressure are applied to bond the rubber components firmly. Proper assembly is vital to prevent premature failure during operational use. -

Wykończenie

The final stage of manufacturing involves quality finishing touches, including surface treatments and coatings that enhance durability and resistance to environmental factors. This stage may also involve the application of buoyancy materials for floating hoses, which are critical in offshore applications. The hoses are then subjected to final inspection and testing to ensure they meet all specifications before being packaged for shipment.

How Is Quality Assurance Implemented in Offshore Marine Hose Manufacturing?

Quality assurance (QA) in offshore marine hose manufacturing is paramount, given the potential risks associated with fluid transfer operations. International standards such as ISO 9001 and industry-specific certifications like API (American Petroleum Institute) and CE (Conformité Européenne) provide frameworks for quality management.

-

What Are the Relevant International Standards for Offshore Marine Hoses?

Compliance with ISO 9001 ensures that manufacturers maintain a consistent quality management system, focusing on continuous improvement and customer satisfaction. API standards, particularly API 17K, specify requirements for the design and testing of marine hoses used in offshore applications. CE marking is crucial for products sold in the European market, indicating conformity with health, safety, and environmental protection standards. -

What QC Checkpoints Should Be Established?

A comprehensive quality control program typically includes several key checkpoints:

– Przychodząca kontrola jakości (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– Kontrola jakości w trakcie procesu (IPQC): Quality checks during the manufacturing process help identify and rectify issues early, ensuring that any deviations from standards are addressed immediately.

– Końcowa kontrola jakości (FQC): At this stage, the finished hoses undergo rigorous testing for pressure, flexibility, and buoyancy, ensuring they meet operational requirements.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods for offshore marine hoses encompass a variety of techniques to ensure performance and safety standards are met:

Illustrative image related to offshore marine hoses

- Hydrostatic Testing: This method involves pressurizing the hose with water to check for leaks and structural integrity.

- Dynamic Testing: Hoses are subjected to simulated operational conditions, including bending and flexing, to evaluate performance under realistic scenarios.

- Chemical Resistance Testing: Samples are exposed to various chemicals to ensure they do not degrade when in contact with substances they will encounter in service.

W jaki sposób nabywcy B2B mogą weryfikować praktyki kontroli jakości dostawców?

B2B buyers must be diligent in verifying the quality control practices of their suppliers. Here are several strategies to consider:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance measures. This process allows buyers to assess compliance with international standards and identify any areas for improvement.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s testing protocols and outcomes. These reports should include data on pass/fail rates for critical tests and any corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of confidence in the products being sourced. These agencies can provide unbiased assessments of the supplier’s quality management systems and product reliability.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding QC and certification nuances is crucial. Different regions may have varying compliance requirements, and navigating these can be complex.

-

Regional Compliance: Buyers should familiarize themselves with regional regulations and standards that may affect product acceptance. For example, certain countries may have stricter environmental regulations that impact material selection or testing methods.

-

Documentation Requirements: Ensuring that suppliers provide the necessary documentation, such as certificates of compliance, test results, and quality management system certifications, is critical. This documentation can facilitate smoother customs clearance and regulatory compliance.

-

Cultural Sensitivity in Communication: Engaging with suppliers from diverse regions may require sensitivity to cultural differences in business practices and communication styles. Building strong relationships based on trust and transparency can enhance collaboration and quality assurance efforts.

In conclusion, understanding the manufacturing processes and quality assurance measures for offshore marine hoses is vital for B2B buyers. By focusing on these areas, buyers can ensure that they procure high-quality products that meet the stringent demands of offshore operations, ultimately safeguarding their investments and enhancing operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore marine hoses’

To effectively procure offshore marine hoses, it is essential to follow a structured approach that ensures all critical factors are considered. This guide provides a step-by-step checklist tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By adhering to these steps, you can streamline your sourcing process and make informed decisions.

Krok 1: Zdefiniuj swoje specyfikacje techniczne

Establishing clear technical specifications is crucial for selecting the right offshore marine hoses. Consider the types of fluids being transferred, the required pressure ratings, and environmental conditions. Specifics such as the Minimum Bending Radius (MBR) and Maximum Rated Buoyancy (MRB) should be included to ensure compatibility with your operational needs.

Krok 2: Research Regulatory Compliance Requirements

Understanding the regulatory landscape is essential for international procurement. Different regions have specific regulations regarding safety, environmental impact, and quality standards for offshore marine hoses. Ensure that the hoses you select comply with relevant local and international standards, such as API, ISO, or DNV GL certifications.

Krok 3: Ocena potencjalnych dostawców

Before committing, it is crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their experience in offshore applications, as well as their track record for quality and reliability. Look for suppliers that demonstrate strong customer service and support.

Krok 4: Assess Quality Assurance Processes

Quality assurance is paramount in the offshore marine industry due to the high risks associated with fluid transfer operations. Inquire about the supplier’s manufacturing processes, testing protocols, and quality control measures. Ensure they conduct rigorous testing for durability, flexibility, and resistance to environmental factors, which are critical for long-term performance.

Illustrative image related to offshore marine hoses

Krok 5: Zamów próbki do testów

Before finalizing your order, request samples of the hoses for on-site testing. This allows you to evaluate their performance under actual working conditions. Check for flexibility, strength, and resistance to abrasion or corrosion, which are vital for ensuring the hoses will meet your operational demands.

Krok 6: Negocjowanie warunków

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, delivery schedules, and after-sales support. Clearly outline warranty conditions and service agreements to protect your investment and ensure prompt assistance when needed.

Krok 7: Plan for Logistics and Installation

Finally, coordinate logistics for the delivery and installation of the hoses. Ensure that the supplier can meet your timeline and that you have the necessary resources for proper installation. Consider training for your personnel on handling and maintaining the hoses to maximize their lifespan and effectiveness.

By following this checklist, you can ensure a thorough and efficient procurement process for offshore marine hoses, ultimately enhancing the safety and reliability of your operations.

Illustrative image related to offshore marine hoses

Comprehensive Cost and Pricing Analysis for offshore marine hoses Sourcing

What Are the Key Cost Components in Offshore Marine Hoses?

When sourcing offshore marine hoses, understanding the cost structure is crucial for effective budget management. The primary cost components include:

-

Materiały: High-quality materials such as synthetic rubber, thermoplastics, and reinforcement fibers are essential for the durability and performance of marine hoses. The choice of materials significantly affects the overall cost, as premium options are often more expensive but offer better resilience in harsh environments.

-

Praca: Skilled labor is required for the production of marine hoses. This includes the workforce involved in manufacturing, assembly, and quality control. Labor costs can vary significantly depending on the region and the complexity of the hose design.

-

Koszty ogólne produkcji: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Oprzyrządowanie: The initial investment in tooling can be substantial, especially for custom hose designs. Tooling costs are often amortized over larger production runs, making high-volume orders more cost-effective.

-

Kontrola jakości (QC): Ensuring the hoses meet industry standards and certifications involves rigorous testing and quality assurance processes. These QC measures are vital for safety and reliability, adding to the overall cost but providing long-term value.

-

Logistyka: Transportation and handling costs can vary based on the distance from the manufacturing facility to the end-user, as well as the mode of transport. For international buyers, understanding the logistics involved is crucial to avoid unexpected expenses.

-

Margines: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s market position, reputation, and the competitive landscape.

How Do Pricing Influencers Affect Offshore Marine Hose Costs?

Several factors influence the pricing of offshore marine hoses, and understanding these can aid in making informed purchasing decisions:

-

Objętość/MOQ: Suppliers often have minimum order quantities (MOQ) that can significantly affect pricing. Larger orders usually come with discounts, allowing buyers to benefit from economies of scale.

-

Specifications/Customization: Custom specifications, such as unique dimensions or additional features, can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materiały: The type of materials selected impacts both performance and cost. For example, hoses designed for extreme conditions will require more robust materials, which can be pricier.

-

Jakość i certyfikaty: Hoses that meet international standards or have specific certifications (e.g., API, ISO) may command higher prices. However, they often provide better reliability and safety, justifying the investment.

-

Czynniki dostawcy: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the terms of shipment and delivery (Incoterms) is essential for calculating the total cost of ownership. Different terms can shift responsibility for costs and risks between buyer and seller, impacting the final price.

What Are Effective Buyer Tips for Sourcing Offshore Marine Hoses?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize sourcing:

-

Negocjacje: Leverage volume and long-term relationships during negotiations. Establishing a good rapport with suppliers can lead to better pricing and terms.

-

Cost-Efficiency: Evaluate the total cost of ownership, not just the purchase price. Consider maintenance, lifespan, and reliability when comparing options.

-

Pricing Nuances: Be aware of currency fluctuations and tariffs that may affect pricing. Understanding the local market conditions can also provide leverage during negotiations.

-

Supplier Research: Conduct thorough research on potential suppliers, including their certifications, customer reviews, and industry standing. This diligence can help ensure you choose a reliable partner.

-

Documentation and Compliance: Ensure all necessary documentation is in place for international shipments, including customs paperwork and compliance certificates, to avoid delays and additional costs.

Disclaimer for Indicative Prices

Prices for offshore marine hoses can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and specific project requirements. Buyers are encouraged to request quotes tailored to their unique needs for the most accurate pricing information.

Alternatives Analysis: Comparing offshore marine hoses With Other Solutions

Introduction: Understanding Alternatives to Offshore Marine Hoses

When evaluating solutions for fluid transfer in offshore operations, it’s crucial to consider various alternatives to offshore marine hoses. Each option presents unique advantages and challenges, impacting performance, cost, and implementation. This section explores how offshore marine hoses compare to alternative technologies, aiding B2B buyers in making informed decisions.

Tabela porównawcza

| Aspekt porównawczy | Offshore Marine Hoses | Flexible Rigid Pipes | Subsea Pipeline Systems |

|---|---|---|---|

| Wydajność | High flexibility, suitable for dynamic movements; resistant to harsh conditions | Good for stable environments; limited flexibility | Excellent for long-distance transport; stable under high pressure |

| Koszt | Moderate initial investment; long-term durability reduces costs | Lower upfront cost but may require frequent replacements | High initial investment; lower ongoing costs due to durability |

| Łatwość wdrożenia | Requires specialized installation and training | Easier installation with standard fittings | Complex installation requiring specialized equipment and expertise |

| Konserwacja | Regular inspections needed; moderate maintenance costs | Higher maintenance frequency; prone to wear | Low maintenance once installed; occasional inspections needed |

| Najlepszy przypadek użycia | Ideal for offshore loading/unloading; emergency response | Suitable for onshore applications or stable offshore environments | Best for large-scale, long-term offshore transport |

Szczegółowy podział alternatyw

Flexible Rigid Pipes

Flexible rigid pipes are often used in offshore applications where flexibility is required but not to the extent of marine hoses. They offer a good balance between performance and cost. Their easier installation process makes them appealing, especially for projects with time constraints. However, they tend to have a shorter lifespan and may require more frequent replacements, leading to higher long-term costs. They are best suited for stable environments where extreme dynamic movement is not a concern.

Subsea Pipeline Systems

Subsea pipelines are designed for long-distance transport of fluids under high pressure. They provide excellent stability and are ideal for extensive offshore projects where continuous fluid transfer is needed. While the initial investment is significantly higher than that of offshore marine hoses, the durability and low maintenance requirements can offset these costs in the long run. However, the installation process is complex and requires specialized equipment, making it less suitable for smaller operations or emergency situations.

Podsumowanie: Wybór rozwiązania odpowiedniego do potrzeb

When selecting the appropriate fluid transfer solution, B2B buyers should carefully evaluate their specific operational requirements, budget constraints, and long-term maintenance capabilities. Offshore marine hoses provide excellent performance in dynamic environments, while flexible rigid pipes and subsea pipeline systems offer viable alternatives depending on the application context. Understanding the nuances of each option will empower buyers to make informed choices tailored to their operational needs, ensuring safety, efficiency, and cost-effectiveness in their offshore operations.

Essential Technical Properties and Trade Terminology for offshore marine hoses

What Are the Key Technical Properties of Offshore Marine Hoses?

Understanding the essential technical properties of offshore marine hoses is crucial for B2B buyers in the oil and gas industry. Here are some critical specifications to consider:

Illustrative image related to offshore marine hoses

1. Material Grade

Offshore marine hoses are typically constructed from high-grade materials such as synthetic rubber, steel reinforcement, or composite materials. The material grade affects the hose’s resistance to abrasion, corrosion, and temperature fluctuations. Selecting the right material grade ensures optimal performance and longevity in harsh offshore environments, reducing maintenance costs and downtime.

2. Minimum Bending Radius (MBR)

The Minimum Bending Radius refers to the smallest radius at which a hose can bend without compromising its structural integrity. This specification is vital for offshore applications where hoses frequently experience bending due to vessel movements and dynamic conditions. Understanding MBR helps buyers select hoses that can handle the specific operational demands of their offshore projects, preventing kinks and potential failures.

3. Maximum Rated Buoyancy (MRB)

Maximum Rated Buoyancy is the highest buoyant force a hose can generate when fully submerged in water. This property is critical for floating hoses used in loading and unloading operations to ensure they remain afloat even when filled with fluids. Properly assessing MRB helps in preventing spills and ensuring safe fluid transfer, which is crucial for environmental protection and regulatory compliance.

4. Pressure Rating

Pressure rating indicates the maximum pressure that a hose can withstand during operation. This specification is essential for ensuring the safety and reliability of fluid transfer operations, as exceeding the pressure rating can lead to hose failure and catastrophic incidents. Buyers must carefully match the pressure rating of the hoses with the operational requirements of their projects to mitigate risks.

5. Tolerance

Tolerance refers to the allowable variations in the hose’s dimensions and properties. A tight tolerance ensures consistency in performance and quality, which is critical for maintaining the efficiency of offshore operations. Buyers should prioritize hoses with stringent tolerances to ensure compatibility with existing systems and to reduce the likelihood of operational disruptions.

What Are Common Trade Terms Related to Offshore Marine Hoses?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marine hose market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of offshore marine hoses, OEMs are crucial for ensuring that hoses meet specific industry standards and performance criteria. Buyers often prefer OEM hoses for their reliability and proven track record.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to assess inventory needs and manage budgets effectively. It helps avoid overstocking while ensuring that sufficient quantities are available for operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of products. For B2B buyers, issuing an RFQ is a critical step in the procurement process, enabling them to compare offers from various suppliers and make informed purchasing decisions.

4. Incoterms

Incoterms, or International Commercial Terms, are predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding Incoterms is vital for buyers to clarify shipping responsibilities, risk management, and cost allocation.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It is a crucial factor for B2B buyers to consider, especially in industries where timely delivery is essential for operational continuity. Understanding lead times helps in planning and inventory management, ensuring that projects remain on schedule.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting offshore marine hoses, thereby enhancing operational efficiency and safety in their projects.

Navigating Market Dynamics and Sourcing Trends in the offshore marine hoses Sector

What Are the Current Market Dynamics and Key Trends in the Offshore Marine Hoses Sector?

The offshore marine hoses sector is witnessing transformative shifts driven by several global factors. A primary driver is the increasing demand for energy, particularly in emerging markets such as Africa and South America, where oil and gas exploration and production are on the rise. Technological advancements in hose manufacturing, such as the introduction of high-performance materials that enhance durability and flexibility, are enabling suppliers to meet the rigorous demands of offshore operations. These innovations are crucial for ensuring efficient fluid transfer in harsh marine environments, thereby minimizing operational downtimes and enhancing safety protocols.

In addition, international B2B buyers are increasingly prioritizing suppliers who offer integrated solutions, including real-time monitoring systems for hose performance and maintenance. This trend is particularly pertinent for companies in Europe and the Middle East, where stringent regulations necessitate a proactive approach to risk management. Moreover, the emphasis on sustainability is reshaping sourcing strategies. Buyers are gravitating towards suppliers who adopt eco-friendly practices and materials, which not only reduce environmental impact but also align with corporate social responsibility goals.

Emerging sourcing trends are also influenced by geopolitical dynamics and supply chain disruptions. For instance, the ongoing transition to renewable energy sources is prompting a reevaluation of traditional sourcing channels, encouraging buyers to explore alternatives that may offer greater resilience. As a result, strategic partnerships and collaborations are becoming increasingly vital for navigating the complexities of the offshore marine hoses market.

How Is Sustainability Influencing Sourcing Decisions for Offshore Marine Hoses?

The importance of sustainability in sourcing offshore marine hoses cannot be overstated. The environmental impact of oil and gas operations has come under scrutiny, prompting buyers to seek out solutions that mitigate ecological risks. This shift is driving demand for hoses constructed from sustainable materials, as well as those that comply with international environmental standards. Buyers are increasingly looking for products that carry certifications such as ISO 14001, which indicates adherence to effective environmental management systems.

Ethical supply chains are becoming a significant focus area for international B2B buyers. The push for transparency in sourcing practices is compelling suppliers to demonstrate their commitment to ethical standards, from material sourcing to labor practices. Companies that can provide proof of sustainable practices are not only appealing to environmentally-conscious buyers but also enhancing their brand reputation in a competitive marketplace.

Additionally, there is a growing trend toward the use of recyclable and biodegradable materials in the production of offshore marine hoses. This shift not only helps companies reduce their carbon footprint but also addresses regulatory pressures related to waste management and pollution. Consequently, suppliers who prioritize sustainability and ethical practices are likely to gain a competitive edge in the global market.

Illustrative image related to offshore marine hoses

What Is the Historical Context of Offshore Marine Hoses That Buyers Should Know?

The evolution of offshore marine hoses has been closely tied to advancements in the oil and gas industry. Initially, these hoses were rudimentary, often constructed from basic rubber materials, which limited their performance and durability in challenging marine environments. However, as offshore drilling operations expanded in the late 20th century, there was a pressing need for more resilient solutions capable of withstanding high pressures and dynamic movements.

The introduction of synthetic materials in the 1980s marked a significant milestone, enhancing the flexibility and strength of marine hoses. This evolution continued into the 21st century, with innovations in technology leading to the development of floating hoses designed for specific applications such as loading and unloading operations. Today, these hoses are integral to offshore fluid transfer processes, underscoring the importance of selecting high-quality products that meet the evolving demands of the industry.

Understanding this historical context is essential for B2B buyers, as it highlights the importance of innovation and quality in sourcing decisions. Buyers can leverage this knowledge to engage with suppliers who not only understand the technical requirements of their products but also have a track record of adapting to industry changes. This awareness can ultimately lead to more informed purchasing decisions and successful operational outcomes.

Frequently Asked Questions (FAQs) for B2B Buyers of offshore marine hoses

-

How do I ensure the quality of offshore marine hoses?

To ensure the quality of offshore marine hoses, it’s crucial to select suppliers that adhere to international standards and certifications, such as ISO 9001 and API specifications. Request detailed documentation regarding the materials used, manufacturing processes, and quality assurance measures. Additionally, consider third-party testing and inspections to verify hose performance under extreme conditions. Establishing a robust vetting process for suppliers, including site visits and reviews of past projects, can further enhance confidence in the quality of the hoses procured. -

What specifications should I consider when sourcing offshore marine hoses?

When sourcing offshore marine hoses, key specifications to consider include the hose’s pressure rating, temperature tolerance, and material compatibility with the fluids being transferred. Additionally, evaluate the Minimum Bending Radius (MBR) and Maximum Rated Buoyancy (MRB) to ensure suitability for dynamic offshore environments. It’s also essential to consider the hose length and diameter based on your operational needs. Lastly, inquire about the hose’s resistance to external factors such as UV exposure, abrasion, and chemicals to ensure longevity and reliability. -

What are the common applications for offshore marine hoses?

Offshore marine hoses are commonly used for fluid transfer in various applications, including the transportation of crude oil, natural gas, and chemicals between offshore platforms, vessels, and terminals. They are integral to loading and unloading operations, ensuring efficient supply chain processes. Additionally, these hoses play a critical role in emergency response scenarios, helping to contain or divert spilled liquids to minimize environmental impact. Understanding these applications can help in selecting the right type of hose for your specific needs. -

What are the payment terms typically offered by suppliers of offshore marine hoses?

Payment terms for offshore marine hoses can vary significantly among suppliers, but common options include net 30, net 60, or advance payment for first-time orders. Some suppliers may offer letters of credit or escrow services to mitigate risk, especially in international transactions. It’s advisable to negotiate favorable terms based on order volume and long-term partnerships. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings and facilitate smoother transactions. -

How can I customize offshore marine hoses to fit my specific requirements?

Many suppliers offer customization options for offshore marine hoses, allowing you to tailor aspects such as length, diameter, and material composition to meet specific operational needs. You may also request features like reinforced sections for added durability, specific end fittings, or color coding for identification. When discussing customization, provide detailed specifications and consult with engineers to ensure the final product meets all safety and operational standards. This collaborative approach can lead to enhanced performance and reliability in demanding environments. -

What is the minimum order quantity (MOQ) for offshore marine hoses?

The minimum order quantity (MOQ) for offshore marine hoses varies by supplier and can depend on factors such as hose specifications and manufacturing capabilities. Generally, MOQs can range from a few units to several hundred, particularly for specialized hoses. It’s essential to discuss your needs with potential suppliers and understand their capacity for small or bulk orders. In some cases, suppliers may offer flexibility in MOQs for long-term contracts or repeat customers, facilitating better inventory management. -

How do I vet suppliers of offshore marine hoses for reliability?

Vetting suppliers for offshore marine hoses involves several steps. Start by researching their industry reputation through online reviews, testimonials, and case studies. Verify their certifications and compliance with international standards. Consider conducting site visits to their manufacturing facilities to assess quality control processes. Additionally, request references from previous clients to gauge satisfaction levels and reliability. Engaging in initial small orders can also help evaluate supplier performance before committing to larger contracts. -

What logistics considerations should I keep in mind when importing offshore marine hoses?

When importing offshore marine hoses, logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder with experience in handling industrial goods to navigate the complexities of international shipping. Be aware of import duties and taxes that may apply, and ensure all necessary documentation is prepared for customs clearance. Additionally, establish clear communication with suppliers regarding shipping schedules and delivery timelines to avoid disruptions in your supply chain.

Top 10 Offshore Marine Hoses Manufacturers & Suppliers List

1. Offshore Marine Hoses – Essential for Oil & Gas Transfer

Domena: offshoremarinehoses.com

Registered: 2023 (2 years)

Wprowadzenie: Offshore marine hoses are essential for the oil and gas industry, facilitating the safe and effective transfer of fluids such as crude oil, natural gas, and chemicals between offshore platforms, vessels, and terminals. They are designed to withstand harsh environmental conditions, including high pressure and dynamic movements. Key applications include fluid transfer, loading and unloading operatio…

2. Continental – Offshore Marine Hoses

Domena: continental-industry.com

Registered: 2018 (7 years)

Wprowadzenie: This company, Continental – Offshore Marine Hoses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Yokohama – GMPHOM 2009 Certified Offshore Marine Hoses

Domena: y-yokohama.com

Zarejestrowany: 2014 (11 lat)

Wprowadzenie: Yokohama offers a complete line of GMPHOM 2009 certified offshore marine hoses. Key design features include superior durability, flexibility, and weight reduction in the double carcass hose. The hoses are manufactured by a highly skilled workforce in state-of-the-art facilities located in Japan and Indonesia.

4. Trelleborg – Offshore Marine Hoses

Domena: trelleborg.com

Zarejestrowany: 1996 (29 lat)

Wprowadzenie: The Trelleborg offshore marine hose selection guide includes a range of long-life offshore marine hoses categorized as SEALINE, KLELINE, REELINE, and TRELLINE. The guide provides a simple application overview for these marine hoses, which are designed for oil applications in offshore fluid transfer. Additional products mentioned include breakaway couplings and connections, composite hoses, expansi…

5. Ridderflex – Offshore Hoses

Domena: ridderflex.com

Zarejestrowany: 2007 (18 lat)

Wprowadzenie: Ridderflex supplies a wide range of hoses for the offshore industry, including:

– Bulk transfer hose

– Bunkering hose

– Chemical hose

– Discharge hose

– Fire rated hose

– Floating hose

– High pressure hose

– Hydraulic hose

– Marine hose

– RIG Supply hose

– Sea-water intake systems

– STS hose (ship-to-ship)

– Suction hose

– Utility hose

Hoses are available in many different types, lengths, and dia…

6. UIP International – Offshore Marine Hoses

Domena: uipintl.com

Zarejestrowany: 2017 (8 lat)

Wprowadzenie: Offshore Oil & Gas Marine Hose | UIP offers full-service design and engineering of marine hoses with high customization for demanding applications. Types of hoses include: 1. Hoses for Ship-to-Shore Service: Single carcass dock loading hoses for oil and gas transfer, available with integrally bonded or swaged fittings. 2. Hoses for Ship-to-Ship Service: Designed for flexibility and strength, suita…

7. The Hose Company – 1/2 SAE 100-R2 SN Hydraulic Hose

Domena: thehosecompany.com

Registered: 2015 (10 years)

Wprowadzenie: {“product_name”:”1/2″ SAE 100-R2 SN 2-WIRE HYDRAULIC HOSE”,”cost_per_foot”:”$2.86″,”assembly_fee”:”$5.00″,”pressure_rating”:”3950 psi”}

8. NexaParts – Maritime Hoses

Domena: nexaparts.com

Registered: 2023 (2 years)

Wprowadzenie: {“maritime_hoses”: [{“type”: “Woven Stainless Steel RVS 316”, “work_pressure”: “125 bar”, “applicable_for”: “Gassen en vloeistoffen”, “price_from”: “€ 10,57”, “shipping_info”: “Ordered Before 15:00, shipped the same day”}, {“type”: “Maritime fuel hose Rubber”, “work_pressure”: “10 bar”, “applicable_for”: “Brandstoffen”, “price_from”: “€ 10,40”, “shipping_info”: “Ordered Before 15:00, shipped the s…

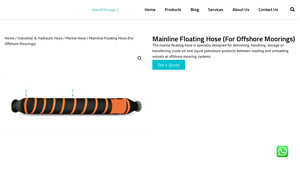

9. Alien Drill – Mainline Floating Hose

Domena: aliendrill.com

Registered: 2024 (1 years)

Wprowadzenie: Mainline Floating Hose for Offshore Moorings is designed for delivering, handling, storage, or transferring crude oil and liquid petroleum products between loading and unloading vessels at offshore mooring systems. It features an independent PE foam layer to prevent water absorption, a rubber compound outer cover for high resistance to UV, corrosion, and wear, and a compact construction for easy i…

10. Offspring International – Fluid Transfer Hoses

Domena: offspringinternational.com

Zarejestrowany: 2000 (25 lat)

Wprowadzenie: Offspring International offers a range of hoses for fluid transfer applications including oil suction & discharge, LPG suction & discharge, fuel transfer, and suction & discharge of petroleum products. All hoses are manufactured and tested according to industry standards such as OCIMF GMPHOM 2009, certified by the American Bureau of Shipping (ABS). The range includes:

1. Single Carcass Hoses: Ava…

Strategic Sourcing Conclusion and Outlook for offshore marine hoses

In the dynamic landscape of offshore operations, strategic sourcing of marine hoses is paramount for ensuring efficiency, safety, and reliability in fluid transfer processes. By understanding the critical applications of offshore marine hoses—such as their role in fluid transfer, emergency response, and drilling operations—buyers can make informed decisions that enhance operational performance. The advancements in hose technology, including features like minimum bending radius (MBR) and maximum rated buoyancy (MRB), underscore the importance of selecting high-quality products that meet industry standards.

Illustrative image related to offshore marine hoses

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the emphasis on sourcing durable and adaptable marine hoses cannot be overstated. Establishing partnerships with reputable suppliers not only mitigates risks associated with offshore operations but also contributes to sustainable practices within the oil and gas industry.

Looking ahead, the demand for innovative solutions in marine fluid handling will continue to grow. Engage with trusted manufacturers and suppliers to stay ahead of industry trends and ensure your operations are equipped with the best marine hose solutions. Take action today to secure your supply chain and enhance the safety and efficiency of your offshore operations.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.