Introduction: Navigating the Global Market for what is vulcanised rubber

Navigating the complexities of sourcing high-quality vulcanised rubber can be a daunting challenge for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding what vulcanised rubber is and how it differs from traditional rubber is crucial for making informed purchasing decisions that can significantly impact product performance and durability. This comprehensive guide delves into the intricacies of vulcanised rubber, including its production processes, various types, and wide-ranging applications across multiple industries, from automotive to manufacturing.

In addition to detailing the benefits of vulcanised rubber—such as enhanced strength, elasticity, and resistance to abrasion—this guide provides actionable insights on supplier vetting, cost considerations, and best practices for procurement. By equipping B2B buyers with essential knowledge and practical strategies, this resource empowers businesses to navigate the global market confidently, ensuring that they can source the right materials to meet their specific needs. Whether you are a manufacturer in Saudi Arabia looking to enhance your product offerings or a distributor in Nigeria seeking reliable suppliers, this guide serves as your go-to reference for all things vulcanised rubber.

Spis treści

- Top 3 What Is Vulcanised Rubber Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is vulcanised rubber

- Understanding what is vulcanised rubber Types and Variations

- Key Industrial Applications of what is vulcanised rubber

- 3 Common User Pain Points for ‘what is vulcanised rubber’ & Their Solutions

- Strategic Material Selection Guide for what is vulcanised rubber

- In-depth Look: Manufacturing Processes and Quality Assurance for what is vulcanised rubber

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is vulcanised rubber’

- Comprehensive Cost and Pricing Analysis for what is vulcanised rubber Sourcing

- Alternatives Analysis: Comparing what is vulcanised rubber With Other Solutions

- Essential Technical Properties and Trade Terminology for what is vulcanised rubber

- Navigating Market Dynamics and Sourcing Trends in the what is vulcanised rubber Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is vulcanised rubber

- Strategic Sourcing Conclusion and Outlook for what is vulcanised rubber

- Ważne zastrzeżenia i warunki użytkowania

Understanding what is vulcanised rubber Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Natural Rubber Vulcanizate | Derived from natural rubber; eco-friendly options available | Automotive tires, footwear, industrial hoses | Plusy: Biodegradable, good elasticity. Wady: Less resistant to heat and chemicals compared to synthetic options. |

| Synthetic Rubber Vulcanizate | Made from petrochemical sources; customizable properties | Seals, gaskets, and vibration dampers | Plusy: High durability, customizable, excellent chemical resistance. Wady: Environmental impact from production. |

| Silicone Rubber Vulcanizate | High-temperature resistance; retains flexibility at extreme temperatures | Medical devices, automotive applications | Plusy: Excellent thermal stability, good electrical insulation. Wady: Higher cost, limited mechanical strength. |

| EPDM Rubber Vulcanizate | Ethylene Propylene Diene Monomer; excellent weather and ozone resistance | Roofing membranes, automotive weather seals | Plusy: Durable, good aging resistance. Wady: Limited high-temperature performance. |

| Neoprene Rubber Vulcanizate | Chloroprene-based; good resistance to oils and chemicals | Wetsuits, industrial applications | Plusy: Versatile, excellent chemical resistance. Wady: Can be less elastic than other types. |

What Are the Characteristics of Natural Rubber Vulcanizate?

Natural rubber vulcanizate is primarily sourced from the sap of rubber trees, making it an eco-friendly option for various applications. It boasts excellent elasticity and resilience, making it a popular choice for automotive tires and footwear. When purchasing natural rubber products, consider the specific environmental certifications and the intended use, as its resistance to heat and chemicals may not match that of synthetic alternatives.

How Does Synthetic Rubber Vulcanizate Differ from Natural Options?

Synthetic rubber vulcanizate is engineered from petrochemicals, allowing for enhanced durability and customizable properties. This type is widely used in seals and gaskets due to its superior chemical resistance. B2B buyers should evaluate the specific performance characteristics required for their applications, as synthetic options can be tailored to meet stringent industry standards, albeit with a higher environmental footprint.

What Makes Silicone Rubber Vulcanizate Unique for High-Temperature Applications?

Silicone rubber vulcanizate excels in high-temperature environments, retaining flexibility even under extreme conditions. This property makes it ideal for medical devices and automotive applications. Buyers should consider the cost versus performance ratio, as silicone products tend to be more expensive but offer unparalleled thermal stability and electrical insulation, which can be crucial for specific applications.

Why Choose EPDM Rubber Vulcanizate for Outdoor Use?

EPDM rubber vulcanizate is known for its exceptional weather and ozone resistance, making it suitable for outdoor applications like roofing membranes and automotive weather seals. Its durability against aging is a significant advantage for long-term use. Buyers should assess the temperature range and environmental conditions the product will face to ensure optimal performance and longevity.

What Are the Advantages of Neoprene Rubber Vulcanizate in Industrial Settings?

Neoprene rubber vulcanizate offers excellent resistance to oils and chemicals, making it a versatile choice for various industrial applications, including wetsuits and protective gear. While it is highly durable, it may lack the elasticity found in other rubber types. B2B buyers should weigh the benefits of chemical resistance against the specific flexibility needs of their applications to make informed purchasing decisions.

Key Industrial Applications of what is vulcanised rubber

| Przemysł/sektor | Specific Application of what is vulcanised rubber | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Automotive | Tire manufacturing | Enhanced durability and performance under stress | Sourcing must consider quality standards and certifications, especially for safety compliance. |

| Industrial Manufacturing | Conveyor belts | Increased efficiency and reduced maintenance costs | Buyers should look for custom sizes and resistance to specific chemicals or temperatures. |

| Consumer Goods | Footwear production | Improved comfort and longevity of products | Ensure suppliers can provide diverse styles and sizes to meet market demands. |

| Aerospace | Seals and gaskets | Critical for maintaining safety and performance | Focus on high-performance materials that meet stringent aerospace regulations. |

| Budowa | Vibration dampers | Enhanced structural integrity and reduced noise | Look for suppliers with expertise in heavy-duty applications and durability testing. |

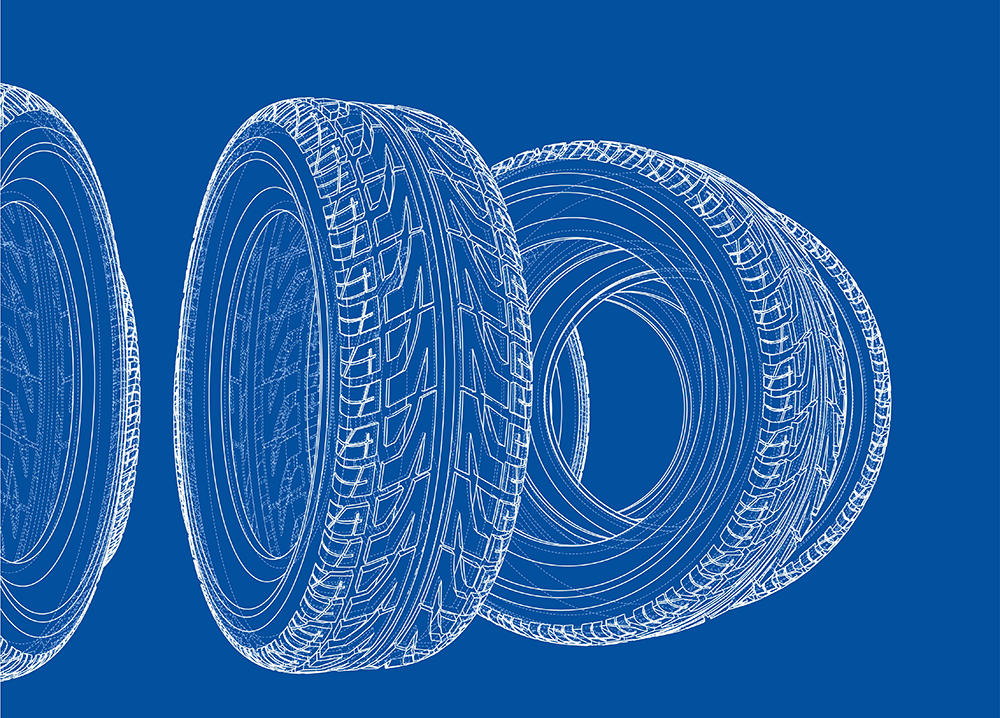

How is Vulcanised Rubber Used in the Automotive Industry?

In the automotive sector, vulcanised rubber is predominantly utilized in tire manufacturing. This material’s enhanced strength and elasticity allow tires to withstand the rigors of driving, including high speeds and varying road conditions. The vulcanization process ensures that tires maintain their shape under stress, providing better traction and safety. International buyers, particularly in regions like Africa and the Middle East, must consider sourcing tires that meet local regulations and quality standards, ensuring safety and durability in diverse climates.

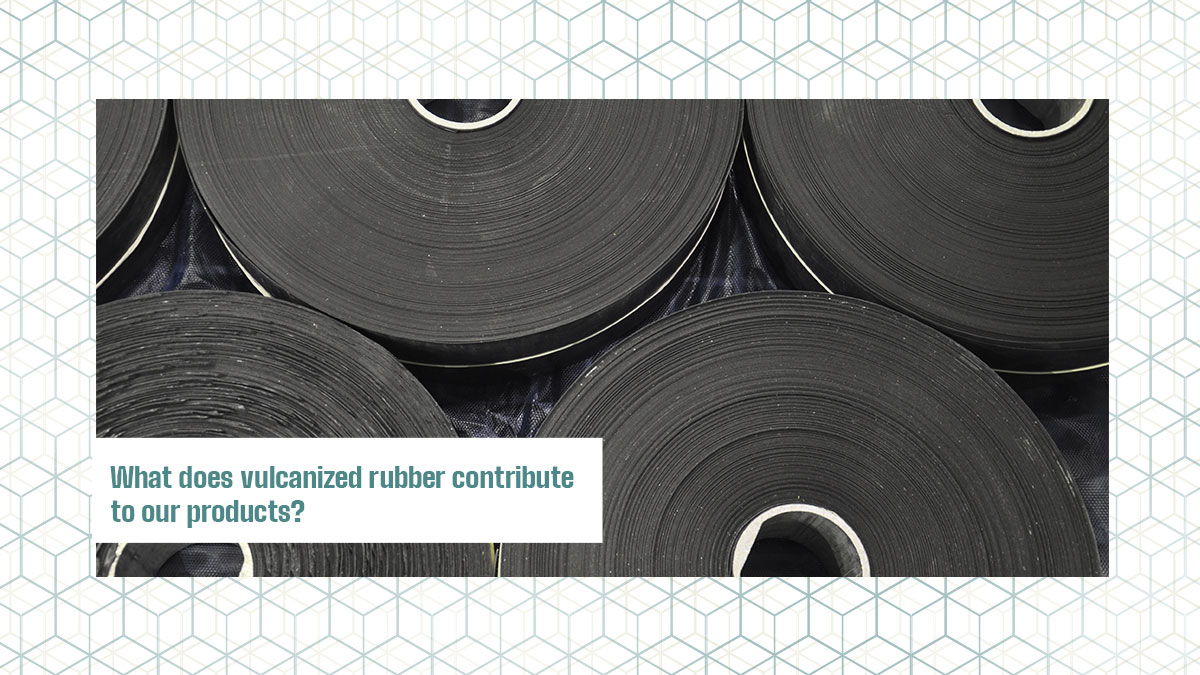

What Role Does Vulcanised Rubber Play in Industrial Manufacturing?

Vulcanised rubber is essential in industrial manufacturing, particularly in conveyor belt systems. These belts require high durability and resistance to wear and tear, which vulcanised rubber provides. The material’s ability to maintain its integrity under heavy loads and abrasive conditions enhances operational efficiency and minimizes downtime for maintenance. Buyers in South America should prioritize suppliers who can offer tailored solutions, including specific chemical resistance and custom sizes, to fit their machinery.

Illustrative image related to what is vulcanised rubber

How is Vulcanised Rubber Beneficial for Consumer Goods?

In the consumer goods sector, vulcanised rubber is widely used in footwear production, where it enhances comfort and longevity. Its elasticity allows for better fit and flexibility, crucial for consumer satisfaction. Additionally, the material’s resistance to wear ensures that products have a longer lifespan, reducing replacement costs for manufacturers. B2B buyers in Europe should look for suppliers that can provide a variety of styles and sizes to cater to diverse consumer preferences.

Why is Vulcanised Rubber Critical in the Aerospace Industry?

In aerospace applications, vulcanised rubber is vital for seals and gaskets, where it plays a crucial role in maintaining safety and performance. The material’s high resistance to extreme temperatures and pressures ensures that aircraft components function optimally under challenging conditions. Buyers must ensure that their suppliers adhere to stringent aerospace regulations and quality standards, as any failure in these components could have severe consequences.

What Benefits Does Vulcanised Rubber Provide in Construction?

In the construction industry, vulcanised rubber is commonly used in vibration dampers, which help enhance structural integrity and reduce noise levels in buildings. By absorbing vibrations, these dampers improve comfort for occupants and prolong the lifespan of structures. Buyers in this sector should focus on sourcing from suppliers with proven expertise in heavy-duty applications, ensuring that the materials meet the demands of various construction environments.

3 Common User Pain Points for ‘what is vulcanised rubber’ & Their Solutions

Scenario 1: Navigating Quality Standards for Vulcanized Rubber Products

Problem: In the diverse markets of Africa, South America, and the Middle East, B2B buyers often struggle with ensuring that the vulcanized rubber products they source meet international quality standards. This challenge is compounded by the lack of consistent regulatory frameworks across countries. Buyers may receive materials that appear satisfactory but fail to perform under specific environmental or mechanical stress conditions, leading to costly production delays and potential safety hazards.

Rozwiązanie: To mitigate these risks, B2B buyers should establish a robust supplier evaluation process focused on quality assurance. This process should include verifying the supplier’s certifications (e.g., ISO 9001) and assessing their adherence to industry standards for vulcanized rubber. Buyers should request detailed product specifications and performance data, ensuring that the material is tested for properties such as tensile strength, elasticity, and resistance to abrasion. Additionally, engaging in direct communication with suppliers about their production processes can provide insights into the quality control measures in place. Conducting regular audits and establishing long-term partnerships with reputable suppliers can also ensure a consistent supply of high-quality vulcanized rubber.

Scenario 2: Understanding the Cost Implications of Vulcanized Rubber

Problem: Many B2B buyers face challenges when trying to balance cost and quality when sourcing vulcanized rubber. The misconception that cheaper products are always viable can lead to the procurement of substandard materials, which ultimately affects product durability and overall performance. This issue is especially prevalent in industries such as automotive and construction, where the reliability of rubber components is critical for safety and functionality.

Illustrative image related to what is vulcanised rubber

Rozwiązanie: Buyers should adopt a total cost of ownership (TCO) approach when evaluating vulcanized rubber options. This involves not just considering the initial purchase price but also the long-term implications of using lower-quality materials, including maintenance costs, potential product failures, and warranty claims. Conducting a thorough cost-benefit analysis can help buyers understand the trade-offs involved. It is advisable to engage suppliers in discussions regarding volume discounts, long-term contracts, or bundled services that can lead to cost savings without sacrificing quality. Investing in higher-quality vulcanized rubber can ultimately enhance product performance and reduce lifecycle costs.

Scenario 3: Overcoming Technical Challenges in Vulcanized Rubber Applications

Problem: B2B buyers often encounter technical challenges when integrating vulcanized rubber into their products. These challenges may include compatibility issues with other materials, difficulties in achieving the desired elasticity, or problems related to the rubber’s resistance to environmental factors such as heat, moisture, or chemicals. Such technical hurdles can lead to delays in product development and increased costs due to re-engineering efforts.

Rozwiązanie: To address these technical challenges, buyers should leverage the expertise of material specialists or engineers during the product design phase. Collaborating with suppliers who offer technical support and customization options can help ensure that the vulcanized rubber chosen is suitable for specific applications. Buyers should conduct material compatibility testing early in the development process, and consider using additives or alternative formulations to enhance performance characteristics. Additionally, attending industry workshops or forums can provide insights into best practices and innovations in vulcanized rubber applications, allowing buyers to stay ahead of technical challenges and optimize their product designs.

Strategic Material Selection Guide for what is vulcanised rubber

What Are the Common Materials Used in Vulcanised Rubber and Their Properties?

When selecting materials for vulcanised rubber applications, it is essential to consider various factors such as performance properties, cost, and manufacturing complexity. Below, we analyze four common materials used in vulcanised rubber, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Natural Rubber

Key Properties:

Natural rubber exhibits excellent elasticity and resilience, making it suitable for applications requiring high flexibility. It has a temperature rating of approximately -50°C to 80°C and is resistant to wear and tear.

Pros & Cons:

Natural rubber is known for its superior tensile strength and elongation, offering durability in dynamic applications. However, it can degrade when exposed to UV light and ozone, limiting its outdoor applications. Additionally, it is less resistant to certain chemicals, which may be a concern in specific industrial environments.

Wpływ na aplikację:

Natural rubber is often used in applications such as tires, gaskets, and seals. Its compatibility with various media is excellent, but caution is advised in chemically aggressive environments.

Uwagi dla międzynarodowych nabywców:

Buyers should ensure compliance with local standards, such as ASTM D2000 or ISO 9001, especially in regions like Europe and the Middle East, where stringent quality regulations are enforced.

2. Synthetic Rubber (SBR)

Key Properties:

Styrene-Butadiene Rubber (SBR) offers good abrasion resistance and aging stability, with a temperature range of -40°C to 100°C. It is also resistant to many chemicals, making it versatile for various applications.

Illustrative image related to what is vulcanised rubber

Pros & Cons:

SBR is generally more cost-effective than natural rubber and can be produced in large quantities. However, it does not possess the same level of elasticity as natural rubber, which can be a limitation in certain applications.

Wpływ na aplikację:

Commonly used in tires, conveyor belts, and footwear, SBR’s chemical resistance allows it to be used in environments where exposure to oils and solvents is a concern.

Uwagi dla międzynarodowych nabywców:

Buyers in Africa and South America should be aware of local manufacturing capabilities and standards, such as DIN or JIS, to ensure that the SBR products meet their specific requirements.

3. EPDM Rubber

Key Properties:

Ethylene Propylene Diene Monomer (EPDM) rubber is highly resistant to heat, ozone, and weathering, with a temperature range of -40°C to 120°C. Its excellent electrical insulation properties make it suitable for various applications.

Pros & Cons:

EPDM is known for its durability and resistance to environmental factors, making it ideal for outdoor applications. However, it has lower tensile strength compared to some other rubber types, which may limit its use in high-stress applications.

Wpływ na aplikację:

EPDM is commonly used in roofing membranes, seals, and automotive parts. Its compatibility with water and steam makes it suitable for plumbing applications.

Illustrative image related to what is vulcanised rubber

Uwagi dla międzynarodowych nabywców:

In regions like the Middle East, where extreme weather conditions prevail, EPDM’s properties can provide significant advantages. Compliance with international standards is crucial for ensuring product reliability.

4. Neoprene Rubber

Key Properties:

Neoprene rubber offers excellent resistance to oil, chemicals, and weathering, with a temperature range of -30°C to 120°C. It is also known for its good flexibility and strength.

Pros & Cons:

Neoprene is versatile and suitable for a wide range of applications, from automotive to industrial uses. However, it can be more expensive than other rubber types, which may impact budget considerations.

Wpływ na aplikację:

Neoprene is widely used in wetsuits, gaskets, and insulation materials. Its chemical resistance makes it suitable for applications involving exposure to oils and solvents.

Illustrative image related to what is vulcanised rubber

Uwagi dla międzynarodowych nabywców:

Buyers in Europe and the Middle East should consider the specific chemical exposure risks in their applications and ensure that Neoprene products comply with relevant safety and environmental regulations.

Summary Table of Material Selection

| Materiał | Typical Use Case for what is vulcanised rubber | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Natural Rubber | Tires, gaskets, seals | Excellent elasticity and resilience | Degrades under UV exposure | Średni |

| Synthetic Rubber (SBR) | Tires, conveyor belts, footwear | Cost-effective and durable | Lower elasticity than natural rubber | Niski |

| EPDM Rubber | Roofing membranes, automotive parts | High resistance to weathering | Lower tensile strength | Średni |

| Neoprene Rubber | Wetsuits, gaskets, insulation materials | Versatile and chemical resistant | Wyższy koszt | Wysoki |

In-depth Look: Manufacturing Processes and Quality Assurance for what is vulcanised rubber

What Are the Main Stages of Manufacturing Vulcanized Rubber?

The manufacturing of vulcanized rubber involves several critical stages that ensure the final product meets the required specifications for strength, durability, and elasticity. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

How Is Material Prepared for Vulcanization?

Material preparation begins with the selection of raw rubber, which can be natural or synthetic. Natural rubber is derived from latex, while synthetic rubber is produced from petrochemicals. The chosen rubber is typically combined with sulfur, accelerators, and other additives in a specified formulation to enhance its properties. This mixture is then processed through milling, where it is blended uniformly, ensuring that all components are well-integrated.

Illustrative image related to what is vulcanised rubber

What Techniques Are Used in the Forming Process?

The forming process involves shaping the prepared rubber mixture into the desired product form. This is achieved through various techniques, including:

- Molding: The rubber is placed into molds that define the shape of the final product. This can be done through compression, transfer, or injection molding.

- Extrusion: This method is often used for products like hoses and belts, where the rubber is forced through a die to create long shapes.

- Calendering: In this technique, the rubber is passed through rollers to create sheets of uniform thickness, often used for flooring or other flat products.

Each technique has its advantages and is selected based on the specific requirements of the end product.

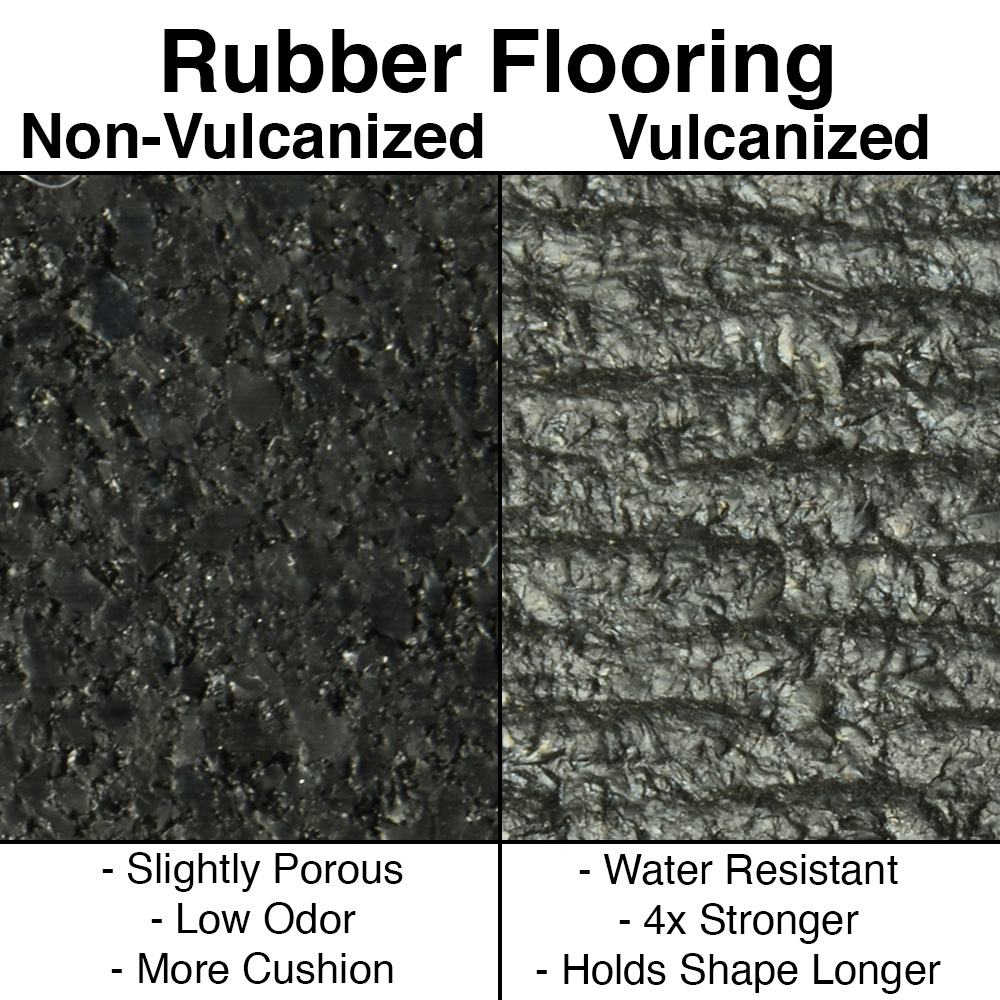

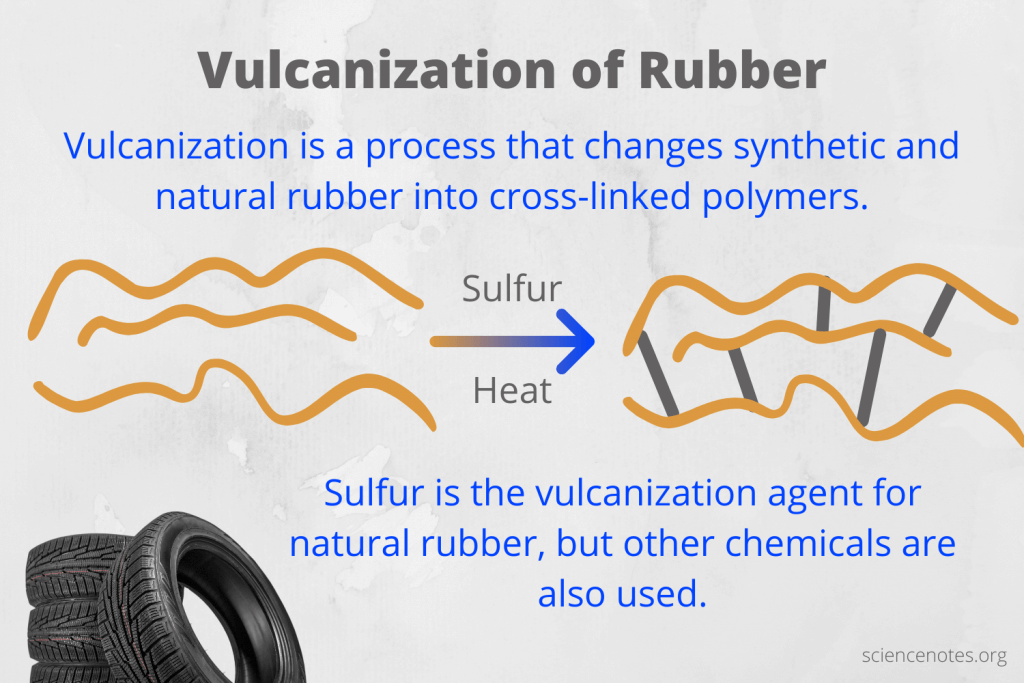

How Is Vulcanization Achieved?

Vulcanization is the key process that transforms the rubber into a stronger, more elastic material. The rubber, after being shaped, is heated in a controlled environment with sulfur and other additives. The typical temperature range for this process is between 300 to 400 degrees Fahrenheit. During this stage, sulfur forms cross-links between the rubber molecules, enhancing their strength and elasticity. This process can take several hours, depending on the thickness and complexity of the product.

What Are the Finishing Steps in Vulcanized Rubber Manufacturing?

After vulcanization, the rubber products undergo finishing processes to ensure they meet quality standards. These steps may include:

- Trimming: Excess material is removed from the molded products.

- Surface Treatment: This can involve grinding, polishing, or applying coatings to improve aesthetics and durability.

- Testing: Final testing is conducted to ensure that the product meets the specified requirements for performance and safety.

What Quality Assurance Practices Are Essential for Vulcanized Rubber?

Quality assurance (QA) is critical in the manufacturing of vulcanized rubber to ensure that products are safe, reliable, and meet international standards.

Jakie międzynarodowe standardy powinni wziąć pod uwagę nabywcy B2B?

B2B buyers should look for suppliers that adhere to recognized international standards, such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For industries like oil and gas, adherence to API standards is crucial for products used in demanding environments.

These certifications provide assurance that suppliers maintain high-quality manufacturing processes.

Jakie są kluczowe punkty kontroli jakości?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Przychodząca kontrola jakości (IQC): This involves inspecting raw materials before production to ensure they meet specifications.

- Kontrola jakości w trakcie procesu (IPQC): Continuous monitoring during manufacturing helps identify any deviations from quality standards early in the process.

- Końcowa kontrola jakości (FQC): This final inspection ensures that the finished products meet all specifications before they are shipped to customers.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to assess the properties of vulcanized rubber:

- Tensile Testing: Measures the strength and elasticity of the rubber.

- Hardness Testing: Determines the hardness level of the rubber using durometers.

- Abrasion Resistance Testing: Evaluates the rubber’s durability against wear and tear.

- Thermal Aging Tests: Assesses how the rubber performs under prolonged heat exposure.

These tests help verify that the vulcanized rubber products will perform as expected in their intended applications.

W jaki sposób nabywcy B2B mogą weryfikować kontrolę jakości dostawców?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

- Przeprowadzanie audytów: Regular audits of suppliers can help assess their compliance with quality standards and identify areas for improvement.

- Żądanie raportów jakości: Suppliers should provide documentation of their quality control processes and test results for products.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality.

What Are the QC Nuances for International B2B Buyers?

When sourcing vulcanized rubber products from different regions, particularly from Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

- Regulatory Compliance: Different countries may have unique regulations regarding materials and manufacturing processes. Understanding these can prevent compliance issues.

- Cultural Differences: Communication styles and business practices can vary significantly across regions. Being culturally aware can facilitate better supplier relationships.

- Logistics and Supply Chain Considerations: International shipping can introduce additional quality risks. Ensuring that suppliers have robust logistics processes in place is essential for maintaining product integrity.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing vulcanized rubber products, ensuring they receive high-quality materials that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is vulcanised rubber’

Wprowadzenie

This practical sourcing guide is designed to assist B2B buyers in understanding and procuring vulcanized rubber. As a material essential for various applications—from automotive parts to consumer goods—vulcanized rubber offers superior strength and elasticity. This checklist will help you navigate the procurement process effectively, ensuring that you select the right materials and suppliers for your needs.

Krok 1: Zdefiniuj swoje specyfikacje techniczne

Clearly outline your technical requirements for vulcanized rubber. This includes factors such as the desired hardness, elasticity, temperature resistance, and specific applications (e.g., tires, seals, or gaskets). Defining these parameters upfront will streamline your sourcing process and ensure that suppliers can meet your needs.

Illustrative image related to what is vulcanised rubber

Krok 2: Badanie potencjalnych dostawców

Conduct thorough research to identify potential suppliers specializing in vulcanized rubber. Look for companies with a proven track record in your industry and geographical region. Key indicators of reliability include years in business, client testimonials, and case studies that demonstrate their expertise.

- Focus on Certifications: Ensure that suppliers possess relevant industry certifications (e.g., ISO 9001) that demonstrate quality management practices.

Krok 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of each potential supplier. This includes their production capacity, technology used, and the range of rubber compounds they offer. Understanding these aspects will help you determine if a supplier can meet your volume and quality requirements.

- Inquire about Customization Options: If your project requires specific formulations or dimensions, verify that the supplier can accommodate custom orders.

Krok 4: Request Samples

Before making a commitment, request samples of the vulcanized rubber products you intend to purchase. Testing samples is crucial to evaluate the material’s performance characteristics, such as durability, flexibility, and resistance to wear and tear.

- Conduct Performance Tests: Implement tests that mimic the conditions under which the final product will be used, ensuring that the rubber meets your expectations.

Krok 5: Verify Compliance and Quality Standards

Ensure that the vulcanized rubber products comply with relevant safety and industry standards. This is especially important in sectors like automotive and construction, where material failure can have severe consequences.

Illustrative image related to what is vulcanised rubber

- Check Regulatory Compliance: Depending on your market, verify adherence to local and international regulations regarding materials used in manufacturing.

Krok 6: Negocjowanie warunków i cen

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Establishing clear terms upfront can prevent misunderstandings later in the process.

- Consider Long-term Partnerships: If you anticipate ongoing needs for vulcanized rubber, discuss the potential for bulk pricing or contract agreements that benefit both parties.

Krok 7: Establish a Quality Assurance Process

After selecting a supplier, implement a quality assurance process to monitor the performance of the vulcanized rubber throughout the supply chain. Regular audits and feedback loops can help maintain the quality of the products received.

- Set Up Communication Channels: Maintain open lines of communication with your supplier to address any quality issues promptly and effectively.

By following these steps, B2B buyers can make informed decisions when sourcing vulcanized rubber, ensuring they select materials that meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for what is vulcanised rubber Sourcing

What Are the Key Cost Components in Sourcing Vulcanized Rubber?

Sourcing vulcanized rubber involves several cost components that can significantly impact the overall pricing structure. These include:

-

Materiały: The primary raw material is natural rubber, which is processed with sulfur and other additives for vulcanization. The cost of these materials can fluctuate based on market demand and availability. For instance, regions rich in rubber production may offer more competitive pricing.

-

Praca: Labor costs vary by region, influenced by local wage standards and expertise in rubber processing. Skilled labor is often necessary for quality assurance and production, which can increase costs.

-

Koszty ogólne produkcji: This encompasses all indirect costs associated with production, including utilities, rent, and maintenance of machinery. Efficient manufacturing processes can help lower these costs.

-

Oprzyrządowanie: Custom molds and tools for shaping vulcanized rubber can require significant initial investment. These costs are amortized over the production volume, making them a crucial factor in pricing.

-

Kontrola jakości (QC): Ensuring that the vulcanized rubber meets specific industry standards and certifications involves rigorous testing, which can add to the overall cost. Buyers should prioritize suppliers with robust QC processes to ensure product reliability.

-

Logistyka: Shipping and transportation costs can vary widely based on the supplier’s location and the buyer’s destination. Incoterms (International Commercial Terms) play a critical role in determining who bears these costs.

-

Margines: Suppliers will include a profit margin in their pricing, which can vary based on their operational efficiencies and market positioning.

What Influences the Price of Vulcanized Rubber?

Several factors can influence the pricing of vulcanized rubber beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate for bulk pricing where possible.

-

Specyfikacje i personalizacja: Customized products that require specific formulations or properties can attract higher prices. Buyers must clearly communicate their needs to avoid unexpected costs.

-

Jakość materiałów i certyfikaty: Higher quality materials and recognized certifications (like ISO or ASTM) can drive up costs but often result in better performance and durability.

-

Czynniki dostawcy: The supplier’s reputation, reliability, and production capabilities can affect pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The choice of Incoterms can significantly affect the total cost, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

How Can Buyers Optimize Cost-Efficiency When Sourcing Vulcanized Rubber?

B2B buyers should consider several strategies to ensure cost-efficiency when sourcing vulcanized rubber:

-

Negotiate Effectively: Understanding the cost structure can empower buyers to negotiate better terms. Discussing volume discounts, payment terms, and delivery schedules can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as longevity, maintenance, and performance. Higher upfront costs may be justified by lower operational costs over time.

-

Research Pricing Nuances for International Sourcing: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of regional market dynamics and logistics implications. Tariffs, import duties, and currency fluctuations can impact total costs.

-

Budowanie relacji z dostawcami: Developing long-term partnerships can lead to better pricing and more favorable terms. Trust and reliability can often yield discounts or priority service.

Zastrzeżenie dotyczące cen orientacyjnych

Pricing for vulcanized rubber can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting competitive pricing tailored to their specific requirements.

Alternatives Analysis: Comparing what is vulcanised rubber With Other Solutions

When evaluating the use of vulcanized rubber in various applications, it’s essential to consider viable alternatives that may also meet specific industrial needs. Each material or method presents unique strengths and weaknesses, influencing decisions based on performance, cost, and suitability for particular uses. Below, we compare vulcanized rubber with two notable alternatives: thermoplastic elastomers (TPE) and polyurethane.

| Aspekt porównawczy | What Is Vulcanised Rubber | Thermoplastic Elastomers (TPE) | Poliuretan |

|---|---|---|---|

| Wydajność | High strength, elasticity, and abrasion resistance. | Good flexibility and resilience; less durable than vulcanized rubber. | Excellent abrasion resistance, versatile hardness levels. |

| Koszt | Generally higher due to complex manufacturing. | Often lower cost, especially for mass production. | Moderate cost; varies with formulation and hardness. |

| Łatwość wdrożenia | Requires specialized equipment for vulcanization. | Easier to process; can be molded and extruded using standard thermoplastic equipment. | Requires specific processing techniques, but relatively easy to mold. |

| Konserwacja | Low maintenance; highly durable and resistant to wear. | Moderate maintenance; can degrade under extreme conditions. | Requires regular checks; sensitive to environmental factors. |

| Najlepszy przypadek użycia | Ideal for heavy-duty applications like tires, seals, and gaskets. | Suited for consumer goods, automotive parts, and medical devices. | Excellent for flexible components, coatings, and adhesives. |

What Are the Advantages and Disadvantages of Thermoplastic Elastomers (TPE)?

Thermoplastic elastomers (TPE) are a blend of rubber and plastic that offer a balance of the two materials’ properties. One of their most significant advantages is ease of processing; TPE can be molded and shaped without the need for curing agents, allowing for quicker production times. They are also recyclable, which may appeal to environmentally conscious companies. However, TPEs generally do not match the durability and heat resistance of vulcanized rubber, making them less suitable for high-stress applications like tires or industrial seals.

What Are the Key Benefits and Drawbacks of Polyurethane?

Polyurethane is a versatile polymer known for its excellent abrasion resistance and ability to be formulated in various hardness levels. This adaptability makes it suitable for a wide range of applications, from automotive components to flexible foam products. The primary advantages of polyurethane include its high resilience and excellent load-bearing capabilities. However, it can be sensitive to moisture and UV light, which may necessitate additional protective measures in certain environments. Additionally, while the initial costs can be moderate, the need for maintenance may increase overall lifetime expenses.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between vulcanized rubber and its alternatives, B2B buyers should consider the specific requirements of their applications. Factors such as operating conditions, required durability, budget constraints, and production capabilities must be weighed carefully. Vulcanized rubber excels in high-stress environments, while TPE and polyurethane may offer cost-effective solutions for less demanding applications. Ultimately, the decision should align with the overall goals of the project, balancing performance with economic viability to ensure long-term satisfaction and success.

Essential Technical Properties and Trade Terminology for what is vulcanised rubber

What Are the Key Technical Properties of Vulcanised Rubber?

When sourcing vulcanised rubber, understanding its technical properties is crucial for ensuring that it meets the specific needs of your application. Here are several essential specifications to consider:

1. Klasa materiału

Material grade refers to the classification of rubber based on its composition and performance characteristics. Vulcanised rubber can be classified into various grades, each suited for different applications, such as automotive, industrial, or consumer products. For B2B buyers, selecting the appropriate grade is essential for durability, performance, and compliance with industry standards.

2. Tensile Strength

Tensile strength measures the maximum stress that a material can withstand while being stretched or pulled before breaking. Vulcanised rubber typically exhibits higher tensile strength than non-vulcanised rubber due to the cross-linking of polymer chains during the vulcanisation process. This property is vital for applications where the material will experience significant stretching or mechanical stress, such as in seals or gaskets.

Illustrative image related to what is vulcanised rubber

3. Elongation at Break

This property indicates the extent to which a rubber material can be stretched before it breaks, expressed as a percentage of its original length. Vulcanised rubber often has a higher elongation at break compared to its unvulcanised counterpart, making it ideal for applications requiring flexibility and resilience, such as in shock absorbers or flexible hoses.

4. Hardness (Shore A)

Hardness is measured using the Shore durometer scale, which quantifies the resistance of rubber to indentation. Vulcanised rubber can range from soft to hard, with specific hardness values tailored for various applications. For instance, softer grades may be used in footwear, while harder grades are suited for industrial applications. Understanding hardness helps buyers select products that will perform optimally under specific conditions.

5. Odporność na ścieranie

Abrasion resistance assesses how well a material can withstand wear and tear due to friction. Vulcanised rubber is generally more resistant to abrasion than non-vulcanised rubber, making it suitable for high-wear applications such as conveyor belts and tire manufacturing. This property is crucial for manufacturers seeking longevity and reduced maintenance costs in their products.

What Trade Terms Should B2B Buyers Know About Vulcanised Rubber?

Navigating the procurement of vulcanised rubber requires familiarity with specific industry jargon. Here are some key terms:

1. OEM (producent oryginalnego sprzętu)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vulcanised rubber, understanding OEM relationships can help buyers identify reputable suppliers who provide high-quality materials that meet original specifications.

2. MOQ (minimalna ilość zamówienia)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For vulcanised rubber products, MOQs can vary significantly between suppliers and may impact your purchasing decisions, especially for smaller businesses or those testing new products.

3. RFQ (zapytanie ofertowe)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing vulcanised rubber, submitting an RFQ can help buyers compare prices, lead times, and terms from multiple suppliers, facilitating informed decision-making.

4. Incoterms (międzynarodowe warunki handlowe)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers involved in international trade, as they clarify who bears the risk and cost at different stages of the delivery process.

5. Czas realizacji

Lead time is the duration from placing an order to receiving the product. In the context of vulcanised rubber, understanding lead times is critical for production planning and inventory management, particularly in industries where timely delivery is crucial.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing vulcanised rubber, ensuring they obtain materials that meet their specific requirements and industry standards.

Navigating Market Dynamics and Sourcing Trends in the what is vulcanised rubber Sector

What Are the Key Drivers Shaping the Vulcanised Rubber Market?

The vulcanised rubber market is currently experiencing significant growth driven by multiple global factors. The automotive industry remains the largest consumer, with over a billion tyres produced annually. This demand is fueled by rising vehicle ownership in emerging markets across Africa and South America, where infrastructure development and urbanization are accelerating. Furthermore, the industrial sector is increasingly utilizing vulcanised rubber in applications such as conveyor belts, hoses, and gaskets due to its superior strength and durability compared to traditional rubber.

Emerging technologies are also influencing sourcing trends. The integration of automation and advanced manufacturing techniques is enabling suppliers to enhance product quality while reducing lead times. For international B2B buyers, this translates into improved supply chain efficiency and cost-effectiveness. Another notable trend is the rise of digital platforms that facilitate sourcing and procurement, allowing buyers from regions like the Middle East and Europe to connect with manufacturers globally. These platforms often provide valuable insights into market pricing, enabling better negotiation strategies.

Finally, geopolitical factors and trade agreements are shaping market dynamics. Buyers should stay informed about tariffs, trade policies, and regional agreements that could impact sourcing strategies, especially in diverse markets like Nigeria and Saudi Arabia.

How Is Sustainability Influencing Sourcing Practices in the Vulcanised Rubber Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the vulcanised rubber sector. The environmental impact of rubber production, particularly from natural rubber sources, raises concerns about deforestation and biodiversity loss. As a result, there is a growing emphasis on ethical sourcing practices and the use of sustainable materials. Companies are increasingly seeking suppliers who can demonstrate compliance with environmental standards and certifications, such as ISO 14001, which focuses on effective environmental management systems.

Moreover, the adoption of “green” certifications for vulcanised rubber products is gaining traction. These certifications assure buyers that the materials used in production have a reduced environmental footprint, are sourced responsibly, and comply with stringent health and safety regulations. This is particularly relevant for buyers in Europe, where consumer preferences are shifting towards eco-friendly products.

B2B buyers should also consider the lifecycle of vulcanised rubber products. This includes evaluating recyclability, end-of-life disposal options, and the potential for using recycled materials in production. By prioritizing sustainability, companies can not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context of Vulcanised Rubber Relevant for Today’s Market?

The evolution of vulcanised rubber dates back thousands of years, with significant advancements occurring in the 19th century. The process of vulcanization, which involves treating natural rubber with sulfur, was first patented by Charles Goodyear in 1844. This innovation revolutionized the rubber industry, making it possible to produce a material that was not only stronger but also more elastic and durable than its non-vulcanised counterparts.

Illustrative image related to what is vulcanised rubber

Historically, vulcanised rubber has been used in a wide array of applications, from waterproof clothing to automotive tyres. This versatility has made it a staple in various industries. Understanding this historical context is essential for B2B buyers as it highlights the long-standing reliability and performance of vulcanised rubber products, reinforcing their continued relevance in modern manufacturing.

In conclusion, the vulcanised rubber market is characterized by dynamic growth influenced by technological advancements, sustainability concerns, and a rich history that underscores its importance in various applications. For international B2B buyers, staying informed about these trends will be crucial in making strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of what is vulcanised rubber

-

How is vulcanized rubber manufactured and what are its key benefits?

Vulcanized rubber is produced through a curing process that involves treating natural rubber with sulfur and other additives, such as accelerators and pigments. This process creates cross-links between polymer chains, enhancing the rubber’s strength, elasticity, and durability. Key benefits include excellent abrasion resistance, low water absorption, and high resilience, making it ideal for applications like tires, hoses, and seals. Understanding these manufacturing intricacies can help buyers assess product quality and suitability for their specific needs. -

What industries primarily use vulcanized rubber products?

Vulcanized rubber is extensively used across various industries, including automotive, aerospace, consumer goods, and construction. The automotive industry, particularly, relies on vulcanized rubber for tires, seals, and gaskets due to its durability and performance under stress. Other applications include rubber hoses, footwear, conveyor belts, and vibration dampers. Identifying the right industry applications can guide buyers in making informed purchasing decisions tailored to their sector. -

What factors should I consider when sourcing vulcanized rubber suppliers?

When sourcing vulcanized rubber suppliers, consider factors such as their production capabilities, quality certifications (like ISO), and experience in your specific industry. Additionally, evaluate their customer service responsiveness, lead times, and whether they can provide custom solutions to meet your requirements. Checking client testimonials and conducting site visits can also help ensure the supplier’s reliability and commitment to quality. -

What are the typical minimum order quantities (MOQ) for vulcanized rubber products?

Minimum order quantities for vulcanized rubber products can vary significantly based on the supplier, product type, and customization requirements. Generally, MOQs range from 100 to 1,000 units for standard products, while custom orders may require larger quantities due to setup costs. It’s essential to discuss MOQs upfront with potential suppliers to align your purchasing strategy with their production capabilities. -

What payment terms are common in international trade for vulcanized rubber?

Payment terms in international trade for vulcanized rubber typically include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may offer a 30% deposit with the balance due before shipment. It’s crucial to clarify payment terms early in negotiations to avoid misunderstandings and ensure smooth transactions, particularly when dealing with international suppliers. -

How can I ensure the quality of vulcanized rubber products?

To ensure the quality of vulcanized rubber products, request samples for testing before placing a bulk order. Additionally, inquire about the supplier’s quality assurance processes, including material inspections and product testing protocols. Certifications like ISO 9001 can also indicate a commitment to quality management. Conducting regular quality audits and utilizing third-party inspection services can further safeguard product quality. -

What logistics considerations should I be aware of when importing vulcanized rubber?

Logistics for importing vulcanized rubber involve understanding shipping methods, lead times, and customs regulations specific to your region. Factors like freight costs, packaging requirements, and potential tariffs should also be considered. Collaborating with a logistics provider experienced in handling rubber products can help streamline the import process and mitigate delays, ensuring timely delivery to your operations. -

Can vulcanized rubber be customized for specific applications?

Yes, vulcanized rubber can be customized to meet specific application requirements, including variations in hardness, elasticity, and color. Many suppliers offer custom formulations and designs based on client specifications, allowing for tailored solutions that enhance performance in unique environments. Engaging with a supplier’s technical team can help you identify the best customization options to suit your needs and application challenges.

Top 3 What Is Vulcanised Rubber Manufacturers & Suppliers List

1. Walker Rubber – Custom Rubber Extrusions

Domena: walker-rubber.co.uk

Registered: 1999 (26 years)

Wprowadzenie: Rubber Extrusions, Custom Rubber Extrusions, Angle Extrusion, Rubber Boat Window Seals, Brick Grabs, Cab Tyres, Rubber Cable Protection, Coloured Extrusions, Container Door Seal Extrusion, Conveyor Side Skirting, Rubber Door Seals, EPDM Extrusions, Rubber Expansion Seals, Rubber Façade Seal Extrusions, Flame Retardant Extrusions, Food Grade Extrusions, Rubber Gate Seals, Rubber Glazing Seals, H Pr…

2. EBSCO – Vulcanized Rubber Solutions

Domena: ebsco.com

Registered: 1990 (35 years)

Wprowadzenie: Vulcanized rubber is a durable material created through a chemical process known as vulcanization, which enhances rubber’s elasticity, tensile strength, and resistance to temperature variations. The process involves mixing natural rubber from the Hevea brasiliensis tree with sulfur and applying heat, resulting in chemical cross-links between polymer molecules. Patented by Charles Goodyear in the m…

3. ScienceDirect – Vulcanization Process

Domena: sciencedirect.com

Zarejestrowany: 1997 (28 lat)

Wprowadzenie: Vulcanization is a chemical process that enhances the elasticity and retractile force of rubbery or elastomeric materials by forming a crosslinked molecular network, reducing permanent deformation after the removal of applied forces. It typically involves the insertion of crosslinks between polymer chains using sulfur or other vulcanizing agents. The process improves mechanical properties, enhance…

Strategic Sourcing Conclusion and Outlook for what is vulcanised rubber

Vulcanized rubber stands as a cornerstone material in various industries due to its remarkable strength, elasticity, and resistance to environmental factors. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the benefits and applications of vulcanized rubber is crucial. This material is not only pivotal in the manufacturing of tires and footwear but also plays a significant role in sectors such as automotive, construction, and consumer goods.

Strategic sourcing of vulcanized rubber can lead to significant cost savings and efficiency gains. By leveraging partnerships with reliable suppliers, businesses can ensure access to high-quality materials that meet specific application needs while optimizing their supply chains. It is essential to evaluate potential suppliers based on their production capabilities, quality assurance processes, and compliance with international standards.

Looking ahead, the demand for vulcanized rubber is expected to grow, driven by advancements in technology and increasing applications across diverse sectors. International buyers should take proactive steps to align their sourcing strategies with market trends, ensuring they remain competitive in a rapidly evolving landscape. Engaging with expert suppliers and investing in sustainable practices will be key to capitalizing on future opportunities in the vulcanized rubber market.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.