Opis

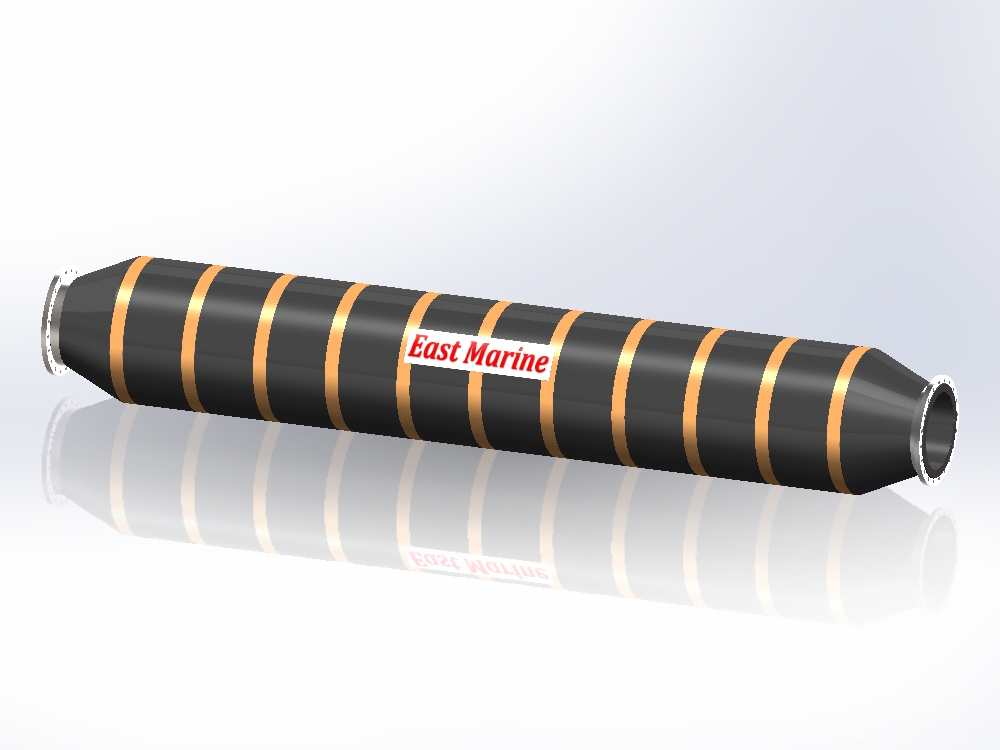

Pływający wąż gumowy

Specifications

| Opis | Szczegóły |

|---|---|

| Nazwa produktu | Pływający wąż gumowy |

| Origin | China |

| Inner Diameter(ID) | 200-1100mm |

| Length | 5800/11800mm |

| Working pressure(WP) | 0.5-4.2Mpa |

| Burst Pressure(BP) | 1.5-12.6Mpa |

| Flange Type | Steel Flange |

| Application | connect with CSD/TSHD dredgers to transport mud,sand,water and others |

Key Benefits and Features

- Highly wear-resistant natural rubber, suitable for demanding dredging conditions, significantly extends service life.

- Flexible rubber combined with flanged ends allows easy maneuvering during operation, enhancing handling performance.

- The inner high-strength steel rings absorb vibration and pulsating pressure generated by the dredge pump and the flowing medium, ensuring smoother system operation and protecting other equipment.

- Maintains long-lasting durability in harsh environments, ensuring stable performance under various working conditions.

Floating Rubber Hose Inspection:

To ensure each floating rubber hose meets the required performance and safety standards, a series of strict inspections and tests are carried out throughout the production process:

-

Raw Material Test: Each batch of raw materials, including natural rubber, tensile textile, and rubber additives, is carefully inspected before entering the warehouse to ensure quality consistency and durability.

-

Hose Dimension Check: The hose’s inner and outer diameters, wall thickness, and flange alignment are measured to confirm they meet design specifications.

-

Weight Check: Each hose is weighed to verify it falls within the acceptable tolerance range, ensuring uniform product quality.

-

Vacuum pressure Test (if specified): The hose is subjected to pressure testing to confirm its ability to safely withstand the specified working pressure without leakage or deformation.

-

Bending Test (if specified): The hose is tested for flexibility and bending resistance to ensure reliable performance under working conditions.

For additional assurance, we can invite third-party inspection agencies to conduct inspections according to customer requirements.

Floating Rubber Hose Packaging Information:

To ensure the safety of transporting discharge rubber hoses and maximize loading efficiency, we adopt different packaging methods according to the order quantity:

-

Bulk cargo: Delivered in loose packing to the port and then consolidated into containers.

-

Small-volume cargo: Secured on wooden pallets before being loaded into containers to ensure stability and safety during transportation.